Harwil Q-5 Service manual

ULTRA RELIABLE SINCE 1956 P. 1

MODEL Q-5 HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

Q-5, Q-5SS, QD-5, QD-5SS

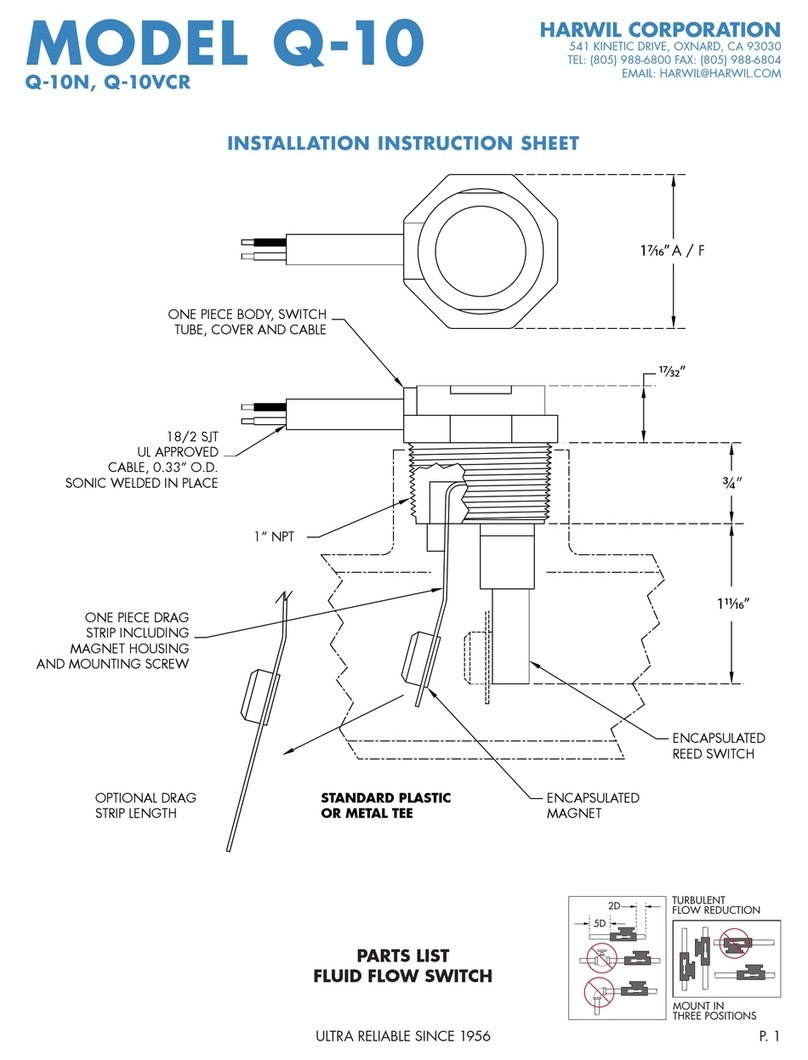

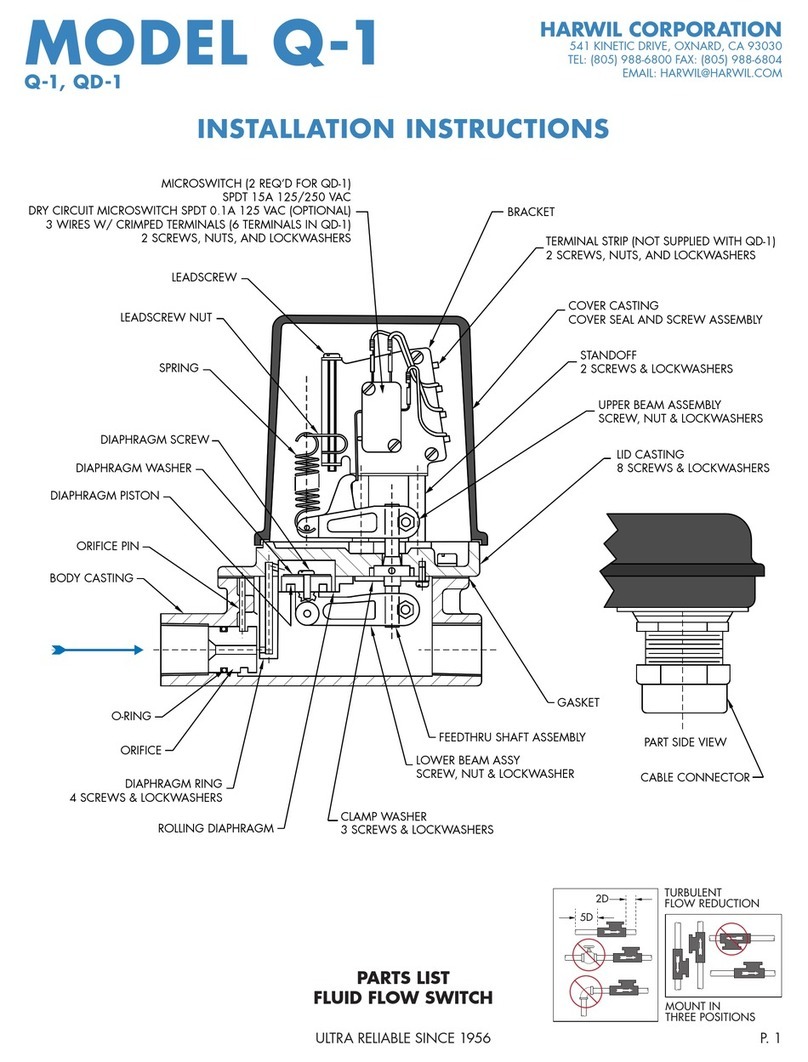

PARTS LIST

FLUID FLOW SWITCH

TERMINAL STRIP

(NOT SUPPLIED WITH QD-5)

BRACKET

2 SPACERS

2 SCREWS & LOCKWASHERS

LEADSCREW

LEADSCREW NUT

SPRING

LARGE SPRING

LID CASTING

7 SCREWS & LOCKWASHERS

CLAMP WASHER

3 SCREWS & LOCKWASHERS

SPDT 15A MICROSWITCH 125/240 VAC (2 REQ'D FOR QD-5)

DRY CIRCUIT MICROSWITCH SPDT 0.1A 125 VAC (OPTIONAL)

3 WIRES W/ CRIMPED TERMINALS (6 TERMS. ONLY QD-5)

2 SCREWS, NUTS & LOCKWASHERS

COVER CASTING,

SEAL, SCREW ASSEMBLY

CABLE STRAIN RELIEF

GASKET

BODY CASTING

FEED THRU SHAFT ASSEMBLY

MODEL Q5/3

MODEL Q5/5

MODEL Q5/7

DRAG DISK 1

DRAG DISK 2

DRAG DISK 3

DRAG DISK 4

DRAG DISK 5

DRAG DISK 6

This parts list applies to all models of Q-5 and QD-5 fluid flow switches: Q-5/3, Q-5/7, QD-5/7.

All letters and numbers added to model number after the above numbers apply to optional drag strips

and electrical strain relief connectors.

TURBULENT

FLOW REDUCTION

MOUNT IN

THREE POSITIONS

2D

5D

INSTALLATION INSTRUCTIONS

ULTRA RELIABLE SINCE 1956P. 2

MODEL Q-5 HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

Q-5, Q-5SS, QD-5, QD-5SS

INSTALLATION AND OPERATING INSTRUCTIONS

The gasket seal located between the main body casting and the lid casting is a cork-rubber composi-

tion, which is subject to a slight creep for a short period after application of the initial clamping load.

All gaskets are properly clamped before shipment, however during shipping and storage, the gasket

may compress, allowing the body-lid clamp bolts to become slightly loose. Tighten these bolts before

assembling the flow switch in-system. No further creep of gasket will occur after second tightening. The

Q-5 fluid flow switch is supplied with a male 1” NPT which is threaded into an appropriate pipe tee,

large pipe with reducer bushing, or directly into a hole threaded 1” NPT in the wall of the pipe. Turn

until tight and arrow on body casting is pointed in direction of flow.

