Harvest-Master Climate User manual

4 Models

•

Climate

•

Climate Pro (with CO2 sensor)

•

Climate Plus

•

Pro Plus (with CO2 sensor)

2

Table of Contents

Introduction pg 3

Contents of Pack pg 4

Harvest-Master Connections pg 6

Harvest-Master Plug and Run pg 8

Set-up Equipment pg 10

Set-up Climate Information pg 11

Set-up Growth Cycle pg 14

Set-up Outputs on Plus model only pg 16

Hints on Setting up Greenhouse pg 19

Equipment for your Greenhouse pg 20

Electrical Safety pg 21

Warranty and Return Policy pg 23

3

Introduction

Harvest-Master Climate Controllers

In four models

•Climate (without CO

2

)

•Climate Pro

•Climate Plus (expanded input/output)

(modem “talk to me” option available (without CO

2

)

•Pro Plus c/w CO

2

(expanded input/output)

(modem “talk to me” option available

•

I take the guesswork out of controlling the environment for growing plants and turning them

into a crop. I’m the “man in the machine”.

•

Just plug me in! I check the lights, fans, air conditioner etc you connected, learning how they

work in YOUR green room. Then I can predict what will happen when I operate them!

•

I look after light, temperature, atmosphere, humidity, and CO

2

. I do it all continuously and

automatically. That’s my job. My factory settings will work great for any crop.

The simple facts are plants need air, water, light and nutrients, in balance.

•Controlling and maximising the climate for the best cropping is what Harvest-master does.

Harvest-master learns continuously how your room works, to keep it that way.

•Easy set up of day/night cycles (16 to 28 hours) for rapid growth.

•Easy selection of Vegetative (grow leaf), Fast or Full Flowering to bring on the crop.

This is what I do.

4

Contents of Pack

Your Harvest-master Climate controller is manufactured using the highest

quality components, by a team of specialists, to suit the demands of a

working horticultural environment. There are no user serviceable parts

inside. If the unit fails for any reason, return it to your supplier or directly

to Harvest-Master for a no questions replacement.

Email us at sales@harvest-master.com for any questions.

Opening the controller will void any warranty. This unit is warranted free

of defects for a period of 12 months from purchase.

Included with your Harvest-Master Climate Controller are:

•Remote relay switches, 3 in Climate models, to connect and switch mains power for Green House

devices (lights, fans, air-cond etc) and an external temperature/humidity sensor. Pro and ProPlus

models have CO

2

sensors and a four relay switch. Relay switches are rated 15amps at 120vAC &

240vAC. Extra relays or replacement units available via your reseller check our website

www.harvest-master.com. Each relay is controlled by a 10ft/3m RCA connector lead.

•Temp and Humidity sensor. High accuracy microchip type.

•The Pro and Pro Plus models include a CO

2

sensor.

•All units are powered by 12vDC, 750mA power pack. Power packs are provided for the country of

sale. Replacements may be obtained locally at any electrical supply store. If using 6 or more

relays, consider upgrading to a 1.3/1.5amp power pack.

•All units have 8 outputs to control lights, fans, CO

2

, cooling, heating, humidify, dehumidify,

spare/watering. These outputs are factory pre-set for your convenience, but may be changed to suit.

•Outputs may also be set as “Cycle timers”, to operate CO

2

cycle timing, watering or nutrient

dispensing systems.

•ProPlus units have expansion to 16 outputs and 8 inputs. Inputs are switch conditions. Outputs can

be switches, cycle or periodic timers. Relays available from Harvest-master stockists check our

website www.harvest-master.com

•Modem option. (For countries and areas with GSM coverage). The modem provides arms length

monitoring and control. Text Harvest-Master to get the current Temperature, Humidity, CO2 and

Day./Night status. Harvest-Master can text your cell phone or pager if there is a problem or if

an alarm has tripped.

5

Specifications

•Controller

RS232 port (DB9)

Power input 12vDC x .1amp (12 watts)

Aux connector (RJ12).

Outputs (RCA): 0.1A Max. Inputs 0.1A max (RCA).

Fuse 1A Blade type.

16 Character x2 line backlit LCD.

LED indicators for power, sensor, output line status (On/Off).

Climate and Pro models; 8 outputs for “switch on demand” or “cycle timer”.

ProPlus model includes 8 Inputs and an additional 8 outputs (16 total).

Operating conditions: 0°C to 50°C, 80% RH

•Controller Power Supply

12VDC 750MA output. 120vAC or 240vAC input (depending on country). Use only specified

power supply. If using 6 or more relays, consider upgrade to 1.3-1.5amp power pack.

