Hartzell CD15K User manual

2900 Selma Highway, Montgomery AL 36108 USA

PH: +1.334.386.5400 (option 2) FAX: +1.334.386.5450 WEB: www.hartzell.aero P a g e | ii

Maintenance Manual

for Hartzell Engine Technologies LLC. Aircraft Combustion Heater

Models CD15K, CD25K, CD35K, CD45K CD50K, CD55K and CD70K

with P/N’s ending in –1 (dash one series) (Includes Airworthiness Limitations)

MM10001

January 1, 2008

REV. L dated May 21, 2015

FAA Approval has been obtained on technical data in this publication

that affects product type design

NOTE:

Instructions for Continued Airworthiness” as outlined on page 8 are required.

The Airworthiness Limitations Section (Section 7.2.) is MANDATORY.

Before performing service consult www.hartzell.aero for latest revision to this manual.

Changes to the Instructions for Continued Airworthiness will be distributed by way of service

bulletins and service letters. The Airworthiness Limitations section is FAA approved and

specifies maintenance required under section 43.16 and 91.403 of the Federal Aviation

Regulations unless an alternative program has been FAA approved.

Model:

P/N

S/N

2900 Selma Highway, Montgomery AL 36108 USA

PH: +1.334.386.5400 (option 2) FAX: +1.334.386.5450 WEB: www.hartzell.aero P a g e | ii

Congratulations!

You have purchased the world’s highest quality heating system.

Hartzell Engine Technologies LLC (HET) has been servicing heating systems for many years.

Using the latest modern technology, Hartzell Engine Technologies has received FAA approval to

manufacture new TSO-C20 heaters for general aviation aircraft. Installations are available for

most twins and some single engine aircraft. Complete heating systems for aircraft with no prior

combustion heater, are also available.

These units are designed with pilots, passengers, and maintenance personnel in mind. We are

confident upon installation and operation of this heater that you will agree on its excellent

quality. If properly serviced (in accordance with the “Instructions for Continued Airworthiness”

contained in this manual) overall safety and reliability of the system will increase.

2900 Selma Highway, Montgomery AL 36108 USA

PH: +1.334.386.5400 (option 2) FAX: +1.334.386.5450 WEB: www.hartzell.aero

Page | 2

MM10001

Dated 1/1/08

Rev L dated 5/21/15

TABLE OF CONTENTS

TABLE OF CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

TABLE OF REVISIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .... . . . . . . . . . . . . . . 4

GENERAL INFORMATION FOR MODEL CD15K, CD25K, CD35K, CD45K, CD50K, CD55K

AND CD70K SERIES COMBUSTION HEATERS:

1. WARRANTY *Must read before proceeding with heater installation, modification or

servicing* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3. SCOPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Listing of P/N’s per model series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4. DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5. CONSTRUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

6. OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7. (ICA) INSTRUCTIONS FOR CONTINUED AIRWORTHINESS LIMITATIONS

SECTION

7.1 Preflight/Operational check and shutdown procedures 14

7.2 Airworthiness Limitations (MANDATORY) 14

7.3 Flight Manual Supplement (FMS) Sample 15

NOTE: The FMS supplied with your new heater must be inserted in the aircraft flight manual

8. HEATER MAINTENANCE AND SERVICING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.1. Removal and Installation Procedures 18

8.2. 100hr/Annual Inspection and operational check 19

8.3. 250hr/2yr service and inspection 19

8.4. 1000hr/250hr 4 year service and inspection 20

8.5. 2000hr overhaul 20

8.6. Heater Pressure Decay(PDT) and combustion air pressure switch test 21

8.7. Heater disabling 23

9. HEATER OVERHAUL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9.1. Cleaning

9.2. Cleaning Comb Tube and Jacket Assembly

9.3. Heater assembly inspection and testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.4. Reassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10. TESTING AFTER INSTALLATION OR OVERHAUL. . . . . . . . . . . . . . . . . . . . . . . . . 34

