Cosmo LS-1866 User manual

OPERATION MANUAL

AIR LEAK TESTER

MODEL LS-1866

No. LS-1866-941B1-H

1 INTRODUCTION

2 GENERAL INFORMATION

AND SPECIFICATIONS

3 LEAK TESTING OVERVIEW

4 FEATURE SUMMARIES

5 INSTALLATION

6 PARTS IDENTIFICATION

AND FUNCTIONS

7 BASIC OPERATIONS

8 COMPENSATION MODE

(MASTER-PRESET)

9 CALIBRATION (CAL) MODE

10 ORIGINAL (ORG) MODE

11 INTERFACE

12 MAINTENANCE AND

TROUBLESHOOTING

13 APPENDIX

TABLE OF CONTENTS 1

TABLE OF CONTENTS

1

1INTRODUCTION...........................................................................................................................5

1.1 Introduction...............................................................................................................................................5

1.2 Safety Hints ..............................................................................................................................................5

1.3 Notes ........................................................................................................................................................6

2

2GENERAL INFORMATION AND SPECIFICATIONS....................................................................7

2.1 General Information..................................................................................................................................7

2.2 Features ...................................................................................................................................................7

2.3 Specifications ...........................................................................................................................................9

2.3.1 General Specifications ......................................................................................................................9

2.3.2 Test Pressure Gauge........................................................................................................................9

2.3.3 Timer Setting...................................................................................................................................10

2.3.4 Leak Rate Limit ...............................................................................................................................10

2.3.5 Model Classifications ......................................................................................................................10

3

3LEAK TESTING OVERVIEW ......................................................................................................11

3.1 Theory of Leak Test................................................................................................................................11

3.1.1Stage Summary ..............................................................................................................................11

3.1.2 Internal pressure changes of the tested part and master...............................................................12

3.2 Leak Rate Theory and Equations...........................................................................................................12

3.3 Estimating the Test Timer.......................................................................................................................14

4

4FEATURE SUMMARIES.............................................................................................................15

4.1 Master-Preset .........................................................................................................................................15

4.1.1 Theory of Master-Preset .................................................................................................................15

4.1.2 Master-Preset operation .................................................................................................................15

4.1.3 When to execute a Master-Preset process ....................................................................................16

4.2 Leak Calibration (Patented)....................................................................................................................16

4.3 Two-Level Limit Setting and Noise Reduction (NR) Mode.....................................................................17

4.4 Air-Operated Valve Performance and DPS Sensitivity Checks .............................................................17

4.5 Sensor Protection ...................................................................................................................................18

4.5.1 Cleaning pneumatic circuit by Exhaust air blow (DL3) ...................................................................18

4.5.2 External exhaust valve-ready .........................................................................................................18

4.6 CAL ports................................................................................................................................................18

4.7 Clamp Output .........................................................................................................................................19

4.8 Exhaust Interference Prevention ............................................................................................................19

5

5INSTALLATION ..........................................................................................................................21

5.1 Installing the Unit ..................................................................................................................................21

5.1.1Using Quick Mounting Brackets (standard) ....................................................................................21

5.2 Electrical Connection..............................................................................................................................23

5.3 Pneumatic Connection ...........................................................................................................................24

5.3.1 Connection ports.............................................................................................................................24

5.3.2 Pressure sources ............................................................................................................................24

5.3.3 Notes on source air.........................................................................................................................25

5.4 Connecting Master and Tested part .......................................................................................................25

5.4.1 Notes on designing a sealing fixture...............................................................................................25

5.4.2 Master installation ...........................................................................................................................27

5.4.3 Choosing proper connection to the tested part and the master .....................................................28

5.5 Leak Tester Installation Environment .....................................................................................................29

5.6 Procedure for installation and adjustment ..............................................................................................30

6

6PARTS IDENTIFICATION AND FUNCTIONS.............................................................................33

6.1 External Appearance ..............................................................................................................................33

6.1.1Indicators ........................................................................................................................................34

6.1.2 Keyboard.........................................................................................................................................35

6.1.3 Characters Appearing on the Digital Indicator ..............................................................................36

6.1.4 Leak Test Stages ............................................................................................................................37

6.2 Settings and LED Indications .................................................................................................................38

7

7BASIC OPERATIONS.................................................................................................................39

7.1 Turning on Power ...................................................................................................................................39

7.2 Setting a Test Pressure ..........................................................................................................................39

7.3 Test Pressure Gauge Upper and Lower Limit Setting............................................................................39

2 TABLE OF CONTENTS

7.4 Names of Test Pressure Gauge Components (Low · Medium / Vacuum Pressure) ............................ 40

7.4.1 Output Mode .................................................................................................................................. 40

7.4.2 Setting test pressure limits............................................................................................................. 41

7.4.3 Locking the key of the test pressure gauge ................................................................................... 42

7.4.4 Zero reset of the test pressure gauge............................................................................................ 42

7.4.5 Test pressure gauge error display ................................................................................................. 42

7.5 Names of Test Pressure Gauge Components (High Pressure) ............................................................ 43

7.5.1 Output Mode .................................................................................................................................. 43

7.5.2 Setting test pressure limits............................................................................................................. 44

7.5.3 Locking the key of the test pressure gauge ................................................................................... 45

7.5.4 Zero reset of the test pressure gauge............................................................................................ 45

7.5.5 Test pressure gauge error display ................................................................................................. 45

7.6 Unlocking the Keyboard ........................................................................................................................ 46

7.7Switching Remote to/from Manual......................................................................................................... 46

7.8 Start and Stop........................................................................................................................................ 46

7.9 Switching Channels ............................................................................................................................... 46

7.10 Switching Modes ................................................................................................................................... 47

7.11 Measurement Mode............................................................................................................................... 47

7.11.1 Viewing Differential pressure sensor (DPS) offset......................................................................... 47

7.11.2 Viewing raw output of detected differential pressure ..................................................................... 48

7.12 Timer Settings........................................................................................................................................ 48

7.12.1 Viewing........................................................................................................................................... 48

7.12.2 Entry............................................................................................................................................... 48

7.13 Limit Setting ........................................................................................................................................... 49

7.13.1 Viewing........................................................................................................................................... 49

7.13.2 Entry............................................................................................................................................... 49

7.13.3 Limit setting with NR (Noise Reduction) is activated ..................................................................... 49

7.13.4 Two-level limit setting..................................................................................................................... 49

7.14 Unit selection ......................................................................................................................................... 50