•Relay Unit

USA, 120v AC, 15A,Thermal cut out protected

Europe/Australasia, 240v AC, 10A,Thermal cut out protected 120/240V

Activation 12V DC from controller via RCA connector lead. LED “ON” indicator to show

signal input status. 12V DC for relay coil activation shall be provided from CLASS 2 power

supply only. C UL USA certificate E242389, tested to meet or exceed UL and CE standards

•Sensor Unit: Temperature and Humidity. Connected to RJ45 “Sensor” port. Accurate to 1.8°F

/ 1°C (0°C to 4°C) and 2%RH (10% to 90%RH). CO2 sensor (+/-10ppm resolution, accuracy

+/- 100ppm or 5% whichever greater) connects “daisy chain”, inserted between

Temp/Humidity sensor and controller, using RJ45 sensor port.

•

Product specifications are subject to change without notice

Important notes

•Read instructions before use.

•No user serviceable parts inside any Harvest-Master controllers or relays. Disassembly

will void warranty.

•For indoor use only.

•Do not immerse any components in water.

•Failure to do so could result in fire or shock

•Take care to avoid overloading relays or power supply circuit.

•For high load items, use a differently fused circuit.

•Do not connect to any equipment that is damaged or faulty.

•Do not use any Harvest-Master article that is damaged.

•Failure to follow instructions could result in fire or shock

6

Input Connections

7

Output Connections

8

Plug & Run.

Locating Harvest-Master.

Harvest-Master is best fitted outside your Green House (only inside it if conditions are dry and no

condensing humidity). Harvest-Master will need to be physically located so that the 10-ft (3 metre)

control cables will reach from Harvest-Master to where you connect remote relay switches. Switch

relays can be located at the power socket or at the end of a power cord. You will need one relay switch

for each device you want to control. You may need more than one relay switch if you have more than

1.8kw at 120v or 2.4kw at 240v, of lights.

Power up Harvest-Master when you have connected everything you wish to control. Make sure

you check the “Harvest-Master Connections” page before connecting devices to Harvest-Master.

Connecting Equipment

Connecting Devices to Harvest-Master. It is recommended that users read the electrical safety section

before proceeding with this installation. This particularly applies if the TOTAL power requirement of

the devices you wish to control EXCEEDS 15 AMPS.

1) Lights. Connect your lights to a relay switch and plug this to the power socket. Run an RCA

control cable from the relay to Harvest-Master and connect it to the LIGHT output. See electrical

safety section. If more than 15 amps is required, several relay switches can be driven from the

single LIGHTS output (up to 6), using “Y” 2 to 1 RCA splitter cables, or use the SPARE output.

2) Extractor Fan(s). Connect fan(s) to a relay and plug this to a power socket. Run control cable

from the relay to Harvest-Master and connect to the FAN output.

3) Carbon Dioxide. Connect the solenoid on your carbon dioxide cylinder or the starter/power line

for your carbon dioxide generator to a relay switch, then plug the relay into a power outlet. Run a

control cable from the relay to Harvest-Master and connect it to the CO2 output.

4) Cooling Device. Connect an air conditioning unit to a relay and plug the relay into a power outlet.

Run control cable from the relay switch to Harvest-Master and connect to the “A/C” output.

5) Heater. Connect heater to a relay and plug the relay pack into a power outlet. Run control cable

from the relay pack to Harvest-Master and connect to the HEAT output.

6) Humidifier. Connect a humidifier to a relay switch, plug into a power outlet. Run a control cable

from the relay pack to Harvest-Master and connect to the HUMIDIFY control output.

7)

Dehumidifier. Connect a dehumidifier to a relay switch and plug into a power outlet. Run a

control cable from the relay to Harvest-Master and plug it to the DEHUMIDIFY output.

Connecting Sensors

1) Systems without Carbon Dioxide Sensor. The Temperature and Humidity sensor is the 10ft (3m)

cable with a RJ45 plug on the end. Plug the connector into the “Sensors” socket on the controller.

2) Systems with Carbon Dioxide Sensor. Connect the 10ft (3m) cable with 2x RJ45 connectors (like a

telephone connector) and plug one end into the “Sensors” connector on Harvest-Master, the other

into one of the connections on the carbon dioxide sensor. The temperature and humidity sensor

plugs into the other RJ45 connector on the carbon dioxide sensor.

Positioning Sensors

When positioning the sensors, make sure:

1) They are not in direct light from your grow lights. Make a paper or cardboard cover from a

piece of white card to protect sensors from direct light if you have no suitable shady spot(s).

2) Do not locate in a “dead spot”, such as a corner where air is poorly circulated.

3) They are at plant level, not above the top of the plants or below the container(s) the plants are in.

4) Carbon dioxide sensor is not too close to the carbon dioxide generator or CO

2

outlets.

5) The temperature and humidity sensor is not located among the leaves of a plant.

9

Powering Harvest-Master for the First Time

Now it is time to power it all up. Turn on the power to all of the devices you have connected and then

power ON the Harvest-Master. Now Harvest Master will perform Room Calibration.

1) SET CLOCK. At first power up, it will prompt you to set the clock. Adjust the time with the

arrow keys then press OK, or Press ‘EXIT’ to leave the time at 00:00, the start of the dark period.

