Harwil L-21 User manual

ULTRA RELIABLE SINCE 1956 P. 1

MODEL L-21 HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

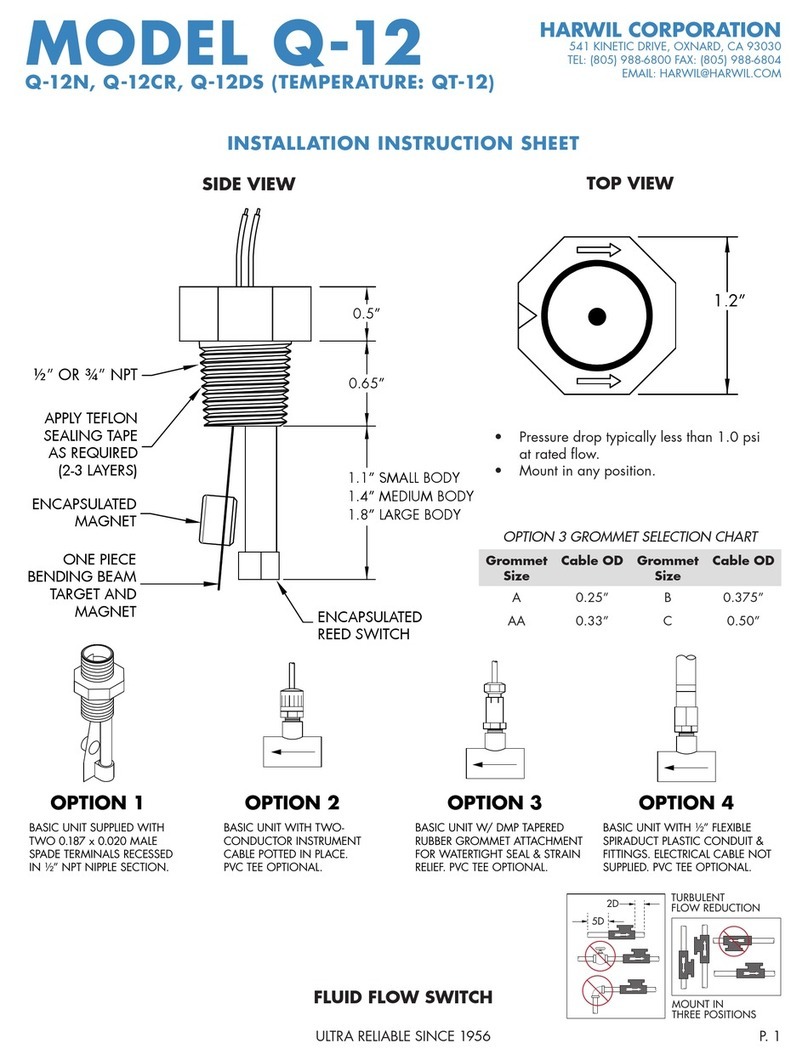

UP

UP

FLOAT DOWNFLOAT UP

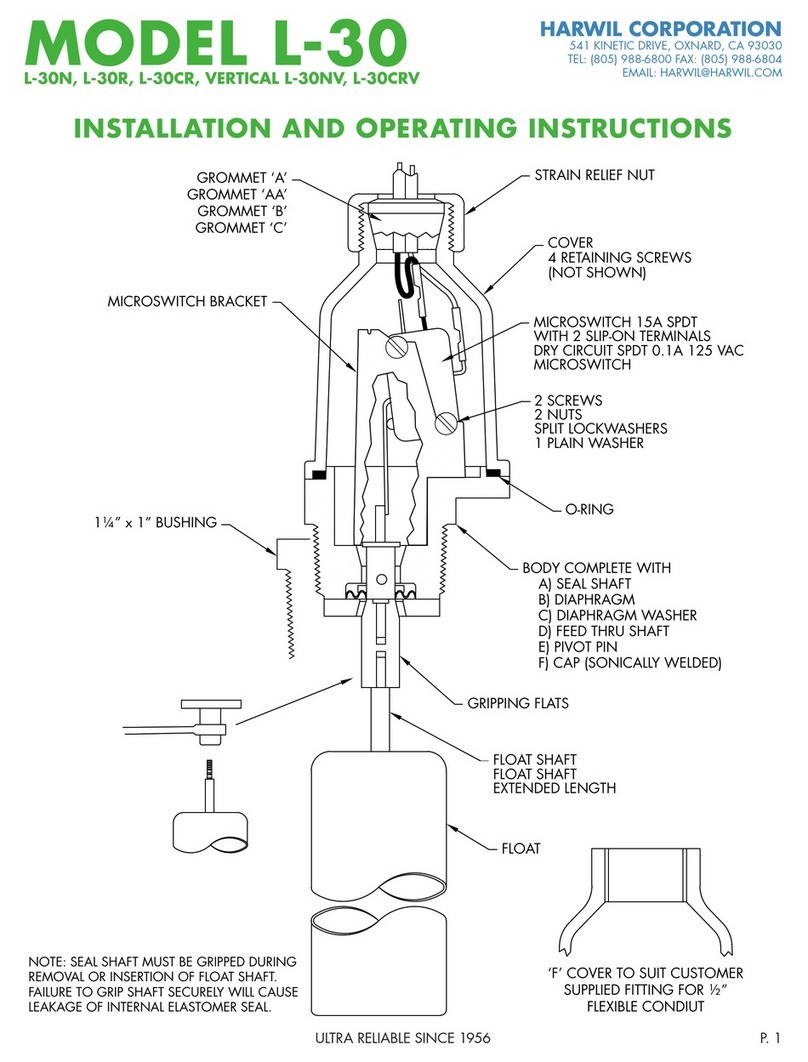

CABLE GROMMET 'A'

CABLE GROMMET 'AA'

CABLE GROMMET 'B'

CABLE GROMMET 'C'

STRAIN RELIEF NUT

INTERNAL 15A MICROSWITCH

1¼” NPT THREAD

COVER, INCLUDING O-RING

SEAL, RETAINING SCREWS

THREADED BODY COMPLETE,

INCLUDING SWITCH BRACKET

FLOAT SHAFT

OR

FLOAT SHAFT

EXTENDED LENGTH

FLOAT

MAGNET HOUSING

10652-12-1 1.0” DIFF.

10652-12-2 2.0” DIFF.

10652-12-3 3.0” DIFF.

10652-12-5 5.0” DIFF.

PIVOT SUPPORT

‘F’ COVER

½” INTERNAL THREADS FIT

STANDARD ½” ELECTRICAL

AND PLUMBING FITTINGS

INSTALLATION AND OPERATING INSTRUCTIONS

ULTRA RELIABLE SINCE 1956P. 2

MODEL L-21 HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

INSTALLATION AND OPERATING INSTRUCTIONS

FLOAT UP/DOWN CONFIGURATION

1. If the shipping container and contents are re-

ceived damaged, immediately call the shipping

company for damage inspection and file the ap-

propriate report, sending a copy to Harwil Corp.

for product replacement and insurance adjust-

ment.

2. If the contents are not damaged, inspect the units

received against the packing list and the original

purchase order. If incorrect units are received,

call Harwil Corp. immediately for resolution of

the problem.

3. Check for damage or scuffing on the Teflon

tape applied to the 1¼” NPT threads of the

switch body. Re-tape as required with 2 to 3 lay-

ers wound clockwise (looking at the end of the

threaded body with the float toward the viewer).

4. Remove the cover and check switch action with a

multimeter while moving the float up and down.

ACTUATION ARM

NORMALLY CLOSED (NC)

NORMALLY OPEN (NO)

COMMON

UP

FLOAT

POSITION

MULTIMETER

CONNECTION METER READING

UP

COMM. AND NO

TERMINALS CONTINUITY

COMM. AND NC

TERMINALS OPEN CIRCUIT

DOWN

COMM. AND NO

TERMINALS OPEN CIRCUIT

COMM. AND NC

TERMINALS CONTINUITY

5. Replace the domed cover on the unit and insert the float through the 1¼” NPT hole in the tank.

Mate the switch body threads with tank threads and tighten with an appropriate wrench until the

thread joint is leak-tight and the arrow on the cover label is pointing vertically upward.