10.1.General 34

10.2.Bench Testing 34

10.3.Operational Test 34

10.4.Determining and setting heat output 35

11. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

11.1. Heat Quick Check 37

11.2.Combustion Heater System 39

11.3.Inspection Results 40

11.4.Heater Accessories 41

11.5.Troubleshooting Guide 44

2900 Selma Highway, Montgomery AL 36108 USA

PH: +1.334.386.5400 (option 2) FAX: +1.334.386.5450 WEB: www.hartzell.aero

Page | 3

MM10001

Dated 1/1/08

Rev L dated 5/21/15

TABLE OF CONTENTS

12. FIGURES FOR REFERENCE

TYPICAL COMBUSTION HEATER CUT-AWAY Figure 25. . . . . . . . . 46

TYPICAL TEST SET-UP PRESSURE DECAY TEST Figure 26. . . . . . . . . 47

COMBUSTION AIR SWITCH INSTALLATION Figure 27 . . . . . . . . . 48

TYP. EXHAUST TUBE SEAL SHOWN INSTALLED Figure 28 . . . . . . . . . 49

SPARK PLUG REFERENCES Figure 29 . . . . . . . . . 50

TYPICAL TEST SETUP Figure 30 . . . . . . . . . 51

TYPICAL WIRING SCHEMATICS Figure 31 . . . . . . . . . 52

13. PARTS VIEW OF HEATER ASSEMBLY– TYPICAL Figure 32 . . . . . . . . . 53

14. ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

15. PARTS VIEW OF EXPLODED HEATER ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . 56

2900 Selma Highway, Montgomery AL 36108 USA

PH: +1.334.386.5400 (option 2) FAX: +1.334.386.5450 WEB: www.hartzell.aero

Page | 4

MM10001

Dated 1/1/08

Rev L dated 5/21/15

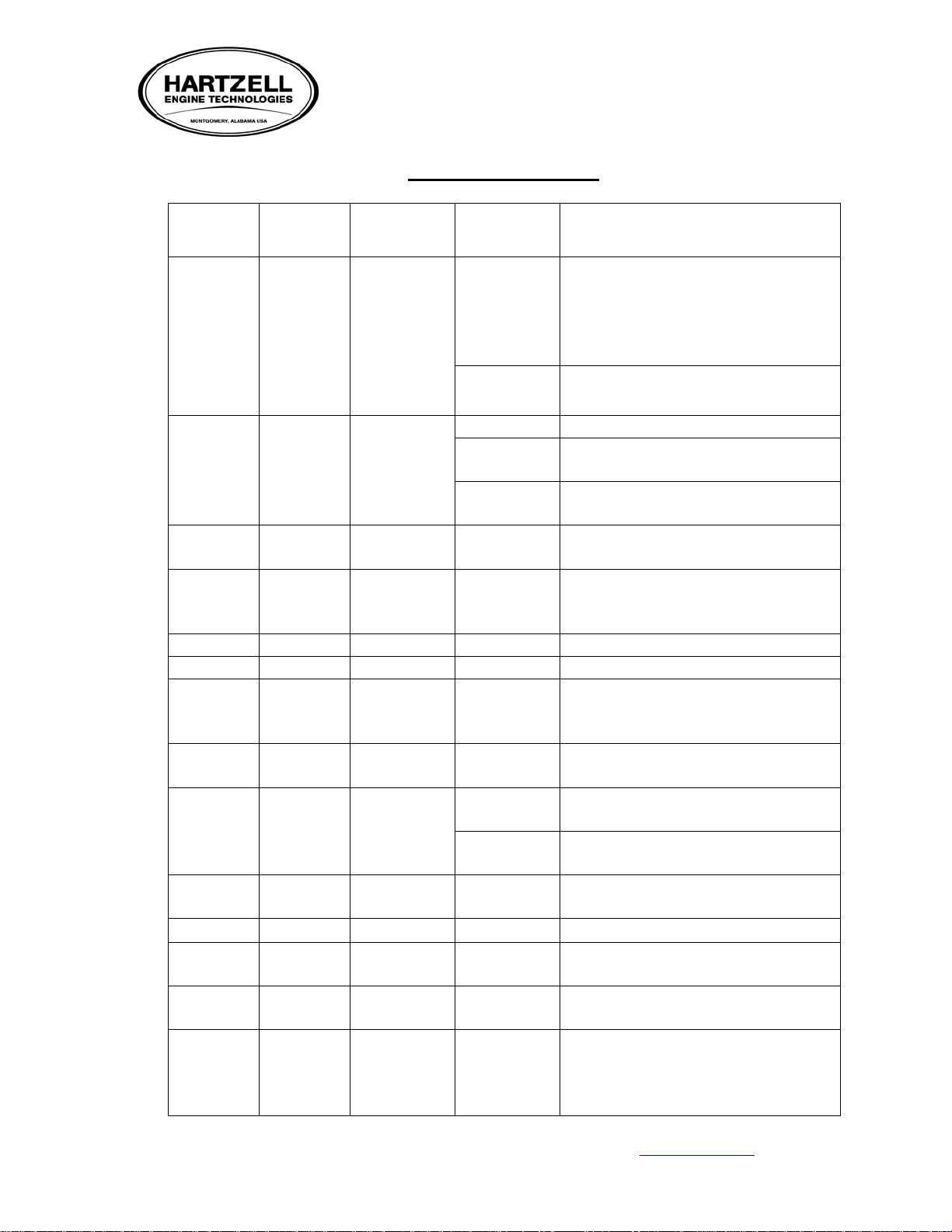

TABLE OF REVISION

REVISION

LETTER

REVISION

DATE

INSERTION

DATE

SECTION

DESCRIPTION

A

3/25/09

3/25/09

Warranty

VII. 4.

IX. A. 11.

IX. H. 1, 3.

IX. H. 1, 3.

Added Teflon notes & purging

delivery line notes.

XIV.

Changed amber light to green on

rotary heat control.

B

9/15/09

9/15/09

Pg 3, 4

Removed model # ref.

VII.E.1

IX.A1

Added recommend tube

replacement note.

XIV.

Changed blue light to amber to

indicate failure.

C

7/27/10

7/27/10

Pg 1

Airworthiness Limitations sect.

corrected from IV.B to VI.B.

D

3/8/11

3/22/11

XV

Removed plug and changed elbow

p/n, added 21794 nozzle holder

option.

E1

7/14/11

7/14/11

Pg 17

Add motor overhaul information.

E2

10/3/11

10/3/11

Pg 1, 3, 7

Added models CD50K & CD70K

E3

10/3/11

10/3/11

Pg 12

Pg 13

Add note about pdt test.

Changed pdt test time from

250hr/2 yr to 250hr/4 yr.

F

2/3/12

2/3/12

Pg 37

Added 4-10 pressurized wiring

schematic.

G

7/24/12

7/24/12

Pg 11

II. iv. O/H temp from 350 deg to

300-450 deg.

Pg 15

VIII.A. Corrected overhaul yr from

5 to 4.

H

9/10/13

9/10/13

Pg 25

XI. B.1.

Corrected “0 to 20” psi for Jet fuel

to “0 to 200”

I

8/1/14

8/1/14

Cover Page

Added models CD50K & CD70K

J

3/26/15

3/26/15

Pg 12, 23,

29, 30, 35

Added torque notes

K

4/16/15

4/16/15

Pg 23

Added “not” to allow lead wire to

twist…..

L

5/21/15

5/21/15

ALL

Reformatted, added more specific

info, clarified procedures, added

warranty page, removed section ref

from ICA’s AL section.

2900 Selma Highway, Montgomery AL 36108 USA

PH: +1.334.386.5400 (option 2) FAX: +1.334.386.5450 WEB: www.hartzell.aero

Page | 6

MM10001

Dated 1/1/08

Rev L dated 5/21/15

1. WARRANTY – *Must read before proceeding with heater installation, modification or

servicing*

1.1. New HET heaters come with 4-yr or 2,000-hr, whichever comes first, full warranties. After 1000-

hrs of heater operation or 4 years (whichever comes first) the pressure decay test and inspection

described in the “Instructions for Continued Airworthiness” becomes mandatory.

1.2. Any warranty work must be pre-authorized in writing by Hartzell Engine Technologies LLC.

1.3. Warranty shipments must be accompanied by proper paperwork reflecting a Warranty

Authorization Number obtained directly from Hartzell Engine Technologies LLC (HET). Return

shipments cannot be accepted without this authorization, HET reserves the right to repair or

replace warrantied items. HET is not responsible for aircraft down-time, lost revenues, customs

or duties. Factory covers ground freight only in the USA if warranty is authorized.

1.4. IN NO EVENT SHALL HARTZELL ENGINE TECHNOLOGIES LLC (HET) BE LIABLE

FOR SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGE: however

arising, whether in warranty, strict liability, contract, tort, negligence or otherwise, including but

not limited to loss of profits, revenue, loss of total or partial use of the products, facilities,

services, downtime costs, or claims of purchaser for such or other damages whether on account of

products furnished hereunder or delays in delivery thereof, HET liability of any claim shall in no

case exceed the purchase price allowable to the product or part thereof which give rise to the

claim. Notice of claims against Hartzell Engine Technologies LLC must be made in writing

within forty-eight (48) hours of discovery affording HET an opportunity to make a prompt

investigation of surrounding facts and mitigate any damage which might ensure. Should the

responsibility be determined to be Hartzell Engine Technologies LLC a waiver by the purchaser

of any right later to assert such a claim will be required. Any cause of action against Hartzell

Engine Technologies LLC arising out of or relating to the contract or the performance hereof

shall expire unless bought within one year of the time of accrual thereof. The forgoing limited

warranty is exclusive and in lieu of all other warranties expressed or implied, including but not

limited to any warranty of merchantability or fitness for particular purpose.