2) SETUP EQUIPMENT. At first start, it assumes that all possible devices are connected. During

Calibration and Climate Analysis, Harvest-Master will check all of these devices and their effect

on climate. To reduce calibration time, enable the devices you use (do nothing to them), set the

rest to “NOTHING”. E.g. if you HAVE a cooling device, do nothing. If NOT, then set the

COOLING (output 4) to “NOTHING”. Check the section on SETUP EQUIPMENT for more

help on how to do this.

3) CLIMATE ANALYSIS. Once the internal clock is set and any changes made to the connection

list, Harvest-Master starts its Climate Analysis phase (Calibration). Harvest-Master tests the

system to determine what devices are connected and how they affect the climate. It collects

information on how your Green House warms, cools, fills with Carbon Dioxide, the rate it leaks

from the room etc. Calibration can take 20 mins to an hour so just leave it to get on with its work.

At the end of Calibration and Climate Analysis, Harvest-Master begins its normal climate control

mode. If there were devices shown in the connection list that could not be found, Harvest-Master will

display the message “Device Errors” for about four minutes. If you do not press any of the buttons for

four minutes, Harvest-Master removes those devices from the connection list and starts climate control.

If you want to see what devices were tested for but not found, the up arrow can be used to step through

the list. If you press Exit, the offending devices are removed from the list. If you press OK, the

devices stay in the connection list and Harvest-Master will try to use them to control the climate.

Set-up Equipment

The Harvest-Master Menu

The Harvest-Master MENU has eight options. These are:

•Equipment - Control what is connected to Harvest-Master.

•Climate - Change the climate parameters.

•GrowCycle –To change the day and night periods

•CO

2

State - Make CO

2

active or suspended (if installed)

•Time - Set the time of day on Harvest-Master

•Watering –Allows the Set up of eight watering times.

•Outputs - Pro Plus model only - designate output types.

•Reset Room - Only if in CO

2

cycle.

•Calibrate - Calibrate all available sensors & devices connected

Note:

If the unit has been powered up prior to all the devices being connected

then the auto calibrate mode will not proceed.

You need to manually select “Calibrate” option)

Set up equipment allows you to manually set what devices you want on the climate outputs 3 - 8.

Outputs 1 & 2 are reserved for lights and fans respectively.

10

1) Types of devices supported are:

a) Lights

b) Fans

c) More Fans

d) Watering

e) Heat

f) Cool

g) Humidify

h) Dehumidify

i) CO

2

j) Alarm

2) Additional points to note:

a) If you have two sets of lights running, you can install both on one output using a standard

RCA "Y" connector to control both relay units. This also applies to using one device from 2

outputs. E.G., A/C and DEHUMIDIFY outputs going to a single relay switch for an Air

Conditioner.

b) When you select Set-up Equipment the up arrow cycles through outputs 3 - 8. The

equipment installed on that output is displayed in brackets.

Set-up Climate Information.

You can change the following set-up values in Climate Set-up.

1) Temp Units – There are two temperature types Celsius (for almost every where) and Fahrenheit

(for USA) choose one or the other.

2) Max Temp –This is the maximum temperature for normal growing - defaults to 32C/90F. If you

have CO

2

operating, fans will turn ON and CO2 pause, when this temperature is reached. Very

hot regions (Central Valley CA) could raise the Max temp to 34-38C/94-99F to accommodate

extreme climate

3) Min Temp - Minimum temperature for normal growing - defaults to 15C/59F.

4) HighTemp Danger – A “survival” setting. This is the temperature that the controller will turn

lights off even during the "Day" part of the cycle to protect against plant damage. Exceeding this

temperature also sets the temperature alarm state. Default is 38C/100F. Very hot regions (Central

Valley CA) could raise the High Temp Danger to 40-43C/104-110F to accommodate extreme

climate.

(Temperature alarm ("Alarm TMP") is displayed on the LCD (display front). If you have one of

the outputs set up as an alarm, then that output will turn on. NOTE: Temperature sensor read

error also causes the temperature alarm to be set but this is cleared next good read, where as the

temp level error is cleared when the temperature falls below the High Temp Danger level.)

5) LowTemp Danger - A “survival” setting to protect against frost. If the temperature falls below

this, the controller may turn lights on to generate some warmth during the cold "night" part of the

cycle. A temperature alarm occurs until the temperature rises. Default is 4C/39F.

6) Reduce NightTemp. Night temperatures should be under day temp by about 6C - 8C or 10F -

15F. Default is 7C/7F

7) Max Humidity - Maximum humidity defaults to 60RH. Used in combination with

“CO

2

HumidityIncr” see (19) below. At this point, a CO

2

cycle will terminate as fans operate.

8) Min Humidity - Minimum humidity. The minimum for normal growing, defaults to 40%RH.

When the humidity falls below here a CO

2

cycle will terminate as the fans turn on.

