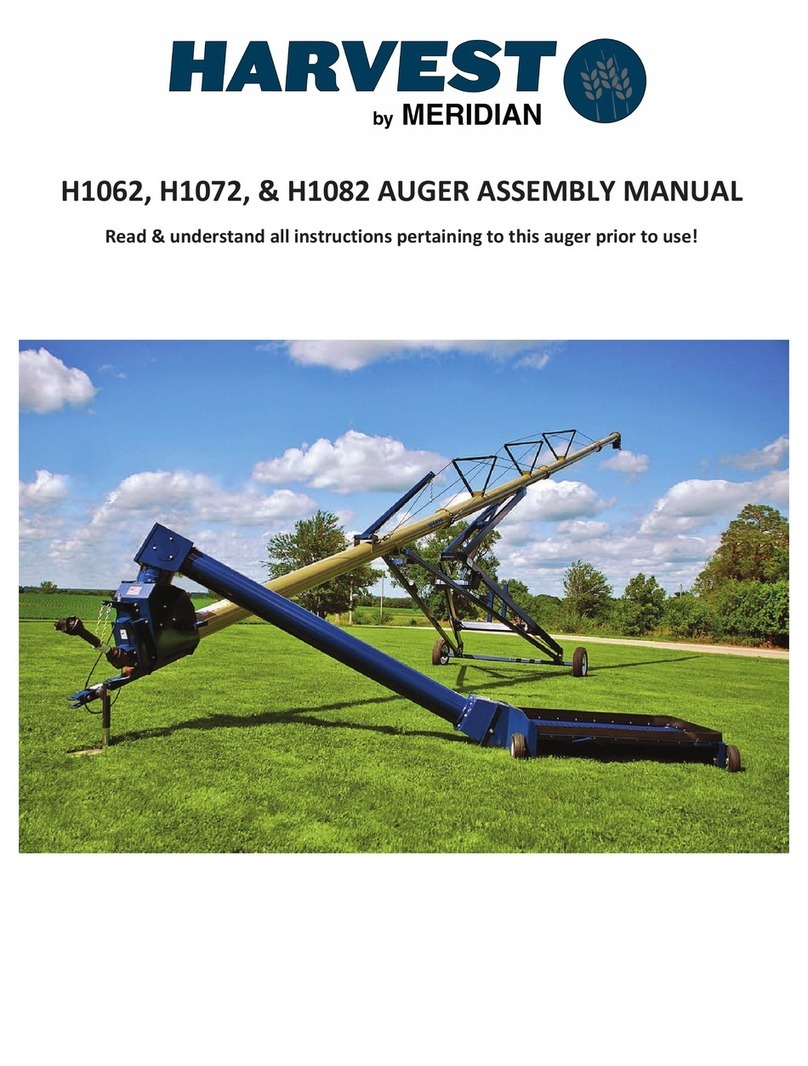

HARVEST H1364XT User manual

This manual suits for next models

2

Table of contents

Other HARVEST Tools manuals

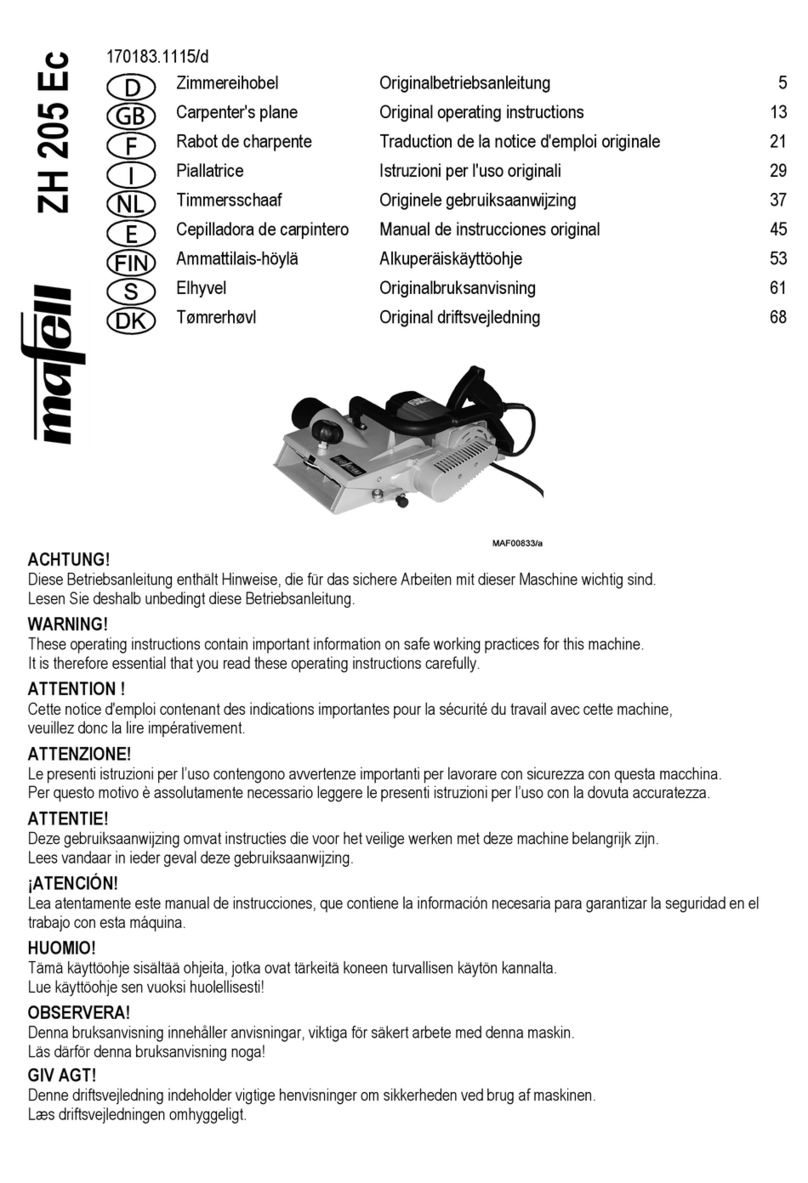

Popular Tools manuals by other brands

Rebar Tools

Rebar Tools DBR-25WH Handling instructions

Constructor

Constructor CTCID144LI2-3IN1-BM Original instructions

Grange

Grange Crane Safety, Operation & Parts Manual

Alemite

Alemite 555CLR Series User and maintenance instructions

Jokari

