HARVEST H13102 User manual

Read this manual before using product. Failure to follow

instructions and safety precautions can result in serious

injury, death, or property damage. Keep manual for future

reference.

*UDLQ$XJHU2SHUDWRU·V0DQXDO

H13102

H13XX Augers:

Important Notes

At 15-20 miles, tire lug nut tightness and

wheel hub temperature need to be checked.

At 50-60 miles, check these a second time.

For the H1392, H13102, and 112, the

maximum transport speed is 25 mph.

For the H1362, 72, and 82, the maximum

transport speed is 45 mph.

2

Harvest International thanks you for your purchase of the best quality auger on

the market. We are proud to have you on our team. Our equipment is

manufactured in the United States of America and is made to improve your

farming operation. Before you operate this auger, we advise that you read this

manual and familiarize yourself with each of the features. Please take all the

precautions necessary for an efficient and safe operation. Harvest International

recommends that anyone using this auger read the operational manual and sign

on the sheet provided below. This is to be kept for your record keeping.

Date

Employee Name

Employee

Signature

3

TABLE OF CONTENTS

1. Introduction_____________________________________________________________5

2. Safety First______________________________________________________________6

3. Transportation & Placement_____________________________________________7

3.1 Before Transporting Your Auger___________________________________7

3.2 Transport Procedure_______________________________________________8

3.3 Placement of Auger________________________________________________8

3.4 Final Placement__________________________________________________10

3.5 Lowering the Auger______________________________________________10

4. Operation______________________________________________________________11

4.1 Pre-Operation Checklist__________________________________________11

4.2 Auger Drive & Lockout___________________________________________12

4.3 Start Up & Break In_______________________________________________12

4.4 Everyday Operation______________________________________________13

4.5 Shutting Down the Auger_________________________________________14

4.6 Completion & Cleanup___________________________________________14

4.7 Lowering the Auger______________________________________________15

5. Hydraulics_____________________________________________________________15

5.1 General Information______________________________________________15

5.2 Cylinder Hydraulics______________________________________________16

6. Storage & Maintenance_________________________________________________17

6.1 General Maintenance_____________________________________________17

6.2 Storage of Auger_________________________________________________19

7. Appendix & Forms_____________________________________________________20

H13XX Parts Book____________________________________________________20

H13XX Lubrication Requirements_____________________________________41

Warranty Policy and Forms___________________________________________44

4

1. Introduction

Congratulations on your choice of a Harvest International auger! This equipment

has been designed and manufactured to meet the needs of the discerning

buyer.

Safe and efficient operation of your auger requires that you, and anyone else

who will be operating or maintaining the auger, read and understand the safety,

operation, maintenance, and troubleshooting information in this manual.

Keep this manual handy for frequent reference and to pass on to new operators

or owners. Call your Harvest International distributor or dealer if you need

assistance, information, or additional copies of the manual.