11

NOTE: OPTIONS 9 - 14 ARE IN PAIRS, DARK HOURS + LIGHT HOURS.

YOU CAN SET A DAY CYCLE AT ANY LENGTH, 12 TO 36HRS.

Set Vegetative cycles shorter to maximise crop rotations.

Short day Flowering cycles to get produce harvested early and to market.

9) Veg Light Hours. Hour’s lights are ON during the vegetative growth stage. Default is 18 hours.

10) Veg Dark Hours. Hour’s lights are OFF during the vegetative growth stage. Default is 6 hours.

11) Fast Flowering Light Hours. Hour’s lights are ON during Flowering stage. Default is 6 hours.

12) Fast Flowering Dark Hours. Hour’s lights are OFF during Flowering growth. Default is 12

hours. Note: this gives an 18-hour day so the lights will be coming on during a different 6-hour

period each day.

13) Full Flowering Light Hours. Hour’s lights are ON during fruiting stage. Default is 12 hours.

14) Full Flowering Dark Hours. Hour’s lights are OFF during the fruiting stage. Default is 12 hours.

15) CO

2

Ppm Target. This is a bench mark value that defaults to 2000ppm. The controller will

dispense CO

2

to give a concentration at least 300ppm above this, then dispense CO

2

when the

concentration falls to this level.

16) CO

2

Start Ticks An additional time allowance to “Top Up” CO

2

to attain 300ppm above target

CO

2

ppm. The default and usual setting for this is zero. You can enter a value from 0 – 99 (1/10

th

of seconds) in this field. If CO

2

over-runs target CO

2

ppm, reset this to 00.

•CO

2

Fine Control (in Versions 1.24 and later.). Auto adjustment of CO

2

Top Up time, to most

accurately attain 300ppm increase. Set to On or OFF

17) CO

2

Ppm/Min. The delivery rate of the CO

2.

Measured and constantly updated every time the

carbon dioxide is dispensed to give a rise of more than 600ppm. You may need to change this

value (enter 3000 – 6000ppm/min) if the controller has lost the CO

2

dispense rate. Symptoms are

when CO

2

levels do not get high enough even though there is plenty of CO

2

.

This value is continually relearned by Harvest-Master.

18) CO

2

Min Duration. The carbon dioxide cycle's minimum duration is measured in minutes. The

controller will not start a CO2 cycle if it calculates that the maximum temperature or humidity

will be exceeded in less than the time you set here. In hot areas, the 30min default value may need

to be reduced to 15 mins.

19) Co2HumidityIncr. The carbon dioxide humidity increase is the allowable humidity increase

above the Maximum Humidity (set in (7) above), during a CO

2

cycle. The value defaults to

15RH. This means if you have a maximum humidity set at 60RH, then during a CO

2

cycle, the

humidity can rise to 60 + 15 = 75RH before the fans are turned on to end the cycle.

20) CO

2

Delay. At the start of a CO

2

cycle, it is likely that the fans have just been turned off. The

delay gives time for fans to stop spinning and removing air (including CO

2

you are dispensing)

from the room. The default is 10 seconds. If in doubt, make it 30 seconds.

21) Humidify&Fans? Should a humidifier be used when Fans are ON? It may be self-defeating. If so,

set to NO. If acceptable, set to YES. The controller will determine, during calibration, if the

humidity can be increased while the fans are removing air from the room. If calibration is carried

out during a humid day the humidifier may not be able to make much difference and the

controller could get it wrong.

22) Dehumidify&Fans? Should a Dehumidifier be used when the Fans are ON? As for (21), select

YES or NO.

23) Off/On Light Mins. In the event of lights being turned OFF by Harvest-Master, most lights used

are HP Sodium or Metal Halide and these must be given time to cool after turning off before they

can be turned on again. This is the delay (minutes) before lights can be turned on.

12

24) Watering Min:Sec. This is the duration in minutes and seconds for each watering cycle.

Set-up Growth Cycle

Harvest-Master uses the term "Growth Cycle" to mean the day and night lengths the plants are under.

Harvest-Master supports three growth cycles, Vegetative, Flowering and Fruiting. The length of "day"

and "night" periods is controlled by the climate settings above. To change the growth cycle just select

this menu option. Use the arrow until the correct cycle is displayed, then OK. Press EXIT to exit.

1) Vegetative. This should be long days and short nights. Most plants can not handle more than 18

hours light per day, so the default "day" length is 18 hours and the night length to 6 hours.

2) Fast Flowering. Setting the length of night to at least 12 hours induces flowering. Normally there

would be 12 hours day as well, but for rapid flowering and early harvesting, reduce the day down

to 6 or 8 hours. Harvest-Master default is 12 hours night and 6 hours day.

3) Full Flowering. For maximum yield, a 12 hours light and 12 hours dark for at least the last three

or four weeks of flowering (or fruiting). Default is 12 hours day and 12 hours night.