1.5. NOTICE:

1.5.1. WARRANTY DEPENDANT ON THE FOLLOWING:

1.5.1.1. Balance between combustion air inlet and exhaust is critical. Any modifications to

the heater, combustion air inlet or the exhaust could cause the heater not to run

properly and voids warranty.

1.5.1.2. ANY modification to any HET component without documented permission from the

PAH voids warranty and excludes Hartzell Engine Technologies LLC (company

and/or personnel from any and all liability.

1.5.1.3. Breaking any tamper-proof seal, or introducing Teflon products (Teflon tape,

dope etc.) for use as a fuel sealant voids warranty.

1.6. TO ACTIVATE WARRANTY AND RECEIVE CORE REIMBURSEMENT, you must fill

out and return warranty activation card included with your heater or go online to

www.hartzell.aero/warranty/

2900 Selma Highway, Montgomery AL 36108 USA

PH: +1.334.386.5400 (option 2) FAX: +1.334.386.5450 WEB: www.hartzell.aero

Page | 7

MM10001

Dated 1/1/08

Rev L dated 5/21/15

2. INTRODUCTION:

Aircraft combustion heaters manufactured by Hartzell Engine Technologies LLC are designed

primarily to provide heat to the passengers and crew during ground and/or flight. Additional uses are

de-icing and engine preheating. Heat output generally is from 15,000 to 70,000 BTU.

Heaters are FAA TSO-C20 approved and are designed to use the aircraft fuel (aviation gas or jet) in

both pressurized and non-pressurized aircraft. Both 12 and 24 volt applications are available.

Designated models are CD15K, CD25K, CD35K, CD45K, CD50K, CD55K & CD70K, with a p/n

ending in “-1”.

2900 Selma Highway, Montgomery AL 36108 USA

PH: +1.334.386.5400 (option 2) FAX: +1.334.386.5450 WEB: www.hartzell.aero

Page | 8

MM10001

Dated 1/1/08

Rev L dated 5/21/15

3. SCOPE:

This manual provides maintenance information for aircraft combustion heaters manufactured by

Hartzell Engine Technologies LLC, 2900 Selma Highway, Montgomery,AL 36108 USA.

www.hartzell.aero.

The purpose of this manual is to guide its reader to a thorough understanding and working knowledge

of the Hartzell Engine Technologies “–1” series combustion heater and subsequent components.

While general concepts in operation mentioned herein apply to all aircraft combustion heater makes,

the design and operation of a “-1” combustion heating unit is completely unique to itself. Models vary,

pictures and information are generic and information provided within this manual may not apply to all

models. Please contact Hartzell Engine Technologies for more specific information regarding your

model. In order to achieve continued efficiency and longer Time Before Overhaul (TBO) the

envelope of operation as outlined in this manual must be met.

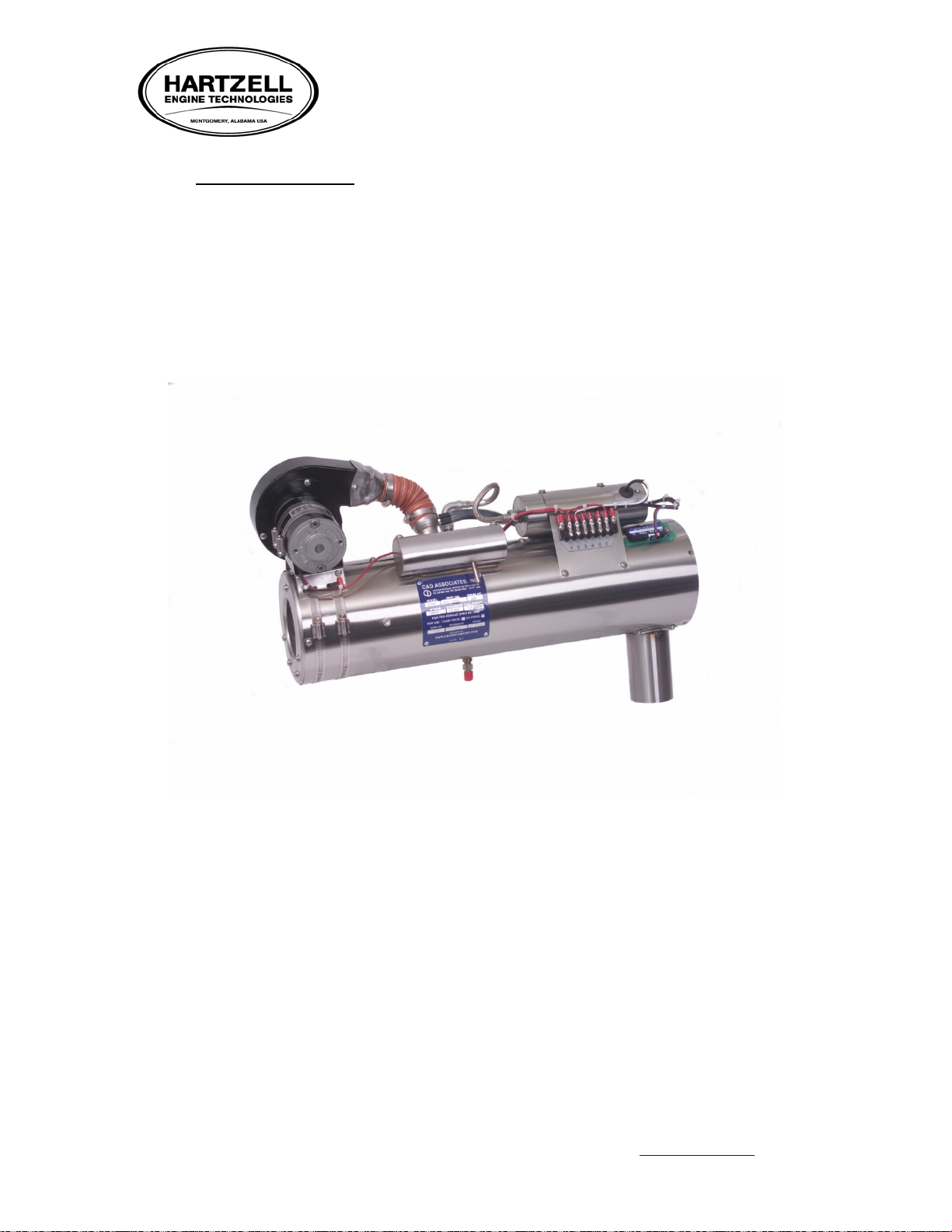

AC&D AIRCRAFT CO MBUSTION HEATER HAS BEEN INSTALLED.