7.15 Charge Hold........................................................................................................................................... 50

8

8COMPENSATION MODE (MASTER-PRESET).......................................................................... 51

8.1 Sampling Master-Preset value .............................................................................................................. 51

8.1.1 Preparation..................................................................................................................................... 51

8.1.2 Sampling by manual operation ...................................................................................................... 52

8.1.3 Sampling externally through control I/O port ................................................................................. 53

8.2 Error message during Master-Preset sampling..................................................................................... 53

9

9CALIBRATION (CAL) MODE ..................................................................................................... 55

9.1 Leak Calibration..................................................................................................................................... 55

9.1.1 Preparation..................................................................................................................................... 55

9.1.2 Sampling drift value ....................................................................................................................... 55

9.1.3 Leak calibration using a Leak Master ............................................................................................ 56

9.1.4 Leak calibration using a volumetric-variable Leak Calibrator ........................................................ 56

9.1.5 Go/No Go judgement during leak calibration................................................................................. 57

9.2 DPS Offset Calibration .......................................................................................................................... 57

9.3 DPS Span Inspection ............................................................................................................................ 58

9.3.1 Connecting a Pressure Calibrator.................................................................................................. 58

9.3.2 Changing gain coefficients............................................................................................................. 58

9.4 No-Leak Test ......................................................................................................................................... 59

9.5 No-Leak Test Under Atmospheric Pressure.......................................................................................... 59

1

10

0ORIGINAL (ORG) MODE ........................................................................................................... 61

10.1 ROM Version Information (P-1) ............................................................................................................. 61

10.2 Memory Switch Settings (P-2) ............................................................................................................... 61

10.2.1 How to move to memory switch to be set ...................................................................................... 61

10.2.2 How to change settings.................................................................................................................. 61

10.2.3 Memory Switch Table .................................................................................................................... 62

10.3 Initialization (P-3) ................................................................................................................................... 65

10.3.1 Manufacturer’s settings.................................................................................................................. 65

10.4 Channel Copy (P-4)............................................................................................................................... 65

10.5 Noise Reduction (NR) (P-5)................................................................................................................... 66

10.6 Serial Number Setting ........................................................................................................................... 66

1

11

1INTERFACE ............................................................................................................................... 67

11.1 Control I/O Port...................................................................................................................................... 67

TABLE OF CONTENTS 3

11.2 Channel Selection ..................................................................................................................................70

11.3 Stage Number Output.............................................................................................................................70

11.4 External Signal Timing Charts................................................................................................................71

11.5 Serial Communications Interface ...........................................................................................................72

11.5.1 Interface specifications ...................................................................................................................72

11.5.2 Output formats ................................................................................................................................77

11.5.3 Data format .....................................................................................................................................78

11.5.4 Checksum .......................................................................................................................................80

1

12

2MAINTENANCE AND TROUBLESHOOTING ............................................................................81

12.1 Daily Items to Check and Maintain.........................................................................................................81

12.2 Monthly Items to Check and Maintain ....................................................................................................81

12.3 Annual or Semiannual Inspection Items.................................................................................................81

12.4 Error Messages ......................................................................................................................................82

12.4.1 Errors and Treatment......................................................................................................................82

12.4.2 E-3: Excessive Differential Pressure Sensor Zero-point Shift......................................................82

12.4.3 E-4 Improper test pressure ..........................................................................................................83

12.4.4 E-5: Air-operated Valve Inactive ..................................................................................................83

12.4.5 E-9 Pressurization valve error......................................................................................................83

12.5 Leak Test Troubleshooting.....................................................................................................................84

12.5.1 When No-Go judgements occur consecutively...............................................................................84

12.6 Locating Leaks in Places Other Than the Leak Tester ..........................................................................85

1

13

3APPENDIX ..................................................................................................................................87

13.1 EXTERNAL APPEARANCE...................................................................................................................87

