Harwil Q-8DS User manual

ULTRA RELIABLE SINCE 1956 P. 1

HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

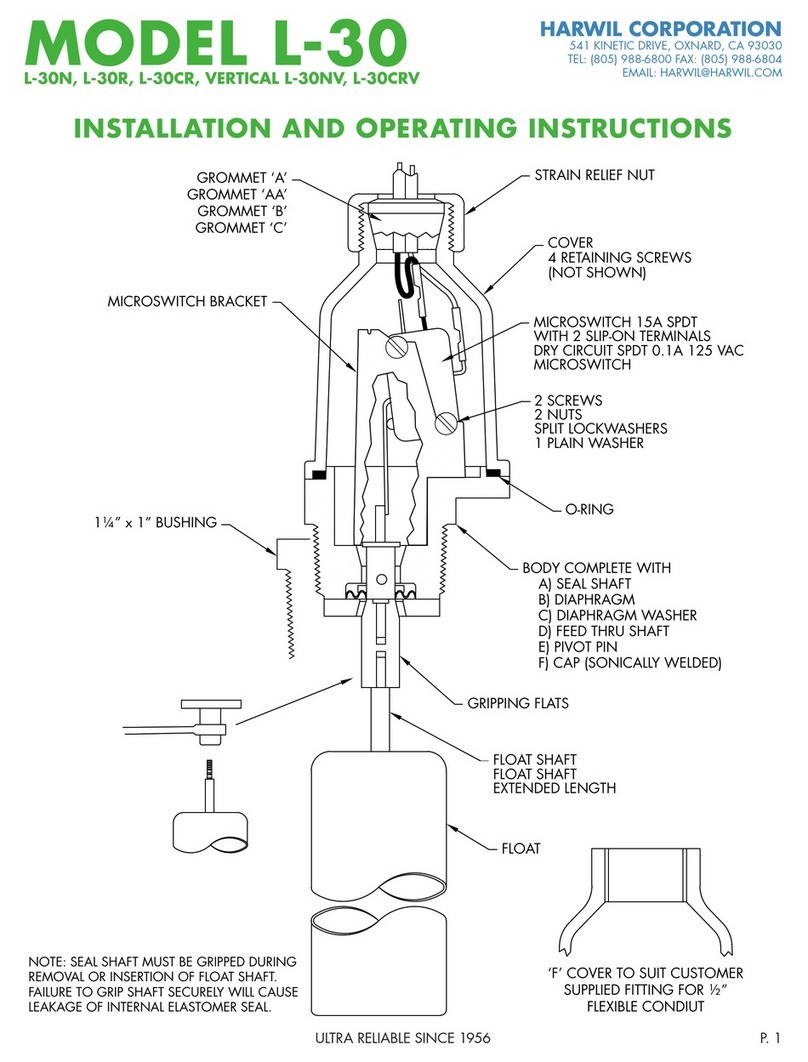

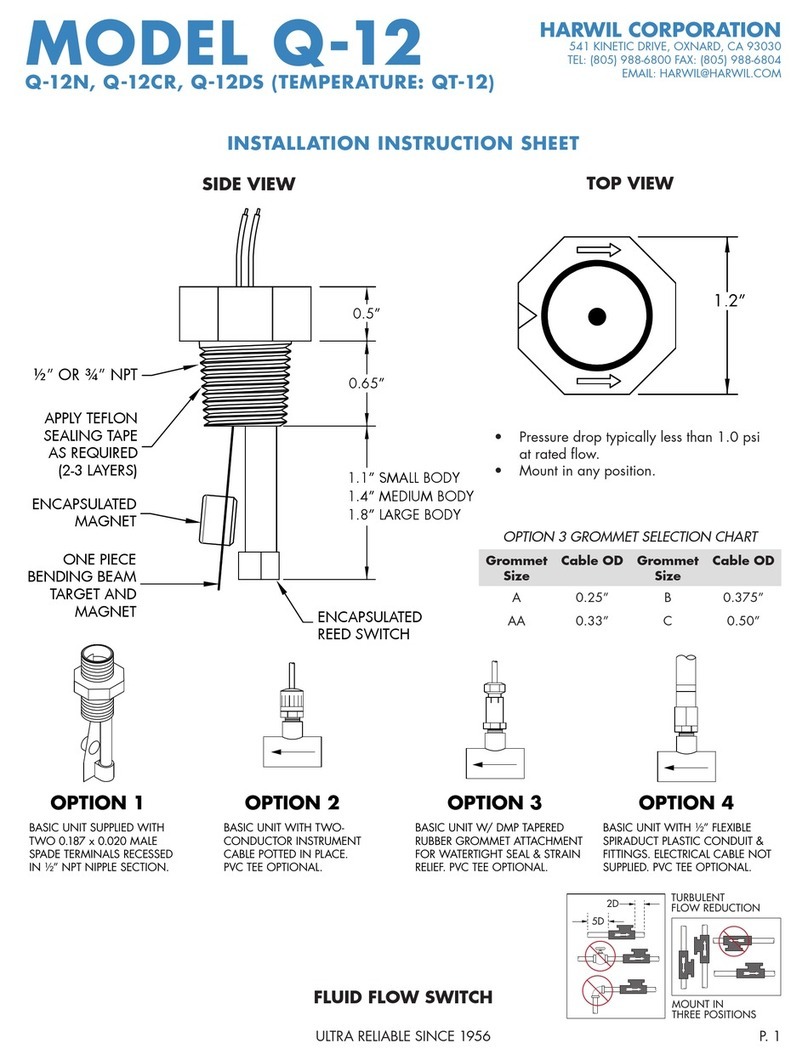

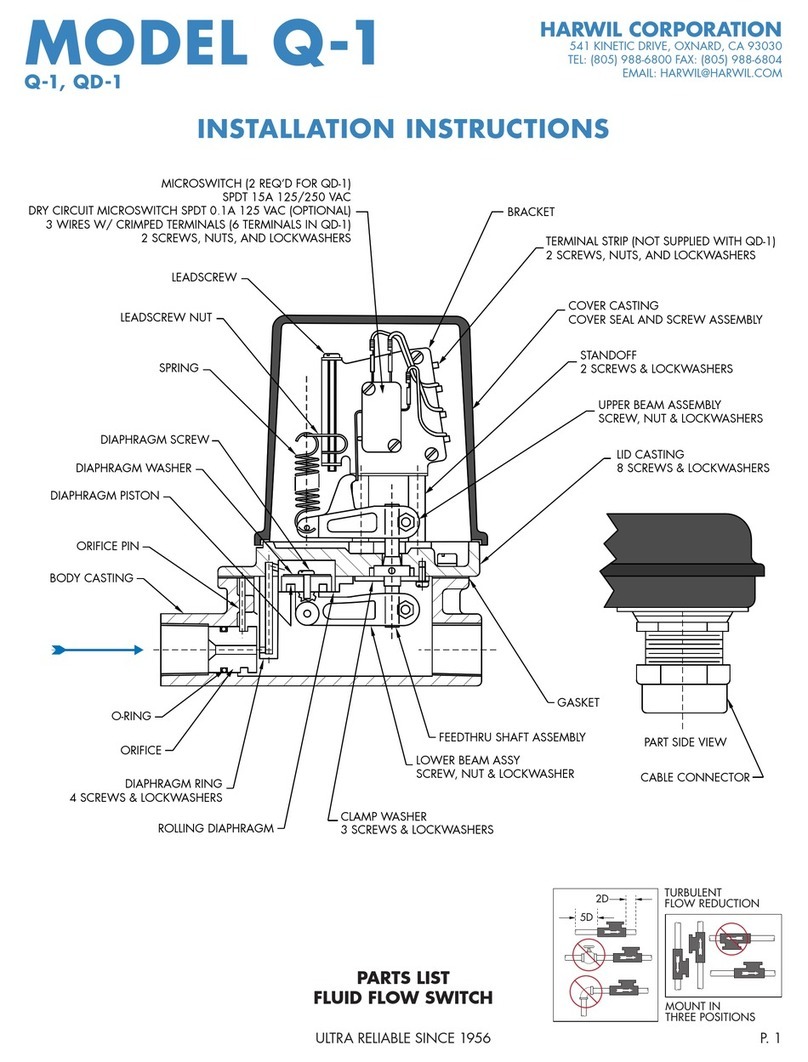

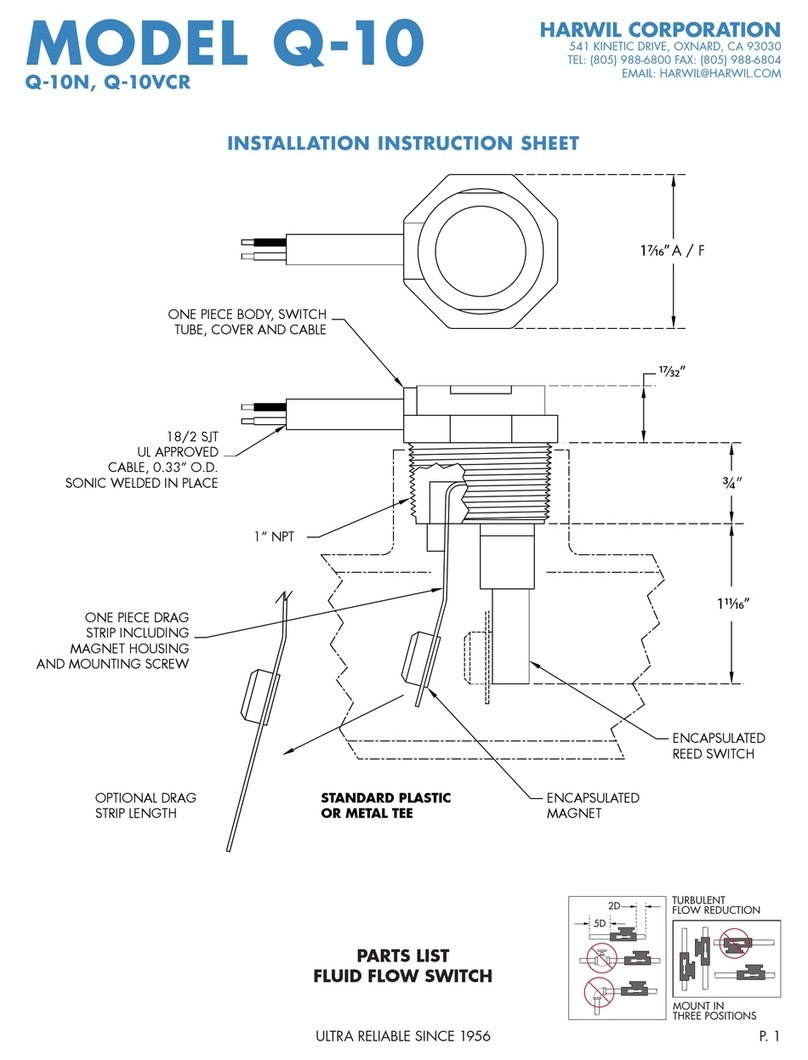

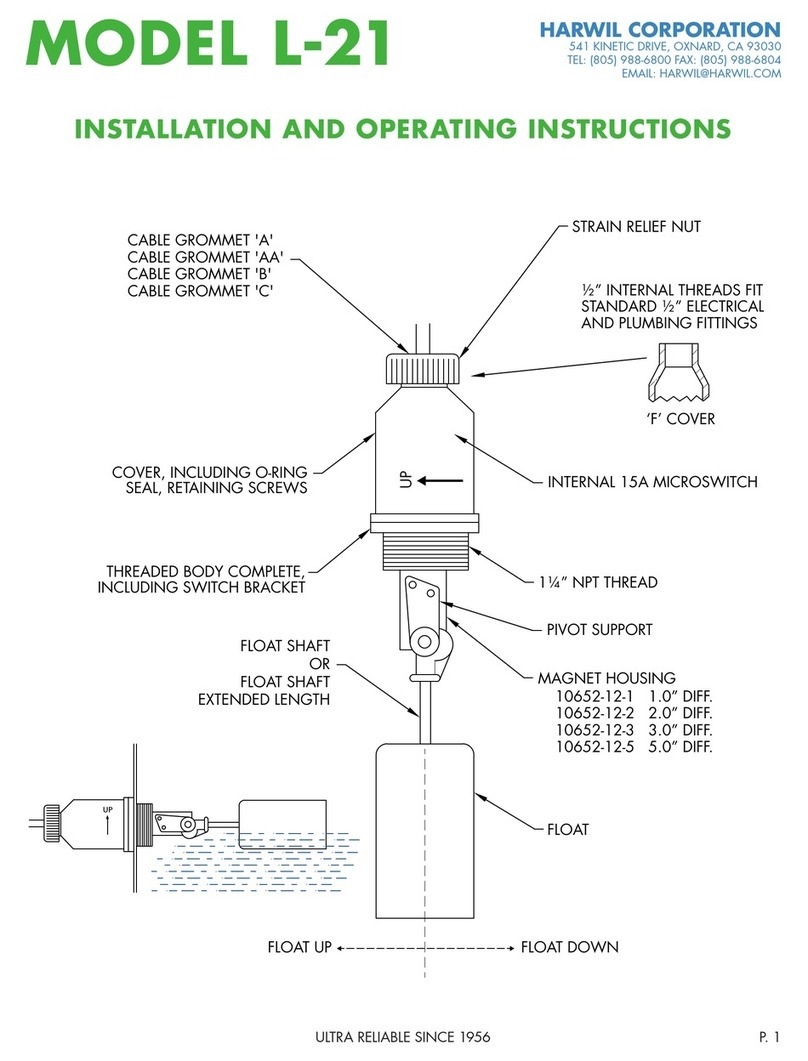

MODEL Q-8DS

PARTS LIST

FLUID FLOW SWITCH

O-RING

BODY, COMPLETE WITH

FEED THRU SHAFT ASSEMBLY

(SEE PARTS LIST)

1” NPT

STRAIN RELIEF NUT

GROMMET ‘A’

GROMMET ‘AA’

GROMMET ‘B’

GROMMET ‘C’

SWITCH COVER

4 RETAINING SCREWS

(NOT SHOWN)

“F” COVER

DO NOT ATTEMPT TO REMOVE

DRAG STRIP WITHOUT FIRST

GRIPPING SEAL SHAFT TO

PREVENT BREAKING OF SEAL

BY UNTHREADING FROM FEED

THRU SHAFT.

DRAG STRIP

CLAMP WASHER

DAMPENER WASHER

