Harvard Apparatus 683 User manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Publication 5375-001-REV-F

Model ‘683’

Small Animal Ventilator

User's Manual

‘683’ Small Animal Ventilator MA1 55-0000

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

EU Directives WEEE and RoHS

To Our Value Customers:

We are committe to being a goo corporate citizen. As part of that commitment,

we strive to maintain an environmentally conscious manufacturing operation. The

European Union (EU) has enacte two Directives, the first on pro uct recycling

(Waste Electrical an Electronic Equipment, WEEE) an the secon limiting the use

of certain substances (Restriction on the use of Hazar ous Substances, RoHS).

Over time, these Directives will be implemente in the national laws of each EU

Member State.

Once the final national regulations have been put into place, recycling will be offere

for our pro ucts which are within the scope of the WEEE Directive. Pro ucts falling

un er the scope of the WEEE Directive available for sale after August 13, 2005 will

be i entifie with a “wheelie bin” symbol.

Two Categories of pro ucts covere by the WEEE Directive are currently exempt

from the RoHS Directive – Category 8, me ical evices (with the exception of

implante or infecte pro ucts) an Category 9, monitoring an control instruments.

Most of our pro ucts fall into either Category 8 or 9 an are currently exempt from

the RoHS Directive. We will continue to monitor the application of the RoHS

Directive to its pro ucts an will comply with any changes as they apply.

• Do Not Dispose Product with Municipal Waste

• Special Collection/Disposal Required

WEEE/RoHS Compliance Statement

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1

H a r v a r d A p p a r a t u s M o d e l ‘ 6 8 3 ’ S m a l l A n i m a l Ve n t i l a t o r U s e r ' s M a n u a l

Publication 5375-001-REV-F

Table o Contents

General Information - Warranty & Repairs 2

General Safety Summary 3

Specifications 4

Description & Features 5

Voltage Selection 6

Fuse Replacement 6

Pump Operation:

Connecting to Animal ........................................7

Selecting Rate & Volume ..................................8

Setting Volume & Rate ......................................9

Using Gas Mixtures............................................9

Creating a PEEP................................................9

Cleaning & Maintenance 10

Changing Piston & Cylinder 11-12

SUBJECT PAGE NO.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2

H a r v a r d A p p a r a t u s M o d e l ‘ 6 8 3 ’ S m a l l A n i m a l Ve n t i l a t o r U s e r ' s M a n u a l

Publication 5375-001-REV-F

General In ormation

Serial Numbers

All inquires concerning our product should refer to the serial number of the unit. Serial

numbers are located on the rear of the chassis.

Calibrations

All electrical apparatus is calibrated at rated voltage and frequency. While the flow will stay

calibrated, the peak will vary.

Warranty

Harvard Apparatus warranties this instrument for a period of one year from date of purchase.

At its option, Harvard Apparatus will repair or replace the unit if it is found to be defective as to

workmanship or material.

This warranty does not extend to damage resulting from misuse, neglect or abuse, normal

wear and tear, or accident.

This warranty extends only to the original customer purchaser.

IN NO EVENT SHALL HARVARD APPARATUS BE LIABLE FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES. Some states do not allow exclusion or limitation of

incidental or consequential damages so the above limitation or exclusion may not apply to

you. THERE ARE NO IMPLIED WARRANTIES OF MERCHANTABILITY, OR FIT-

NESS FOR A PARTICULAR USE, OR OF ANY OTHER NATURE. Some states do not

allow this limitation on an implied warranty, so the above limitation may not apply to you.

f a defect arises within the two-year warranty period, promptly contact Harvard Apparatus,

84 October H ll Road, Bu ld ng 7, Holl ston, Massachusetts 01746-1371 using our toll

free number 1-800-272-2775. Goods will not be accepted for return unless an RMA (returned

materials authorization) number has been issued by our customer service department. The

customer is responsible for shipping charges. Please allow a reasonable period of time for com-

pletion of repairs, replacement and return. f the unit is replaced, the replacement unit is cov-

ered only for the remainder of the original warranty period dating from the

purchase of the original device.