Set-up CO2 State.

The purpose of this is to allow you to suspend CO

2

use. This is useful if you run out of CO

2

(or LPG if

using a burner). When CO

2

is suspended it does not try to execute CO

2

cycles. If Harvest-Master tries

to dispense CO

2

but the concentration does not rise, it waits for 10 minutes and tries again. If it gets

three “Not enough CO

2

” attempts in a row it “suspends” CO

2

. It will not try again until the next day

starts. You can start CO

2

again by using the CO

2

state menu option to change the CO

2

setting from

SUSPENDED to ACTIVE.or,….wait until the next day when Harvest-Master will try again.

Set-up Unit Time.

Harvest-Master's internal clock is not restricted to a 24-hour day. The length of the Harvest-Master day

is determined by the values entered for Vegetative light and dark hours, Fast Flowering light and dark

hours, and Full Flowering light and dark hours.

The dark period ALWAYS starts at 00:00. Clock setting is 24hr format

When you set the time the display will look something like:

10:45 0600/1800

Light 1315->Dark

The time is 10:45 in a day with 6 hours dark and 18 hours light.

It is “Light” with 13 hours and 15 minutes to the “Dark” point (midnight in Harvest-Master time).

Use the “Time calculation wheel” to work out the correct time to use. Instructions are provided

on the wheel.

(If you have lost the calculation wheel!)

Suppose in this Vegetative cycle, you want the lights on from 4pm through the night to 10am, so the

lights are off during the hottest period of the day. “10am” real time has to match up to

“midnight/24:00” in Harvest Master time.

•Work out how many hours/minutes you are before or after 10am now, and set the Harvest Master

time that much before or after midnight.

•For example, it is now 1:00pm. That is 3 hrs after 10am.

•That is 3 hrs into Harvest Master dark period after midnight.

•Set Harvest Master time to 03:00

If you are in a Grow Cycle with other than 24hrs per cycle, the Harvest Master day will keep getting

13

out of step with real world 24hrs anyway, so just let it go!

Set-up Watering

The spare climate output (or any other unused outputs) can be set to control cycling a hydroponics

system, repeat CO2 dispensing or just watering your plants. To do this, select "Set-up Equipment",

select the output you want to change, press Ok, then again to select "Watering" then "OK".

There are up to eight “watering” times you can set. The default values are:

00.01, 0300, 0600, 0900, 1200, 1500, 1800, 2100.

To set the watering times you go to the main menu. Skip to "Set-up Watering", press Ok. Now you

can use the up arrow to step through the watering entries until you reach the watering entry you want to

change. Press Ok. You will see a screen something like:

Watering No. 3

06:00

Use the left arrow to move to the digit to be changed, then use the up arrow to change it. The software

will sort the watering times into order. You could change the 21:00 entry to say 4:00 and the software

will sort the list so that 4:00 comes before the current 6:00 first watering.

Note: the watering duration is entered in "Set-up Climate"

Set-up Outputs

Pro Plus Model only

The Pro Plus model has 8 additional general-purpose outputs and 8 digital inputs, all using RCA plugs.

The inputs are closed contact type. I.e. if you have two wires plugged into the input, it is ON when you

join the wires together, and OFF when the wire is not joined.

The outputs can be configured as one of six different types.

Explanation

1) Timer Output. This is a simple timer that you enter a Start time and a Stop time.

2) Periodic Output. This output has a start time, a period between cycles, and duration of cycle.

E.G. You have a spray to come on every three hours for 5 minutes. Set the start time to 8am (so it

is LIGHT), the period to 3 hours, the duration to 5 minutes. This could be used as unmonitored

CO2 dispenser.

3) “Input Tied” Output. This output turns on or off depending on an INPUT switch. The set up has

a polarity field to set the way the input operates the output.

I.E., you have carbon dioxide burner. You this output to turn a fan on when the door is opened

(Input switch) so that air in the room is evacuated in case of carbon monoxide build up.

4) “Input Tied” to Periodic Output. Periodic output (2 above) but triggered by an input rather than

time. To set this output, select which input (1-8), whether it starts when the input is ON or OFF,

the period and duration. NOTE: Output holds only while the input stays triggered.

5) Dual Input Output. Controlled By Two Inputs - This allows an output to be turned on by one input

and turned off by the other. For such things as filling a tank with two float switches - the pump

turned ON by a lower float switch, turned OFF when the water level activates upper float switch.

6) Input Controlled “Burst Output”. This output is tied to an input as (3) above. When the input goes

ON (or OFF) the output comes ON for a duration set. It does not come on again until the input

has become inactive then active again.

14

Setting up outputs on the Harvest-Master unit.

When you choose "Set-up Output" from the menu, the display will look like:

CHOOSE OUTPUT NO

9 (NOTHING )

The output number is displayed on the second line with the current setting of the output in

brackets. Use the up arrow

button to select the output number you want to change, then press OK.

