Contents:

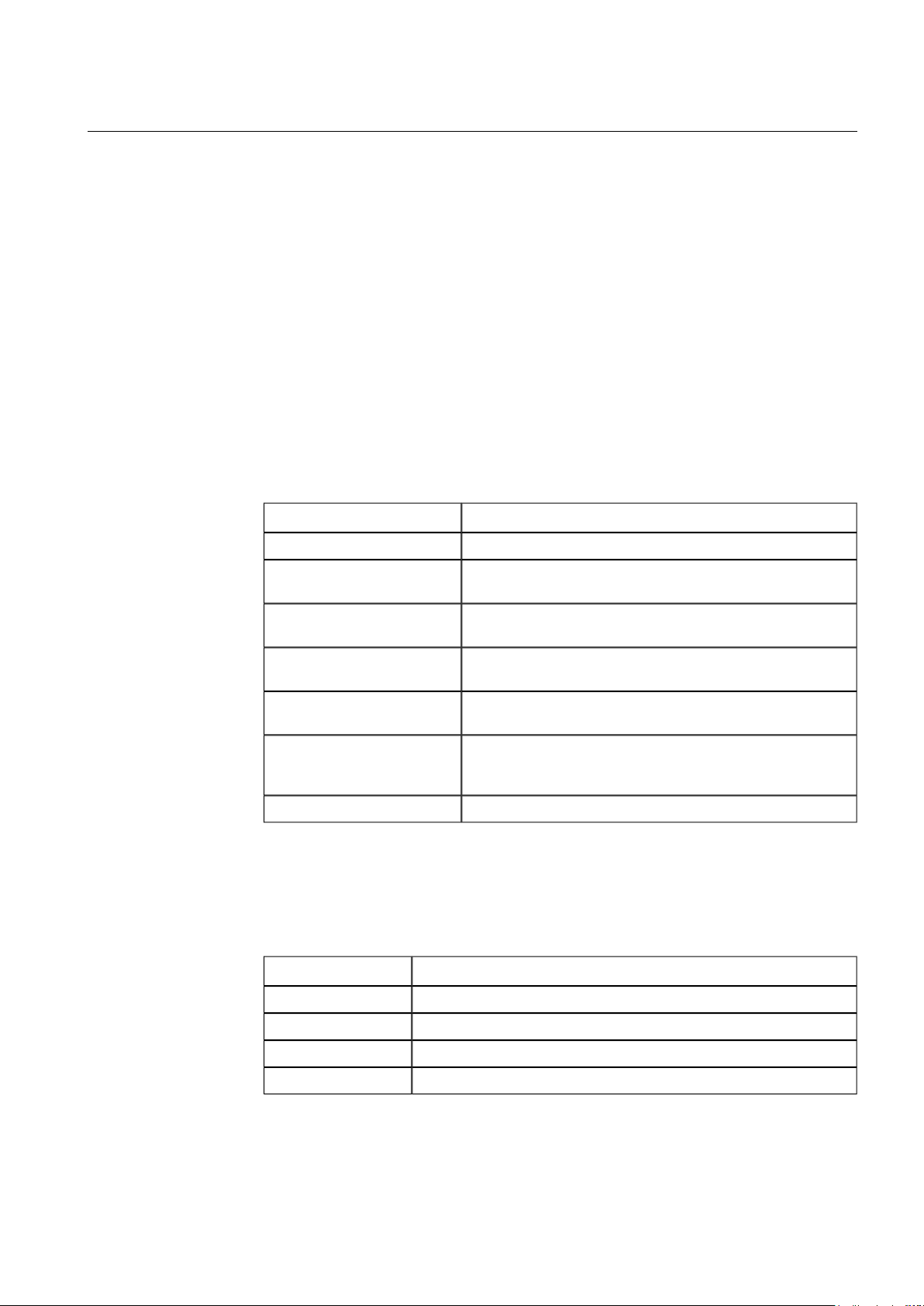

1. About this manual .................................................................................. 5

1.1. Copyrights ...................................................................................... 5

1.2. Trademarks .................................................................................... 5

1.3. General .......................................................................................... 5

1.4. Use of symbols .............................................................................. 5

1.5. Document conventions .................................................................. 6

1.6. Terminology .................................................................................... 7

1.7. Abbreviations ................................................................................. 7

1.8. Related documents ........................................................................ 8

1.9. Document history ........................................................................... 8

2. Introduction ............................................................................................. 9

2.1. Product overview ........................................................................... 9

3. HMI operations ...................................................................................... 10

3.1. General about HMI ....................................................................... 10

3.2. Predefined user account .............................................................. 10

3.3. Connecting HMI to the COM 600 computer ................................. 10

3.4. Substation and communication structures ................................... 11

3.4.1. Substation structure ...................................................... 11

3.4.2. Communication structure .............................................. 12

3.5. Single Line Diagram ..................................................................... 13

3.5.1. General about Single Line Diagram .............................. 13

3.5.2. Switch Device Control ................................................... 14

3.5.3. Busbar coloring ............................................................. 15

3.6. Alarms .......................................................................................... 16

3.6.1. General about alarms ................................................... 16

3.6.2. Monitoring and handling alarms .................................... 17

3.6.3. Acknowledging alarms .................................................. 18

3.6.4. Filtering alarms ............................................................. 18

3.7. Events .......................................................................................... 19

3.7.1. General about events .................................................... 19

3.7.2. Monitoring and handling events .................................... 19

3.7.3. Filtering events .............................................................. 20

3.8. Disturbance data upload .............................................................. 21

3.8.1. Disturbance recordings ................................................. 21

3.9. User management ....................................................................... 22

3.9.1. General about managing users ..................................... 22

3.9.2. Adding new users ......................................................... 23

3.9.3. Modifying user properties .............................................. 24

3.9.4. Changing user's password ............................................ 25

3.10. Parameter setting ......................................................................... 27

3.10.1. Changing parameters ................................................... 27

3.11. Measurements ............................................................................. 28

3

COM 605 3.0

COM 600 Station Automation Series1MRS756121

Operator's Guide

Issued: 16.10.2006

Version: B/22.1.2007