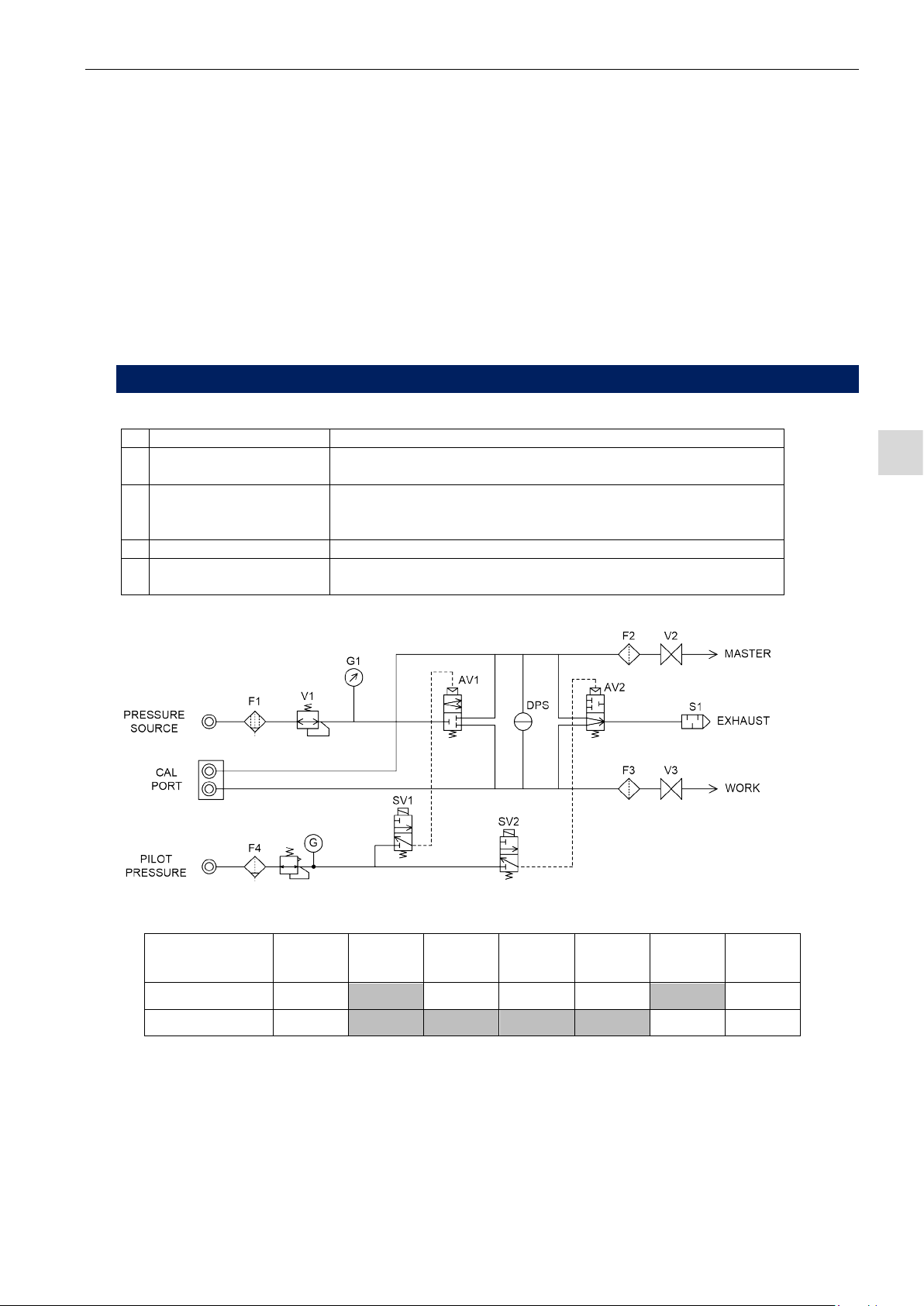

13.2 PNEUMATIC CIRCUIT...........................................................................................................................88

13.2.1 INTELLIGENT I AIR CIRCUIT LS-1866 .........................................................................................88

13.3 Pressure Unit Conversion Table ............................................................................................................89

13.4 Flow Unit Conversion Table ...................................................................................................................89

13.5 CE Marking.............................................................................................................................................89

13.6 Information to Users (FCC Rules) ..........................................................................................................90

1 INTRODUCTION 5

1

1

INTRODUCTION

1

1.

.1

1

I

In

nt

tr

ro

od

du

uc

ct

ti

io

on

n

Thank you very much for purchasing COSMO’s LS-1866 Air Leak Tester. This operation manual provides

information about the LS-1866 Air Leak Tester, including its functionality, operating instructions, and precautions

in handling. Before using the product, read this manual carefully to assure proper handling. After reading, keep

the manual in a safe place for reference.

1

1.

.2

2

S

Sa

af

fe

et

ty

y

H

Hi

in

nt

ts

s

Instructions to abide by for using the product safely without risking physical injury to the user and other persons,

and property damage are given below.

[Explanations of the signs]

Signs

Explanation

WARNING Failure to take or avoid a specific action could result in death or serious physical harm to

the user.

CAUTION Failure to take or avoid a specified action could result in small physical harm to the user

or property damage.

[Explanation of the symbols]

Δ This symbol denotes a warning to alert the user. A specific description of the warning follows.

(Example: Electrical shock hazard)

a) Ground the unit before plugging it into a power source.

The unit, if not grounded, would be liable to electrical

shock hazards. Never connect the grounding

conductor to a gas pipe. Grounding the unit to a gas

pipe could result in fires or electrical shock hazards.

b) If the metallic part of the power plug or any

surrounding area is found dusty, wipe off thoroughly

with a dry cloth. Continued use could result in fires or

electrical shock hazards.

c) Never run the unit from source voltages other than

marked rated. Running the unit from a nonstandard

source voltage could result in fires or electrical shock

hazards.

d) If the unit should be dropped or damaged, switch it off

and disconnect the power plug from the receptacle.

Continued use could result in fires or electrical shock

hazards.

e) Do not apply air pressure beyond the pressure rating

of the unit. Excessive pressure input could cause

catastrophic component failure and/or injury.

f) If foreign matter, such as water and oils, should get

inside the instrument, switch it off immediately and

unplug it from the receptacle. Continued use could

result in fires or electrical shock hazards. Use

particular care when installing the unit in an

environment where water or oils are used nearby.

g) The instrument should be located in a situation where

the power plug can be accessed immediately in case

of an emergency.

h) This unit is not customer-serviceable. Customer

servicing could result in fires or electrical shock

hazards.

i) Replace with a fuse of the same rating as the one that

is built in the unit. Use of a nonstandard fuse could

result in fires or electrical shock hazards.

j) Discontinue using the unit when:

• The unit smokes.

• The unit emits abnormal noises.

• The unit developed problems not covered in the

operations manual.

• The unit cannot be operated as indicated in the

operations manual.

To avoid electrical shock hazards or physical harm,

disconnect the power cable and remove the pressure

source from the unit. Continued use could result in

fires or electrical shock hazards.

WARNING

6 1 INTRODUCTION

a) Do not use the unit in places that are damp, that are

exposed to direct sunlight or that are outside the

temperature range of 5°C to 40°C. Using the unit in

such environments could result in malfunctions or

failures.

b) To avoid damage to the power cable, which could

result in fires or electrical shock hazards, observe

these precautions:

• Do not damage, modify or apply undue force to

the power cable.

• Before servicing the unit, disconnect the power

plug from the receptacle.

• Do not handle the power plug with wet hands.

• When disconnecting the power plug, do not pull

the power cable.

c) Ensure correct cabling. Incorrect cabling could result

in damage to the unit and surrounding hardware.

d) Mount the unit in firm position in a frame capable of

fully sustaining its load. Do not install the unit in a

violently vibrating, sloped or any other rickety place. If

installed in these environments, the unit could fall

down or drop, resulting in physical harm.

e) Do not step on top of the unit or place a container filled

with water, oils/soapy water, or other similar objects on

its top. These objects might spill, causing physical

harm, or electrical shock hazard, rust or other

damage.

f) Do not disassemble the unit. If disassembled, the unit

could malfunction, resulting in physical harm or

electrical shock hazards.

g) Do not install or remove the tubing with the product

connected to an air pressure source. It could result in

physical harm.

Wear a safety goggle to protect your eyes.

h) When a leak test is completed, unclamp the tested

part after the unit has completely exhausted. Residual

pressure could result harm.

i) When carrying the unit, hold it by the bottom to keep it

from dropping. If dropped, unit could be damaged or

caused result in breakage or physical harm.

j) When packing the product for shipment, remove its

projections, such as rear panel-mounted filters and

regulators, and wrap it with cushioning material as a

whole to guard against damage during transit.

k) Wipe out the unit lightly with a dry and soft cloth for

maintenance. When the unit is with heavy dirt, dilute

the neutral detergent with water, soak the cloth in the

detergent, squeeze the cloth, and wipe the dirt out.