SCREW x 3/8” LG

2 PLAIN WASHERS

SPLIT LOCKWASHER

SCREW x 7/8” LG

NUT

PLAIN WASHER

SPLIT LOCKWASHER

SCREW x ¾” LG

NUT

PLAIN WASHER

SPLIT LOCKWASHER

MICROSWITCH COMPLETE

W/ 2 SLIP-ON TERMINALS

“F” COVER TO SUIT CUSTOMER

SUPPLIED FITTING FOR ½”

FLEXIBLE CONDUIT

TURBULENT

FLOW REDUCTION

MOUNT IN

THREE POSITIONS

2D

5D

INSTALLATION INSTRUCTION SHEET

ULTRA RELIABLE SINCE 1956P. 2

HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

MODEL Q-8DS

INSTALLATION INSTRUCTIONS

ELECTRICAL WIRING

Model Q-8DS is normally mounted in a 1½” x 1½” x 1” or 2” x 1” SST PVC Tee, which may be

plumbed into the system in vertical or horizontal lines, right side up or inverted using normal PVC

pipe cement. Make sure that flow direction arrow on the cover is aligned with the flow in the pipe.

An unmounted Q-8DS should be threaded into the 1” NPT stem of the Tee after checking for uniform

coating of threads with Teflon tape. Tighten sufficiently to produce a leak-tight seal and continue tight-

ening up to one full turn to align flow direction arrow on cover parallel with flow axis of Tee. Check

through open end of Tee that drag strip moves freely and is perpendicular to the flow axis. Install in

pipe with flow direction arrows pointing correctly in flow direction.

1. Remove strain relief nut, grommet, and switch

cover.

2. Strip outer jacket of electrical cord back ap-

proximately 1¼”, stagger ½” and strip leads

¼”.

3. Remove slip-on connectors from microswitch

terminals and crimp or solder to leads.

4. Feed cable through strain relief nut, grommet,

and cover.

5. Apply slip-on connectors to appropriate termi-

nals of microswitch. Slide cover down cable

and fasten to body with 4 screws. Slide grom-

met down cable until small end is level with

outer jacket. Push grommet into tapered hole

of cover, hold cable jacket to prevent rotation

and tighten strain relief firmly.

6. If type “F” cover is supplied, connect desired

conduit fitting to cover. Prepare leads, attach

to slip-on connectors per STEP 2 and apply

to appropriate microswitch terminals. Attach

electrical conduit-to-conduit fitting. Exercise

reasonable care when assembling metal flex-

ible conduit to prevent fracture of plastic cover.