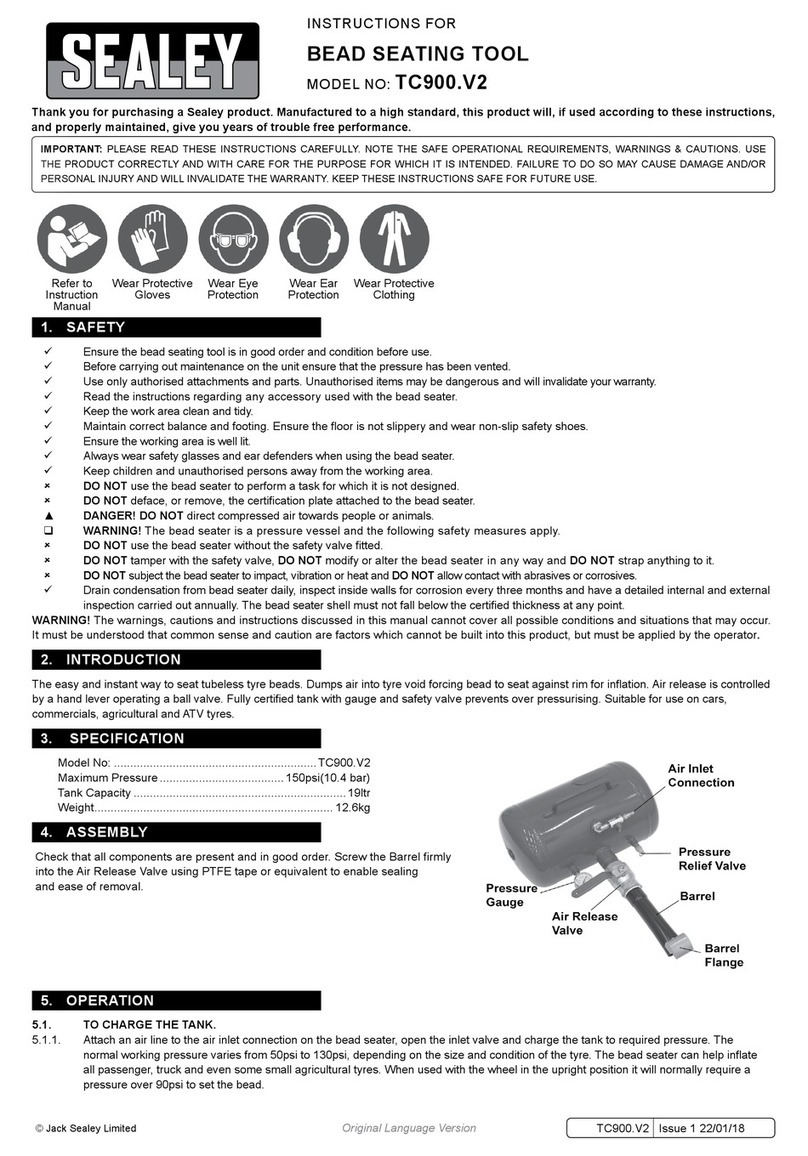

Always give your dealer the serial number of your Harvest International Grain

Auger when ordering parts or requesting service or information.

The serial number on your auger is located where indicated by the arrow in the

picture above. Please mark the number in the space provided below for easy

reference.

Model Number:_____________________________________

Serial Number:______________________________________

Production Year:_____________________________________

5

2. Safety First

Safety is a priority in your everyday work habit, especially if you work with

machinery. Whether you are an owner, an operator, or an employee, it is your

responsibility to know the operational requirements and safety precautions of

the machinery.

Why is safety important to you?

1. Accidents disable and kill.

2. Accidents cost.

3. Accidents can be avoided.

SIGNAL WORDS:

Note the use of the signal words DANGER, WARNING, CAUTION, and NOTICE

with the safety messages. The safety alert symbol identifies imminent and

potential hazards to personal health and safety. The appropriate signal word for

each message has been selected using the definitions below as a guideline:

DANGER: indicates an imminently hazardous situation that, if not

avoided, will result in serious injury or death.

WARNING: Indicates a hazardous situation that, if not avoided, could

result in serious injury or death.

CAUTION: Indicates a hazardous situation that, if not avoided, may

result in minor or moderate injury.

NOTICE: Indicates a potentially hazardous situation that, if not

avoided, may result in property damage.

6

3. Transportation and Placement

3.1 Before Transporting your Auger _

Remove wheel chocks, so wheels are free to move.

DANGER:

If auger wheels are stuck in grain, mud, dirt, or snow. remove the

restraining substance from around the wheels before transport. Failure to

do this could cause damage to the auger, and serious injury or death.

All Harvest International augers have minimum clearance positions when in

transport mode. Place auger in full down position.

DANGER:

Electrocution Hazard! Make sure that all unauthorized personnel are clear

from the transport zone. This auger is not insulated. Be alert to overhead

obstructions and electrical wires. Electrocution can occur without direct

contact. Do not raise or lower auger until hazardous area is cleared. Failure

to maintain proper clearance can result in serious injury or death.