ELECTRICAL WIRING

FIGURE 1: Wiring schematic for power applied to load when flow is GREATER than the set point (pow-

er to load interrupted when flow is LESS than set point).

FIGURE 2: Wiring schematic for power applied to load when flow is LESS than the set point (power to

load interrupted when flow is GREATER than set point).

MICROSWITCH

TERMINAL STRIP

INCREASING FLOW MOVES

ACTUATOR IN DIRECTION SHOWN

COM (BLACK)

NC (ORANGE)

NO (WHITE)

(HOT)

LOAD

LINE

MICROSWITCH

TERMINAL STRIP

COM (BLACK)

NC (ORANGE)

NO (WHITE)

(HOT)

LOAD

LINE

DECREASING FLOW MOVES

ACTUATOR IN DIRECTION SHOWN

ULTRA RELIABLE SINCE 1956 P. 3

MODEL Q-5 HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

Q-5, Q-5SS, QD-5, QD-5SS

Q-5 FLOW SWITCH OPERATIONAL ADJUSTMENT

SWITCH POINT ADJUSTMENT

1. Remove cover.

2. Adjust fluid flow in system to desired rate WITHOUT regard to Q-5 switch point setting.

3. The switch point adjusting mechanism consists of an adjusting screw, a “U” shaped lead screw nut,

and a helical spring.

CLOCKWISE rotation of the adjusting screw changes the microswitch actuation point toward HIGHER

flow rates.

NOTES: All Q-5 units are factory set at the lower end of the flow range, e.g. the adjusting screw is set

at the low flow counter-clockwise position.

The lead screw nut locks the adjusting screw in position, maintaining the flow switch set point under all

environmental conditions.

4. Turn the adjusting screw in a clockwise direction until the microswitch is actuated, while maintaining

the desired fluid flow rate in the system. Turn the adjusting screw TWO (2) additional turns in the

clockwise direction and then slowly back off in a counter-clockwise direction, until the microswitch

is again actuated. The Q-5 flow switch is now set for maximum sensitivity for detecting small flow

changes.

5. When set for maximum sensitivity (100% point) as described above, flow turbulence may cause

rapid on/off switching (dithering) of the microswitch contacts, resulting in reduced switch contact life

ADJUST LEADSCREW

BEST ADJUSTMENT POINT

(CENTERED)

MICROSWITCH

LEADSCREW

SPRING POSITION

WHEN DELIVERED

REMOVE COVER

ULTRA RELIABLE SINCE 1956P. 4

MODEL Q-5 HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

Q-5, Q-5SS, QD-5, QD-5SS

and “noise” in the electrical circuit. This is eliminated by turning the adjusting screw in a counter-

clockwise direction.

6. Microswitch actuation point may be monitored during the adjustment procedure detailed in steps 4

and 5 by an audible click or with an ohmmeter before connecting line power to the terminal strip,

or by monitoring the voltage supplied to the load through the microswitch.

7. If the system flow rate is changed, the Q-5 can be adjusted to monitor the new flow rate by turning

the adjusting screw in a counter-clockwise direction to the minimum flow position and then proceed-

ing as in 4 and 5 above.

8. In the event that the system flow is at the desired rate and the adjustment mechanism runs out of

80%

50%

ADJUSTED MAX. SENSITIVITY

AS DESCRIBED IN 5.

REDUCED SET POINT TO

ELIMINATE DITHER AND

MAINTAIN SENSITIVITY

NORMAL SET POINT WHICH

ELIMINATES BOTH DITHERING AND

NUISANCE TRIPS WILE PROVIDING

SAFE FLOW SIGNAL OUTPUT.

LEADSCREW

BOTTOM OF LEADSCREW

50%

80%

100%

100%

ULTRA RELIABLE SINCE 1956 P. 5

MODEL Q-5 HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

Q-5, Q-5SS, QD-5, QD-5SS

travel (e.g., the lead screw nut is at either end of the support bracket before the microswitch is actu-

ated), then the drag disk must be changed to shift the flow switch flow range so that it straddles the

system flow rate.

