i

CONTENTS

Form No. FDWDM-1207

Important Owner Information...............................i

Introduction ...........................................................i

Important Safety Information..............................1

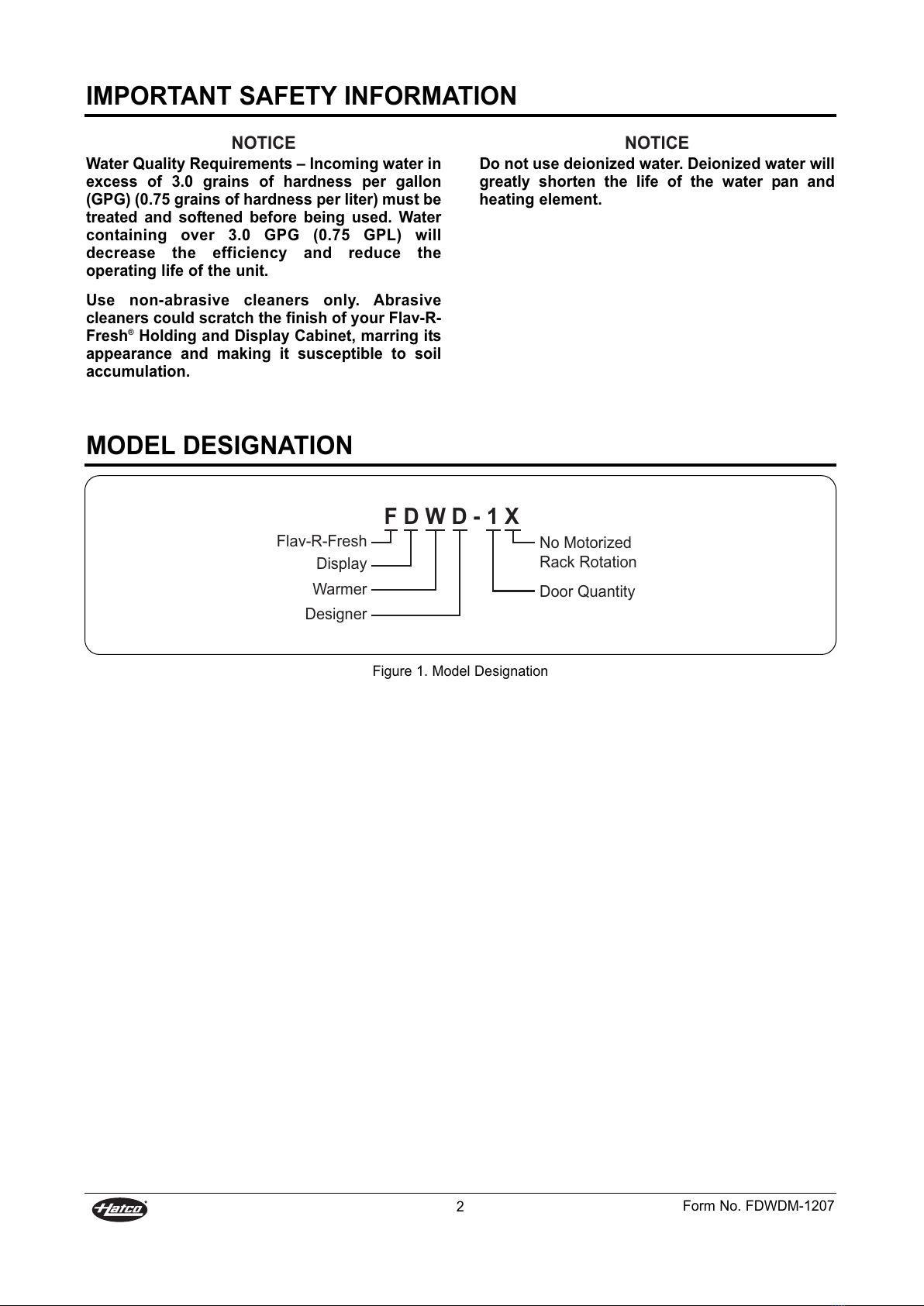

Model Designation ...............................................2

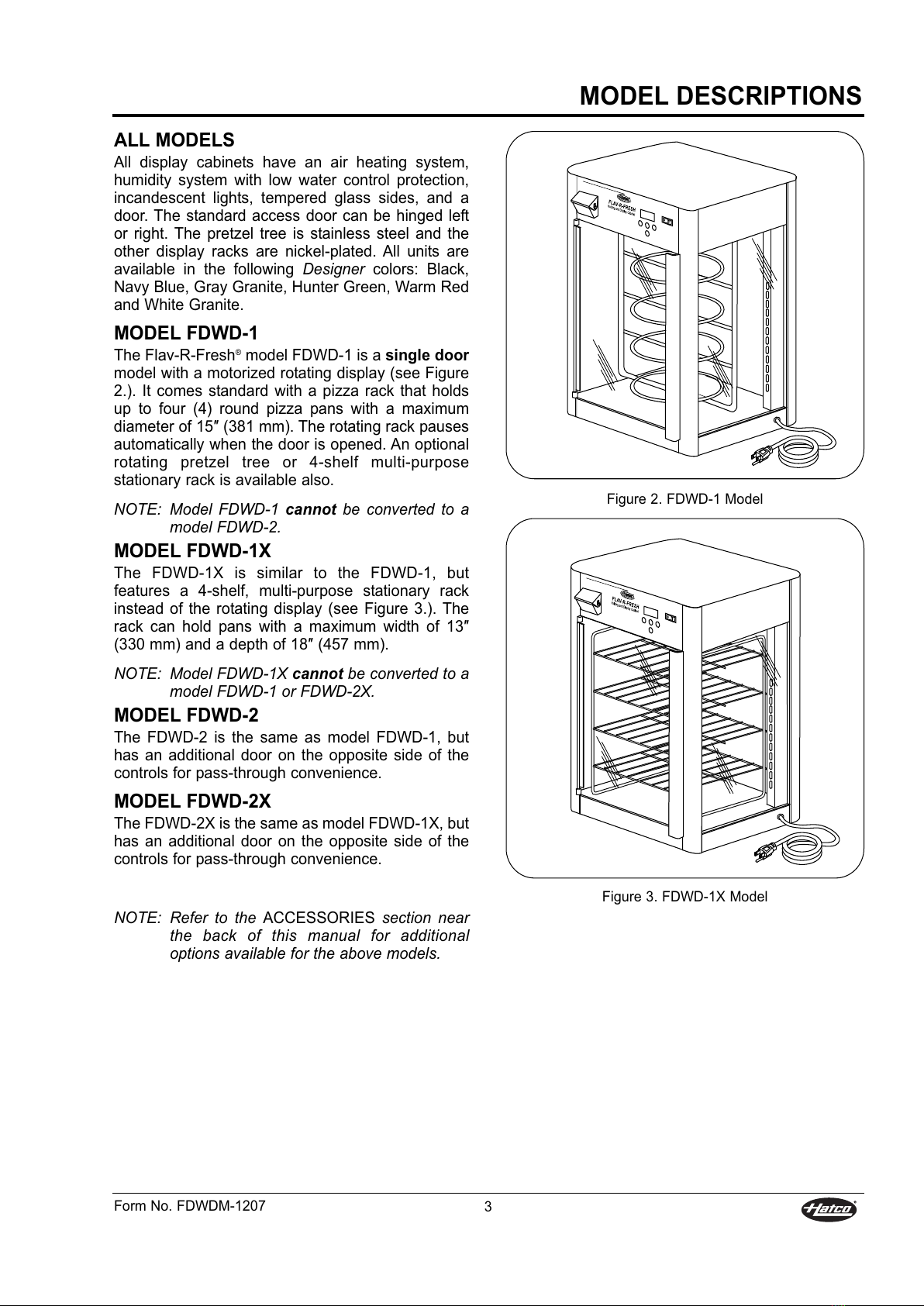

Model Descriptions..............................................3

Specifications.......................................................4

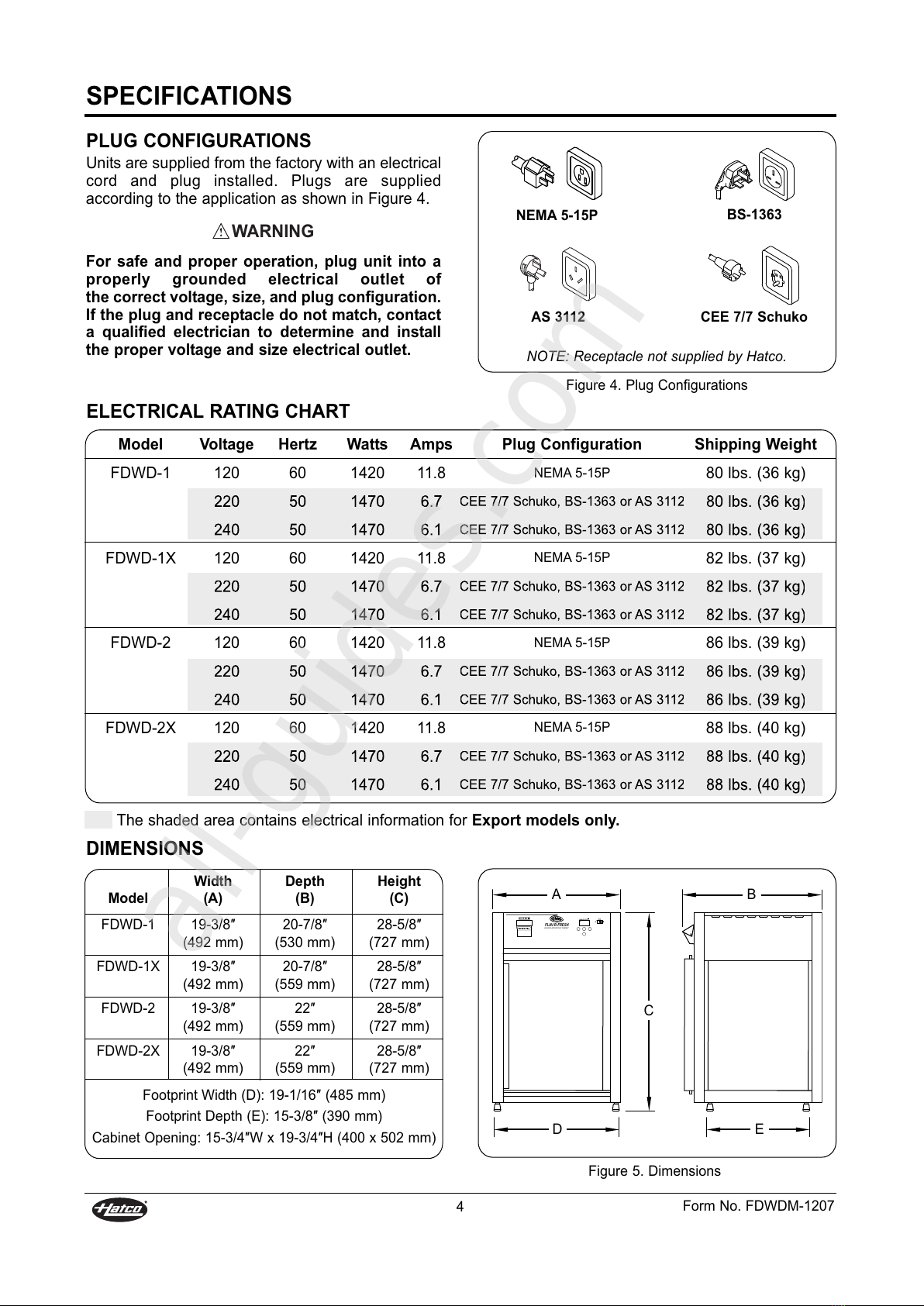

Plug Configurations.........................................4