Put hitch pin in place, and ensure that the safety chain is properly attached. Use

a type of hitch pin that will not allow the auger to detach itself from the tractor.

If you have questions about appropriate hitch pins, contact your tractor

manufacturer.

Put PTO driveline and swing hopper into transport position and lock into place.

If swing hopper is not in transport position, the hopper will be damaged during

transport.

Put jack in raised position and lock into place. Use caution when working with

hitch jack.

If you have a light package for your auger, make sure the connections are

fastened securely and not dragging on the ground.

7

3.2 Transportation Procedure _

Move auger with a tractor only. Never attempt to move by hand.

Under no condition should you allow riders on the auger or tractor.

Transport the auger no faster than 15 mph. When roads are rough or surfaces

are uneven, slow down to ensure safe travel.

DANGER:

Do not transport the auger on slopes greater than 20 degrees. This could

cause the auger to tip, resulting in damage to the auger, and personal

injury or death.

When visibility is reduced, please use caution and add extra lights to the auger.

Consider using a pilot vehicle for safer travel.

Use extreme caution when turning or cornering with the auger in tow.

Check regulations with local authorities regarding auger transportation. Follow

all over-width regulations. Equip auger with all necessary lighting, and use

hazard warning flashers on your tractor, when required by law.

3.3 Placement of Auger _

Before raising or lowering your auger, check that the area is clear of

obstructions, children and unauthorized personnel.

DANGER:

Electrocution Hazard! Make sure that all unauthorized personnel are clear

from the transport zone. This auger is not insulated. Be alert to overhead

obstructions and electrical wires. Electrocution can occur without direct

contact. Do not raise or lower auger until hazardous area is cleared. Failure

to maintain proper clearance can result in serious injury or death.

Ensure that your auger is on level ground that is free of debris.

DANGER:

If ground is very uneven, auger can tip and cause damage to the

equipment and personal injury or death.

8

WARNING:

Never position raisers of any kind under the wheels of the auger to

increase height. This includes pieces of wood, cement blocks, bricks, etc.

Attempting this could result in damage to the equipment and personal

injury or death.

Make sure that the hitch is secured to the tractor, and that all hydraulic

connections are tight and in good working condition. If there are any leaks or

damaged hoses, you must replace these before using your auger. Replacement

hoses and hose ends must have a minimum strength of 1900psi working

pressure.

Make sure that the wheels of your auger are free to move before you raise or

lower your auger.

CAUTION:

If the auger wheels are buried in any type of material, do not attempt to

raise or lower the auger. Remove dirt, snow, grain, or whatever other

material is obstructing the auger before use.

Check that the valve on the hose to the lift cylinder is open. Double check that

the area above and around the auger is clear of obstructions. Raise auger to

desired height, and

close hose valve after auger is positioned.

WARNING:

If hose valve remains open, a loss of hydraulic pressure within the tractor

system will allow the auger to lower by itself; this could cause damage to

the auger and personal injury or death.

NOTICE:

Do not use the auger as a hoist or crane, no matter the size or weight of

the object being lifted. This will create an unsafe condition and void your

warranty.

9

3.4 Final Placement of Auger _

When you are ready to use your auger, place the auger in its lowered position,

and slowly back it up to your bin or storage facility, keeping an eye out for any

people or obstructions in the hazard zone.

DANGER:

Avoid any electrical wires and overhead obstructions. Electrocution can

occur without direct contact. Failure to listen to this warning can result in

personal injury or death.

Use tractor hydraulics to raise the auger into position. Slowly back the auger

into position until the spout is over the opening of the bin or storage facility

and use tractor hydraulics to slowly lower the spout into the opening.

As soon as the auger is in position, the wheels of the auger must be chocked

on both sides. To prevent tipping, anchor or support the discharge end to the

bin or storage facility to further stabilize the auger.

3.5 Lowering the Auger _

Attach auger to tractor, making sure that your hydraulics are also attached to

the tractor. Raise the auger, to ensure that the outlet end is above the bin or

storage facility. Remove wheel chocks and ensure area is clear of personnel and

obstructions.