9 CHOOSE TYPE

NOTHING

Use up arrow key to step though the output options then press OK for the output type you require.

These are: TIMER, PERIODIC, INPUT, INPUTPER (Input Periodic), 2INPUT, and INBURST.

1) TIMER Output. The software prompts for a start time and stop time.

9 START TIME

04:15

Use the arrow keys to change the digits so that the start and stop time values are set

2) PERIODIC Output. The start time is prompted for first:

10 START TIME

10:45

Set the start time desired then OK. Next entry is the period between the start of each cycle.

10 PERIOD MINS

00:10

The value is minutes and seconds. Press Ok. The software will prompt for duration of cycle.

10 DURATION Secs

0020

The units are seconds. This example gives Output 10, Periodic Timer, starts at 10:45, cycles

every 10 minutes, turns ON for 20 seconds.

3) INPUT Tied Output.

11 Choose Input

Input 1

Use the up arrow to select the input. Any inputs already used will not be displayed.

WHEN INPUT 1 ON

Output 11 OFF?

Press the up arrow to switch the display ON or OFF

WHEN INPUT 1 ON

Output 11 ON?

Once the combination you want is displayed, press Ok.

4) INPUTPDC (Input Tied To A Periodic Output).

12 CHOOSE INPUT

Input 2

Select Input, press Ok

WHEN INPUT 2 ON or WHEN INPUT 2 ON

Output 12 OFF? Output 12 ON?

Select by using the up arrow. (The first example above is called reverse polarity because the

periodic output is active while the input is off.)

15

5) 2INPUT or Dual Input Controlled Output. The software needs to know which two inputs to

use and what their polarity is to be. You are prompted first for the input A:

12 CHOOSE INPUTA *

Input 3

Choose the input using the up arrow then pressing Ok, then set polarity of InputA must be

set. There are two choices:

WHEN INPUT 3 ON * or WHEN INPUT 3 ON

Output 12 OFF? Output 12 ON?

Select the first option if you want the output to be ON when the input is OFF. Once selected

with the Ok button you will be prompted for the input number for the output OFF.

12 CHOOSE INPUTB *

Input 4

Set the input number and press Ok. Enter the polarity of this input control.

WHEN INPUT 4 ON or WHEN INPUT 4 ON *

Output 12 OFF? Output 12 ON?

Select the first option if you want the output to turn OFF when input is ON.

The example (two level tank switch), would cause output 12 to turn ON when input 3 goes

to OFF (low), then turn OFF when input 4 goes to ON (full).

6) INBURST or Input Controlled Burst Output. Select the input to control it

13 CHOOSE INPUT *

Input 5

Set desired input, press Ok. Select the polarity of the input.

WHEN INPUT 5 ON or WHEN INPUT 5 ON *

Output 13 OFF? Output 13 ON?

Select one then enter the duration

13 DURATION Secs *

0020

The number of seconds is the length of the burst. If we chose the options marked (*) then

Output 13 would turn on for 20 seconds each time input 5 changed from Off to ON.

Hints for Setting up Green House

Step 1/ Make sure the room is the right size. . The ceiling should be at least 5’ high.

Step 2/ Enclose the room. Make sure furniture, curtains etc are not in the room as they harbour fungi.

Step 3/ Cover walls, ceiling and floor with material like flat white paint or whitewash, or white plastic

lining. A 1,000 watt HID will efficiently illuminate a 10’x10’ room with a light balancer. .

Maximise the light using a reflective hood. The more reflection the better.

Step 4/ Set up vent fan. An exhaust fan, vented outside pulling in new fresh air. A small oscillating fan

for air circulation in the room. Not too close to the plants. Could cause windburn on tender plants.

Step 5/ Irrigation, it’s much easier to run a hose with an on/off valve or install a hose bib in the room.

Remember once your plants are growing a 10’x 10’ garden may need as much as 30 gallons of

water. Harvest-master can be used for the watering system with a timer switch or moisture sensor.

Step 6/ A floor drain is handy. Trays placed underneath or visqueen plastic to save floors from damp.

16

Step 7/ Mount lights with a strong, supportive, adjustable chain between the ceiling hook and the lamp

fixture. This allows the proper distance to be maintained for growth. Note that a hot HID may

explode if water touches it. Be sure to put up or protect when servicing the garden.

Step 8/ There are some necessary tools required to ensure that plants are showing correct growth.

Necessary Tools

•Spray bottle

•pH & soil test kit

•Pruner or scissors

•Wire (like twist ties)

•Hammer/Nails

•Measuring cup/cylinder

•Pencil/pen

•Notebook!!!

•Yardstick (to measure growth)

Harvest-master already has the humidity/temperature sensor built in.

Check out our website www.Harvest-master.com for users tips, FAQ’s and other hints.

Equipment for Your Green House

A) Devices you will need.