Organic solvent should not be used.

l) Put on steel-toe boots when transferring the product

for shipping, installation, dismantling. Neglecting it

could result in physical harm by dropping the product.

m) Handle the product according to the instructions in this

operation manual or the protection feature equipped

with the product will be compromised.

1

1.

.3

3

N

No

ot

te

es

s

a) The information in this document is subject to change without notice for the sake of performance or functional upgrades.

b) This document may not be reproduced in whole or in part without prior approval of the publisher.

c) We are not held responsible for the items tested using this unit and the consequences of the tests.

d) To minimize incorrect test results, this unit comes complete with self-check functions to detect certain improper settings

and operations, and internal equipment malfunctions and thus to prevent incorrect judgments from being delivered. The

scope of monitoring by self-checking, however, is limited. Verification of the unit performance and operations using

separately specified apparatus is recommended.

e) This unit performs measurements based on the principle of differential pressure detection, using the master comparison

method. In addition to actual product leakage there are a number of additional variables that can affect test results, the

most common of these are temperature changes, volume changes and system leakage (on either side of the DP

sensor).

f) The user is encouraged to consult us directly (or your dealer) for any questions the user has about using our product.

CAUTION

2 GENERAL INFORMATION AND SPECIFICATIONS 7

2

2

GENERAL INFORMATION AND SPECIFICATIONS

2

2.

.1

1

G

Ge

en

ne

er

ra

al

l

I

In

nf

fo

or

rm

ma

at

ti

io

on

n

LS-1866 is an air leak tester based on a differential pressure method that tests the air tightness of various

parts and products. Air leak tester allows not only enhancing a detection capability but also an automated

detection process. Ideal for professional and industrial use.

Housing a high-sensitivity, high-pressure differential sensor and air-operated valves free from thermal

effects, the unit is built of intelligent air circuitry that makes on various checks during each run of testing,

including valve action and sensor sensitivity checks, to assure exceptional performance and reliability. Its

Master-Preset feature and noise reduction feature support assures enhanced detectability or shorter test

times. Other user conveniences include compatibility with various kinds of tested parts, direct reading of

leak rates, and easy-to-service CAL ports.

2

2.

.2

2

F

Fe

ea

at

tu

ur

re

es

s

a) Master-Preset compensation feature

• This feature compensates the drift errors caused by the volume difference between the tested part

and the master, adiabatic compression effect and change in ambient temperature.

• Cosmo’s patented Master Chamber that is easy to adjust and maintain can be used as a Master

(Reference) to reduce installation cost.

• Suitable measurement for different part can be achieved by executing Master-Preset process.

b) 2 levels of limit settings and Noise Reduction (NR) mode

• Sorts out NG-judged part by magnitude of leakage.

• In NR mode, DET stage is repeated for the rejected parts fell between the two limits to minimize

false rejection good parts.

c) Leak rate unit (mL/min) can be displayed.

• Differential pressure is converted into leak rate by calibration with Leak Master (LM-1B).

d) High-performance differential pressure sensor and Intelligent I Pneumatic Circuit

• Equipped with a differential pressure sensor that is highly sensitive, proof against high pressure

and low volume. The pneumatic circuit is simple yet full function.

• Equipped with air operated valves with high flow capacity, which is free from thermal effect.

• Includes self-cleaning feature to protect sensor from being contaminated with water and oil inside

the tested part.

• The sensor and the valve performance is automatically checked at the end of the each test cycle to

ensure reliability of leak testing.

e) Multi-channel

• 16 different sets of test parameters can be programmed independently. A channel copy feature

eases multi-channel setting.

f) CAL ports

• CAL ports are easily accessible on the front panel for daily sensitivity check using a Leak Master or

a Leak Calibrator. These ports are also convenient for periodic calibration of the differential

pressure and the pressure gauge.

g) Test pressure and Leak limit setting monitoring

• Test pressure is digitally displayed.

• Upper and lower limits of test pressure can be programmed

• Leak limit setting can always be monitored on the sub-panel

h) Serial communication

• The tester can be connected to computer and/or printer through the serial communication port to

maintain and control the test data.

• Use of a multiplexor enables to connect multiple testers to a single computer.

8 2 GENERAL INFORMATION AND SPECIFICATIONS

i) Quick mounting brackets

• Tester can be removed from the machine easily from the front side by using these brackets.

j) Clamp signal

• This tester can control external solenoid valve to drive air cylinder. Use of this feature allows

building a simple and low cost machine system.

k) Fitness to overseas use

• The power inlet can accept 100 to 240 VAC ±10 % at 50/60 Hz single-phased power supply,

100VA max. The standard power cord supplied with the leak tester is rated for 100 to 120.

Special power cord for 125 to 240 VAC is available upon request.

l) Data storage in flash memory

• There is no need of battery replacement because all the test parameters are stored in flash

memory.

m) Channel copy

• Test parameters of a channel can be copied to the another. This makes multi-channel program

easier.

n) Exhaust interference prevention

• When using several leak testers to measure different cavities on the same part simultaneously, this

prevents jumps in the leak tester readout during the exhaust of one of the other testers.

2 GENERAL INFORMATION AND SPECIFICATIONS 9

2

2.