Drive forward, pulling auger slowly away from the bin or storage facility. Be

sure that the wheels are free to move, and lower the auger. Make sure auger is

in full down position before proceeding.

10

4. Operation

Wear protective gear at all times when operating auger, such as hard hats,

protective shoes, eye protection, and gloves. Do not wear loose clothing, and

be sure that hair is tied back.

4.1 Pre-Operation Checklist _

Before operating the auger, the operator must follow this checklist:

All safety shields are in place, secure, and in good working order.

Cables are secure.

Fasteners are secure.

PTO driveline is securely attached to driveshaft and tractor.

PTO driveline rotates freely.

PTO driveline telescopes easily.

Tube alignment is reasonably straight.

Auger wheels and tractor wheels are chocked.

Intake hopper and discharge spout are free of any obstructions.

A second qualified person is present during operation.

All operators have read manual and are aware of safety

precautions.

Maintenance has been performed properly.

Power to PTO and hydraulic system is in offposition before starting

tractor.

Hydraulic system has been thoroughly checked for leaks. (see

Section 5 “Hydraulics” for details).

11

4.2 Auger Drive & Lockout _

The proper operation of this auger requires that the operator pre-inspect the

drive system, know how to shut down the system in an emergency, and

generally monitor the system during operation.

Drive System and PTO Driveline: Ensure that the PTO drive on the tractor is in

the offposition before starting the tractor. Stay clear of PTO hazard area. Do

not exceed the maximum operation length of 34 inches of PTO driveline, or the

maximum angularity of 30 degrees.

Lockout/Shutdown of PTO Driveline: Turn offengine. Remove ignition key

from tractor. If for some reason, you cannot remove the key, remove the PTO

driveline from the tractor.

4.3 Start Up & Break In _

DANGER:

Electrocution Hazard! Make sure that all unauthorized personnel are clear

from the operation zone. This auger is not insulated. Be alert to overhead

obstructions and electrical wires. Electrocution can occur without direct

contact. Do not raise or lower auger until hazardous area is cleared. Failure

to maintain proper clearance can result in serious injury or death.

Have you completed the pre-operational checklist? If everything is satisfactory,

prepare for a 30 minute operation at half speed to break in your auger. Double

check that the intake hopper is properly positioned, and the PTO drive on the

tractor is in the offposition.

NOTICE:

When starting the auger for the first time, be prepared for an emergency

shutdown in case of excessive vibration or noise. The auger may run

roughly until the tube is polished.

Start the tractor and idle at low RPM. Slowly engage the PTO driveline.

12

Gradually begin to feed grain into the intake hopper, bringing the speed of the

PTO to 200 RPM. Do not over-feed the hopper on initial loads; keep the feed of

the grain at half capacity. After the auger tube is polished and runs smoothly,

proceed to unload at full speed (at but not to exceed 540 RPM for maximum

efficiency).

Upon completion of initial run, slow down until the auger is empty of grain, and

stop auger. Lock out the power source and conduct a complete inspection of

the auger, following the pre-operation checklist. After the initial start up and

inspection, the auger should be shut down and inspected at least three times

during the first hours of operation. Once your auger is broken in, the pre-

operation checklist should be part of the daily routine before you operate the

auger.

4.4 Everyday Operation _

WARNING:

When auger is in operation, keep your hands, clothing, and other objects

away from intake hopper, drive chains, and all other parts of auger to avoid

personal injury.

For normal auger operations, the following procedure and safety precautions

are strongly recommended:

Complete the pre-operation checklist before using your auger.

Remember to ground motor before using auger if an electric motor is being

used.

When using the auger, work with another trained operator present to monitor

the operation and help with a shutdown in case of an emergency. Monitor the

auger during operation for vibration and abnormal noises. If anything out of the

ordinary is noted, shut down and lock out the auger, determine the source, and

correct before continuing operation.

Keep the hopper full and running at 540 RPM for maximum capacity. Pour grain

in the middle of hopper, closest to the tube for best results.

