Hartmann T1HCK3 User manual

T1HCK3

Up to 8 Door Kit

Fully assembled kit includes:

- Trove1 enclosure with THC1 Altronix/Hartmann Controls backplane

- One (1) AL600ULXB - Power Supply/Charger

T1HCK34

Up to 8 Door Kit with Fused Outputs

Fully assembled kit includes:

- Trove1 enclosure with THC1 Altronix/Hartmann Controls backplane

- One (1) AL600ULXB - Power Supply/Charger

- One (1) ACM4 - Fused Access Power Controller

Access & Power Integration

Rev. T1HCL011122

Installing Company: _________________________ Service Rep. Name: __________________________________________

Address: _________________________________________________________ Phone #: _________________________

All registered trademarks are property of their respective owners.

Installation Guide

All components of these Trove kits are UL Listed sub-assemblies.

Please refer to the included corresponding Sub-Assembly Installation Guides for further information.

- 2 - THC1 ULXB Kits Installation Guide

Overview:

Altronix/Hartmann Controls Trove kits are pre-assembled and consist of Trove enclosure with factory installed Altronix power supply/chargers and

sub-assemblies. Each kit also accommodates one (1) Hartmann Controls PRS_Master boards and up to four (4) PRS_TDM or PRS_IO8 boards.

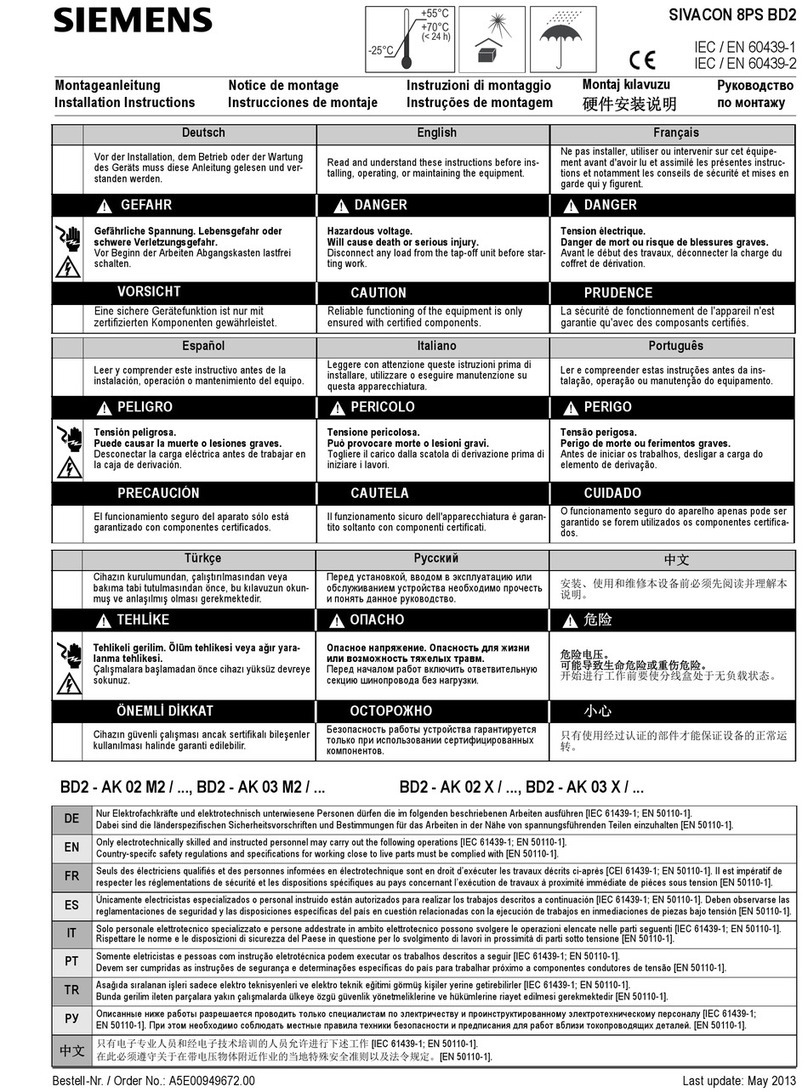

Configuration Chart:

Altronix

Model Number

115VAC

60Hz

Input

Current

(A)

Power

Supply

Board

Input Fuse

Rating

Nominal DC Output

Voltage Options

Maximum

Supply Current for

Output on Power

Supply board and

ACM4 Access Power

Controller’s

outputs (A)

Fail-Safe/

Fail-

Secure

or Dry

Form “C”

Outputs

Current

Per

ACM4

Output (A)

ACM4

Board

Input

Fuse

Rating

ACM4

Board

Output

Fuse

Rating

12VDC

Output

Range

(V)

24VDC

Output

Range

(V)

T1HCK3 3.5 5A/

250V

AL600ULXB

12 or 24VDC @ 6A ––––

10.0-13.2 20.19-26.4

T1HCK34 3.5 5A/

250V

AL600ULXB 12VDC @ 5.4A

or

24VDC @ 5.7A

4 2.5 10A/

32V

3A/

32V

10.0-13.2 20.19-26.4

Hardware and Accessories:

Installation Instructions:

Wiring methods shall be in accordance with the National Electrical Code/NFPA 70/ANSI, and with all local codes and authorities having jurisdiction.

Product is intended for indoor use only.

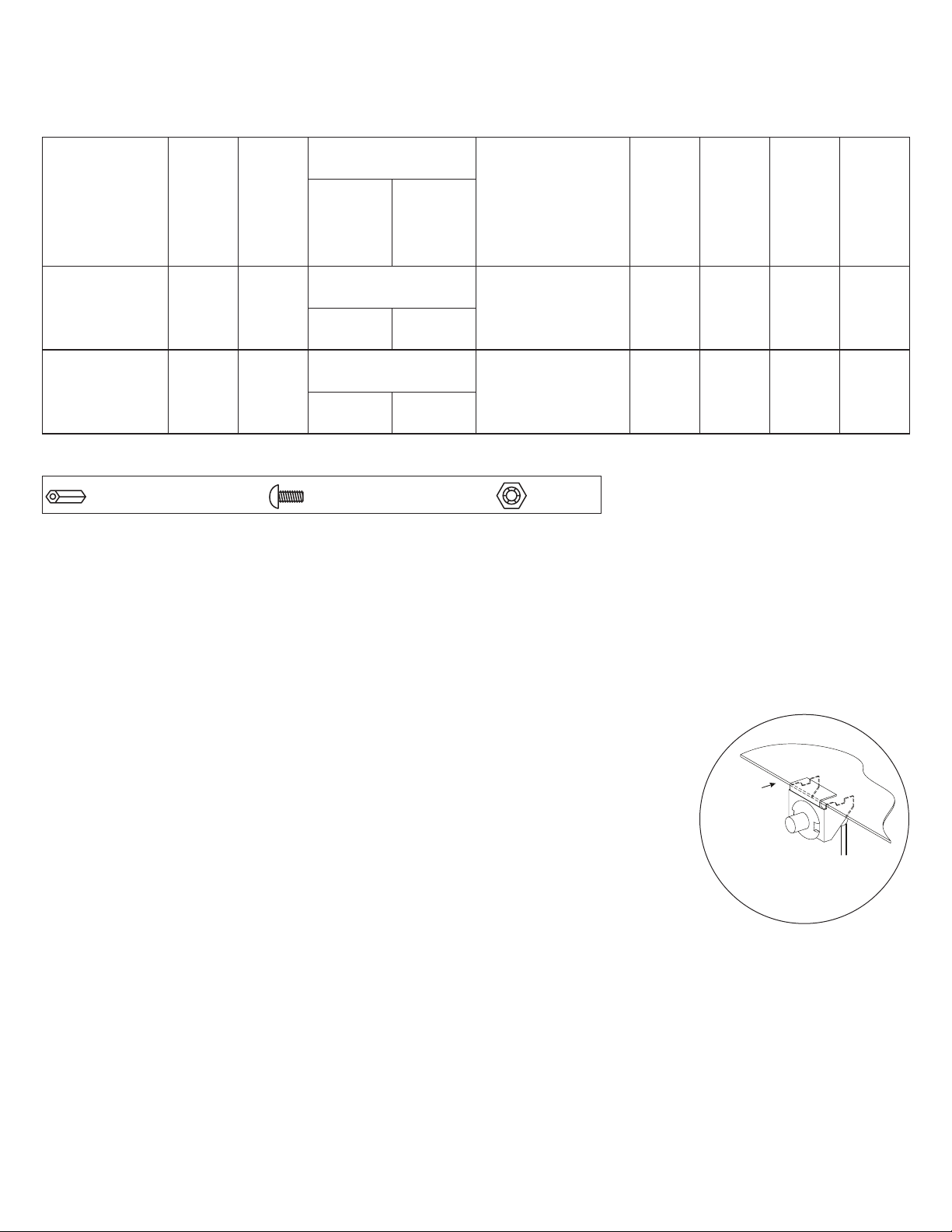

1. Remove backplane from enclosure. Do not discard hardware.

2. Mark and predrill holes in the wall to line up with the top three keyholes in the enclosure. Install three upper fasteners and screws

in the wall with the screw heads protruding. Place the enclosure’s upper keyholes over the three upper screws; level and secure.

Mark the position of the lower three holes. Remove the enclosure. Drill the lower holes and install

the three fasteners. Place the enclosure’s upper keyholes over the three upper screws.

Install the three lower screws and make sure to tighten all screws.