PLEASE FOLLOW THE AIRCRAFT OPERATING MANUAL FOR COMBUSTION

HEATEROPERATING SEQUENCE AN D ASSOCIATES, INC. "INSTRUCTIONS

FOR CONTINUED AIRWORTHINESS" EDITION, DATED 4-4-02 REVI SION

NONE OR LATER FAA APPROVED RE .

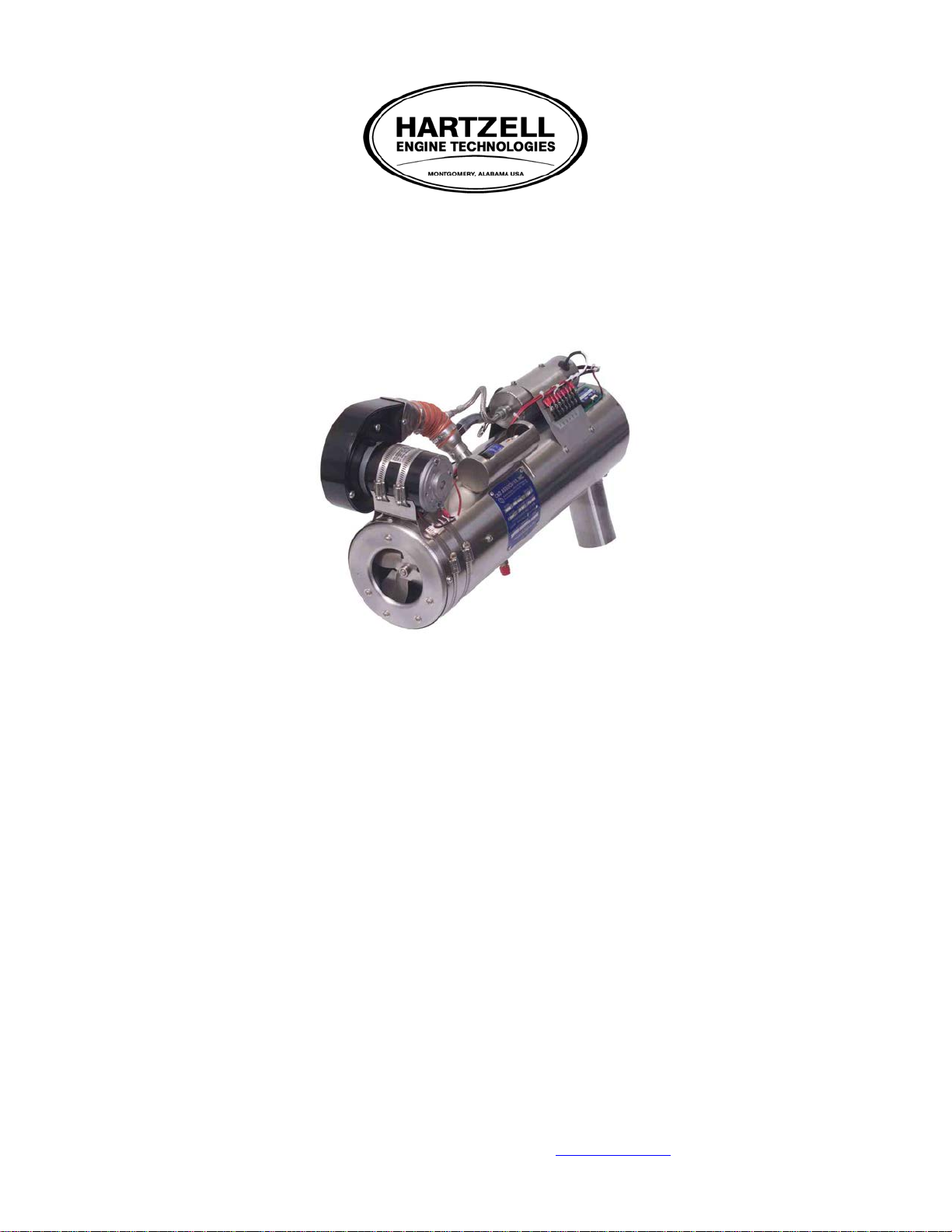

FORELIGIBILITY SEE WWW .AIRCRAFTHEATER.COM

COMBUSTION

AIR INLET

FUEL ADAPTER &

FILTER ASSEMBLY

FUEL SOLENOID

OVERHEAT

SWITCH

21528

SCEET HOSE

& CLAMPS

IGNITION

LEAD

HOSE & CLAMPS

IGNITION UNIT

& MOUNT

POWER& COMB.

FUEL PUMP

HEATER HOBBS (OPT)

&/OR SHUTOFF

THERMOSTAT

GROUND

(OPT)

VENTBLOWER

(OPT)

WARNING

OVERHEAT

ADAPTER

COMBUSTION TUBE

& JACKET

REGULATOR

DRAIN

EXHAUST SHROUD

EXHAUST PIPE

CYCLING

SWITCH

MIXER,

HEAD GASKET

FUEL BOX

COMUSTION

BLOWER

ASSEMBLY

NOZZLE,

ORING,

NOZZLE HOLDER

5 BLADE OR

SQUIRREL CAGE

FAN

AIRBLOWER

56 34

56 34

2 1

2 1 NUMBER PLATE

TERMINAL BLOCK

WIRING HARNESS

C&D ASSOCIATES, INC.

FUEL BOX TOP

ROTORY SWITCH

DATAPLATE

COMBUSTION

AIR SWITCH

THERMOSTAT

FAN ENDPLATE

SPARK PLUG

FUEL PUMP

BLOWER

MOUNTING

CLAMPS

-Heater configurations may differ- (For reference only)

BTU’S LENGTH DIAMETER VDC/AMP

WEIGHT

FUEL

PRESS

AV/JET

MAX.