1) Lights. These must be strong enough for the number of plants you want to grow. Your

supplier can help you with this. If you plan on using CO

2

then ducted lights are best. Ducted

lights have an enclosed reflector. Cold air from outside the room is helps reduce the build up of

heat since the cold air cools the hot bulb as it blows past it. Heated air passes to outside.

2) Extractor Fan(s). These are vital since it is the main method of controlling heat and humidity

build up. If you plan on using CO

2

, louvered fans that close when they are not running are best.

Extractor fan(s) must be able to replace the air in the Green House several times per hour.

3) Circulating Fan(s). The number of these depends on the size of your Green House. The best type

of fan is an oscillating desk fan with 15 to 40 watts of power. The object is to maintain steady

breeze in the room to keep air circulating over the leaves. This provides fresh carbon dioxide as it

is used up in air around the leaves and removes water vapour that would create high humidity

around leaves. High humidity increases the chance fungal infections and lowers photosynthesis.

B) Devices that are an advantage.

1) Carbon Dioxide. Millions of years ago when plants were evolving, the concentration of CO

2

was

much higher than the 0.04% concentration in our present atmosphere. Plants have never lost this

ability to use a higher concentration of carbon dioxide (up to 2000ppm). We recommend

compressed CO

2

with a regulator/flow control and a solenoid valve. A LPG or Propane burner

can be used if it is designed for automatic control. It will require a mains power switch ON/OFF.

2) Dehumidifier. These are a significant help to maintain humidity between 40% and 60%RH. A

dehumidifier will improve plant growth if you are using CO

2

due to longer CO

2

cycles.

3) Humidifier. An advantage if you live in a dry area where humidity is frequently 40%RH or lower.

You can buy one or,..we made one from a desk fan, rubbish bin, plastic trough, and small

aquarium pump. A fan blowing over dish cleaning cloths, which are hanging into a bowl of water

(as a wick) works pretty neat too!

4) A Heater. If your Green House can get cold when the lights are off, a small fan heater is a great

addition to your Green House. Low cost and valuable during cold nights.

5) A Cooling Device. These will increase the length of the carbon dioxide cycles by decreasing the

heat build up in the room caused by lights. More efficient cooling device can be used in place of ,

or in conjunction with ducted lights, removing the heat created by the lights.

17

Electrical Safety.

Setting up a Green House requires normal care when dealing with electricity such as keeping

cables, plugs and sockets dry and in good order etc. There is the potential to overload circuits.

NOTE: The power requirement of electrical appliances can be found on the electrical

specification label located near the power connector. If it does not specify the wattage it will have

the voltage and current requirements e.g. 110-120 volts and 5 amps. Multiply the voltage by the

current to get the wattage. In the example above 120volts x 5amps = 600watts. If the current is

specified in milliamps instead of amps, divide the result of (Voltage x Amps) by 1000.

Warning: Overload of power outlet can be a serious fire risk

A Domestic electrical circuit can power a total of just over 2000w at 240v / 1800w at 120v.

A small Green House with 1x 1000watt light, fans, a dehumidifier and carbon dioxide, could run

from one mains output. I.e.

Lights 1000Watts

Fans 40Watts

Dehumidifier 300Watts

CO2 Solenoid 10Watts

Harvest-Master 10Watts

--------------

Total 1360Watts

What about a Green House with three 1000Watt lights, fans, a cooling device, a dehumidifier, and

carbon dioxide.

Lights 3000Watts

Fans 40Watts

Dehumidifier 300Watts

Cooling Device 800Watts

CO2 Solenoid 10Watts

Harvest-Master 10Watts

--------------

Total 4160Watts

A total of 4160Watts needs to be distributed over at least two, or preferably 3 electrical circuits

(usually two different wall sockets on different fused circuits). Equipment could be arranged so

that two 1000Watt lights are on different circuits and the rest of the equipment sharing those, or on

the other circuit.

18

Warranty & Return Policy

We provide full replacement for a faulty item within 12 months of purchase

If you have any problem with your Harvest-Master Controller or accessories, please contact your

reseller or Harvest-Master. Technical Support at e-mail support@harvest-master.com

We’ll assist with any technical difficulties you may have. If you think your controller is defective, take

it to your local dealer/distributor. He can check it with you on the spot.

The item must then be returned to us by the reseller or the local distributor.

When contacting Harvest-master, please provide the following information assist us:

Date and place of purchase

Model and Serial number of product

Description of fault and how you use it.

Limited Warranty, Disclaimer, Limitation of Liability

For a period of 12 months from the date of purchase by the retail customer,

Triton Commercial Systems Ltd (New Zealand) (hereafter TCS) warrants the “Climate/Climate

Pro/Climate Pro Plus” controller and Harvest-Master accessories against defects in materials and

workmanship. TCS will not honour this warranty if there has been any attempt to tamper with or

disassemble the controller or components.

This warranty does not cover and TCS will not be liable for, any direct or contingent damage or loss or

failure caused by misuse, abuse, acts of God, accidents or other causes beyond TCS’s control, or by

other than the original purchaser.

