Legend Aircraft Maintenance Manual –AL18 7

© American Legend Aircraft Company Rev 2.0

Date of Revision: 9/27/2013

Table of Figures

Figure 1-1 Aircraft Specification............................................................................................................. 9

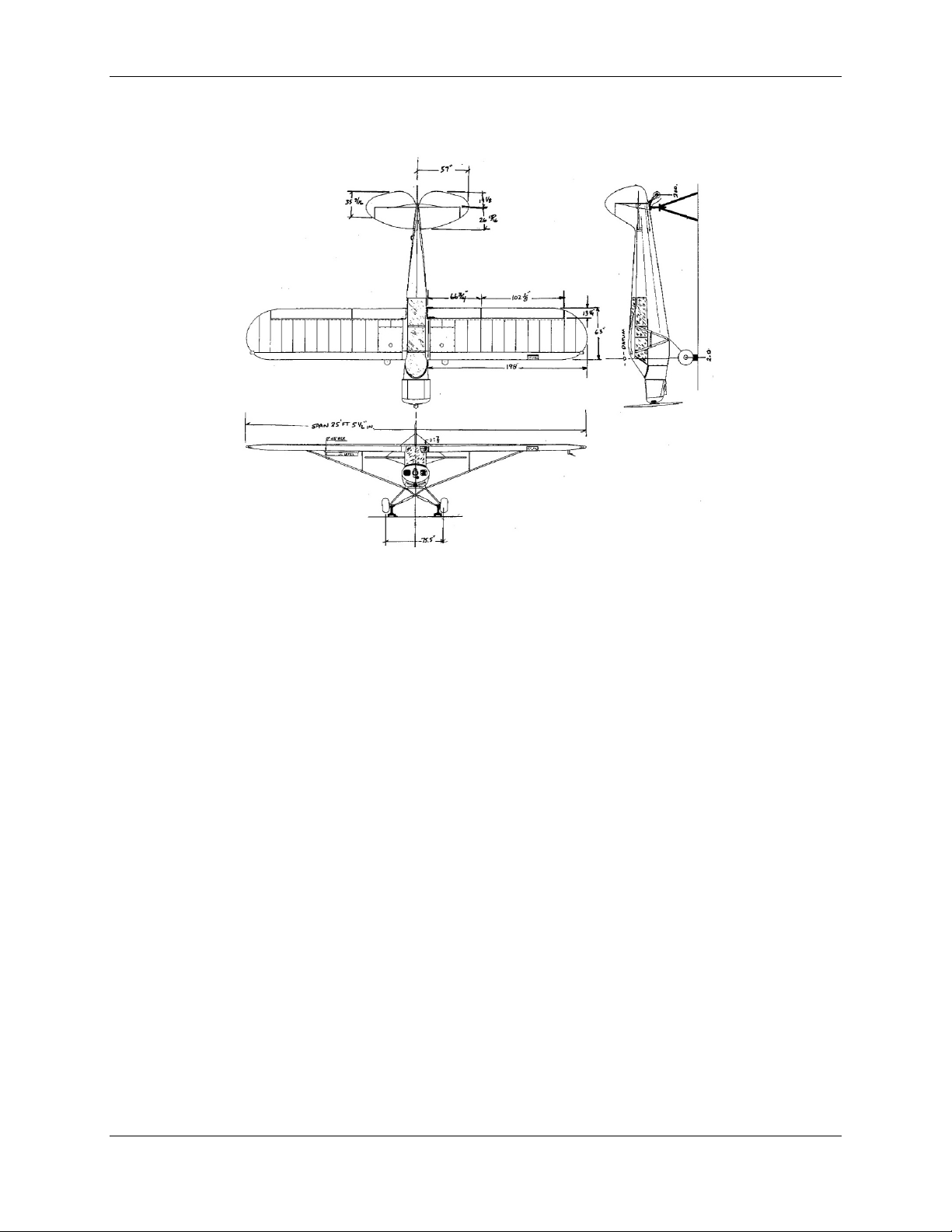

Figure 1-2 Aircraft Three View Drawing..................................................................................................... 10

Figure 1-3 Engine Specifications .......................................................................................................... 11

Figure 1-4 Sample Loading Problem ....................................................................................................12

Figure 1-5 Center of Gravity Limits ......................................................................................................12

Figure 1-6 Main Tire Inflation............................................................................................................... 12

Figure 1-7 Tailwheel Tire Inflation ....................................................................................................... 12

Figure 1-8 Lycoming YO-233 Approved Oils / Capacities..................................................................... 13

Figure 3-1 Wing View.................................................................................................................................. 15

Figure 3-2 Jackscrew ..................................................................................................................................18

Figure 3-3 Jackscrew Access .......................................................................................................................18

Figure 3-4 Torque Tube Rear ...................................................................................................................... 19

Figure 3-5 Torque Tube Front ..................................................................................................................... 19

Figure 3-6 Landing Gear.............................................................................................................................. 20

Figure 3-7 –Landing Gear Cabane / Struts ................................................................................................. 21

Figure 3-8 Landing Gear Leg ....................................................................................................................... 21

Figure 3-9 Tailwheel Rear View.................................................................................................................. 23

Figure 3-10 Tailwheel Side View ................................................................................................................. 23

Figure 3-11 Aileron Balance Cable .............................................................................................................. 24

Figure 3-12 Aileron Lower View................................................................................................................. 25

Figure 3-13 Aileron Upper View..................................................................................................................25

Figure 3-14 Elevator....................................................................................................................................27

Figure 3-15 Rudder ..................................................................................................................................... 30

Figure 3-16 Control Surface Travels ....................................................................................................... 31

Figure 3-17 Flap, Lower View...................................................................................................................... 34

Figure 3-18 Flap, Upper View...................................................................................................................... 35

Figure 4-1 Lycoming YO-233 Installation Top View .................................................................................... 37

Figure 4-2 YO-233 Gascolator .....................................................................................................................38

Figure 4-3 YO-233 Side View....................................................................................................................... 38

Figure 4-4 YO-233 Front View.....................................................................................................................39

Figure 4-5 Exhaust, Right Side.....................................................................................................................41

Figure 4-6 Exhaust, Left Side.......................................................................................................................41

Figure 4-7 Exhaust, Rear ............................................................................................................................. 42

Figure 4-8 YO-233 Alternator...................................................................................................................... 44

Figure 5-1 Fuel Tank Caps / Covers............................................................................................................. 47

Figure 5-2 Fuel Sight Gauges....................................................................................................................... 47

Figure 5-3 Fuel System Diagram ................................................................................................................. 48

Figure 5-4 Gascolator.................................................................................................................................. 50

Figure 5-5 Fuel Sight Gauges....................................................................................................................... 51

Figure 6-1 ....................................................................................................................................................54

Figure 6-2 ....................................................................................................................................................55

Figure 6-3 ....................................................................................................................................................55

Figure 7-1 Cabin Heat Inlet .........................................................................................................................56

Figure 7-2 Cabin Heat Outlet ......................................................................................................................56

Figure 8-1 Instrument Panel .......................................................................................................................60

Figure 9-1 Battery Installation ....................................................................................................................62

Figure 9-2 Electrical System Block Diagram................................................................................................ 63