FUEL

GAL/HR

15-25,000 9-17” 5.50

12VDC/3-18 AMPS

24 VDC/3-14 AMPS

10-25 lbs 7/100 .25 GPH

25-35,000 17-20” 6.00 12VDC/14-20AMPS

24VDC/7-12AMPS

20-30 lbs 7/100 .5 GPH

35-45,000

20-23”

6.00

20-30 lbs

7/100

.65 GPH

45-55,000

21-24”

6.00

20-30 lbs

7/100

.75 GPH

55-75,000

21-24”

6.00

20-30 lbs

7/100

.85 GPH

FIGURE 1

2900 Selma Highway, Montgomery AL 36108 USA

PH: +1.334.386.5400 (option 2) FAX: +1.334.386.5450 WEB: www.hartzell.aero

Page | 9

MM10001

Dated 1/1/08

Rev L dated 5/21/15

LISTING OF P/N’S PER SERIES

* INDICATES JET A APPLICATIONS

CD11000 SERIES

CD11000-1

CD11001-1

CD11002-1

CD11003-1

CD11004-1

CD11005-1

CD11006-1

CD11007-1

CD11008-1

CD11010-1

CD11014-1

CD11047-1

CD11049-1

CD11050-1

CD11214-1

CD11215-1

CD12000 SERIES

CD12003-1

CD12004-1*

CD12006-1

CD12007-1

CD12008-1

CD12009-1

CD12010-1

CD12011-1

CD12012-1

CD12013-1

CD12015-1

CD12016-1

CD12017-1

CD12018-1

CD12022-1*

CD12030-1

CD12031-1

CD12032-1

CD12036-1

CD12039-1

CD12043-1

CD12044-1

CD12059-1

CD12060-1

CD12061-1

CD12064-1

CD12065-1

CD12066-1

CD12067-1

CD12089-1

CD12090-1

CD12091-1

CD12099-1

CD12188-1

CD12189-1

CD14000 SERIES

CD14010-1

CD14019-1

CD14020-1

CD14025-1

CD14026-1

CD14027-1

CD14028-1

CD14041-1

CD14045-1

CD14046-1*

CD14048-1

CD14050-1

CD14055-1

CD14060-1

CD14066-1

CD14067-1

CD14070-1

CD14071-1

CD14072-1

CD14073-1

CD14075-1

CD14076-1

CD14077-1

CD14078-1

CD14079-1

CD14080-1

CD14090-1

CD14125-1

CD14126-1

CD14127-1

CD14152-1

CD14186-1

CD14187-1

CD14188-1

CD14190-1

CD14192-1

CD14193-1

CD15000 SERIES

CD15010-1

CD15011-1 CD15020-1

CD15025-1 CD15030-1

CD50000 SERIES

CD50000-1

CD52002-1 CD52000-1

CD52001-1

2900 Selma Highway, Montgomery AL 36108 USA

PH: +1.334.386.5400 (option 2) FAX: +1.334.386.5450 WEB: www.hartzell.aero

Page | 10

MM10001

Dated 1/1/08

Rev L dated 5/21/15

4. DESCRIPTION

Each heater system generally consists of a combustion chamber assembly, a ventilation air blower, a

combustion air blower, nozzle holder, solenoid valve assembly, spark plug, high-voltage ignition

system, combustion air pressure switch, overheat switch and cycling switch. These components are

combined in a complete assembly. Optional equipment includes thermostat, fuel pump, fuel regulator

and remote shut off valve, heater circuit breaker, controls, and operation indicator lights. The optional

equipment items are provided as separate components since they may be mounted remotely in the

aircraft and subject to customer preferences.

Aviation Gasoline Applications may use an electric fuel pump that provides fuel at 7.0 to 9 PSI for

operation. The heater may be operated from the engine fuel pump, provided the fuel pressure output is

controlled within the operating pressure range of the heater and does not adversely affect engine

operation.

Jet Fuel Applications use an electric fuel pump assembly that fuels through a fuel control system

providing fuel pressure at 105 +5.-0 PSI.

2900 Selma Highway, Montgomery AL 36108 USA

PH: +1.334.386.5400 (option 2) FAX: +1.334.386.5450 WEB: www.hartzell.aero

Page | 11

MM10001

Dated 1/1/08

Rev L dated 5/21/15

5. CONSTRUCTION:

The majority of the heater is manufactured using corrosion resistant stainless steel. The combustion

tube is a welded, gas tight container consisting of the combustion chamber/ radiator assembly with

HET’s exclusive Durakoat coating applied to high wear areas for longer life. The combustion tube is

encased in a stainless steel shroud or 'jacket' assembly. Space between the tube and shroud provides an

area for heat transfer. The ventilation fan, combustion air inlet and fuel feed assembly are located at

one end while the air outlet and exhaust are generally located at the other. On the inlet end of the

combustion tube is the ‘head assembly' where the fuel feed and nozzle assembly that houses the spray

nozzle are attached. Externally mounted is the ignition assembly, fuel solenoid, & wire mounting

terminal board. A combination of mechanical and solid state switches are used to regulate heat and

airflow. These switches also provide safety control for shut down of unit in the event of malfunction.

2900 Selma Highway, Montgomery AL 36108 USA

PH: +1.334.386.5400 (option 2) FAX: +1.334.386.5450 WEB: www.hartzell.aero

Page | 12

MM10001

Dated 1/1/08

Rev L dated 5/21/15

6. OPERATION:

In order for the heater to operate properly, it must have (1) an external power source, (2) ignition, (3)

combustion air, (4) ventilation air and (5) a fuel source. Heat in the combustion chamber or tube is

achieved by burning a fuel to air mixture of proper proportions. Any deviation of this ratio will cause

reduced heat output, poor operation, and shortened TBO. For the following, assume that these are

provided as required.

Properly atomized spray from a specially designed fuel nozzle, a balanced combustion air inlet and

exhaust, coupled with a continuous spark ignition, ensures instant firing and continuous burning under

all flight conditions. Heat is provided by burning this fuel-air mixture in the combustion chamber of

the heater. Jet or aviation fuel is injected into the combustion chamber through the spray nozzle. A

cone-shaped fuel spray mixes with combustion air and is ignited by a spark from the spark plug.

Electric current for ignition is supplied by an ignition unit which converts 12- volts or 24 volts to high-

voltage, oscillating current to provide a continuous spark across the spark gap. A shielded, high voltage

lead connects the spark plug to the ignition assembly. Combustion air enters the combustion chamber

tangent to its surface and imparts a whirling or spinning action to the air. This produces a whirling

flame that is stable and sustains combustion under the most adverse conditions.