Run the auger only when moving material. Running the auger without grain

moving through causes unnecessary wear.

13

4.5 Shutting Down the Auger _

Empty the auger of all grain. Disengage the PTO drive. Shut down and lock out

power.

WARNING:

Never use your hands to clean out debris from auger. Rather, use a small

shovel or other tool.

In the case where there has been an interruption or emergency shutdown,

restart the auger as follows:

If auger is full of grain, do not restart at full speed. Engage PTO at low RPM and

gradually increase power until normal operating speed is achieved.

CAUTION:

Starting the auger under load may result in damage to the auger. Make sure

there is no blockage.

4.6 Completion and Cleanup _

At completion of operation, the auger needs to be moved into storage position.

Make sure that the entire work area is clean, remove all supports and wheel

chocks, move auger out of working position, and fully lower the auger (see

lowering procedure below).

The proper steps for clean out of the auger are as follows:

1) Disengage power source; lower the auger into transport position.

2) Shut offtractor and lock out power.

3) Move intake hopper into transport position and latch with safety chain.

4) If necessary, clean out grain using small shovel or other tool.

WARNING:

Do not leave auger in raised position when not in use. Auger could drop

rapidly in case of hydraulic failure. High winds may also upset the auger.

Because the hydraulic scissor lift is faster than a hand crank system, use

extra caution and clear area of personnel before raising or lowering auger.

14

4.7 Lowering the Auger _

Check that auger and hose couplers are securely attached to your tractor.

You may need to raise the auger discharge end up and out of bin or storage

facility before proceeding.

Remove wheel chocks, and check that the area around and under the auger is

clear of debris and unauthorized personnel. Wheels must be free to move when

raising or lowering the auger.

Slowly pull away from bin or storage facility. As soon as you are clear, engage

the hydraulics and lower the auger. Once valves are open, the auger lowers by

gravity. Rate of descent increases the closer the auger gets to the down

position. Be cautious.

Transport auger only in fully lowered position.

5. Hydraulics

5.1 General Information _

Be sure that all safety precautions and proper operation procedures are fully

understood before connecting the auger hydraulic hoses. Harvest International

strongly recommends doing a daily visual check for damage to the hoses and

connectors. Replace any damaged parts before operation.

WARNING:

Wear proper face and hand protection when searching for hydraulic leaks.

Fluid can escape under pressure, causing infection or toxic reaction on

skin. See a doctor immediately if injured.

Escaping hydraulic fluid can be nearly invisible under high pressure. Use some

type of backdrop when searching for leaks.

Harvest International augers have a velocity fuse for hydraulic safety. If the

hydraulic line breaks, it locks the system. Our shut offvalve is equipped with a

15

flow restrictive orifice. After you have repaired the hydraulic hose, the system

resets itself and is ready for operation.

There are various types of tractor hydraulic systems; the quick connect couplers

are supplied by the owners. Please consult your tractor manual for the proper

couplers.

Before you connect your hydraulic hoses, check that the quick connect couplers

on the auger and tractor are clean and free of any dirt or debris; wiping them

down with a cloth.

CAUTION:

Dirt in the hydraulic system can damage the cylinder o-rings. This may

cause leakage and possible system failure.

Do not disconnect the hydraulic coupler when the system is under pressure.

Relieve all pressure and then disconnect.

5.2 Cylinder Hydraulics _

The testing done on Harvest International auger hydraulics was done using a

pressure gauge with 3000psi maximum rating. This was used simply as a

guide. The psi requirements for an individual auger may vary slightly.

Auger

Size

PSI

H1062

10” x 62’

1300

H1072

10” x 72’

1400

H1082

10” x 82’

1600

H1362

13” x 62’

1600

H1372

13” x 72’

1800

H1382

13” x 82’

1900

Have approximately four liters of hydraulic fluid in your system. Check that the

valve on the hose to lift the cylinder is open. Start tractor and engage

hydraulics. Raise the auger to desired height, and close hose valve. You must

turn valve while the hydraulic system is pressurized; do not disconnect

hydraulic couplers.