.3

3

S

Sp

pe

ec

ci

if

fi

ic

ca

at

ti

io

on

ns

s

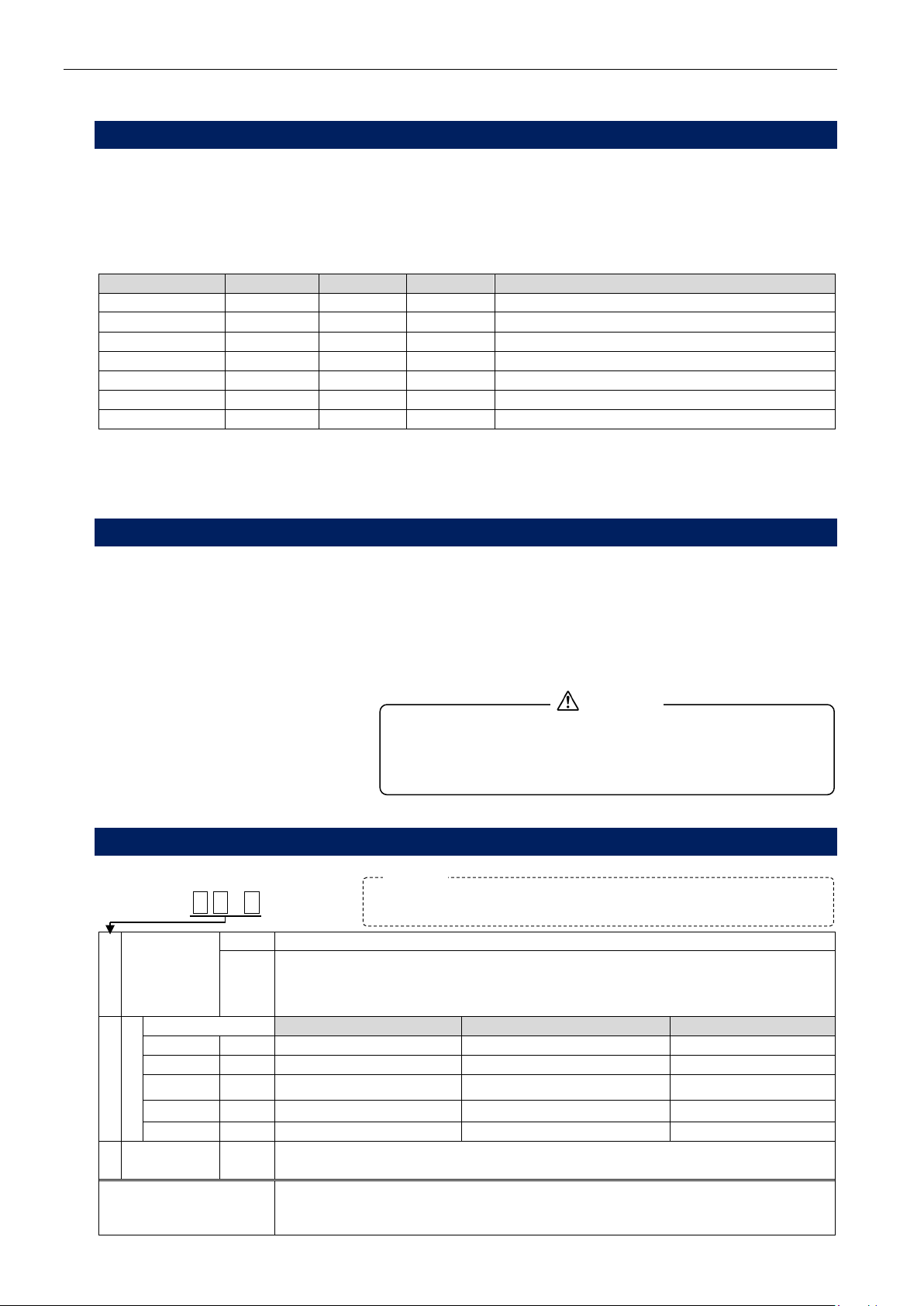

2.3.1 General Specifications

Differential

pressure

Minimum reading

Display range (Guaranteed)

Sensor range

Sensor proof pressure

Reading accuracy *1

Standard: 0.1 Pa

Standard: ±999 Pa

Standard: ±2000 Pa

5 MPa

±2.5% of rdg ±1Pa for range above 50Pa, ±2Pa for 0-50Pa range

(within guaranteed accuracy range)

Leak rate reading range

0.00 to ±999mL/min (floating point)

Leak rate limit setting range

HI (Work), LO (Master)

Differential pressure unit reading: 0 to±999 Pa

Flow rate unit reading: 0.01 to ±999 mL/min

Number of channels

16 (0 to 15 ch)

Timer

Setting range

0 to±999.8s (infinite 999.9 setting)

Resolution

0.1s

Power supply

100 to 240 VAC ±10 % at 50/60 Hz single-phased power supply, 70

VA max

Test pressure source

Clean air sufficiently higher than the test pressure. Be sure to

connect regulator to eliminate fluctuation of plant air.

Pilot pressure source

Clean air regulated from 400 to 700 kPa

Tubing port inner diameter

Rc (PT) 1/4 (Pressure source, Work and Master ports)

6mm one-

touch joint (Pilot pressure for M, L range is connected to

pressure source by 6mm tubing) (Pilot pressure port)

Control I/O port

Current-sink Open collector Outputs: DB-37P Male connector

Communications functions

Serial communication port (can be switched to printer format)

Operating temperature

5 to 40°C

Storage temperature

-20 to 70°C

Ambient humidity

80 % RH or less, no dew condensation

Weight

M, L, V : 6.3 kg H10, H15 : 8.1kg

Standard components

Pressure regulator, Oil mist separator (except Vacuum pressure type)

Air filter regulator for pilot pressure, Clamp signal connector

Standard accessories

and components

Power cord (withstandability 125VAC, 3 m), Quick mounting

brackets, Control I/O connector,

Inspection record and Operations

manual, Traceability related documents

Optional accessories

5 m power cord, Power cord (withstandability 240 VAC), Leak Master,

Fitting for CAL port and Master Chamber

*1 For the option D4: DPS 10kPa, the reading accuracy is ±5% of rdg ±0.01 kPa. However, ±0.02 for 0.2

kPa or lower..

2.3.2 Test Pressure Gauge

Upper and lower limit setting of digital pressure gauge

Test pressure

pressure range

Proof pressure

Setting resolution

L (Low)

0 to 100.0 kPa

500 kPa

0.1 kPa

M (Medium)

0 to 1.000 MPa

1.5 MPa

0.001 MPa

M10 (High)

0 to 1.000 MPa

1.5 MPa

0.001 MPa

M15 (High)

0 to 1.998 MPa

4 MPa

0.002 MPa

V (Vacuum)

0 to -101.3 kPa

500 kPa

0.1 kPa

Display digits: 3 1/2 digit LED display (Sampling period 5 times/sec)

Display accuracy: ± 2 % F.S. ±1 digits or less (under ambient temperature 25 ± 3°C)

10 2 GENERAL INFORMATION AND SPECIFICATIONS

2.3.3 Timer Setting

Accuracy: Setting ± 1 digit

Setting range: 000.0 to 999.8 s (999.9 s for infinity)

Timers can be set at the user's discretion between 0 and 999.8. A timer setting of 999.9 represents an

infinite timer value. A stage whose timer is set to 0 will be skipped.

Maximum and minimum settings

Stage

Symbol

Minimum

Maximum

Notes

Charge delay

DL1

0.1

999.8

Charge

CHG

0.0

999.8

*1

Balance delay

DL2

0.1

999.8

Balance

BAL

0.1

999.8

Detection

DET

0.1

999.8

End delay

DL3

0.0

999.8

Set to 0.0 s for the high-pressure model (H15).