NOTE: Model L-21 can be supplied with 1½” x 1¼” or larger reducer bushings as required to fit existing

large holes in a tank wall.

6. Remove the cover and wire as indicated on page 3.

ULTRA RELIABLE SINCE 1956 P. 3

MODEL L-21 HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

LOW LIQUID LEVEL ALARM

Fig 1: Wiring schematic for power applied to load when

liquid level is less than set point (power to load interrupted

when level increases to above set point).

Decreasing liquid level moves actuator in direction shown.

HIGH LIQUID LEVEL ALARM

Fig 2: Wiring schematic for power applied to load when

liquid level is greater than set point (power to load inter-

rupted when level decreases to below set point).

Increasing liquid level moves actuator in direction shown.

MICROSWITCH

NC

NO

(HOT)

LOAD

LINE

COM

MICROSWITCH

NC

NO

(HOT)

LOAD

LINE

COM

Microswitch actuation point may be monitored by an audible click or with an ohmmeter before connecting line power to the

switch terminals or by monitoring the voltage supplied to the load through the microswitch.

* Pump Up wiring diagram same as low level alarm shown in Fig. 1

* Pump Down wiring diagram same as high level alarm shown in Fig. 2

* Electrical Wiring (Strain Relief Grommet):

Step 1) Remove the gland nut, grommet, and switch cover.

Step 2) Strip the outer jacket of the electrical cord back

approximately 1¼” (inches). Strip insulation from

individual conductors back approximately ¼”

(inch).

Step 3) Slip-on terminals are supplied with each switch.

Remove from switch terminals and crimp on or solder to electrical leads.

Step 4) Feed the electrical cable through the strain relief nut, grommet, and switch cover.

Step 5) Apply slip-on terminals to appropriate contacts of microswitch. Slide cover down the cable and fasten it to the body

of the switch with four (4) screws provided. Slide grommet down the cable and push the grommet into the tapered

end of the cover. Hold the cable jacket to prevent rotation and thread gland nut firmly onto cover.

¼”

1¼”

* Electrical Wiring (‘F’ Cover):

Step 1) Remove switch cover.

Step 2) Strip the outer jacket of the electrical cord back

approximately 1¼” (inches). Strip insulation from in-

dividual conductors back approximately ¼” (inch).

Step 3) Slip-on terminals are supplied with each switch. Re-

move from switch terminals and crimp on or solder

to electrical leads.

Step 4) Thread user supplied ½” flexible conduit fitting into

½” female thread on end of cover. Feed electrical

cable through conduit fitting.

Step 5) Apply slip-on terminals to appropriate male spade

contacts on microswitch. Slide cover down cable

and fasten to body of switch with four (4) screws

provided. Be sure to install the “O” ring between

the body and cover. Connect flexible ½” metal or

plastic conduit-to-conduit fitting on end of cover per

standard procedure.

ULTRA RELIABLE SINCE 1956P. 4

MODEL L-21 HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

1, 2, 3, AND 5 INCH

LINE REPLACEABLE

DIFFERENTIAL FLOAT

UNITS AVAILABLE AS

SEPARATE ITEMS.

ULTRA RELIABLE SINCE 1956 P. 5

MODEL L-21 HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

14

8

10

11

9

7

13

19

16

15

617 18

4

5

1

2

3

12

L-21N (Series 21300)