Electrical Rating Chart ....................................4

Dimensions......................................................4

Installation ............................................................5

Unpacking .......................................................5

Location...........................................................5

Reversible Access Door ..................................6

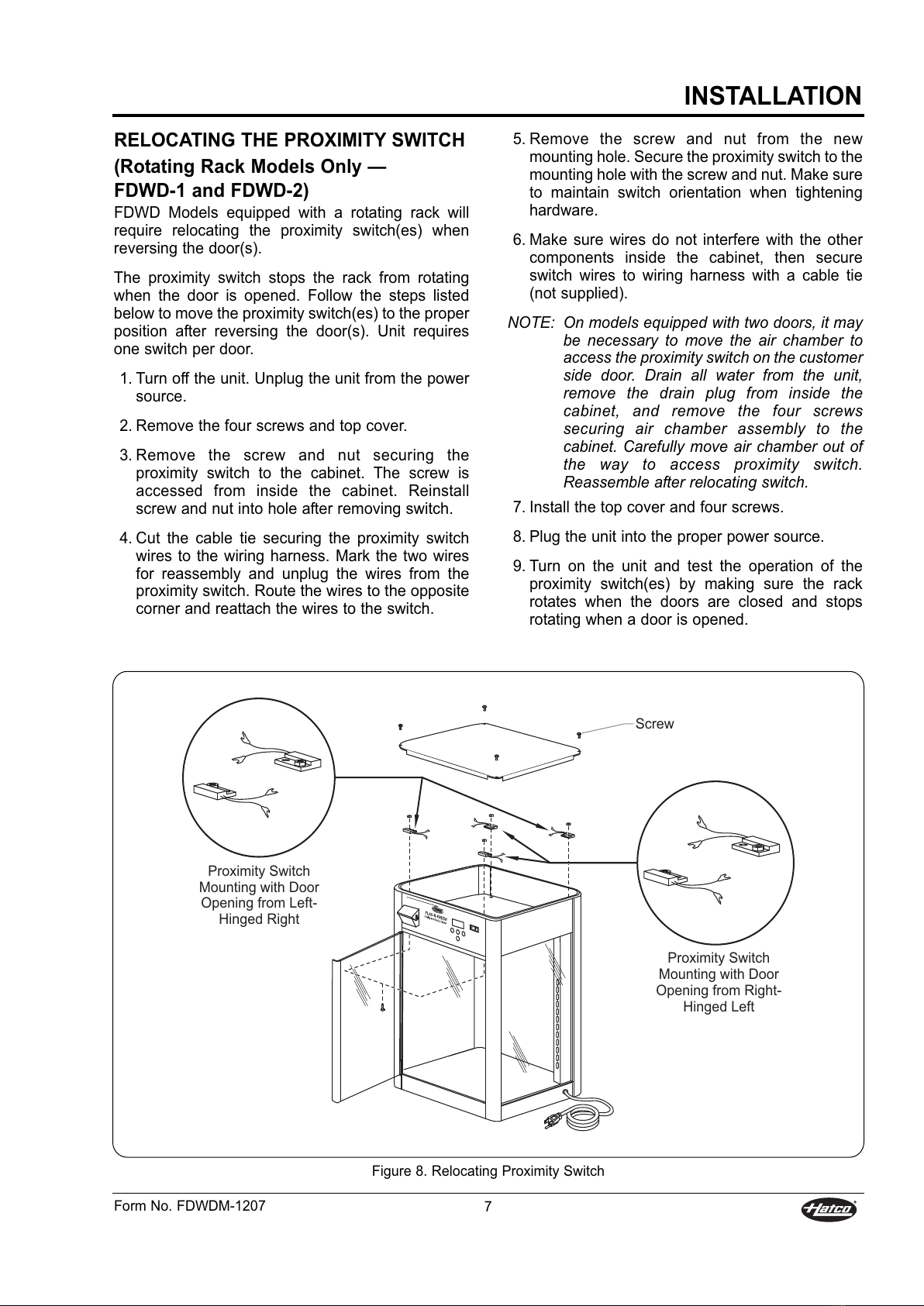

Relocating the Proximity Switch......................7

Operation ..............................................................8