End

END

0.2

999.8

*1 When memory switch 24 is set to 0, the maximum value of the CHG timer is 6000.0.

When a value of 6001.0 or greater is set, the timer value is infinite.

When a value of 1000.0 or greater is set, the digits following the decimal point are truncated.

2.3.4 Leak Rate Limit

1) HI and LO limit settings for Balance (BAL) and Detection (DET) stages

Differential pressure display: 0 to ±999 Pa (standard: 2000 Pa DPS range)

0.01 to 9,99 kPa (option: 10 kPa differential-pressure sensor range)

Leak rate display: 0.01 to ± 999 mL/min (floating point)

2) HIH and LL limit settings for DET stage

Set to somewhere between +10 and +90% of the HI and LO limits of the DET stage.

3) Judgment accuracy

Matches with leak rate readings.

2.3.5 Model Classifications

LS-1866 AB-C

A

Pneumatic

Circuit

A1

Intelligent I Pneumatic Circuit

AS01

Small-volume Intelligent I Pneumatic Circuit

Recommended test condition: Part volume small (50 mL or smaller) and

leak

standard is extremely low. Tester internal volume: 6 mL

B

Test pressure

Pressure range

Digital pressure gauge range

Regulator range

Low

L

10 to 95kPa

0 to 100kPa

5 to 200kPa

Medium

M

50 to 800kPa

0 to 1MPa

0.05 to 0.8MPa

High H10 100 to 990kPa 0 to 1MPa 0.05 to 1.6MPa

High

H15

0.1 to 1.5MPa

0 to 2MPa

0.05 to 1.6MPa

Vacuum

V

-5 to -100kPa

0 to -101.3kPa

-1.3 to -100kPa

C

Options D4

Display of wide differential pressure range.

Differential pressure range 10 kPa (Standard: 1 kPa)

External equipment

available for standard

models

Compatible with external exhaust valve: G-3ME; Remote controller: RC-12B

Limit settings exceeding the DP sensor output range may

cause sensor output saturation during measurement, delivering

an incorrect judgement. Be sure that those limits are within

the range.

CAUTION

The maximum working pressure for the vacuum pressure model

(V) is also constrained by atmospheric pressure conditions.

NOTE

3 LEAK TESTING OVERVIEW 11

3

3

LEAK TESTING OVERVIEW

3

3.

.1

1

T

Th

he

eo

or

ry

y

o

of

f

L

Le

ea

ak

k

T

Te

es

st

t

After a tested part is charged with an air pressure, the resulting change in its internal pressure is measured

to detect a leak. A non-leaking reference part (master) is made available and is charged with a pressure

concurrently with the tested part in Leak Testing. After the air supply is stopped, a high-sensitivity differential

pressure sensor (DPS) detects the pressure change in the tested part resulting from a leak.

3.1.1 Stage Summary

Stages

A

Start

After clamping and sealing a tested part, initiate a start signal.

B Charge (CHG) stage Pressurizes the tested part and the master.

C Balance (BAL) stage

Isolates tested part and master from pressure supply and each

other to let the internal pressure stabilize.

Large leak is detected during this stage as No-Go.

D

Detection (DET) stage

Detects small leaks.

E

Air blow, Exhaust and

End (DL3, END)

Transmits judgment signal, and exhaust pressure inside the

tested part and master from the exhaust port.

Basic Type Pneumatic Circuit

Timing Chart

Solenoid valve DL1

Delay

CHG

Charge

DL2

Delay

BAL

Balance

DET

Detection

DL3

Air blow

Exhaust

END

Exhaust

End

SV1

SV2

12 3 LEAK TESTING OVERVIEW

3.1.2 Internal pressure changes of the tested part and master

In the BAL and the DET stage, the differential pressure

resulting from leaks rises at a constant rate with time. In the

DET stage, the differential pressure sensor (DPS) output is

zeroed through an auto-zero operation before a differential

pressure reading is produced.

3

3.

.2

2

L

Le

ea

ak

k

R

Ra

at

te

e

T

Th

he

eo

or

ry

y

a

an

nd

d

E

Eq

qu

ua

at

ti

io

on

ns

s

When a differential pressure is detected, it can be converted to leak rate unit mL/min by using a conversion

equation derived from Boyle's Law. Using the unit's leak calibration facility removes the need for

calculations based on the conversion equation.

(See Section 4.2. →)

a) Pressure and Volume Relationship

The relationship between pressure and volume is stated in Boyle’s law. Boyle’s law: for an ideal gas,

pressure multiplied by volume is a constant if the temperature is constant. In mathematical form:

PV = constant (where P is in absolute pressure units.)

A leak is measured by a change in pressure. The amount of leakage to atmosphere is calculated and

expressed by the following equation derived from Boyle’s law.

Leakage (ΔVL) = Ve × ΔP / Patm

Where:

Ve: Equivalent internal volume

∆P: Pressure drop due to a leak

Patm: Atmospheric pressure

The definition of internal equivalent volume (Ve) is the volume of air of

the entire Work-side pneumatic circuit at a particular test pressure. It

also includes a diaphragm deformation factor of the DPS. Ve is used

as leak coefficient K(Ve) in the leak rate calculation.

NOTE

3 LEAK TESTING OVERVIEW 13

b) Equivalent internal volume calculation

Differential pressure can be converted into a leak rate by calculating the equivalent internal volume with

the following equation:

Ve = Vw + Vt + [ Ks × { 1 + ( Vw + Vt ) / ( Vm + Vt )} + Kw ] × (101.3 + P ) …………………1

Where:

Ve: Equivalent internal volume [mL]

Vw: Internal volume of the Work side: tested part and the tubing [mL]

Vm: Internal volume of the Master side: master and the tubing [mL]

Vt: Tester internal volume (mL) Vt = 11 mL (Standard pneumatic circuit)

Ks: Change in internal volume of the sensor per unit pressure change [mL/kPa]

Kw: Change in internal volume of the tested part per unit pressure change [mL/kPa]

P: Test pressure [kPa]

If the Master side has the same internal volume as the Work side and

both are so rigid that the test pressure does not physically change their

dimensions, then

Ve = Vw + Vt + 0.01(101.3 + P) …………………2

Where:

Vw = Vm

Ks = 0.005 [mL/kPa] (measured value)

Kw = 0 [mL/kPa]

Ks {(1 + ( Vw + Vt ) / ( Vm + Vt)} + Kw = 2Ks = 0.01 [mL/kPa]

c) Calculation of a Leak Rate

If the volume of air that leaked out of a part is known, this can be converted to a leak rate by knowing for

how long (t) the pressure change (ΔP) was measured.