16

WARNING:

If valve hose remains open, a loss of hydraulic pressure within the tractor

system could allow the auger to lower unexpectedly, causing damage to the

auger and personal injury.

To lower the auger, reconnect hose couplers to the tractor. Ensure that area is

clear and wheels are free to move. Open the hose valve, start your tractor, and

engage hydraulics. The auger is fully lowered when the tube is resting on the

tube saddle.

NOTICE:

After valves are opened, the auger lowers by gravity. As the auger nears

the full down position, the rate of descent will increase.

6. Maintenance & Storage

Proper maintenance of auger will result in both a longer life of the auger and a

safe and efficient operation.

6.1 General Maintenance _

Always replace damaged or worn parts before using the auger. Use only

replacement parts manufactured by Harvest International, Inc. Use of

unauthorized parts will void the warranty of your auger. Contact your Harvest

International dealer to order parts.

Harvest International augers are designed and tested for a safe, efficient

operation. Do not modify the equipment in any way. Modification to the auger

can create an unsafe working condition, affect the life of the equipment, and

will void your warranty.

Before performing maintenance on your auger, shut down and lock out all

power. Disconnect the PTO driveline from the tractor. Support the auger tube

before attempting maintenance on the undercarriage. The auger should be in

full down position before attempting maintenance.

17

After Maintenance is completed, replace and secure all safety shields, safety

devices, service doors and cleanout covers.

See section 5, “Hydraulics” for information on maintenance of hydraulic hoses.

See section 7, “Appendix & Forms” for expanded lube information.

Truss Cables: Replace cables if frayed or damaged. Be sure clamps are secure.

Adjust cables as needed to keep the auger tube reasonably straight.

Wheel Hubs: Repack hubs every two to three years to lengthen the life of the

hubs.

Tire Pressure: Check tire pressure monthly. The recommended tire pressure

should be maintained at 40 to 45 psi.

PTO Driveline: Lubricate both universal joints after every eight hours of

operation. Lubricate the center portion of the driveline on a yearly basis. The

first lube maintenance should be done in the first 16 to 24 hours of operation.

Then follow a regular schedule of lubing.

Lube Recommendation: Lube cross and bearing every 8 hours of use. Lube

telescoping members yearly.

NOTICE:

Replacement parts are not lubricated. When you receive these parts in,

make sure to lubricate and tighten screws.

Mechanical Chain Drive: Keep drive chain tension adjusted to about ¼”

deflection by loosening the four bolts on the lower bearing, then retightening.

Oil the chain frequently enough to keep a film of oil on the chain. This must be

done through the maintenance portal. Replace shield after maintenance.

Universal Joint: Remove PTO guard cover and lubricate grease fitting in the U-

Joint every eight hours of use. Check PTO retain bolt and retighten if necessary.

18

6.2 Storage of Auger _

Make sure that auger is in the full down position. Remove all residual material

from the hopper and auger tubes. Touch up all scratches on the auger to

prevent rusting.

Clean and re-lubricate spline on the PTO driveline. Cover with plastic bag to

protect from weather, and place it in the transport latch.

Move auger to your storage area, park, and chock wheels.

Before using the auger after storage, replace any damaged parts or decals,

remove plastic bag from PTO driveline and re-lubricate, and conduct general

maintenance procedure.