This warranty gives you specific rights, and you may also have other rights which vary from

state to state.

Repair Facilities and Parts

Harvard Apparatus stocks replacement and repair parts. When ordering, please describe parts

as completely as possible, preferably using our part numbers. f practical, enclose a sample or

drawing. We offer a complete reconditioning service.

CAUTION

This ventilator is not registered with the FDA and is not for clinical use on human or veteri-

nary patients. t is intended for research use only.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3

H a r v a r d A p p a r a t u s M o d e l ‘ 6 8 3 ’ S m a l l A n i m a l Ve n t i l a t o r U s e r ' s M a n u a l

Publication 5375-001-REV-F

General Sa ety Summary

Please read he following safe y precau ions o ensure proper use of your ven ila or.

To avoid po en ial hazards and produc damage, use his produc only as ins ruc ed in

his manual. If he equipmen is used in a manner no specified by he manufac urer,

he pro ec ion provided by he equipmen may be impaired.

To Prevent Hazard or Injury:

UUssee PPrrooppeerr LLiiee CCoorrdd

Use only he specified line cord for his produc and make sure line cord is cer ified

for coun ry of use.

GGrroouudd tthhee PPrroodduucctt

This produc is grounded hrough he grounding conduc or of he power cord. To

avoid elec ric shock, he grounding conduc or mus be connec ed o ear h ground.

Before making any connec ions o he inpu or ou pu erminals of he produc , ensure

ha he produc is properly grounded.

MMaakkee PPrrooppeerr CCooeeccttiiooss

Make sure all connec ions are made properly and securely.

OOrriieett EEqquuiippmmeett PPrrooppeerrllyy

Do no posi ion he equipmen such ha i is difficul o reach he disconnec ing

device.

OObbsseerrvvee aallll TTeerrmmiiaall RRaattiiggss

Review he opera ing manual o learn he ra ings on all connec ions.

UUssee PPrrooppeerr FFuussee

Use only specified fuses wi h produc .

AAvvooiidd EExxppoosseedd CCiirrccuuiittrryy

Do no ouch any elec ronic circui ry inside of he produc .

DDoo NNoott OOppeerraattee wwiitthh SSuussppeecctteedd FFaaiilluurreess

If damage is suspec ed on or o he produc do no opera e he produc . Con ac qual-

ified service personnel o perform inspec ion.

PPllaaccee PPrroodduucctt ii PPrrooppeerr EEvviirroommeett

Review he opera ing manual for guidelines for proper opera ing environmen s.

OObbsseerrvvee aallll WWaarriigg LLaabbeellss oo PPrroodduucctt

Read all labels on produc o ensure proper usage.

Protective Ground

Terminal

CAUTION

Refer to Manual

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

4

H a r v a r d A p p a r a t u s M o d e l ‘ 6 8 3 ’ S m a l l A n i m a l Ve n t i l a t o r U s e r ' s M a n u a l

Publication 5375-001-REV-F

Speci ications

‘683’ Small Animal Ventilator Specifications

Rat Adjustable from 30 to 150 strokes/min while the ventilator is running

Phas Ratio 1:1 fixed

Dim nsions, 25 x 32.5 x 20 cm

H x L x W (10 x 13 x 8 in)

W ight 9.5 kg (21lbs)

Pow r 100-120 VAC/200-230 VAC, 0.7A/0.35A max., 50/60 Hz

Strok Rat Continuously variable from 30 to 150 strokes/min while the ventilator

is running, with IGHT-EMITTING DIODE ( ED) DISP AY.