Mathematically this is expressed as follows:

Where:

Q: Leak rate in volume per time [mL/min]

∆P: Pressure drop due to a leak [Pa]

Ve: Equivalent internal volume [mL]

T: Detection time

The LS-1866 uses the above equation for the calculation of the leak rate. Note that the tester uses

standard atmospheric pressure for this calculation. If the tested part is tested under standard pressure,

1.013 × 105Pa, and standard temperature, 20°C, then the tester displays a standard volume per time.

Example: Converting the differential pressure, ΔP = 50 [Pa] under following test condition into leak

rate using formula 2and 3.

Test pressure (P) = 400 [kPa]

Part internal volume (Vw) = 80 [mL] (including tubing) = Vm

DET timer (T) = 3 [s]

Tester internal volume (Vt) = 11 [mL]

Differential pressure during DET stage (ΔP) = 50 [Pa]

Using formula 2,

Equivalent internal volume (Ve) = 80+11+0.01×(101.3+400) 96 [mL]

Using formula 3,

(mL/min)0.95

3

60

101.013

50

96

5

≒×

×

×

Leak rate (Q) = 0.95 [mL/min]

T

60

10013.1

P

VeQ5×

×

∆

×=

3

Tester internal volume,

Vt, including CAL port

1) Standard: 11 mL

2) AS01 : 6 mL

14 3 LEAK TESTING OVERVIEW

3

3.

.3

3

E

Es

st

ti

im

ma

at

ti

in

ng

g

t

th

he

e

T

Te

es

st

t

T

Ti

im

me

er

r

a) Required measurement timer increases under the following conditions:

• Test pressure is rather high.

• Internal volume of the tested part is large.

• Surface area of the tested part is small

• Leak specification is small.

• Pressure deformation of the part and/or the clamp seal occurs

• Part temperature is different from the ambient temperature.

b) Setting CHG and BAL timers

Generally, a longer CHG timer reduces the ratio of noise presence in the DET stage, contributing to

better measurement accuracy. Set the timers with reference to the general timer ratios, suggested

below and the Table E).

General timer ratios: CHG timer :BAL timer = 3 :1

In setting a CHG timer at installation and adjustment, first run a leak test with a sufficiently long CHG

timer setting. Then, start sampling data by gradually reducing the CHG timer to find out the shortest

CHG and BAL timers in which compliance data gets stabilized in the vicinity of zero.

c) Limitation on the BAL timer setting

A long BAL timer and a large leak limit setting during BAL initiates the DET stage without a large leak

being detected in this stage. In this case, the differential pressure exceeds its LIMIT before the DET

timer ends, resulting in a DPS output saturation. Further, when Leak Master differential pressures are

sampled to establish an equivalent internal volume (leak coefficient), too long a BAL timer can produce

a differential pressure past the measuring range, inhibiting measurement.

Too short a BAL timer, on the other hand, can give rise to differential pressure variations arising from

valve action as errors. Generally, a BAL timer between 1 and 5 seconds is recommended.

d) Setting the DET timer

Typical recommendation for the DET timer is from 2 to 10 seconds and those for the limit setting are

from ±10 to ±100 Pa in differential pressure terms. It is important to make the ratio of the CHG timer

as high as possible to the extent permitted by the limited measurement timer and to avoid indiscriminate

increases in the BAL and DET times. Even a short DET timer can provide a high degree of

detectability.

e) General guidelines for the setting of CHG and stabilization times

(0.01 to 0.1 MPa) (0.1 to 0.6 MPa)

The graph above does not include DET timer. DET timer varies

depending on the leak specifications.

NOTE

4 FEATURE SUMMARIES 15

4

4

FEATURE SUMMARIES

4

4.

.1

1

M

Ma

as

st

te

er

r-

-P

Pr

re

es

se

et

t

4.1.1 Theory of Master-Preset

The measured pressure change in a leak test typically contains both the true leakage and drift errors due to

adiabatic compression and change in the ambient temperature. The pressure change due to leak remains

consistent over time, while the drift errors tend to decrease over time until completely stabilized. The below

graph, Differential pressure change when DET timer is extended shows this. The Master-Preset uses the

drift (Master-Preset value) calculated from the differences in characteristics between drifts and true leakage

to compensate for the leak test data for better detection accuracy

(See Section 8 →).

4.1.2 Master-Preset operation

1) Master-Preset value calculation

The Master-Preset operation is executed by using an actual tested part. In this stage, D1 is measured

in the same measurement time as in a regular leak test. Then, the STB stage (stability time) is

initiated to equalize the pressure of the tested part and that of the master with each other through CHG

until drifts virtually no longer exist, when D2 is measured. The drift value (Master-Preset value) can be

determined by subtracting D2 (leak differential pressure) from D1 (drift value - leak differential pressure).

Master-Preset Value = D1 – D2

where

D1: measured leak rate value in DET (1)

D2: measured leak rate value in DET (2)

2) Compensation using a Master-Preset value in a leak test

Because the value that is detected in a regular leak test is equal to D1 shown above, a precise reading

of the leak rate can be provided by subtracting the Master-Preset value from DET value ΔP for

conformance judgement.

D = ΔP – Master-Preset Value

where

D: Differential pressure after compensation

∆P: Differential pressure detected in the DET stage

16 4 FEATURE SUMMARIES

4.1.3 When to execute a Master-Preset process

Master-Preset process is recommended under one of the following conditions:

1) Production part changeover

For production lines that produce multiple part models, each model should be assigned to a specific

leak tester channel. Therefore, a Master-Preset process is required on the new channel immediately

after the model changeover. Master-Preset is also required when switching parts with different volume

and/or test pressure in a same channel.

2) When test parameters such as test pressure and/or timer settings are changed.

3) When test environment changed

4) When No-Go judgments occur consecutively

The seals in the fixture may be damaged in this case, assuming that production line is unlikely to

produce consecutive defects. Since the test result of a Master-Preset process shows almost true

leakage, it would help in determining if these No-Go judgments are from leaks or from fluctuations due

to drift.

4

4.