2900 Selma Highway, Montgomery AL 36108 USA

PH: +1.334.386.5400 (option 2) FAX: +1.334.386.5450 WEB: www.hartzell.aero

Page | 13

MM10001

Dated 1/1/08

Rev L dated 5/21/15

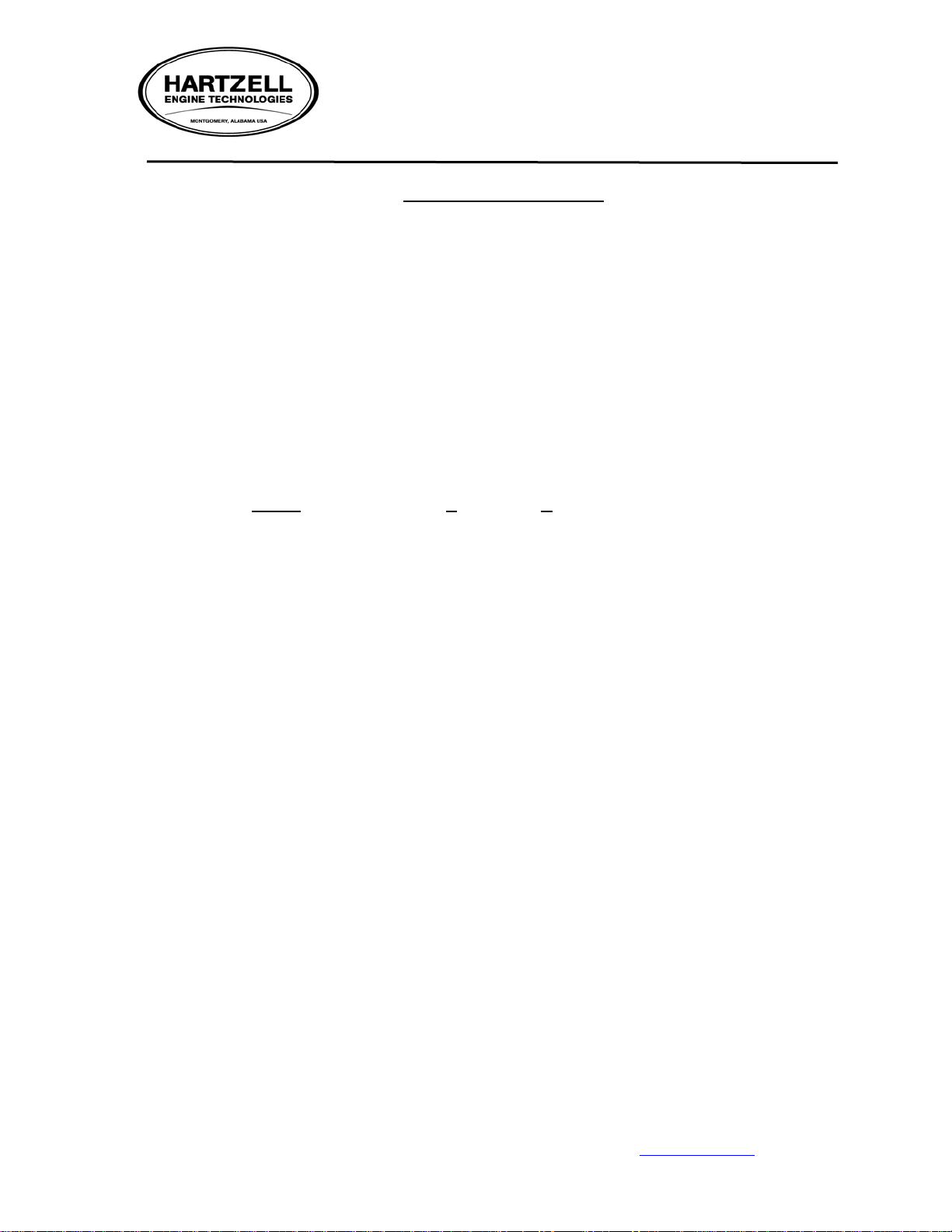

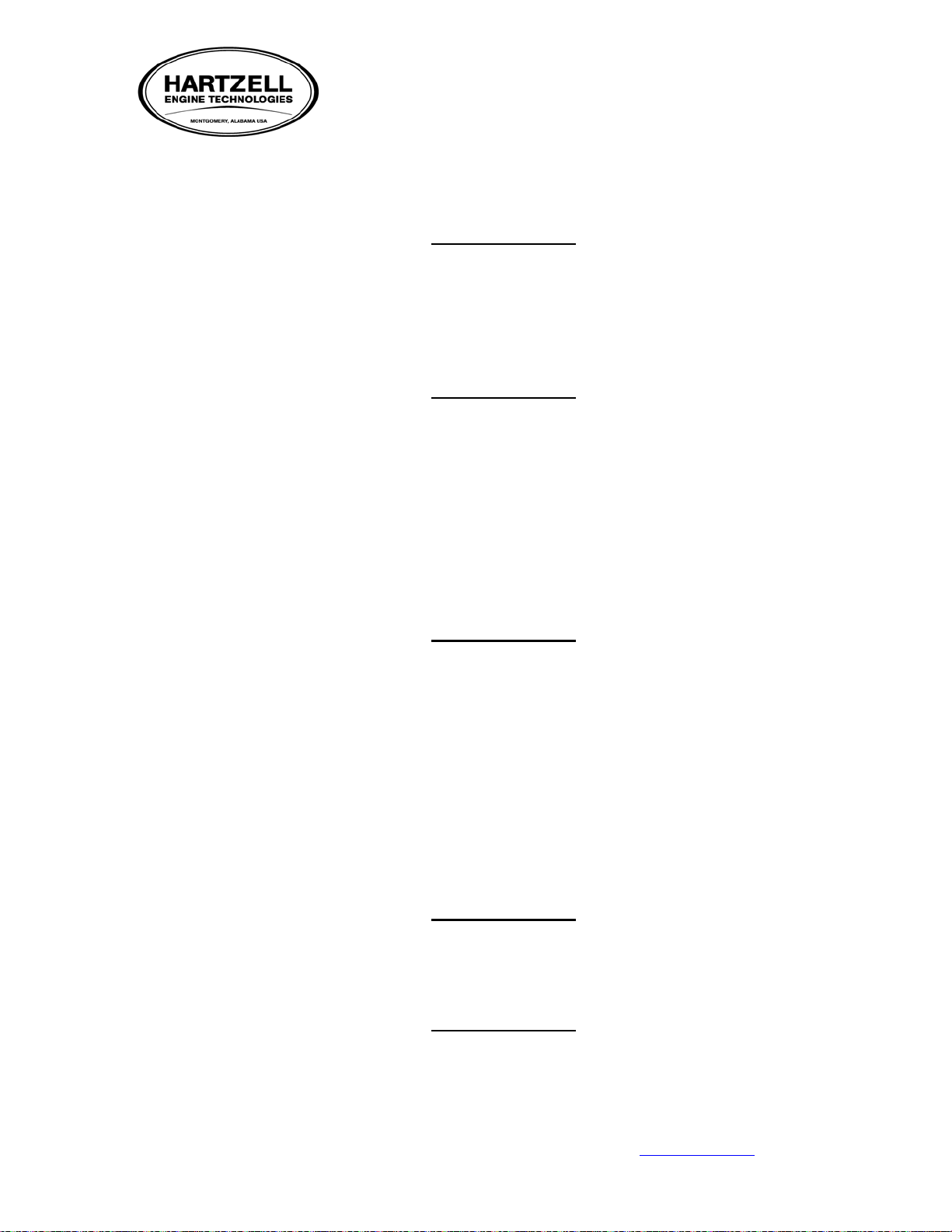

A

BC

D

D

CONVEX

END DOME

EXHAUST

COMBUSTION

CHAMBER/FLAME TUBE

BAFFLES

HEAT

EXCHANGER

CROSSOVER

MIXER ASSEMBLY

HEAD

ASSEMBLY

FUEL

INJECTOR

REVOLVING

SPARK

FUEL SUPPLY

INCOMING

COMBUSTION

AIR

IGNITOR

JACKET

E

E

HEATED AIR

VENT/FRESH AIR

FIGURE 2

A. Combustion Air Supply. This is provided by way of an external ram air scoop and or a blower

assembly independent of the vent/fresh air supply. Combustion air enters the head assembly, and

then is metered into the mixer chamber.

B. Ignition is supplied via high-voltage oscillating current, this coupled with the igniter design, create

a revolving continuous spark located in the head assembly. This igniter is positioned in the path of

an internal fuel injector designed to atomize the fuel at a pre-determined pressure.

C. This ignited fuel/air mix is then dragged from mixer assembly as additional combustion air

channels through the head assembly into the combustion chamber portion of the liner. The

majority of combustion is created at this point in the combustion chamber or flame tube area.

D. The flame travels full length of the flame tube hitting the end dome, it then doubles back along the

inside wall and on into the outer layer of the heat exchanger. The spent gasses again travel the

length of the tube around a series of baffles then exiting out the exhaust.

E. Air for the ventilation system is picked up via an external ram air scoop and/or a blower assembly

typically mounted on the inlet end of the jacket. Air is forced through the heated external passages

of the combustion chamber. Ventilating air thus comes in contact with the heated cylindrical

surfaces subsequently pushing heated air into the cabin.

2900 Selma Highway, Montgomery AL 36108 USA

PH: +1.334.386.5400 (option 2) FAX: +1.334.386.5450 WEB: www.hartzell.aero

Page | 14

MM10001

Dated 1/1/08

Rev L dated 5/21/15

7. ICA (INSTRUCTIONS FOR CONTINUED AIRWORTHINESS)

Second Edition: Rev E dated 5-21-15

When Hartzell Engine Technologies LLC (HET) heater is installed in an aircraft, the following action is

required. A description of its operational principals, controls, servicing, maintenance, troubleshooting and

testing can be found in the attached MM10001 maintenance manual in the “Table of Contents.”

APPLICATION

Applies to HET Model #CD15K, CD25K, CD35K, CD45K, CD50K, CD55K and CD70K with part

number ending in “–1”. Combustion heaters marked as meeting the standards of FAA TSO-C20, installed

in aircraft certified in any category.

7.1. PREFLIGHT/OPERATIONAL CHECK AND SHUTDOWN PROCEDURE

NOTE: Pilots operating under FAR91 may perform the checks required

7.1.1. Ensure that combustion and ventilation air inlets are free of any obstructions or

constrictions and are not damaged.