Volum Adjustable from 0.2 to 5.0 cc/stroke or 1.5 to 30.0 cc/stroke while

the ventilator is running

Environm ntal:

Op rating T mp ratur 0˚C to 40˚C (32˚F to 104˚F)

Op rating Humidity 20% to 80% RH, non-condensing

Installation Cat gory II

Pollution D gr 1

Port:

Part Numb r 5121-074

Siz

ID .128" (3.25mm)

OD .188" (4.78mm)

Catalog No. 55-0000

Acc ssori s

55-5282 Overhaul Kit for 5cc Small Animal Ventilator; contains O-rings,

valve springs, lubricants, etc. to overhaul Ventilator

55-5283 Overhaul Kit for 30cc Small Animal Ventilator; contains O-rings,

valve springs, lubricants, etc. to overhaul Ventilator

73-3076 Connection Kit for Anesthesia/Pressurized Gas Connection

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5

H a r v a r d A p p a r a t u s M o d e l ‘ 6 8 3 ’ S m a l l A n i m a l Ve n t i l a t o r U s e r ' s M a n u a l

Publication 5375-001-REV-F

Description & Features

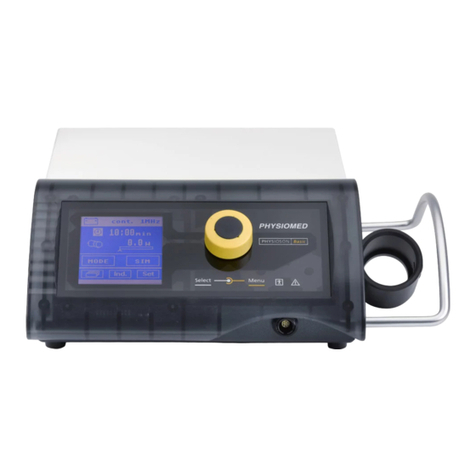

The current MODEL 683 (NEW STYLE W TH D G TAL READOUT) is an improved

volume controlled small animal/rodent respirator that is functionally identical to previous

MODELS (680, 681, and 683 OLD STYLE W THOUT D G TAL READOUT) with the

following major changes:

• New, stronger motor and motor speed control with LED

(light emitting diode) read-out of rate (stroke rate or breaths/min).

• A new design of the vertical slide valve that has no “O”-Rings or

passive check valves and requires no adjustments.

• A new orientation allows for minimal system dead space and thus more precise

tidal volume delivery to the animal

NOTE: In any correspondence, please refer to t e ventilator as “MODEL 683 wit LED RATE

READ-OUT”

The MODEL 683 is a positive volume ventilator intended to meet the respiratory requirements

of small laboratory animals weighing up to 5 kg (11 lb), covering rodents through rabbits.

This ventilator is furnished with two interchangeable piston/cylinder assemblies of 0.2 to

5.0 ml/breath (5 CC) and 1.5 to 30.0 ml/breath (30 CC). The smaller cylinder is factory

installed, and the larger one is supplied separately. The mechanical design features a linkage

that enables the piston to touch the end of the cylinder at each stroke regardless of the

volume. This assures that all the air/gas mixture taken into the ventilator is expelled

at each stroke.

A positive mechanical slide valve is actuated by a cam on the motor to synchronize inspiration

and expiration with the motion of the piston. Any NON-EXPLOSIVE gas/air mixture can

be used with the ventilator. Connection kit (73-3076) is suggested for this connection. A

three-way slide valve is attached to the mechanism plate at the end of the cylinder and actu-

ated by a cam on the motor.

These ventilators (MODELS 680, 681, 683 OLD or NEW STYLES) are NOT TO BE

USED IN AN EXPLOSIVE ATMOSPHERE OR WITH ANY EXPLOSIVE GASES

SUCH AS ETHER OR CYCLOPROPANE, ETC. THESE VENTILATORS ARE NOT

EXPLOSION-PROOF.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6

Publication 5375-001-REV-F

Voltage Selection/Fuse Replacement

VVoollttaaggee SSeelleeccttiioo

1. The ‘683’ Ventilator is equipped with a 115/230V selector feature, which is incorporat-

ed into the power entry module located on the side of the unit (see figure below). The

Ventilator is shipped from the factory with the voltage selector set at 115V. To change

voltage from 115V to 230V, follow these steps:

a. Turn off main power, and disconnect power cord.

b. Using a small flathead screwdriver, pry open the fuse access door on the power

entry module (see figure below).

c. Remove fuse holder by using the small flathead screwdriver.

d. Rotate the red fuse holder 180 deg. and install back into power entry module.

e. Close small access door firmly until fully closed. n power entry module window

(see detail below) 230V should be seen.

f. Re-install power cord.