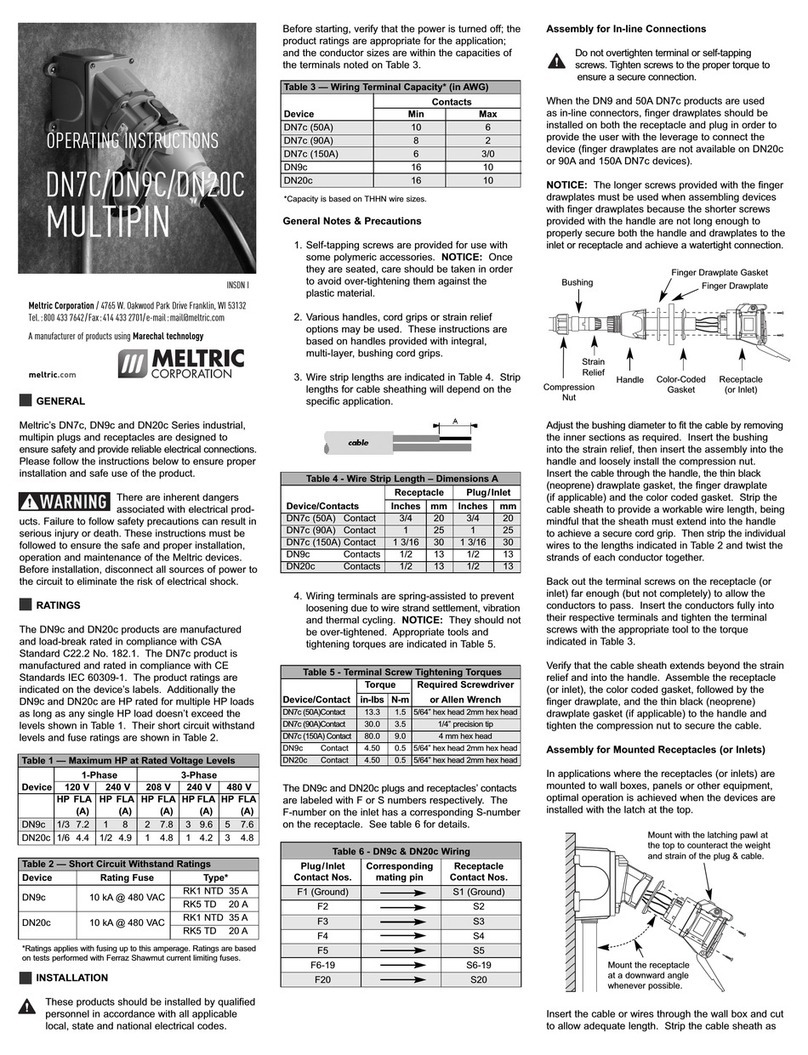

3. Mount included UL Listed tamper switch (Altronix Model TS112 or equivalent) in desired location,

opposite hinge. Slide the tamper switch bracket onto the edge of the enclosure approximately 2” from the

right side (Fig. 1, pg. 2). Connect tamper switch wiring to the Access Control Panel input or the

appropriate UL Listed reporting device. To activate alarm signal open the door of the enclosure.

4. Mount Hartmann Controls boards to backplane, refer to pages 3-4.

5. Refer to the ULXB Power Supply/Charger Installation Guide for AL600ULXB and

Sub-Assembly Installation Guide for ACM4 for further installation instructions.

Fig. 1

Tamper Switch

(included)