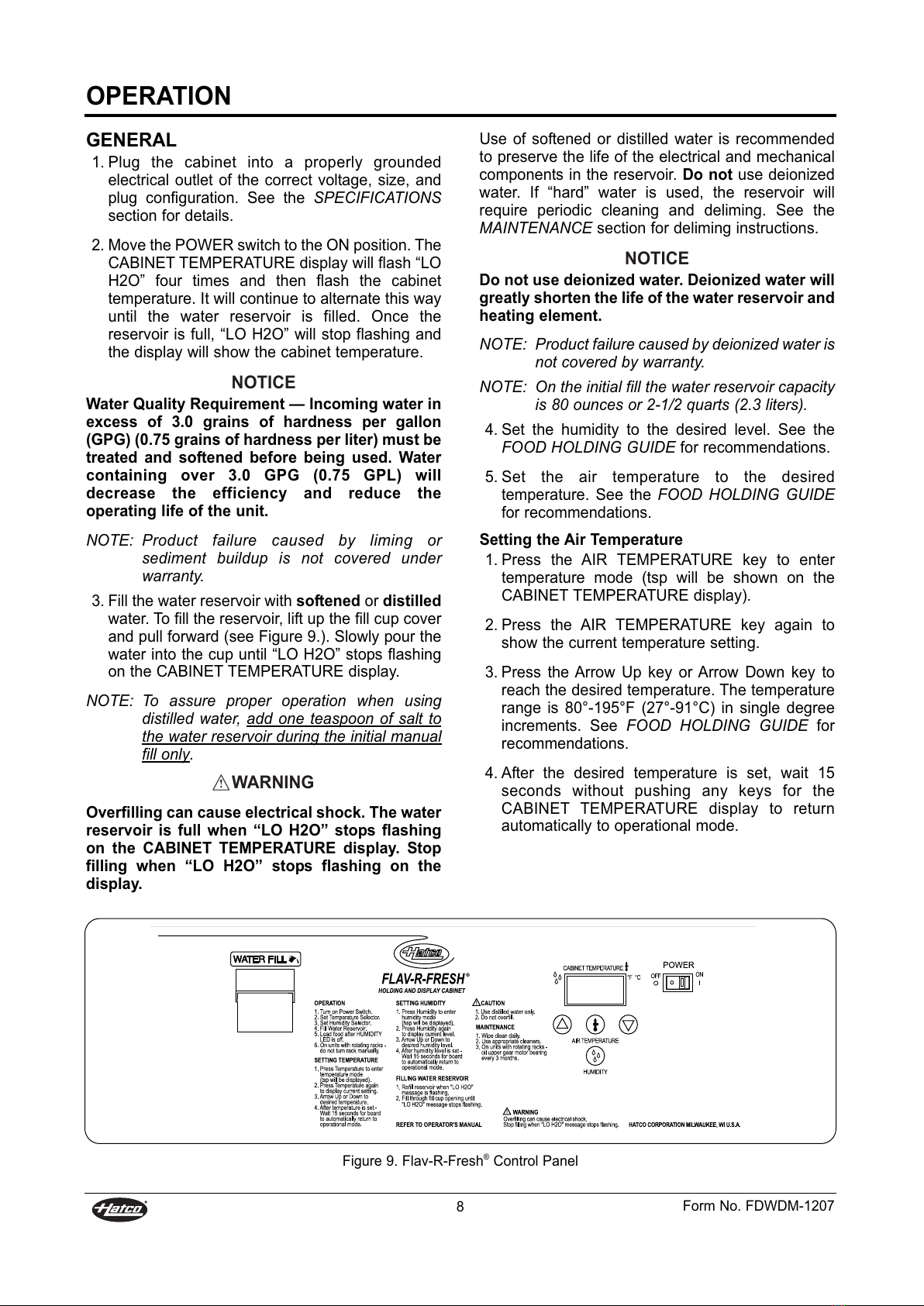

General............................................................8

Food Holding Guide ........................................9

Maintenance .......................................................10

General..........................................................10

Cleaning ........................................................10

Draining The Reservoir .................................11

Removing Lime and Mineral Deposits ..........11

Display Light Bulb Replacement ...................12

Troubleshooting Guide......................................13

Accessories ........................................................15

Hatco imited Warranty.....................................17

Authorized Parts Distributors ............Back Cover

IMPORTANT OWNER INFORMATION

Record the model number, serial number

(identification decal located on the lower right hand

side, rear corner of the unit), voltage, and purchase

date of your Flav-R-Fresh®Holding and Display

Cabinet in the spaces provided. Please have this

information available when contacting Hatco for

service assistance.

Model No. ________________________________

Serial No. ________________________________

Voltage __________________________________

Date of Purchase __________________________

Business 8:00 a.m. to 5:00 p.m.

Hours: Central Standard Time

(Summer Hours: une to September –

8:00 a.m. to 5:00 p.m. C.S.T.

Monday through Thursday

8:00 a.m. to 2:30 p.m. C.S.T. Friday)

Telephone: (800) 558-0607; (414) 671-6350

Fax: (800) 690-2966 (Parts and Service)

(414) 671-3976 (International)

24 Hour 7 Day Parts and Service

Assistance available in the

United States and Canada

by calling (800) 558-0607.

Additional information can be found by visiting our

web site at www.hatcocorp.com.