2. Turn on main power switch located on the rear panel. The display will now illuminate.

The number displayed is the current strokes per minute rate.

FFuussee RReeppllaacceemmeett

KKeeyy Informat on

1. Make sure power cord is disconnected from the main power supply before servicing the fuse.

2. Use only Type 3AG, 1/4” x 1-1/4”, 0.75 amp, 250 volts; Type T (time delay) fuses

(Harvard Apparatus part # 5153-554 or equivalent).

Turn off power and remove power cord from power module. Use a straight blade screwdriv-

er to pry open the access door. Remove the fuse holder and then remove the fuses from this

holder as shown in the figure below. Replace fuses using only 0.75A amp, 250 volts, Type T

fuses. Then replace the fuse holder.

Note: A non-operator-replaceable fuse exists inside of t e equipment. T is fuse is rated T 40mA

250V, 5 x 20mm.

H a r v a r d A p p a r a t u s M o d e l ‘ 6 8 3 ’ S m a l l A n i m a l Ve n t i l a t o r U s e r ' s M a n u a l

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

7

H a r v a r d A p p a r a t u s M o d e l ‘ 6 8 3 ’ S m a l l A n i m a l Ve n t i l a t o r U s e r ' s M a n u a l

Publication 5375-001-REV-F

Operating the Pump

Connection to t e Animal

The vertical slide valve has four ports (see figure below):

• The top port (furthest from the chassis in new orientation) is the return channel from the

animal, which leaves the Pump at the port on the side. t is at this top port that expired

air can be collected or recycled.

• The middle port is the room air/gas channel to the animal.

• The bottom port (closest to the chassis in new orientation) is the room air or gas

mixture intake.

Note: It is important t at t e tubes to and from t e animal be as s ort as possible. T e new

orientation allows t e animal to be as close as possible to t e Ventilator for minimal dead space

in t e system.

The actual connection to the animal can be either:

• Tracheal cannula with y adapter

• ntubation cannula with y adapter

A selection of trachael cannula and endotracheal tubes are listed in the Harvard Apparatus Catalog

and on our website www.harvardapparatus.com. t is important that the volume of tubing shared

by inspired and expired air (dead space) be kept to a minimum by having the “Y” or “T”

connector as close to the animal as possible.

CHASSIS

ROOM AIR

TO ANIMAL

ANIMAL

EXHAUST

OUT

IN

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

8

H a r v a r d A p p a r a t u s M o d e l ‘ 6 8 3 ’ S m a l l A n i m a l Ve n t i l a t o r U s e r ' s M a n u a l

Publication 5375-001-REV-F

Operating the Pump (Cont’d)