19

20

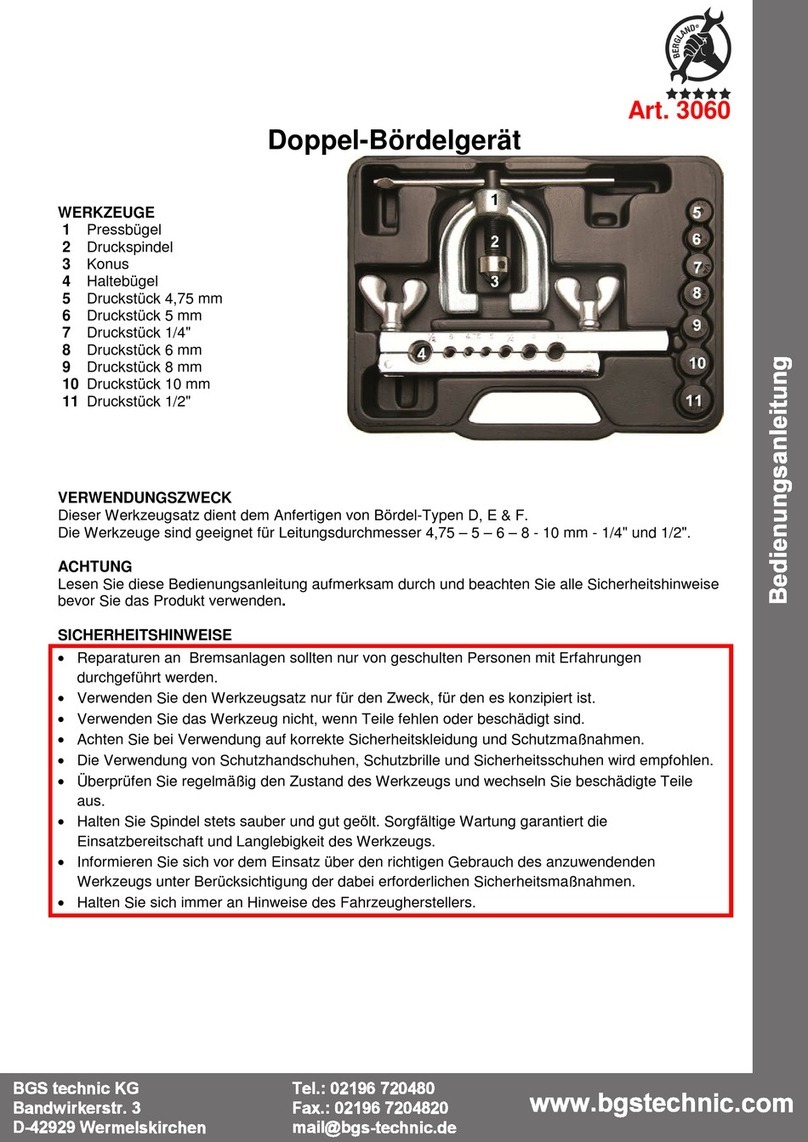

DETAIL A

2

X24

DETAIL B

1

X8

X1

X1

A

5

X2

4

X2

3

X2

6

X1 7

X1

X1

8

X1

12

X1

10

X1

11

X1

13

X1

15

9

14

B

AUGER, BASE MODEL, H13102

DRAWING NO.

PBH13102

PART/ASSEMBLY DESCRIPTION

REV MODEL(S)

H13102

ITEM NO. PART NO.

DESCRIPTION

QTY

1 10303

CLAMP, 3/8" CABLE, ZINC

8

2 10367

CLAMP, CABLE, 1/2" ZINC PLATED

24

3 11955

CABLE, TRUSS, LONG, 1/2" X 96FT

2

4 11957

CABLE, TRUSS, MEDIUM, 1/2" X 71FT

2

5 11958

CABLE, TRUSS, SIDE, 3/8 X 52FT

2

6 PBH13014

HOPPER ASM, SWING, H13XX

1

7 PBH13015

SWING TUBE ASM, H13XX

1

8 PBH13026

INFEED HOUSING ASM, H1392, H13102, & H13112

1

9 PBH13031

TUBE ASM, 5TH SECTION, H13112

1

10 PBH13036

TUBE ASM, 2ND SECTION, H13112

1

11 PBH13037

TUBE ASM, 3RD SECTION, 10FT TUBE, H13112

1

12 PBH13038

TUBE ASM, 1ST SECTION, H13112

1

13 PBH13039

TUBE ASM, 4TH SECTION, H13112

1

14 PBH13043

CARRIAGE ASM, H13112

1

15 PBH13047

TUBE ASM, DISCHARGE, H13102

1

Table of contents

Other HARVEST Tools manuals