INTRODUCTION

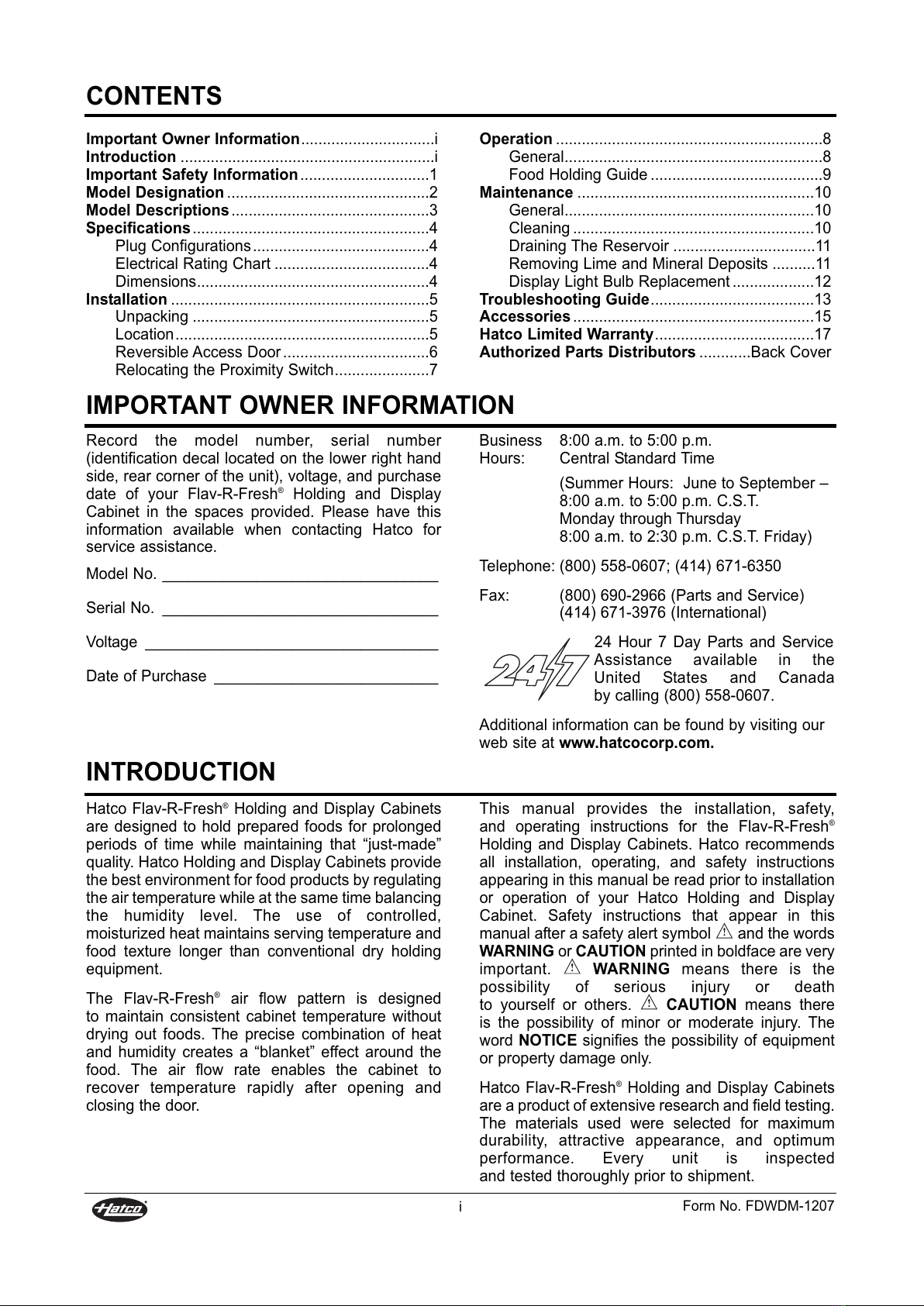

Hatco Flav-R-Fresh®Holding and Display Cabinets

are designed to hold prepared foods for prolonged

periods of time while maintaining that “just-made”

quality. Hatco Holding and Display Cabinets provide

the best environment for food products by regulating

the air temperature while at the same time balancing

the humidity level. The use of controlled,

moisturized heat maintains serving temperature and

food texture longer than conventional dry holding

equipment.

The Flav-R-Fresh®air flow pattern is designed

to maintain consistent cabinet temperature without

drying out foods. The precise combination of heat

and humidity creates a “blanket” effect around the

food. The air flow rate enables the cabinet to

recover temperature rapidly after opening and

closing the door.

This manual provides the installation, safety,

and operating instructions for the Flav-R-Fresh®

Holding and Display Cabinets. Hatco recommends

all installation, operating, and safety instructions

appearing in this manual be read prior to installation

or operation of your Hatco Holding and Display

Cabinet. Safety instructions that appear in this

manual after a safety alert symbol and the words

WARNING or CAUTION printed in boldface are very

important. WARNING means there is the

possibility of serious injury or death

to yourself or others. CAUTION means there

is the possibility of minor or moderate injury. The

word NOTICE signifies the possibility of equipment

or property damage only.

Hatco Flav-R-Fresh®Holding and Display Cabinets

are a product of extensive research and field testing.

The materials used were selected for maximum

durability, attractive appearance, and optimum

performance. Every unit is inspected

and tested thoroughly prior to shipment.