Selection of Rate and Volume

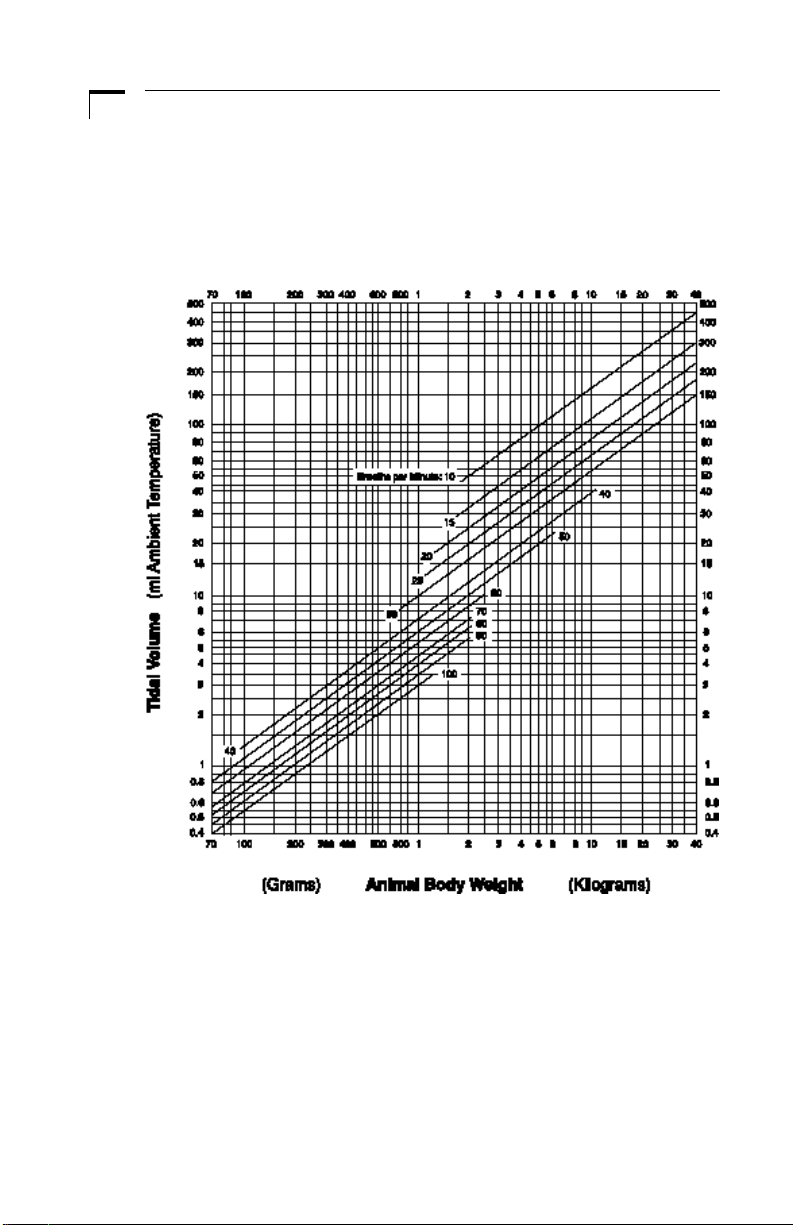

Refer to the Ventilator Graph (above) to select the appropriate tidal volume and respiration

rate as a function of animal body weight. As a rough guide an adult rat will weigh between

200 and 500 grams with tidal volumes between 0.6 to 1.25 cm3with respiration rates between

66 to 210 breaths/min. The average rate is 100 breaths/min. For most rodents the 5 cc

cylinder will be adequate. For larger animals it will be necessary to change the cylinder.

Ventilator Grap

Tidal Volume vs. Weight & Rate

for Laboratory Mammals in Resting State.

(Apparatus dead space must be added)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

9

H a r v a r d A p p a r a t u s M o d e l ‘ 6 8 3 ’ S m a l l A n i m a l Ve n t i l a t o r U s e r ' s M a n u a l

Publication 5375-001-REV-F

Operating the Pump (Cont’d)

SSeettttiigg VVoolluummee

The volume delivered is read by observing the excursion of the O-ring, on the piston, which is

closest to the valve block. This piston O-ring excursion is relative to the volume scale on the

outside of the cylinder wall. Volume change is accomplished while the Ventilator is running by

turning “volume” knob in the desired direction.

SSeettttiigg RRaattee

Adjust the “Rate” control until the desired rate appears on the LED display. Avoid running the

Ventilator at rates exceeding 150 breaths/min for periods in excess of 2 hours.

CAUTION - Do not over inflate t e animal. A good rule of t umb is to observe t e

dept of respiration in t e normal calm unanest etized animal and adjust t e volume

to approximate t is respiration dept w en t e animal is attac ed to t e ventilator.