.2

2

L

Le

ea

ak

k

C

Ca

al

li

ib

br

ra

at

ti

io

on

n

(

(P

Pa

at

te

en

nt

te

ed

d)

)

To obtain a volumetric leak rate, mL/min, the relationship between the pressure change caused by a leak

and the volume of leakage from the part must be known. The Leak Calibration feature gives a known leak

to the Work-side pneumatic that creates a measurable differential pressure in order to measure its

equivalent internal volume. The definition of internal equivalent volume (Ve) is the volume of air of the

entire Work-side pneumatic circuit at a particular test pressure. It also includes a diaphragm deformation

factor of the DPS. Ve is used as leak coefficient K(Ve) in the leak rate calculation.

Once equivalent internal volume is measured, the differential pressure detected in the leak test DET stage

can be displayed in mL/min (See Section 9.1. →).

a) Measuring equivalent internal volume using a Leak Master

Leak calibration is normally carried out using a Leak Master (reference leak generator). The

equivalent internal volume is calculated from the Leak Master flow rate and the measured differential

pressure.

b) Measuring equivalent internal volume using a Leak Calibrator

When using a Leak Calibrator to determine an equivalent internal volume, convert the volume change

measured during the DET stage into a volumetric leak rate under the atmospheric pressure by using the

following equation and enter it.

(See Section 9.1.4. →)

Where:

Q: Value to input in mL/min (Leak rate corresponding to the volume

change)

∆V: Volume change (mL)

P: Test pressure (kPa)

T: DET timer

c) Sampling compensation values

It is necessary to measure only the differential pressure due to leak to determine the accurate

equivalent internal volume. To accomplish this, do a leak test with a known non-leaking part prior to

the leak test. The resulting measurement value is noted as a drift, by which the value measured in

leak calibration is compensated.

(See Section 9.1.2. →)

T

60

×

3.101

P+3.101

×VΔ=Q

4 FEATURE SUMMARIES 17

4

4.

.3

3

T

Tw

wo

o-

-L

Le

ev

ve

el

l

L

Li

im

mi

it

t

S

Se

et

tt

ti

in

ng

g

a

an

nd

d

N

No

oi

is

se

e

R

Re

ed

du

uc

ct

ti

io

on

n

(

(N

NR

R)

)

M

Mo

od

de

e

a) Two-level limit setting

This leak tester permits setting a small leak limit (Hi-NG) and a large

leak large leak limit (HH-NG) in the DET stage. In the normal leak

test cycle, nonconforming parts can be screened out according to

the amount of leakage. Limit settings for the master are similar to

those on the tested part.

b) Noise reduction (NR)

If the NR feature is enabled, HH-NG is set as a noise reduction limit and the range between HH-NG and

Hi-NG is taken as an uncertain judgement area. If the leak rate detected in the DET stage falls in this

range, a longer stability time is allowed to cancel the noise interference before the leak rate is

redetected.

This feature is useful where there is a high percentage of noise presence caused by temperature or

volume changes. It helps set more critical specifications. A small leak (Lo-NG) and a large leak

(LL-NG), and the NR feature can be set as limit settings on the master as on the tested part. Master

Pre-set is not effective from the second test.

4

4.

.4

4

A

Ai

ir

r-

-O

Op

pe

er

ra

at

te

ed

d

V

Va

al

lv

ve

e

P

Pe

er

rf

fo

or

rm

ma

an

nc

ce

e

a

an

nd

d

D

DP

PS

S

S

Se

en

ns

si

it

ti

iv

vi

it

ty

y

C

Ch

he

ec

ck

ks

s

Air-operated valve malfunction or DPS sensitivity degradation can lead to serious measurement errors. In

order to prevent such failure the sensor and air-operated valve performance is automatically checked at the

end of the each test cycle to ensure reliability of leak testing.

a) Intelligent I Air Circuit (Function Type A)

Air is supplied and air is exhausted from the master and the tested part simultaneously during DL3

stage (Air blow). If the air-operated

valves are functioning normally, the

orifice difference between the exhaust

ports of the master and the tested part

introduces a pressure difference.

This pressure difference is used to

check the test and the pilot pressure

deterioration and DPS sensitivity

degradation as well as the air-operated

valve performance.

b) Other Circuits: H15

The high-pressure Intelligent Ipneumatic circuit, H15, detect the pilot pressures for the air-operated

valves with pressure switches to check their performance.

Large leaks are detected as failures in the BAL stage.

The stage number output allows for discrimination

among Hi-NG, HH-NG, and BAL-NG.

(See Section 7.13.4 →)

NOTE

High pressure model, H15, omits air blow and

self-check.

NOTE

Low pressure models require an optional orifice.

NOTE

18 4 FEATURE SUMMARIES

4

4.

.5

5

S

Se

en

ns

so

or

r

P

Pr

ro

ot

te

ec

ct

ti

io

on

n

If the tested part contains water or an oil, or if the leak tester is used along with water-immersion test, water

and/or oil may enter the tester from the tested part during exhaust stage causing malfunctioning. The

feature protects sensor from such contamination

4.5.1 Cleaning pneumatic circuit by Exhaust air blow (DL3)

Air blow of DL3 is used to clean the pneumatic circuit and prevent DPS from contaminated by blowing off

water, oils and other foreign matter inside the pneumatic circuit along with self check mentioned in section

4.4. Air blow can be disabled by setting DL3 timer to zero. This feature is not available on the

high-pressure model (H15).

(See Sections 4.4 →) (See Sections 10.2.3 →)

4.5.2 External exhaust valve-ready

Air-operated valve are installed between the tested part and the master and the leak tester to effect external

exhaust. An external exhaust valve unit (G3) is separately required.

The standard leak tester controls the G3.

This feature is not available for vacuum pressure leak tester.

4

4.

.6

6

C

CA

AL

L

p

po

or

rt

ts

s

The front panel contains inspection ports that connect to the

tested part and master measurement systems. Connect a

Leak Master, a Leak Calibrator (volume change method), flow

meter to these ports to make a daily check on leak sensitivity

and carry out leak calibration.

Use of the following standards manufactured by us is

recommended to check the test pressure and differential

pressure on a scheduled basis:

The CAL port connectors leading to both the tested part and

master measurement systems are M10 ×1.5 (O-ring S-12).

The conversion fitting M10-Rc1/4 (option) is used to connect an

instrument other than a Leak Master (LM-1B).

G3-ME

Table of contents

Other Cosmo Test Equipment manuals