Rigid conduit is not recommended.

WIRING SCHEMATIC

Contacts are closed when flow rate is above

microswitch set point (15-20 GPM). Power to load

interrupted when flow decreases below this point.

1¼”

½”

¼”

MICROSWITCH

INCREASING FLOW MOVES

ACTUATOR IN DIRECTION

SHOWN

COM

NC

NO

HOT

LOAD

LINE

ULTRA RELIABLE SINCE 1956 P. 3

HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

MODEL Q-8DS

Q-8DS (SERIES 65000)

# PART NAME QTY PART #

1 BODY WITH SWITCH BRACKET (1) 65101

2 FEED THRU SHAFT (ASSEMBLY ONLY) (1) 65103

A) SEAL SHAFT (1) 65104

B) DIAPHRAGM (1) 65105

C) DIAPHRAGM WASHER (1) 65106

D) PIVOT PIN (1) 65107

E) CROSS PIN (1) 65108

3 MICROSWITCH (1) 65109

4 SCREW (2) 119-S

5 WASHER (2) 301-W

6 WASHER (2) 300-W

7 WASHER (3) 311-W

8 NUT (2) 219-N

9 O-RING (1) 65110

10 SPRING (1) 65111

11 SCREW (1) 102-S

12 CLAMP WASHER (1) 65112

13 WASHER (2) 300-W

14 DAMPENER WASHER (1) 65113

15 WASHER (1) 302-W

16 SCREW (1) 120-S

# PART NAME QTY PART #

17 DRAG STRIP (OPTIONAL)

A - DRAWING 10502 (1) 65115

B - DRAWING 10507 (1) 65116

C - DRAWING 10512 (1) 65117

D - DRAWING 10539 (1) 65118

E - DRAWING 10564-A (1) 65119

F - DRAWING 10566 (1) 65120

G - DRAWING 10570-A (1) 65121

H - DRAWING 10593 (1) 65122

I - DRAWING 10596 (1) 65123

J - DRAWING 10600 (1) 65124

18 TERMINALS (3) 706-T

19 COVER (MALE) (OPTIONAL) (1) 60125

20 COVER (FEMALE) (OPTIONAL) (1) 60126

21 SCREW (4) 109-S

22 GROMMET #A (OPTIONAL) (1) 10440

GROMMET #AA (OPTIONAL) (1) 10441

GROMMET #B (OPTIONAL) (1) 10442

GROMMET #C (OPTIONAL) (1) 10443

23 STRAIN RELIEF NUT (1) 60127

23

22

21

20

19

3

18

6

4

5

11

10

1

6

7

8

9

5

7

8

2

17

12

13 14

15

7

16

ULTRA RELIABLE SINCE 1956P. 4 ULTRA RELIABLE SINCE 1956

CERTIFICATE OF CONFORMANCE

All Harwil Corporation (“HARWIL”) products are manufactured using new materials and components.

Our products meet the applicable performance and materials specifications indicated in our current

Specifications Sheets and Parts List. HARWIL endeavors to obtain its materials and components from

American Companies.

DOMINANCE OF HARWIL LIMITED EXPRESS WARRANTY

Each user MUST make appropriate analysis and tests to determine the suitability of the HARWIL product

for the intended use prior to purchase.

HARWIL warrants that all HARWIL products will be free from defects in material and workmanship for a

period of one year from the date of original shipment. This Warranty shall be LIMITED to the replacement

and reconditioning of our products and parts. HARWIL reserves the right and sole discretion to modify

or change the composition, design and appearance of its products at anytime.

THIS WARRANTY SHALL BE IN LIEU OF ALL WARRANTIES OF MERCHANTABILITY AND OF ALL WAR-

RANTIES OF FITNESS FOR A PARTICULAR PURPOSE RELATING TO HARWIL PRODUCTS AND PARTS.

BUYER’S SOLE REMEDY SHALL BE REPLACEMENT OR RECONDITIONING AS SET FORTH HEREIN.