UUssee ooff GGaass MMiixxttuurree

t is possible to introduce non-explosive air/gas mixtures into the lower room air port.

However, the source of gas mixture is usually from a tank delivering gas is at a constant rate

while the Ventilator takes in air/gas intermittently. Some sort of buffer/expansion chamber

must be provided between the tank and the Ventilator. Harvard Apparatus offers a connection

kit (73-3076) to depressurize the gas prior to entering the ventilator. This Ventilator is not

designed to take air/gas inputs under pressure.

CCrreeaattiigg aa PPoossiittiivvee EEdd--EExxppiirraattoorryy PPrreessssuurree ((PPEEEEPP))

To create a PEEP pressure when using the ventilator, simply connect a length of tubing to the

“Exhaust” port and submerge the other end in a column of water. There are two locations in

which the clip and cylinder can be installed - depending on the chosen orientation. The depth of

the end of the tubing (in cm) below the water surface will give the PEEP pressure in cmH2O.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

10

H a r v a r d A p p a r a t u s M o d e l ‘ 6 8 3 ’ S m a l l A n i m a l Ve n t i l a t o r U s e r ' s M a n u a l

Publication 5375-001-REV-F

Maintenance

CClleeaaiigg

To clean the exterior surfaces, use a lint-free cloth to remove loose dust. Use care to avoid

scratching the clear display window. For more efficient cleaning, use a soft cloth dampened

with water or an aqueous solution of 75% isopropyl alcohol.

MMaaiitteeaaccee

No special maintenance is required other than periodic lubrication of the piston O-rings and the

slide valve with the special non-toxic grease provided. To get to the slide valve for lubrication:

1. Remove the four screws holding the valve to the 1/4" aluminum black back plate.

2. Remove the screws in front that hold the cylinder and valve together.

3. Lift entire valve assembly up and out of Ventilator.

4. Pull stainless steel valve rod free of valve block.

5. Lubricate sparingly.

MMooddeell 668833 RRooddeett VVeettiillaattoorr RReeppllaacceemmeett PPaarrttss

LLuubbrriiccaattiioo

This Model 683 Ventilator is shipped with the appropriate grease to lubricate the piston and

O-rings in the cylinders and the inside of the slide valve.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

11

H a r v a r d A p p a r a t u s M o d e l ‘ 6 8 3 ’ S m a l l A n i m a l Ve n t i l a t o r U s e r ' s M a n u a l

Publication 5375-001-REV-F

Changing Piston and Cylinder

This Ventilator is furnished with a 5 cc piston and cylinder installed. A 30 cc cylinder and

piston is also supplied for users that require larger tidal volumes.

Note: It s extremely mportant when chang ng p ston and cyl nders that they

be al gned to be concentr c and n l ne w th the p ston shaft.

The cylinder is fastened to the 4 port vertical slide valve by means of two screws located

between the “room air inlet” port and the “to animal” port on the front of the slide valve.

For ease of mounting, there is an alignment bracket located below the valve body. When re-

attaching a valve to the 683 Ventilator, the cut-out in the valve should sit square and parallel

with the corner of the alignment bracket. This should ensure that the valve and piston shaft

are in line with each other.

The vertical slide valve is fastened to the black 1/4" aluminum sub base by four screws locat-

ed on the opposite side from the printed label. After mounting a valve; if coupling does not

engage piston shaft, loosen cylinder mounting screws and adjust cylinder position until piston

shaft enters coupling with ease.

ALIGNMENT BRACKET

VALVE

MOUNTING

SCREWS

CYLINDER

MOUNTING

SCREWS

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

12

H a r v a r d A p p a r a t u s M o d e l ‘ 6 8 3 ’ S m a l l A n i m a l Ve n t i l a t o r U s e r ' s M a n u a l

Publication 5375-001-REV-F

Changing Piston and Cylinder (Cont’d)

To remove t e cylinder and piston

1. Set the Ventilator volume to maximum.

2. Run Ventilator at lowest speed and stop when the helical coupling is exposed.

3. Using a 0.050 Allen wrench (provided), disconnect the white piston from the coupling,

leaving the coupling on the piston shaft.