If, after inspection, TCS or its agent determines there is a defect, Harvest-Master will repair or replace

the controller at no cost to the purchaser (excluding freight).

To return a faulty item, either take to the point of purchase or contact us at: USA (775) 8413235

NZ/AUST ±6495792057 or support@harvest-master.com

In no event shall TCS be responsible or liable for any damages arising from the use of the product, for

any loss of use, revenue or profit of the product; or as a result of any event, circumstance, action or

abuse beyond the control of TCS, whether such damages be direct, indirect, consequential, special or

otherwise and whether such damages are incurred by the person to whom this warranty extends or a

third party.

Harvest-Master USA, #4879, 2533 North Carson St, Carson City, NV89706, USA. PH (775) 841-3235

Harvest-Master NZ/AUST, 411Great South Road, Penrose, Auckland, 1030 New Zealand PH +64 95792057

This manual suits for next models

4

Table of contents

Popular Controllers manuals by other brands

Homematic IP

Homematic IP HmIP-RGBW Installation and operating manual

Muller Elektronik

Muller Elektronik ISOBUS TRAIL-Control Operator's manual

gefran

gefran GFW 400A Installation and operation manual

ESAB

ESAB Aristo U82 instruction manual

Danfoss

Danfoss AK-PC 520 instructions

Barco

Barco EC Series Safety guide

Aqua Environment Inc

Aqua Environment Inc 1310 Operation and maintenance

Aeon Labs

Aeon Labs AEOEZW062 quick start

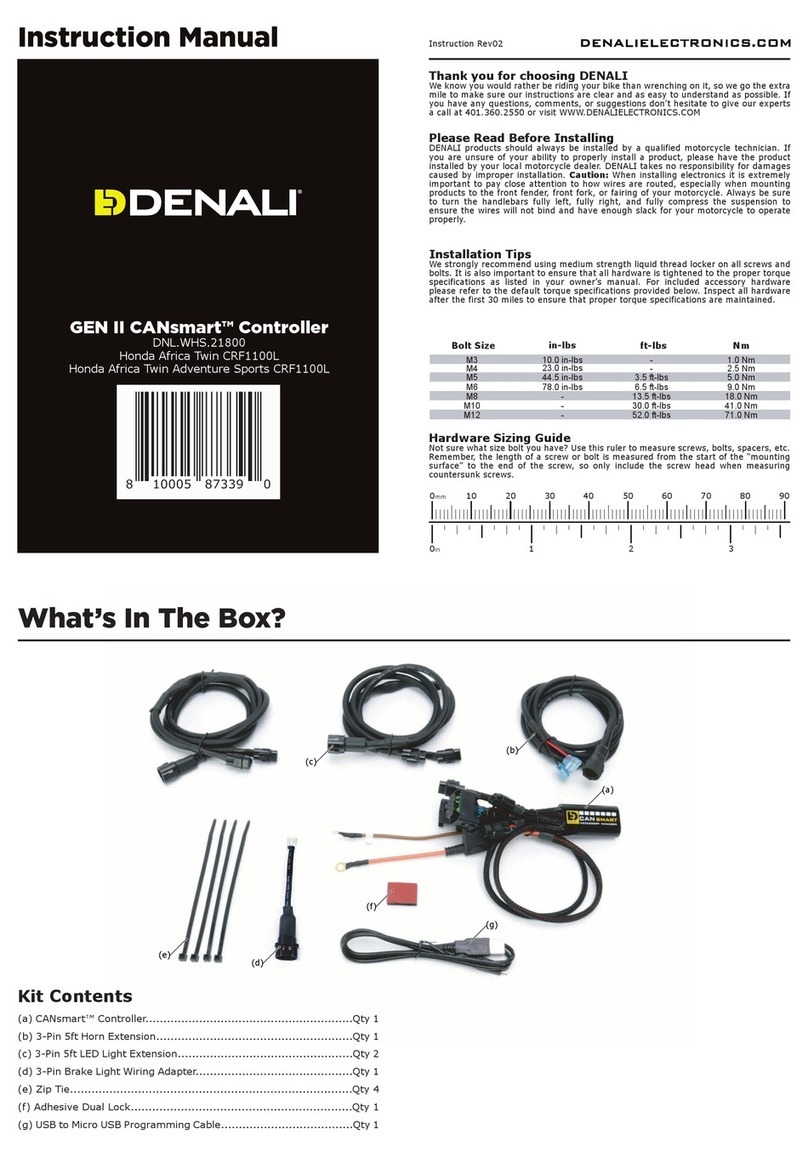

Denali

Denali GEN II CANsmart DNL.WHS.21800 instruction manual

Pride Mobility

Pride Mobility Microdrive Controller INFMANU2581 Operation instructions

WYTRON

WYTRON MagicCD Series Operation manual

Advantage Controls

Advantage Controls MegaTronMT manual