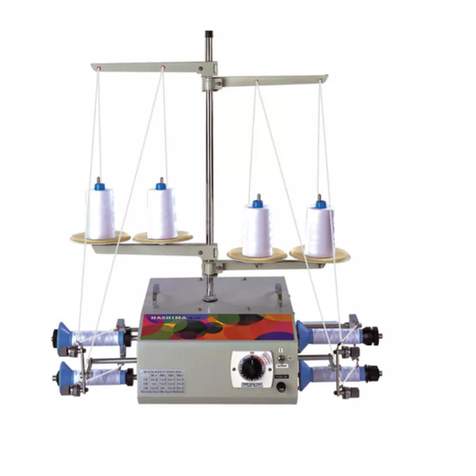

HASHIMA HP-450CS User manual

HASHIMA

HASHIMA COMPACT PRESS

HP-450C/CS

INSTRUCTION MANUAL

HASHIMA CO.,LTD

SPECIFICATIONS

MODEL HP-450C/CS

POWER SUPPLY 1P-220V

RATED OUTPUT HEATER 4.5KW

MOTOR 40W

TEMPERATURE A(MAX) 200℃

PRESSURE (MAX) 1.5KG/cm

BELT SPEED 8.7m/min.

HEATING TIME 5 − 20 sec.

FUSING WIDTH 450mm

DEMENTIONS W 1660mm

D 880mm

H 490mm

WEIGHT 152kg

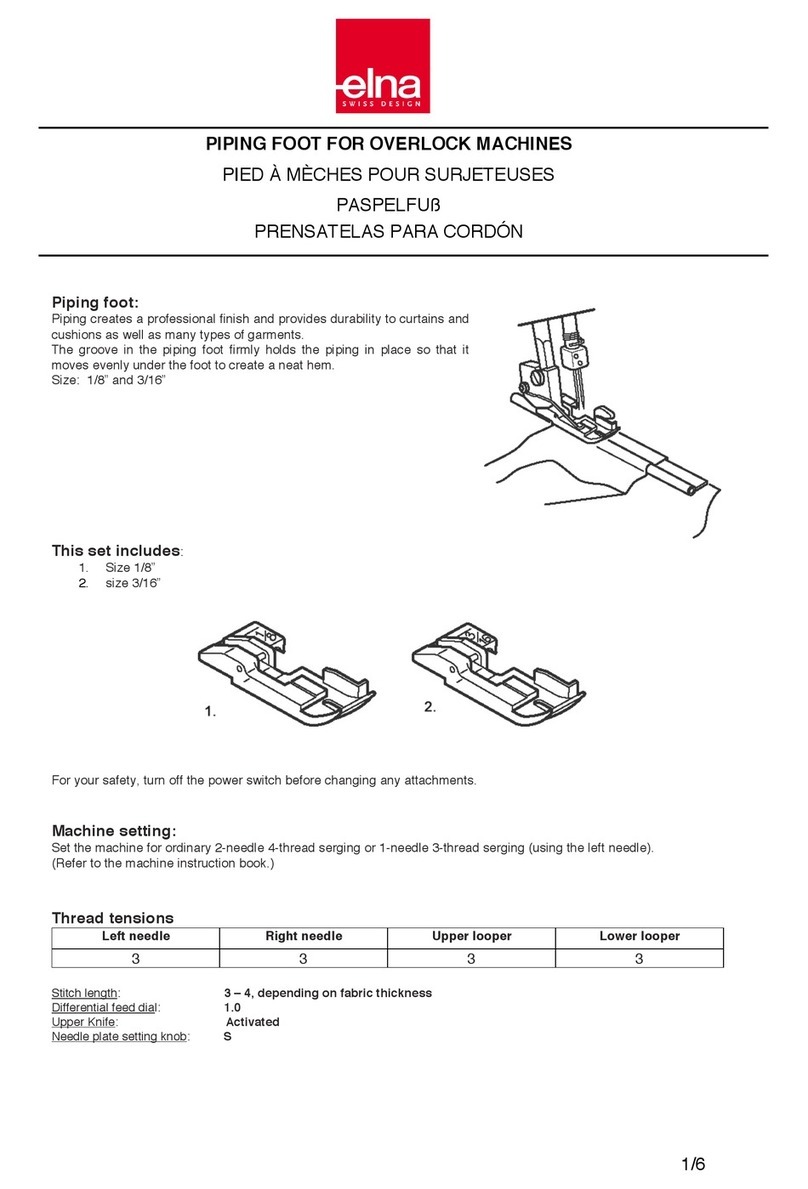

Attention to be paid at the time of installation

1. Install this machine, which weights 152kg, in regard to the 450C/CS

respectively, on the robust foundation horizontally.

2. Don’t install this machine near the object easy to burn, as it generates high

temperature when it has been put into use. Exclude, in addition, dusts and

others stuck onto this machine periodically.

3. Connect the machine to an exclusive power source corresponding with the

ratio consumption power by referring to the specifications.

