GB - 6

This product is equipped with an internal

combustion engine. DO NOT use on or near

any unimproved, forest or brush covered land

unless the exhaust system is equipped with a

spark arrestor meeting applicable local, state

or federal laws. A spark arrestor, if used,

must be maintained in effective working order

by the operator.

Wear approved safety glasses when

operating this equipment. The operation of

any powered machine can result in foreign

objects being thrown by high-speed rotating

parts.

Wear work gloves, sturdy footwear, and

hearing protection when operating this

equipment.

Remove hearing protection and watch for

traffic when operating near, or when crossing

roadways.

Before inspecting or servicing any part of

equipment, shut off engine, disconnect spark

plug wire from spark plug, and make sure that

all moving parts have come to a complete

stop. Be aware that rotating blades slow

down gradually after engine is shut off.

Never leave equipment unattended when

engine is running. Shut off engine and

disconnect spark plug wire from spark plug

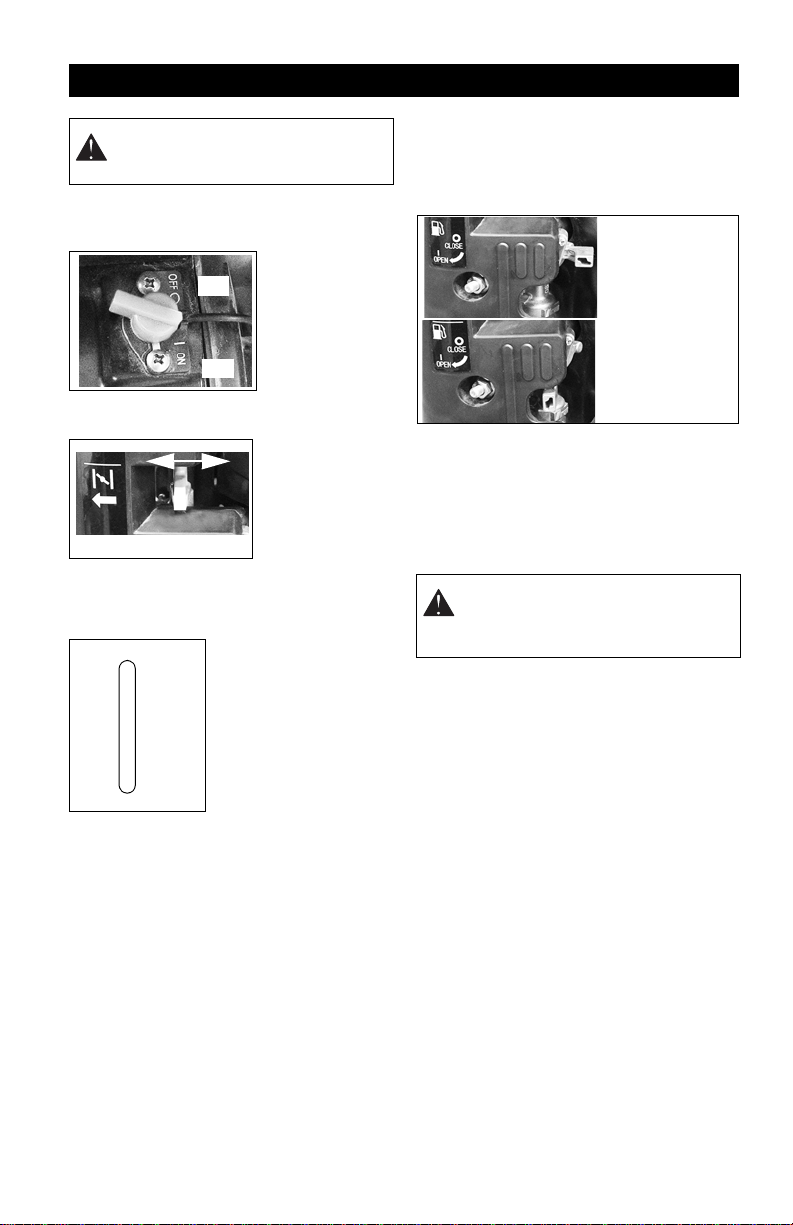

before leaving equipment. Close the fuel

shut-off valve.

Exercise extreme caution on slopes and

avoid excessively steep slopes.

Use extreme caution when moving backward

or pulling the machine towards you.

Do not change the engine governor or over

run the engine.

Do not tilt the equipment when starting the

engine or switching on the motor.

Do not start the engine when standing in front

of the air discharge outlet.

Walk, never run.

ALWAYS be sure of your footing. Use caution

to avoid slipping and falling.

Operate machine only in daylight or good

artificial light.

NEVER operate after or during the use of

medication, drugs or alcohol. Unit requires

complete and unimpaired attention.

If the machine should start to vibrate

abnormally, stop the engine (motor) and

check for the cause immediately. Vibration is

generally a warning of trouble.

Do not weld or repair damaged or worn

impeller. Replace only.

Never allow children or untrained adults to

operate this equipment.

Keep the area of operation clear of all

persons, particularly small children, and pets.

Keep bystanders at least 25 feet away from

the area of operation.

Do not run engine in an enclosed area.

Engine exhaust contains carbon monoxide

gas, a deadly poison that is odorless,

colorless, and tasteless.

Before making air flow adjustments, shut off

engine, and allow all moving parts to come to

a complete stop.

Do not move through or stand in the air flow

with the engine running. Blown debris can

cause injury.

Do not allow hands or any other part of the

body or clothing inside the air intake or

discharge areas.

Do not start engine or operate this equipment

with any safety guards removed.

See manufacturer’s instructions for proper

operation and installation of accessories.

Only use accessories approved by the

manufacturer.

Fuel is highly flammable and its vapors are

explosive. Handle with care. Use only an

approved gasoline container with an

appropriately sized dispensing spout.

Fuel is highly flammable and its vapors can

explode. ONLY use approved fuel containers.

•NOSmoking!

•NOSparks!

•NOFlames!

• Allow engine to cool before filling fuel

tank.

Never fill containers inside a vehicle or on a

truck or trailer bed with a plastic liner. Always

place containers on the ground away from

your vehicle before filling.

When practical, remove gas-powered

equipment from the truck or trailer and refuel

it on the ground. If this is not possible, then

refuel such equipment on a trailer with a

portable container, rather than from a

gasoline dispenser nozzle.

Keep the nozzle in contact with the rim of the

fuel tank or container opening at all times until

fueling is complete. Do not use a nozzle lock-

open device.

Check fuel supply before starting engine.

DO NOT fill gasoline tank indoors, when

engine is running, or while engine is hot.

Allow engine to cool several minutes before

removing fuel cap.

Do not mix oil with gasoline.

DO NOT overfill. Allow about 1/2” (12 mm) of

tank space for fuel expansion.