# PART NAME QTY PART #

1 STRAIN RELIEF NUT (1) 60127

2 GROMMET

#A BUNA N (OPTIONAL) (1) 10440

#AA BUNA N (OPTIONAL) (1) 10441

#B BUNA N (OPTIONAL) (1) 10442

#C BUNA N (OPTIONAL) (1) 10443

3 COVER (MALE) NORYL (OPTIONAL) (1) 60125

4 COVER (FEMALE) NORYL (OPTIONAL) (1) 60126

5 SCREW (4) 109-S

6 MICROSWITCH (ASSEMBLY ONLY) (1) 21301

STEEL PLATE (1) 21302

CERAMIC MAGNET (3) 21303

EPOXY 21350

7 BODY - NORYL (INCL SWITCH BRACKET) (1) 21304

8 PIVOT SUPPORT (1) 21305

# PART NAME QTY PART #

9 MAGNET HOUSING (ASSEMBLY ONLY) (1) 21306

1.0” CERAMIC MAGNET (OPT) (1) 21307

2.0” CERAMIC MAGNET (OPT) (1) 21308

3.0” CERAMIC MAGNET (OPT) (1) 21309

5.0” CERAMIC MAGNET (OPT) (1) 21310

10 SHAFT - 316 STAINLESS STEEL (1) 21311

11 FLOAT - NORYL (1) 65601

12 FLOAT - POLYPROPYLENE (OPT) (1) 65602

13 O-RING (1) 65110

14 SCREW (2) 147-S

15 TERMINALS (3) 706-T

16 SCREW (2) 101-S

17 SCREW (1) 116-S

18 SCREW (1) 104-S

19 NUT (1) 202-N

ULTRA RELIABLE SINCE 1956P. 6

MODEL L-21 HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

14

8

10

11

9

7

13

19

16

15

617 18

4

5

1

2

3

12

L-21R (Series 21400)

# PART NAME QTY PART #

1 STRAIN RELIEF NUT - FORTRON (1) 65301

2 GROMMET

#A BUNA N (OPTIONAL) (1) 10440

#AA BUNA N (OPTIONAL) (1) 10441

#B BUNA N (OPTIONAL) (1) 10442

#C BUNA N (OPTIONAL) (1) 10443

3 COVER (MALE) FORTRON (OPTIONAL) (1) 65302

4 COVER (FEMALE) FORTRON (OPTIONAL) (1) 65303

5 SCREW (4) 109-S

6 MICROSWITCH (ASSEMBLY ONLY) (1) 21301

STEEL PLATE (1) 21302

CERAMIC MAGNET (3) 21303

EPOXY 21350

7 BODY - FORTRON (INCL SWITCH BRACKET) (1) 21401

8 PIVOT SUPPORT (1) 21402

# PART NAME QTY PART #

9 MAGNET HOUSING (ASSEMBLY ONLY) (1) 21403

1.0” CERAMIC MAGNET (OPT) (1) 21307

2.0” CERAMIC MAGNET (OPT) (1) 21308

3.0” CERAMIC MAGNET (OPT) (1) 21309

5.0” CERAMIC MAGNET (OPT) (1) 21310

10 SHAFT - 316 STAINLESS STEEL (1) 21311

11 FLOAT - FORTRON (1) 65805

12 FLOAT - POLYPROPYLENE (OPT) (1) 65602

13 O-RING (1) 65110

14 SCREW (2) 147-S

15 TERMINALS (3) 706-T

16 SCREW (2) 101-S

17 SCREW (1) 116-S

18 SCREW (1) 104-S

19 NUT (1) 202-N

ULTRA RELIABLE SINCE 1956 P. 7

MODEL L-21 HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

14

8

10

11

9

7

13

19

16

15

617 18

4

5

1

2

3

12

L-21VCR (Series 21500)