Example: If the Q-5 is fitted with a #2 drag disk and procedure 4 has been followed, the adjusting

lead screw has been turned clockwise until the lead screw nut is at the extreme end of the support

bracket and the microswitch has still not been actuated, then the flow is too low and different drag

disk must be substituted and procedure 4 repeated.

GENERAL RULES FOR SELECTING A NEW DRAG DISK

TILTED UPSTREAM

SPRING FULLY EXTENDED

DESIRED FLOW RATE DESIRED FLOW RATE

THEN REPLACE DRAG DISK

WITH NEXT SMALLER SIZE THEN REPLACE DRAG DISK

WITH NEXT LARGER SIZE

IF IF

TILTED DOWNSTREAM

SPRING NOT EXTENDED

Drag Disk Change

1. Remove the flow switch from the pipe line.

2. Remove the small screws attaching the drag disk target to the feed thru shaft.

3. Replace the old target with a new one and tighten the screws.

Terminal Strip Wiring

1. Loosen the round gland nut located on the electrical cable fitting.

2. Insert the cable through the grommet in the electrical cable fitting and tighten the gland nut sufficient-

ly to seal the cable in place.

3. Strip the conductor ends approximately 3/16”

4. Loosen the appropriate terminal strip screw and remove the empty terminal. Insert bare wire in

terminal barrel and crimp. Place terminal strip in SAME orientation as received. This is IMPORTANT,

since terminals and wires may interfere with the cover if the orientation is changed.

ULTRA RELIABLE SINCE 1956P. 6

MODEL Q-5 HARWIL CORPORATION

541 KINETIC DRIVE, OXNARD, CA 93030

TEL: (805) 988-6800 FAX: (805) 988-6804

EMAIL: HARWIL@HARWIL.COM

Q-5, Q-5SS, QD-5, QD-5SS

Q-5 (SERIES 20200)