Jokari Secura 2K 20100 user guide

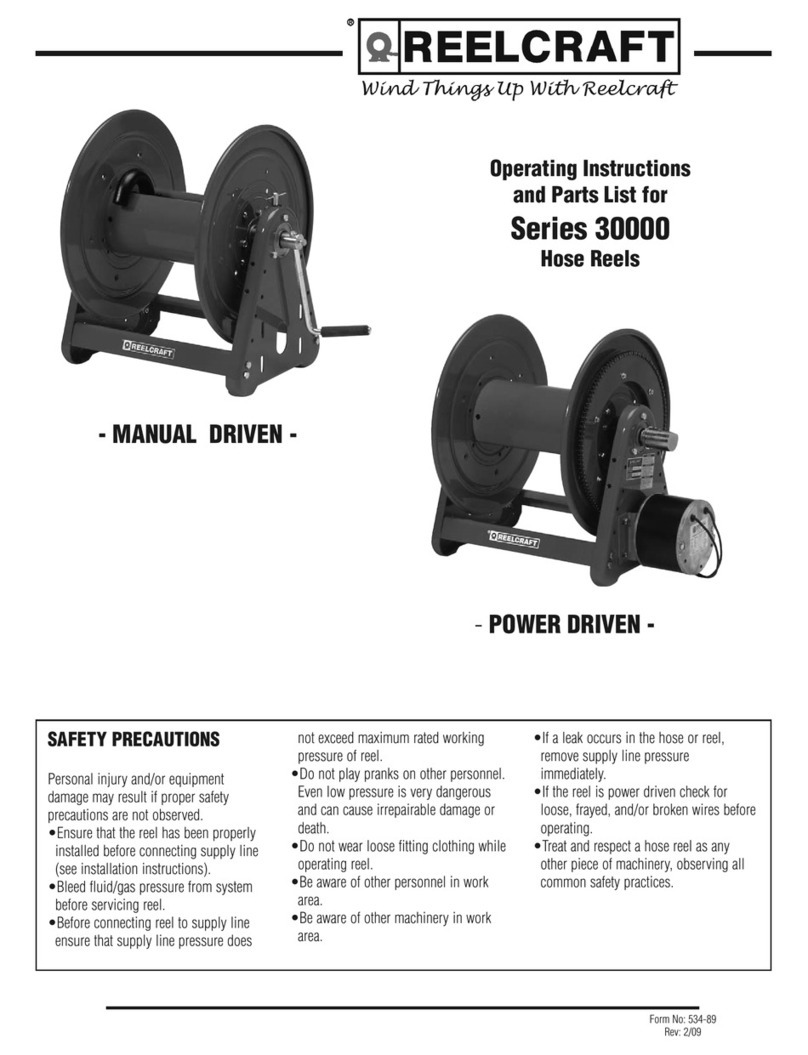

ReelCraft

ReelCraft 30000 Series operating instructions

Clarke

Clarke IT1500 Operation & maintenance instructions

BGS technic

BGS technic 8867 instruction manual

American Legend

American Legend AL18 Super Legend 2019 Maintenance manual

King Industrial

King Industrial K-1500 instruction manual

Rothenberger

Rothenberger ROBEND 4000 E Instructions for use

Powerfix Profi

Powerfix Profi PFRS 1.5 A1 operating instructions