To Access Control Panel or

UL Listed Reporting Device

Edge of

Enclosure

Enclosure

Nylon or Metal Spacer | 5/16” Pan Head Screw | Lock Nut

THC1 ULXB Kits Installation Guide - 3 -

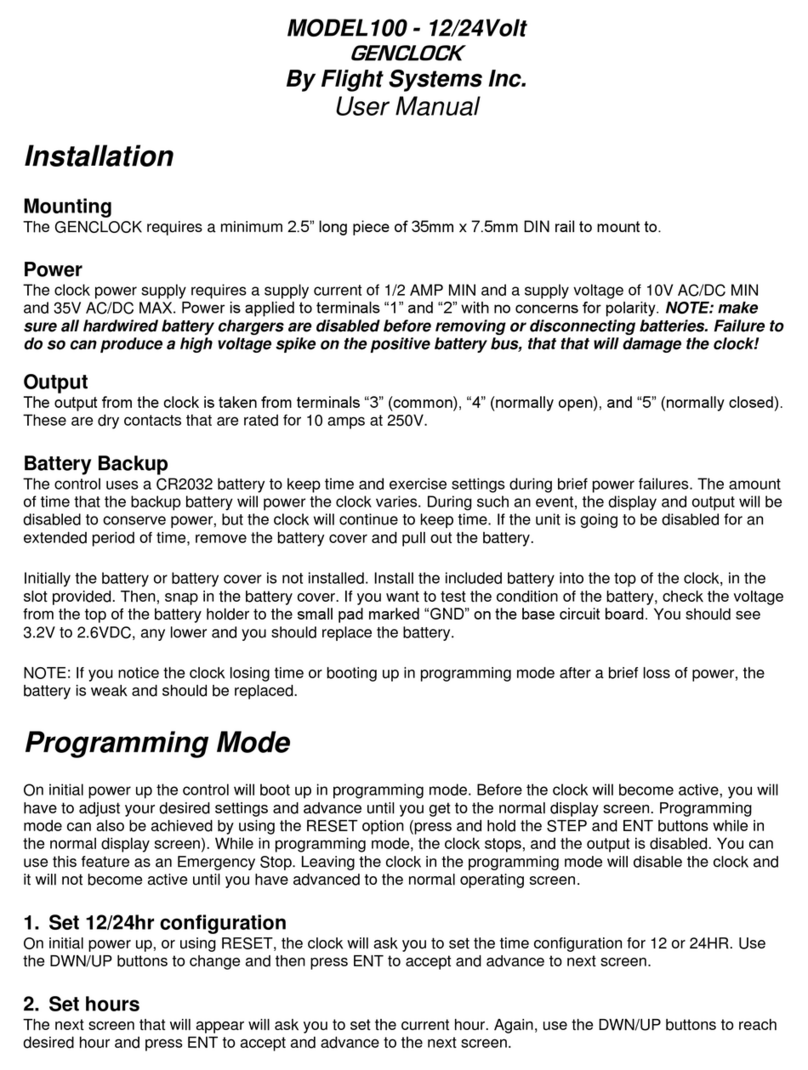

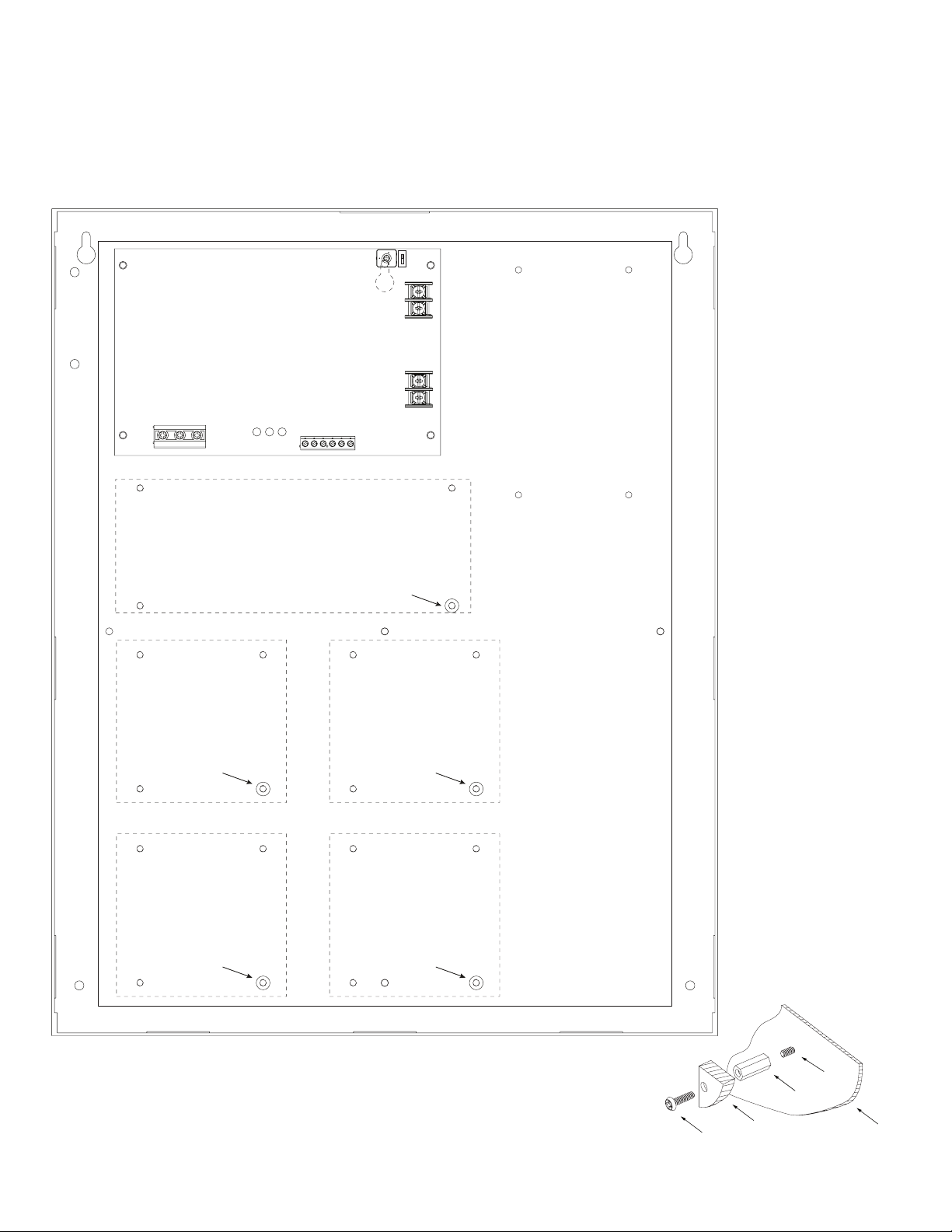

T1HCK3: Configuration of Hartmann Controls Boards:

1. Align the Hartmann Controls boards on the backplane to match the boards’ mounting holes with corresponding pems.

2. Fasten spacers (provided) to pems that match the hole pattern for Hartmann Control boards (Fig. 2, 2a, pg. 3).

Note: Hartmann Controls boards must be properly grounded.

Please use provided metal spacers for the lower right mounting holes (Fig. 2, pg. 3).

3. Mount Hartmann Controls boards to spacers utilizing provided 5/16” pan head screws (Fig. 2a, pg. 3).

4. Fasten backplane to Trove1 enclosure utilizing lock nuts (provided).

PRS_MASTER

Metal Spacer

PRS_TDM

or

PRS_IO8

Metal Spacer

PRS_TDM

or

PRS_IO8

Metal Spacer

PRS_TDM

or

PRS_IO8

Metal Spacer

PRS_TDM

or

PRS_IO8

Metal Spacer

BAT FAIL NC C NO NC C NO AC FAIL

AC DC BAT

+BAT- + DC -

L G N

OFF - 24V

ON - 12V

ON

AL600ULXB

Pem

Spacer

Hartmann Controls

Board

Backplane

Pan Head

Screw

Fig. 2a

Fig. 2 - T1HCK3 Configuration

- 4 - THC1 ULXB Kits Installation Guide

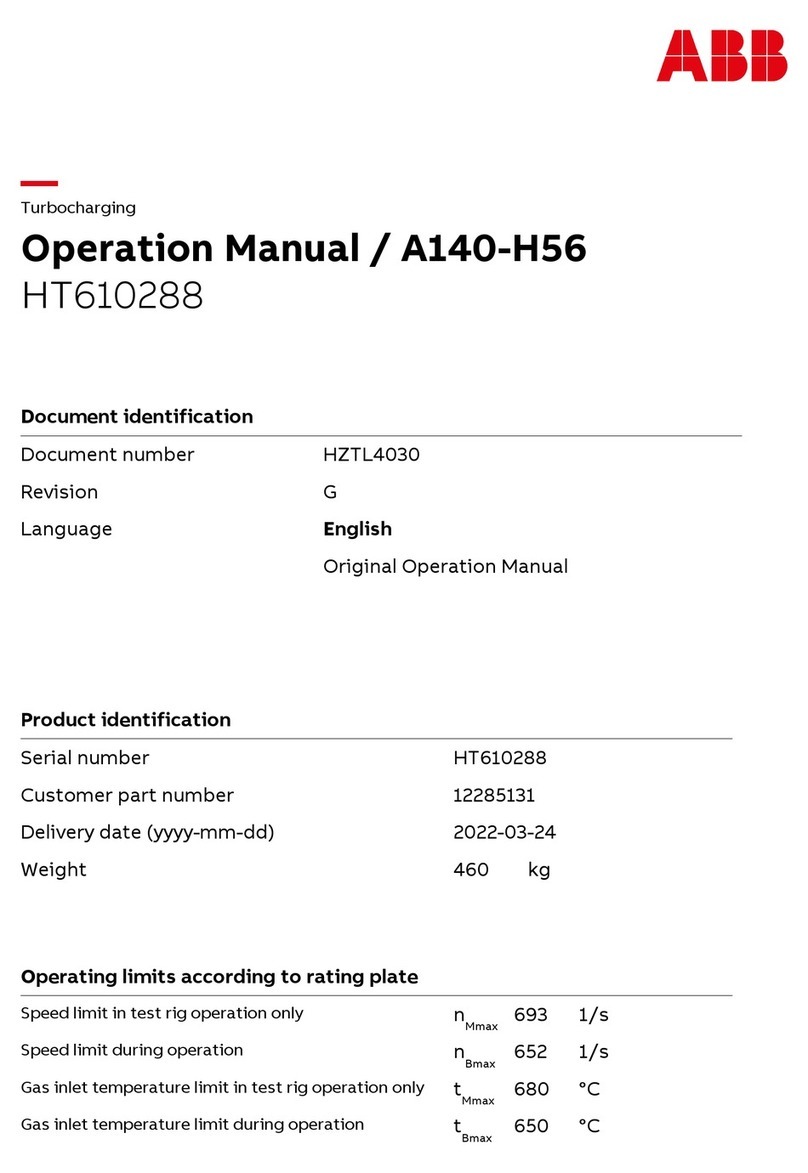

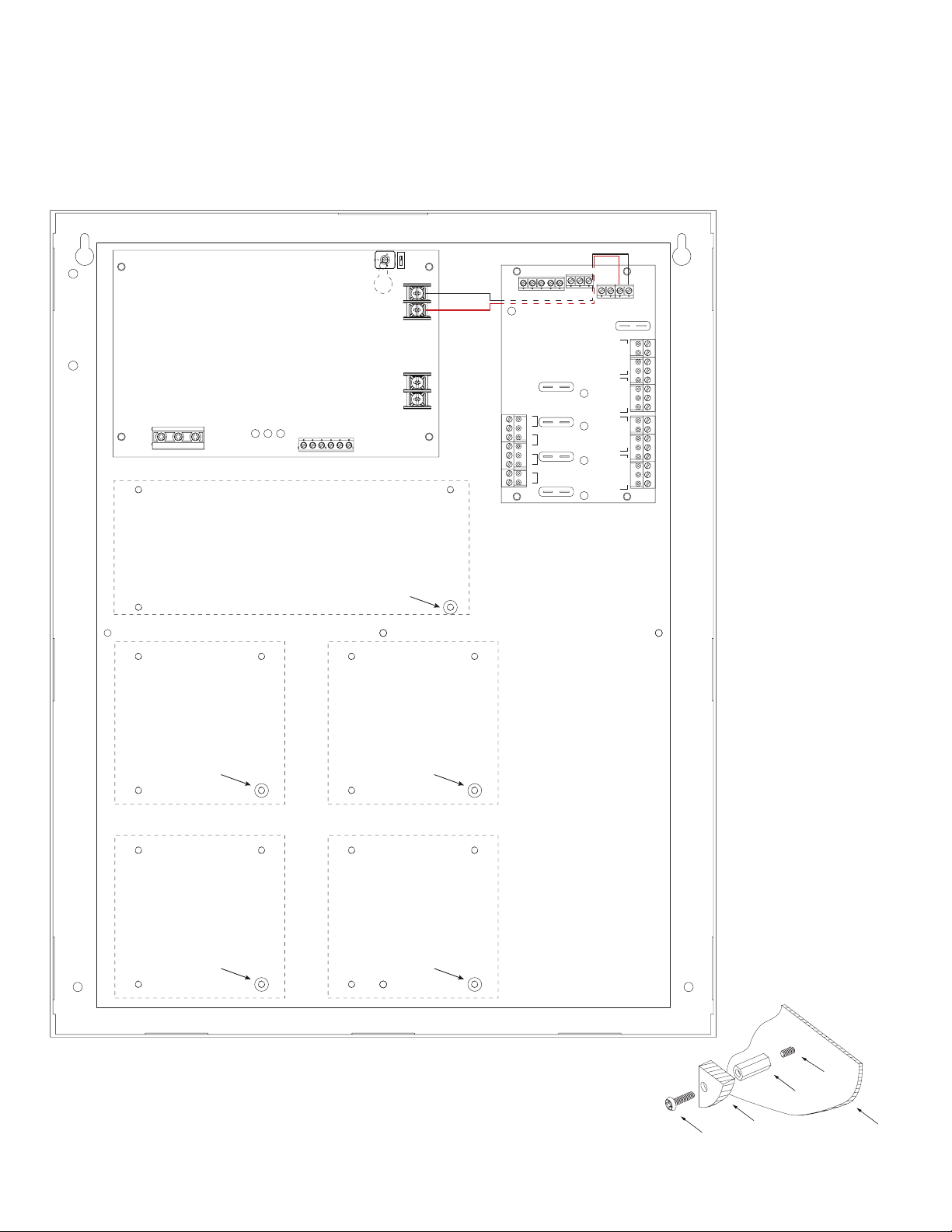

T1HCK34: Configuration of Hartmann Controls Boards:

1. Align the Hartmann Controls boards on the backplane to match the boards’ mounting holes with corresponding pems.

2. Fasten spacers (provided) to pems that match the hole pattern for Hartmann Control boards (Fig. 3, 3a, pg. 4).

Note: Hartmann Controls boards must be properly grounded.

Please use provided metal spacers for the lower right mounting holes (Fig. 3, pg. 4).

3. Mount Hartmann Controls boards to spacers utilizing provided 5/16” pan head screws (Fig. 3a, pg. 4).

4. Fasten backplane to Trove1 enclosure utilizing lock nuts (provided).

PRS_MASTER

Metal Spacer

Metal Spacer Metal Spacer

PRS_TDM or PRS_IO8 PRS_TDM or PRS_IO8

PRS_TDM or PRS_IO8 PRS_TDM or PRS_IO8

Metal Spacer Metal Spacer

TRG

TRIGGER

INPUT

ACM4

ACCESS POWER

CONTROLLER

LED1 LED2 LED3 LED4

MAIN

OUTPUT 1

NC C NO COM NC C NO COM NC C NO COM NC C NO COM

OUTPUT 2 OUTPUT 3

IN GND

1

IN GND

2

IN GND

3

IN GND

4

OUTPUT 4

-- +

CONTROL

-- +

POWER

+INP- T +RET-

INTERFACE

NO C NC

FACP

Altronix - ACM4

BAT FAIL NC C NO NC C NO AC FAIL

AC DC BAT

+BAT- + DC -

L G N