4. Don’t fail to the ground .By the way ,it has no relations to the rotary direction

of the belt.

5. In the case where you change the power source plug or lengthen construction

shop near by.

6. When the machine has been brought in or when it has been transferred, don’t

fail to remove the main unit’s cover, before ensuring that the upper and lower

belt warping prevention limit switches place correctly the belt between them

from both sides. (Refer to next page.)

Attention to be paid at the time of using

1. Don’t fail to read the User’s Manual prior to the usage.

2. Don’t fail to remove the main unit’s cover and ensure that the upper and lower

warp prevention limit switches place correctly the belt between them from

both sides, before connecting the power source. (Refer to next page.)

3. Wipe off dusts using a dry floor mat, before inserting the material.

4. Pay sufficient attention not to make contact with the belt and the upper cover

whose temperature rises high nor mount things on them.

5. Don’t absolutely put your hands on to the roller inside the machine beyond the

necessity at the time you insert the material for fear that they might be

caught in.

6. Don’t put any things to the main unit of the press except the materials to be

inserted.

7. Disconnect the power source breaker immediately and insert the manual

handle (an accessory) to the emergency screw, then, turn it to the arrow

marked direction in order to remove the unusual things before the operation,

if they have been inserted.

8. When the material, has twined rounded the strip off device at the exit of the

material, don’t fail to disconnect the power source breaker, before removing it.

9. Don’t fail to pull the power source plug off when you inspect the inside.

10. This machine is an exclusive use for fusing and folding the clothes. Don’t put it

to use for other purposes, otherwise resulting in troubles.

11. After the operation ensure that the machine has stopped completely, before

disconnecting the power source breaker without fail.

Procedure of usage

1. Set the power source to ‘ON’.(Ensure the ‘off ’condition of the timer switch.)

2. Press the start button. The lamp will light up and the machine will start

moving.

3. Set pressure to the designated by using the pressure adjust knob.

4. Set the fusing time by using the speed controller .Use it within the limit

between 5 and 20 seconds for the warp prevention.

5. Set the setting temperature by using the thermostat .It takes about 15

minutes before you’ll get the usable thermo-lamp will start blinking.

6. Here, you are able to start the operation.

At the time the operation is over.

1. Set the pressure to 0(zero).

2. Set the timer switch to ‘ON’. The machine stop automatically and the

surface temperature of the belt is below 100 degrees.

3. When the machine has stopped , set the power source breaker to ‘OFF’.

The holding’s adjustment

In the case where you want to strengthen the holding at the injecting entrance

of the machine when you’ve put the inside belt scale, pocket folding and others to

use, turn the holding’s handle to the right. Set the holding’s adjustment to

0(zero),when you try to fuse the interlining.

How to prevent and adjust roller moiré (puckering)

In the case where roller moiré has taken place on the fused material, fuse it by

lowering heat and pressure as low as possible. Even when the prevention is

impossible in spite of the efforts, adjustments to be shown below will be

necessary.

1. Remove the main unit’s cover.

2. Remove the rear cover.

3. You’ll find a screw for securing the moiré adjust roller on the side of the

machine . And you will find an other when you open the rear cover of the

machine loosen both of the stop screws and rise right and left equally.

4. The moiré is hard to appear when you bring up the roller.

5. Tighten both of the stop screws.

How to move the machine by hand at the emergency

Press the stop switch in order to stop the machine before setting the pressure to 0

(zero), when you’ve put other things to the belt’s injecting entrance by mistake.

Put the T-typed wrench (an accessory) on to the screw for emergency on the side of

the main unit and turn it to the arrow marked direction, before you will unload

the finished material. In the case where a hard thing has been put in the machine,

ensure the safety before resuming the operation for fear that the teflon belt and

rubber parts of the pressure roller might be damaged. And in the case of an

electric failure, put the T-typed wrench (an accessory ) on to the screw for

emergency use on the side of the main unit and turn it to the arrow marked

direction. before you’ll unload the finished material

Daily maintenance <<Pay attention to fear such accidents as burn and caught

–in.>>

Cleaning belts

Clean the belt while it is hot. Use the Hashima New Ace or the New Clean Spray

to clean the belt. In the case where you put the latter to use . pay attention not to

spray such electric parts as the warp prevention limit switch and others, resulting

in troubles. Moreover, don’t use the powders New Cleaning except when dirt is

remarkable. Wipe with sure the powders which have a character to be hardened

when it is cool. Apply the Hashima New Ace onto the belt for the prevention of

dirts.

Cleaning the cleaner

The cleaner is provided at the rear part of the machine. At the start of the

cleaning, don’t fail to pay attention so that the clean surface could make contact

with to belt. And observe it about twice a day to change the dirty surface if

necessary. The cleaner is to be removed when you push it to the manipulation

panel’s side. When you wind a new cloth. make it coincide with the rotary

direction of the belt and, then ,wind it ,not being caught in.

Cleaning the brush scraper.(C)

The brush, too, is provided at the rear part of the main unit of the machine. Raise the scraper

three or four times a day in order to clean.