# PART NAME QTY PART #

1 COVER CASTING (1) 20300

2 SCREW (1) 112-S

3 LOCK WASHER (1) 321-W

4 SCREW (7) 107-S

5 WASHER (7) 319-W

6 LID CASTING (1) 20301

7 CONNECTOR CABLE (OPTIONAL) (1) 60116

BODY (1) 10429

NUT (1) 10430

GROMMET #A (OPTIONAL) (1) 10440

GROMMET #AA (OPTIONAL) (1) 10441

GROMMET #B (OPTIONAL) (1) 10442

GROMMET #C (OPTIONAL) (1) 10443

LOCK NUT (1) 101-DC

O-RING (1) 20117

8 CONNECTOR CABLE (OPTIONAL) (1) 20115

9 CONNECTOR CABLE (OPTIONAL) (1) 20116

10 FEED THRU SHAFT (ASSEMBLY ONLY) (OPTIONAL) (1) 20201

11 FEED THRU SHAFT (ASSEMBLY ONLY) (OPTIONAL) (1) 20202

12 FEED THRU SHAFT (ASSEMBLY ONLY) (OPTIONAL) (1) 20203

RUBBER MOLDED (1) 20134

PIN (1) 20135

13 DRAG DISK #1 (OPTIONAL) (1) 20303

DRAG DISK #2 (OPTIONAL) (1) 20304

14 DRAG STRIP #3 (OPTIONAL) (1) 20204

DRAG STRIP #4 (OPTIONAL) (1) 20205

DRAG STRIP #5 (OPTIONAL) (1) 20206

DRAG STRIP #6 (OPTIONAL) (1) 20207

# PART NAME QTY PART #

15 SCREW (1) 152-S

16 WASHER (2) 311-W

17 CLAMP WASHER (1) 324-W

18 SCREW (3) 118-S

19 GASKET (1) 20307

20 BODY CASTING (1) 20208

21 SPACER (2) 20305

22 SPRING (Q-5/3 ONLY) (1) 20316

23 SPRING (Q-5/5 AND Q-5/7) (1) 20108

24 LEAD SCREW NUT (1) 20107

25 LEAD SCREW (1) 132-S

26 SHRINK WRAP (1) 901-F

27 NUT (2) 201-N

28 WASHER (1) 300-W

29 WASHER (2) 311-W

30 BRACKET (1) 20314

31 TERMINAL STRIP (1) 20102

32 WASHER (2) 313-W

33 SCREW (2) 117-S

34 MICROSWITCH (1) 20103

35 SCREW (2) 116-S

36 TERMINALS (3) 708-T

37 TERMINALS (3) 706-T

38 WIRE (1) 20318

39 WIRE (1) 20317

40 WIRE (1) 20319

41 LABEL (1) 20320

16

15

19

6

5

41

2

3

36

40

38

37

39

31

35

34

21

25

22

23

26

24

27

30

28

29

33

32

20

15

13

17

18

10

11

12

7

9

8

ULTRA RELIABLE SINCE 1956 P. 7ULTRA RELIABLE SINCE 1956

CERTIFICATE OF CONFORMANCE

All Harwil Corporation (“HARWIL”) products are manufactured using new materials and components.

Our products meet the applicable performance and materials specifications indicated in our current

Specifications Sheets and Parts List. HARWIL endeavors to obtain its materials and components from

American Companies.

DOMINANCE OF HARWIL LIMITED EXPRESS WARRANTY

Each user MUST make appropriate analysis and tests to determine the suitability of the HARWIL product

for the intended use prior to purchase.

HARWIL warrants that all HARWIL products will be free from defects in material and workmanship for a

period of one year from the date of original shipment. This Warranty shall be LIMITED to the replacement

and reconditioning of our products and parts. HARWIL reserves the right and sole discretion to modify

or change the composition, design and appearance of its products at anytime.

THIS WARRANTY SHALL BE IN LIEU OF ALL WARRANTIES OF MERCHANTABILITY AND OF ALL WAR-

RANTIES OF FITNESS FOR A PARTICULAR PURPOSE RELATING TO HARWIL PRODUCTS AND PARTS.

BUYER’S SOLE REMEDY SHALL BE REPLACEMENT OR RECONDITIONING AS SET FORTH HEREIN.

HARWIL SHALL INCUR NO OBLIGATIONS HEREUNDER AND NO LIABILITY IN THE EVENT OF (1)

BUYER NOT FULFILLING ITS RESPONSIBILITIES; INCLUDING AS SET FORTH HEREIN; (2) NEGLECT,

ALTERATION OR IMPROPER PRODUCT USE, INCLUDING USE WITH NON-COMPATIBLE DEVICES OR

CHEMICALS; OR (3) REPAIR BY ANOTHER COMPANY OR PERSON THAN HARWIL.

ANY LAWSUIT RELATING TO THIS LIMITED EXPRESS WARRANTY MUST BE COMMENCED WITHIN

ONE YEAR OF THE DATE THE LAWSUIT ACCRUES.

HARWIL provides NO WARRANTY and ASSUMES NO RESPONSIBILITY for corrosive attack on

any material, component or design features associated with any of its products.

Corrosion resistance information listed in HARWIL specification sheets, information sheets and product

brochures is solely for general background information. This information table has been compiled from

literature published by various material suppliers and by equipment manufacturers who use these materi-

als in their products. Inasmuch as these data are based on tests by entities over which HARWIL has no

control, HARWIL DOES NOT GUARANTEE AND DOES NOT ACCEPT ANY RESPONSIBILITY FOR THE

ACCURACY OF SUCH THIRD PARTY TESTING. When using the table, please remember that in any

given case several factors such as concentration, temperature, degrees of agitation and presence of impu-

rities influence the rate of corrosion. The information table is intended, in a general way, to rate materials

for resistance to chemicals which contain their usual impurities and for types of equipment in common

use. Ratings should be used only as a general tool to first approximation of your material requirements

rather than as the final answer.

WHEN IN DOUBT, TEST MATERIALS BEFORE INSTALLATION.

AFTER INSTALLATION, FOLLOW UP WITH SCHEDULED PREVENTATIVE MAINTENANCE AND

PERIODIC INSPECTION.

16306

Table of contents

Other Harwil Switch manuals