# PART NAME QTY PART #

1 STRAIN RELIEF NUT - FORTRON (1) 65301

2 GROMMET

#A VITON (OPTIONAL) (1) 65701

#B VITON (OPTIONAL) (1) 65703

#C VITON (OPTIONAL) (1) 65704

3 COVER (MALE) FORTRON (OPTIONAL) (1) 65302

4 COVER (FEMALE) FORTRON (OPTIONAL) (1) 65303

5 SCREW (4) 109-S

6 MICROSWITCH (ASSEMBLY ONLY) (1) 21302

STEEL PLATE (1) 21302

CERAMIC MAGNET (3) 21303

EPOXY 21350

7 BODY - FORTRON (INCL SWITCH BRACKET) (1) 21407

8 PIVOT SUPPORT (1) 21402

# PART NAME QTY PART #

9 MAGNET HOUSING (ASSEMBLY ONLY) (1) 21403

1.0” CERAMIC MAGNET (OPT) (1) 21307

2.0” CERAMIC MAGNET (OPT) (1) 21308

3.0” CERAMIC MAGNET (OPT) (1) 21309

5.0” CERAMIC MAGNET (OPT) (1) 21310

10 SHAFT - HASTELLOY C (1) 21501

11 FLOAT - FORTRON (1) 65805

12 FLOAT - POLYPROPYLENE (OPT) (1) 65602

13 O-RING (1) 65110

14 SCREW (2) 145-S

15 TERMINALS (3) 706-T

16 SCREW (2) 101-S

17 SCREW (1) 116-S

18 SCREW (1) 104-S

19 NUT (1) 219-N

ULTRA RELIABLE SINCE 1956P. 8

CERTIFICATE OF CONFORMANCE

All HARWIL Corporation (“HARWIL”) products are manufactured using new materials and components.

Our products meet the applicable performance and materials specifications indicated in our current

Specifications Sheets and Parts Lists. HARWIL endeavors to obtain its materials and components from

American Companies.

DOMINANCE OF HARWIL LIMITED EXPRESS WARRANTY

HARWIL warrants that all HARWIL products will be free from defects in material and workmanship for a

period of one year from the date of original shipment. This warranty shall be limited to the replacement

and reconditioning of our products and parts. HARWIL reserves the right and sole discretion to modify or

change the composition, design and appearance of its products at anytime.

This warranty shall be in lieu of all warranties of merchantability and of all warranties of fitness for a par-

ticular purpose relating to harwil products and parts. Buyer’s sole remedy hereunto shall be replacement

or reconditioning as set forth herein.

HARWIL shall incur no obligations hereunder and no liability in the event of (a) buyer not fulfilling its re-

sponsibilities, including as set forth herein; (b) neglect, alteration or improper product use, including use

with non-compatible devices or chemicals; or (c) repair by other than HARWIL. ANY LAWSUIT RELATING

TO THIS WARRANTY MUST BE COMMENCED WITHIN ONE YEAR OF THE DATE IT ACCRUES.

Each user of our product should make appropriate analysis and tests to determine the suitability of the

product for the intended use prior to purchase. HARWIL provides no warranty and assumes no respon-

sibility for corrosive attack on any material, component or design features associated with any of its

products.

Corrosion resistance information listed in HARWIL specification sheets, installation sheets and product

brochures is solely for general background information. This table has been compiled from literature

published by various material suppliers and by equipment manufacturers who use these materials in

their products. Inasmuch as these data are based on tests by entities over which HARWIL has no control,

HARWIL does not guarantee or accept responsibility for the accuracy of such tests. When using the table,

please remember that in any given case several factors such as concentration, temperature, degrees of

agitation and presence of impurities influence the rate of corrosion. The guide is intended, in a general

way, to rate materials for resistance to chemicals which contain their usual impurities and for types of

equipment in common use. Ratings should be used only as a general guide to first approximation of your

material requirements rather than as the final answer.

• When in doubt, test materials before installation.

• After installation, follow up with preventative maintenance and periodic inspection.

Table of contents

Other Harwil Switch manuals

Popular Switch manuals by other brands

Dell

Dell Powerconnect W-ClearPass Hardware Appliances Hardware installation guide

Brocade Communications Systems

Brocade Communications Systems A7533A - Brocade 4Gb SAN Switch Base Troubleshooting

Digitus

Digitus DS-15202-1 Quick installation guide

Manhattan

Manhattan 161527 instructions

ZyXEL Communications

ZyXEL Communications ES1100 Series user guide

H3C

H3C S5120-EI Series Configuration guide

Belkin

Belkin OmniView F1DS102J Specifications

SMART

SMART SMART PE260 Configuration guide

Delta Electronics

Delta Electronics Agema Series installation guide

TRENDnet

TRENDnet TI-PG541i user guide

Tork

Tork W100 Installation and operating instructions

Rohde & Schwarz

Rohde & Schwarz R&S OSP-B157W8 PLUS Getting started