Cleaning the rotary strip off blade (CS)

Pick the blade, using a piece of the cloth and move it left to right and right to left

in order to take the fusing resin resin and others away. Here. if the blade remains

lying ,raise it before cleaning it.

ATTENTION TO BE PAID MAINTANANCE OF FUSING MACHINE

Put-off electric sources, fill “grease” inside rollers every two weeks

You should use HASHIMA genuine grease and never use grease which contains

MOLYBDENUM (LACK OF THIS GIVES DAMAGES TO BEARINGS)

1. TAKE OUT MAIN COVER A.

2. FULL GREASE INTO THE PLACE OF ARROW MARKS.

上ベルト交換方法

HOW TO EXCHANGE UPPER BELT

次頁参照

Refer next page

1.電源ブレーカーを切り、圧力調整ツマミで圧力を−1にし、くわえ込み調整を0にしてくだ

さい。

Disconnect the power source from its origin and set the pressure –1, and pull-in adjuster

set to 0.

2.本体カバー(A)を持ち上げて外してください。本体カバー(パネル側)のネジを外し、近

くに置くか、パネル側の線をコネクターから外し操作ボックスを取り外してください。

Take off main cover (A). Take off screw of main cover (panel side) and put it near the

machine or take off connector of panel side and control box.

3.上側蛇行リミットステーを外してください。さらに子ネジ 2本(黄色)

Take off belt warping prevention limit switch stay. 2 pan screw. (yellow marks)

4.断熱板を外してください。さらに子ネジ 2本、六角ボルト 1本(黄色)

Take off the adiabatic cover. 2 Pan screw, 1 Hex bolt (yellow marks)

5.クリーナー棒(上)を外してください

Take the cleaner bar(upper) off.

6.テンションスプリング(上)を左右外してください。

Take the tension spring (upper) off of both side.

7.テンションローラー(上)を外してください。

Take the tension roller (upper) off.

8.ハケステー(上)を外してください。 六角ボルト2本(黄色)

9.上フレームの外側を通し、ベルトを抜いて下さい。

上ベルトを交換する場合、フレームスペーサーを外した方が楽に交換できます。

ただしその場合、前テーブル、作業テーブル、補助フレーム、ベルト保護ステー、

左側補強ステーを外してください。(外し方は下ベルト交換方法参照)

Take off a belt from upper frame.

When change upper belt, it is easier by taking off frame spacer.

In this case, take off front table, working table, sub-table, belt protection stay and

Left frame support stay. (Refer how to change lower belt)

10.組立は分解の逆の手順で行ってください。

Reassemble in the reverse order.

下ベルト交換方法

How to change lower belt.

1.電源ブレーカーを切り、圧力調整つまみで圧力を−1にしてください。

又、くわえ込み調整を0にしてください。

Disconnect the power source from its origin and set the pressure to -1 by the

pressure adjusting knob. Set the holding’s adjustment to 0.

2.作業テーブルを外してください。

Take the front table off.

3.作業テーブル補助フレームを外してください。

Take the front table stay off.

4.ベルト保護ステーを外してください。さら子ネジ 2本 (黄色)

Take the belt protection stay off. Pan screw 2 (yellow mark)

5.サイドテーブルを外してください。 六角ナット 1ヶ (黄色)

Take the side table off. Hex. Nut 1 (yellow mark)

6.左側フレーム補強ステーを外してください。 六角ボルト 2本(黄色)

Take the left frame support stay off. Hex. bolt 2 ( yellow mark)

7.左下側蛇行リミットステーを外してください。さら小ネジ 2本(黄色)

Take the left lower belt warping prevention limit stay off. Pan screw 2 (yellow mark)

8.圧力メーターの位置を確認してから外してください。 六角ボルト 1本

Take the pressure meter off. Hex. bolt 1

9.圧力調整ノブを外してください。六角穴付き止めネジ 2本

Take the pressure adjusting knob off. Hex holed set screw. 2

10.クリーナー棒(下)を外してください。

Take the cleaner bar (lower) off.

11.テンションスプリング(下)を左右外してください。

Take the tension springs (lower) off.

12.テンションローラー(下)を外してください。

Take the tension roller (lower) off.

13.ハケステー(下)を外してください。

Take the blade stay (lower) off.

14.フレームスペーサーを外してください。 六角ボルト 3本 (黄色)

Take the frame spacer off. Hex. Bolt 3 (yellow mark)

15.ベルトを下フレームの外側から通し、抜いてください。下ベルトを交換する場合、

上側カバーを外した方が楽に交換できます。

Press the belt through the outside of the lower frame in order to pull it out.

When change lower belt, it is easier by taking off upper cover.

16.組立は逆の手順で行ってください。圧力メーターの位置、左下側蛇行リミットステー

の位置合せを注意してください。

Reassemble in the reverse order. Give attention to set the position of the pressure

Meter and left lower belt prevention limit stay.

This manual suits for next models

1

Table of contents

Other HASHIMA Sewing Machine Accessories manuals