7.1.2. Check that the fuel drain line is free of obstructions, constrictions and damage.

7.1.3. Check that the area of the aircraft external skin surface behind the exhaust pipe does not

have indications of excess exhaust slip stream build up.

7.1.4. Perform operational check

7.1.5. Adjust the thermostat or duct limit switch to the minimum setting.

7.1.6. After heater has begun to burn, allow it to cycle a minimum of two minutes to ensure

proper operation in low. Verify medium and high positions also function.

7.1.7. Verify during operation that the exhaust from the heater does not indicate excess smoke.

7.1.8. Prior to shut down, set thermostat to low (cold) and/or fan position. Allow heater to run at

this setting two minutes so as to purge the combustion chamber.

Note: Many “-1” series heaters are equipped with auto-reset overheat switches. If overheat

condition occurs, continue cool down process until automatic reset occurs. (around 100 °F)

7.2. AIRWORTHINESS LIMITATION SECTION (MANDATORY)

The Airworthiness Limitations section is FAA approved and specifies maintenance required under

43.16 and 91.403 of the Federal Aviation Regulations unless an alternative program has be FAA

approved.

AIRWORTHINESS LIMITATION SECTION IS MANDATORY PER FAR 23

PERFORM FOLLOWING CHECKS AS OUTLINED IN THE CIRCUMFERENCE OF THIS

MM10001 MAINTENANCE MANUAL

1. 100 HOUR/ANNUAL OPERATIONAL CHECK (see MM10001 (latest revision) ‘Heater

Maintenance and Servicing’ Section.)

2. 250-HOUR/2 YEAR SERVICE AND INSPECTION (see MM10001 (latest revision)

‘Heater Maintenance and Servicing’ Section.)

3. 1000-HOUR/4 YEAR HEATER INSPECTION AND SUBSEQUENT 250-HOUR/PDT

TEST INTERNAL INSPECTION (see MM10001 (latest revision) ‘Heater Maintenance

and Servicing’ Section.

4. 2000-HOUR/10 YEAR OVERHAUL [to be accomplished in accord with MM10001

(latest revision)]

2900 Selma Highway, Montgomery AL 36108 USA

PH: +1.334.386.5400 (option 2) FAX: +1.334.386.5450 WEB: www.hartzell.aero

Page | 18

MM10001

Dated 1/1/08

Rev L dated 5/21/15

8HEATER MAINTENANCE AND SERVICING

NOTE: Prior to servicing, verify you are using the latest revision of the HET MM10001 Maintenance

Manual. Please consult www.hartzell.aero for latest revisions.

Many hours have been spent to provide the most comprehensive instructions as reasonably possible. It is

strongly recommended that installation and servicing be done by skilled, licensed aircraft mechanics with a

working knowledge of the following:

Fuel lines installed in accordance with AC43.13-1B Chapter 8 section 2 paragraph 8-31.

Electrical installation completed in accordance with AC43.13-1B Chapter 11.

Riveting and metal work in accordance with AC 43.13-1B Chapter 4 Section 4 paragraph 4-57.

The following instructions are outlined and worded with this assumption.

8.1 REMOVAL AND INSTALLATION PROCEDURES

NOTE: Use of Teflon products as a fitting sealer anywhere in a combustion heater fuel system could

contaminate heater fuel nozzle and voids warranty.