4. Remove the two screws located in the front of the slide valve.

5. Remove piston and cylinder.

6. Be careful to save the O-ring that is recessed in the slide valve block between the screws.

The O-ring provides the airtight seal between the plastic cylinder and the valve block.

To install t e piston and cylinder

1. Pick out the new piston and cylinder.

2. Using pliers, remove the piston and lubricate with the grease provided.

3. nsert the lubricated piston in the cylinder so that the rear of the piston is flush with the

rear of the cylinder with the 1/8" diameter coupling stud protruding.

4. Fasten the cylinder to the valve block with the two screws, making sure the O-ring is in

place. Do not tighten these two screws completely, but just enough to hold the cylinder

in place.

5. The object of alignment is to have the stud at the end of the piston be exactly in line

with its mating hole in the helical coupling. This insures that the piston moves freely

within the cylinder without undue friction.

6. The two screws at the front of the valve block control left to right alignment while the

four screws at the rear of the slide valve control up and down alignment. By adjustment

of these 6 screws the proper alignment can be made. Remember that the screws inter-

act with one another so the procedure may have to be repeated one or more times.

7. When proper alignment is achieved, the helical coupling should be connected. f align-

ment is correct, the coupling should slide onto the piston stud without bending of the

piston rod.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

13

H a r v a r d A p p a r a t u s M o d e l ‘ 6 8 3 ’ S m a l l A n i m a l Ve n t i l a t o r U s e r ' s M a n u a l

Publication 5375-001-REV-F

O-RING

5013-051

O-RING

5013-019

VALVE BLOCK

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

14

H a r v a r d A p p a r a t u s M o d e l ‘ 6 8 3 ’ S m a l l A n i m a l Ve n t i l a t o r U s e r ' s M a n u a l

Publication 5375-001-REV-F

Notes

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

15

H a r v a r d A p p a r a t u s M o d e l ‘ 6 8 3 ’ S m a l l A n i m a l Ve n t i l a t o r U s e r ' s M a n u a l

Publication 5375-001-REV-F

Notes

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Declaration of Conformity

Appli ation of

Coun il Dire tive(s): 73/23/EEC, 89/336/EEC

Standard(s) to whi h

Conformity is De lared:

Safety: EN 61010-1, 2nd Edition (2001)

Emissions/Immunity: EN 61326:1997 w/ A1:1998

EN 61000-4-2:1995

EN 61000-4-3:1996

EN 61000-4-4:1995

EN 61000-4-5:1995

EN 61000-4-6:1996

EN 61000-4-11:1994

EN 61000-3-2:2000 w/ A.14

EN 61000-3-3:1995 w/ 1997

Manufa turer’s Name: Harvard Apparatus

Manufa turer’s Address: 84 O tober Hill Road

Holliston, Massa husetts 01746

U.S.A.

Type of Equipment: Small Animal Ventilator

Model No.: 683

I, the undersigned, hereby de lare that the equipment spe ified above onforms

to the above Dire tive(s) and Standard(s).

EMC omplian e was evaluated by Intertek/ETL Semko.

Referen e test report file number: Box 3091685-001

Pla e: United States of Ameri a

Date: February 2006

Beth Bauman

VP Engineering / Operations

(Signature)

(Full Name)

(Position)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

This manual suits for next models

2

Table of contents

Other Harvard Apparatus Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Vitalograph

Vitalograph copd-6 4000 Instructions for use

PROVOX

PROVOX LaryButton Sizer Kit manual

Azoi

Azoi Kito user manual

GF Health Products

GF Health Products John Bunn Vacutec 800 EV2 user manual

Dräger Medical

Dräger Medical Fabius GS premium Instructions for use

DeVilbiss

DeVilbiss 525 Series Instruction guide