• Never allow hands, clothing or any

part of the body to enter the discharge

chute or near moving parts.

• Avoid wearing loose-fitting clothing.

• Wear approved eye and ear protection

while operating the machine.

• The machine should be operated on

level surfaces only.

• Before starting the machine, visually

inspect all nuts, bolts and other

fasteners to see that they are properly

secured. Nuts, bolts and other

fasteners should be checked every 8

to 10 hours of operation for proper

alignment and tightness.

Operation

• Make certain the impeller chamber is

empty before starting the machine.

• If a foreign object should strike the

impeller mechanism of the machine

and cause an unusual noise or

vibration, shut the engine or PTO off

immediately and allow it to come to a

complete stop. Disconnect the spark

PTO shaft from the power unit, and

then do the following:

1. Inspect for damage.

2. Repair or replace any damaged

parts.

3. Check for and tighten any loose

bolts, nuts, fasteners or parts.

• Keep debris material from building up

in the discharge and inlet area, as this

may prohibit proper discharge of

airflow and can cause poor

performance.

• Keep the impeller inlet area clean from

debris and other accumulations.

• Keep all safety shields and guards in

place and in good working condition.

• Keep your face and all body parts

away from inlet and discharge

openings.

• Stay away from the discharge area

when machine is in operation.

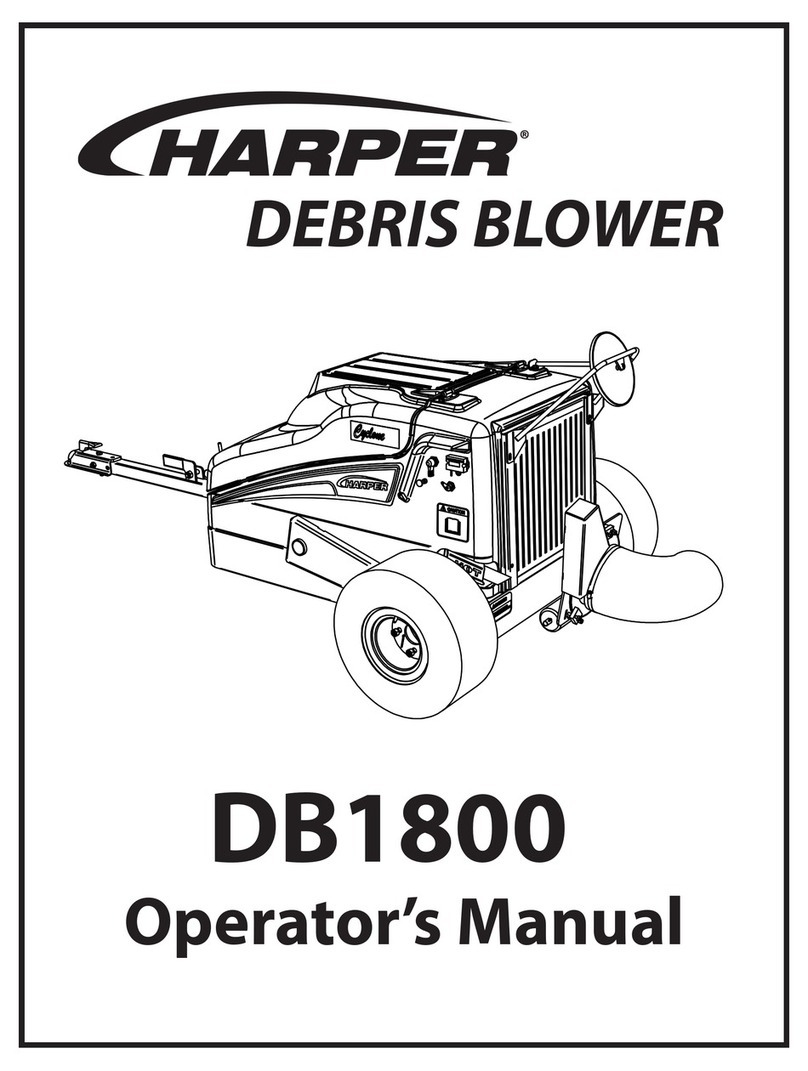

• If the Debris Blower should become

clogged, shut off the engine or PTO

and allow it to come to a complete

stop. Disconnect the spark plug wire

from the spark plug or PTO shaft

before clearing debris.

• Do not allow hands, clothing or any

part of the body to enter the discharge

chute, impeller inlet or near any

moving parts.

• Replace damaged or missing safety

decals.

• Keep hands, feet and clothing away

from PTO driven parts.

• Keep all guards and shields in place

during operation. Disengage PTO and

shut off the engine before removing

guards or shields.

• Never attempt to adjust, clean or

lubricate the machine while it is in

operation.

• Operator should never wear loose

clothing when working around PTO.

• Before starting tractor, make sure that

the transmission and PTO are

disengaged.

• Make sure the tractor’s engine is at

idle speed before engaging the PTO.

• Be sure the tractor’s engine is at idle

before changing the airflow of the

Debris Blower Diverter.

6