HARWIL SHALL INCUR NO OBLIGATIONS HEREUNDER AND NO LIABILITY IN THE EVENT OF (1)

BUYER NOT FULFILLING ITS RESPONSIBILITIES; INCLUDING AS SET FORTH HEREIN; (2) NEGLECT,

ALTERATION OR IMPROPER PRODUCT USE, INCLUDING USE WITH NON-COMPATIBLE DEVICES OR

CHEMICALS; OR (3) REPAIR BY ANOTHER COMPANY OR PERSON THAN HARWIL.

ANY LAWSUIT RELATING TO THIS LIMITED EXPRESS WARRANTY MUST BE COMMENCED WITHIN

ONE YEAR OF THE DATE THE LAWSUIT ACCRUES.

HARWIL provides NO WARRANTY and ASSUMES NO RESPONSIBILITY for corrosive attack on

any material, component or design features associated with any of its products.

Corrosion resistance information listed in HARWIL specification sheets, information sheets and product

brochures is solely for general background information. This information table has been compiled from

literature published by various material suppliers and by equipment manufacturers who use these materi-

als in their products. Inasmuch as these data are based on tests by entities over which HARWIL has no

control, HARWIL DOES NOT GUARANTEE AND DOES NOT ACCEPT ANY RESPONSIBILITY FOR THE

ACCURACY OF SUCH THIRD PARTY TESTING. When using the table, please remember that in any

given case several factors such as concentration, temperature, degrees of agitation and presence of impu-

rities influence the rate of corrosion. The information table is intended, in a general way, to rate materials

for resistance to chemicals which contain their usual impurities and for types of equipment in common

use. Ratings should be used only as a general tool to first approximation of your material requirements

rather than as the final answer.

WHEN IN DOUBT, TEST MATERIALS BEFORE INSTALLATION.

AFTER INSTALLATION, FOLLOW UP WITH SCHEDULED PREVENTATIVE MAINTENANCE AND

PERIODIC INSPECTION.

16306

Table of contents

Other Harwil Switch manuals

Popular Switch manuals by other brands

Ubiquiti

Ubiquiti US-8-150W quick start guide

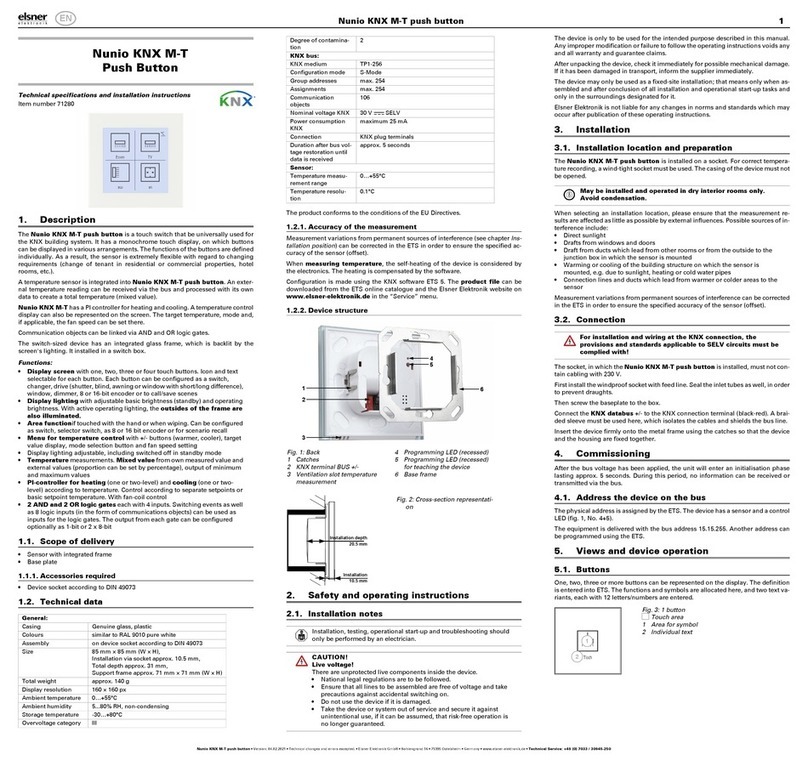

elsner elektronik

elsner elektronik Nunio KNX M-T Technical specifications and installation instructions

NETGEAR

NETGEAR ProSafe JGSM7224 Hardware installation guide

TP-Link

TP-Link JetStream TL-SG3424P user guide

Accton Technology

Accton Technology VS4512DC Management guide

Heltun

Heltun HE-HLS01 user manual