OFF - 24V

ON - 12V

ON

AL600ULXB

Pem

Spacer

Hartmann Controls

Board

Backplane

Pan Head

Screw

Fig. 3a

Fig. 3 - T1HCK34 Configuration

THC1 ULXB Kits Installation Guide - 5 -

Notes:

- 6 - THC1 ULXB Kits Installation Guide

Notes:

THC1 ULXB Kits Installation Guide - 7 -

Notes:

- 8 - THC1 ULXB Kits Installation Guide

Enclosure Dimensions (H x W x D approximate):

18” x 14.5” x 4.625” (457mm x 368mm x 118mm)

4.5” (114.3mm) 4.5” (114.3mm) 2.75”

(69.9mm)

1.115” (28.3mm)

1.36” (34.5mm)

1.25” (31.8mm) 1.25” (31.8mm)

1.5” (38.1mm)

8.5” (215.9mm)6.5” (165.1mm)

1.5” (38.1mm)

8.5” (215.9mm)6.5” (165.1mm)

4.5” (114.3mm)

13.0” (330.2mm)

0.6” (15.2mm)

14.5” (321.3mm)

1.45” (36.8mm)

7.25” (184.2mm)

1.95” (49.5mm)

1.1” (27.9mm)

0.6” (15.2mm)

0.57” (14.5mm)

18.0” (457.2mm)

1.25” (31.8mm)

Hartmann Controls is not responsible for any typographical errors.

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

10 Lockhart Rd, Barrie, ON L4N 9G8, Canada | phone: 1-877-411-0101

IITHC1 ULXB Kit Series A11V

This manual suits for next models

1

Table of contents