NOTE: It is also highly recommended that the fuel system and delivery lines be purged prior to being

connected to heater. This applies to new installations as well as during maintenance involving

any fuel system component. This will greatly reduce the risk of nozzle contamination.

8.1.1 Follow the aircraft manufacturers (OEM) recommendations in the OEM’s maintenance

manual. In most cases the heater operating controls remain the same. If not, operation

will be clarified in the FAA-Approved “Airplane Flight Manual Supplement” provided

for the specific aircraft.

8.1.2 Where deviation from the original heater controls are required the installation instructions

provided with the Hartzell Engine Technologies LLC (HET) heater will address these

changes. Refer to appropriate installation instructions.

8.1.3 For new HET TSO-C20 Supplemental Type Certificate (STC’d) heater kits, the

installation instructions from HET will contain complete procedures for operation and

integrating in the aircraft.

8.1.4 To achieve optimal performance and reliability some new HET FAA-

PMA heater installations require change to the combustion air inlet.

Please follow all instructions specific to your installation closely.

2900 Selma Highway, Montgomery AL 36108 USA

PH: +1.334.386.5400 (option 2) FAX: +1.334.386.5450 WEB: www.hartzell.aero

Page | 19

MM10001

Dated 1/1/08

Rev L dated 5/21/15

8.2 100 HOUR/ANNUAL HEATER INSPECTION AND OPERATIONAL CHECK

NOTE: This inspection must be recorded in accordance with FAR43.9 and maintained as required by

FAR 91.417.

8.2.1 Perform the following checks at the end of 100 hours of heater operation or annual

inspection:

Check that the combustion air and ventilating air inlets are free of any obstructions

or damage of any kind.

Check that the exhaust outlet is free of obstructions or constrictions, is secure, is free

of excessive carbon formations, abnormal stains and/or discoloration, which would

indicate poor heater operation.

Check that the fuel drain lines are free of obstructions, constrictions and damage.

Check the entire length of all fuel lines for security and any visible signs of leakage.

Be sure all joints and shrouds are secure and in good condition.

Check that the heater wiring has no loose connections, cracked or broken wires, or

frayed insulation and is secure at the attachment points.

Check the ignition system for security at the spark plug, making sure there is no

evidence of burning or discoloration of the lead.

Perform the Preflight/operational check to assure correct heater performance.

8.3 250 HOUR/ 2 YEAR HEATER INSPECTION

NOTE: Once the combustion heater has reached 1000 hrs. time in service, pressure decay tests are

required every 250 hours or four years (whichever comes first).

Replace the heater fuel filter by installing filter kit CD21346

Verify the torque of the ignition lead both at the igniter plug (15-20 ft. lbs.) and ignition unit

(12-15 ft. lbs.).

Complete 100hr/Annual inspection and operational check.

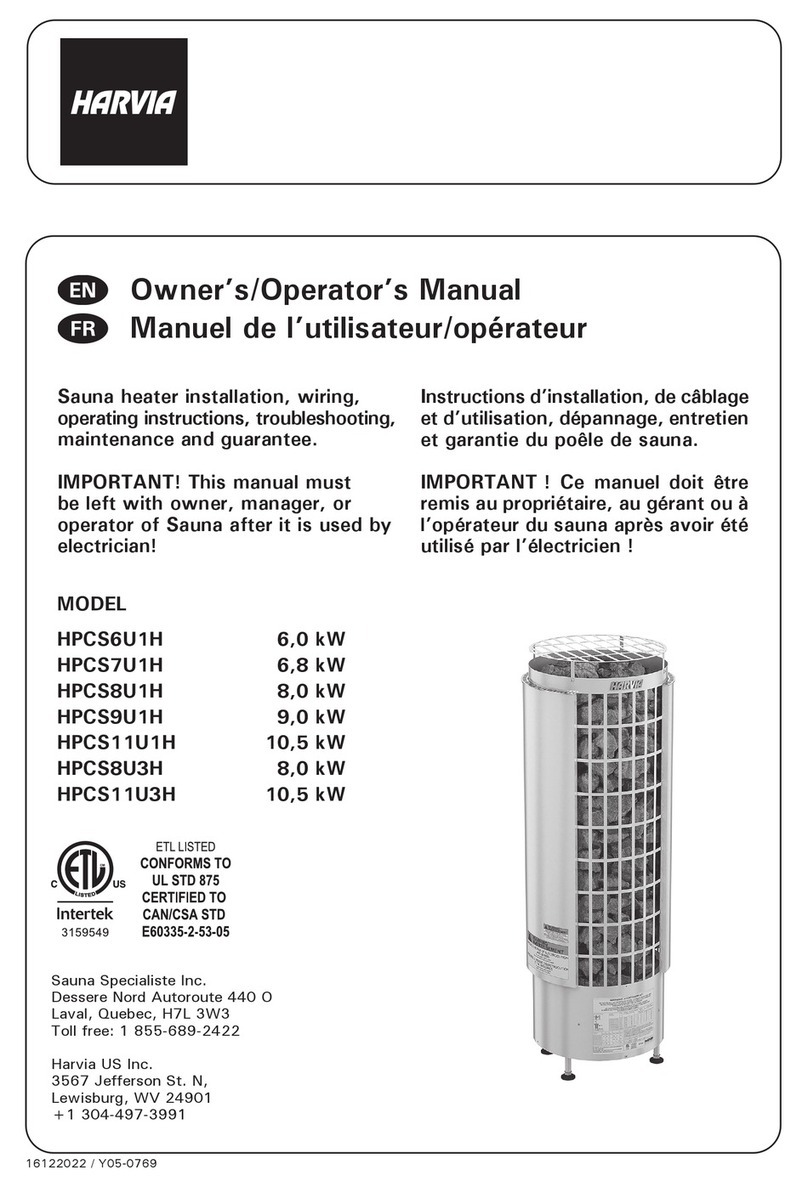

This manual suits for next models

6

Popular Heater manuals by other brands

Harvia

Harvia HPCS6U1H Owner's/operator's manual

Luxstar

Luxstar Royal Slim36 Important instructions & operating manual

Helo

Helo 1712-45-1706 Installation and operating instructions

Sunshower

Sunshower PURE XL installation guide

Kogan

Kogan KAHTP1KXXXA quick start guide

CLIMASTAR

CLIMASTAR ETNA instruction manual

Pfannenberg

Pfannenberg FLH 275SLM operating instructions

Calix

Calix Compact L Instructions for use

Chromalox

Chromalox SDRA-RG Installation & operation manual

Crane

Crane EE-6492 instruction manual

Claudgen

Claudgen Heat-Zone Installation, operation and maintenance instructions

Conrad

Conrad 67 15 75 operating instructions