3

INSTALLATION MANUAL

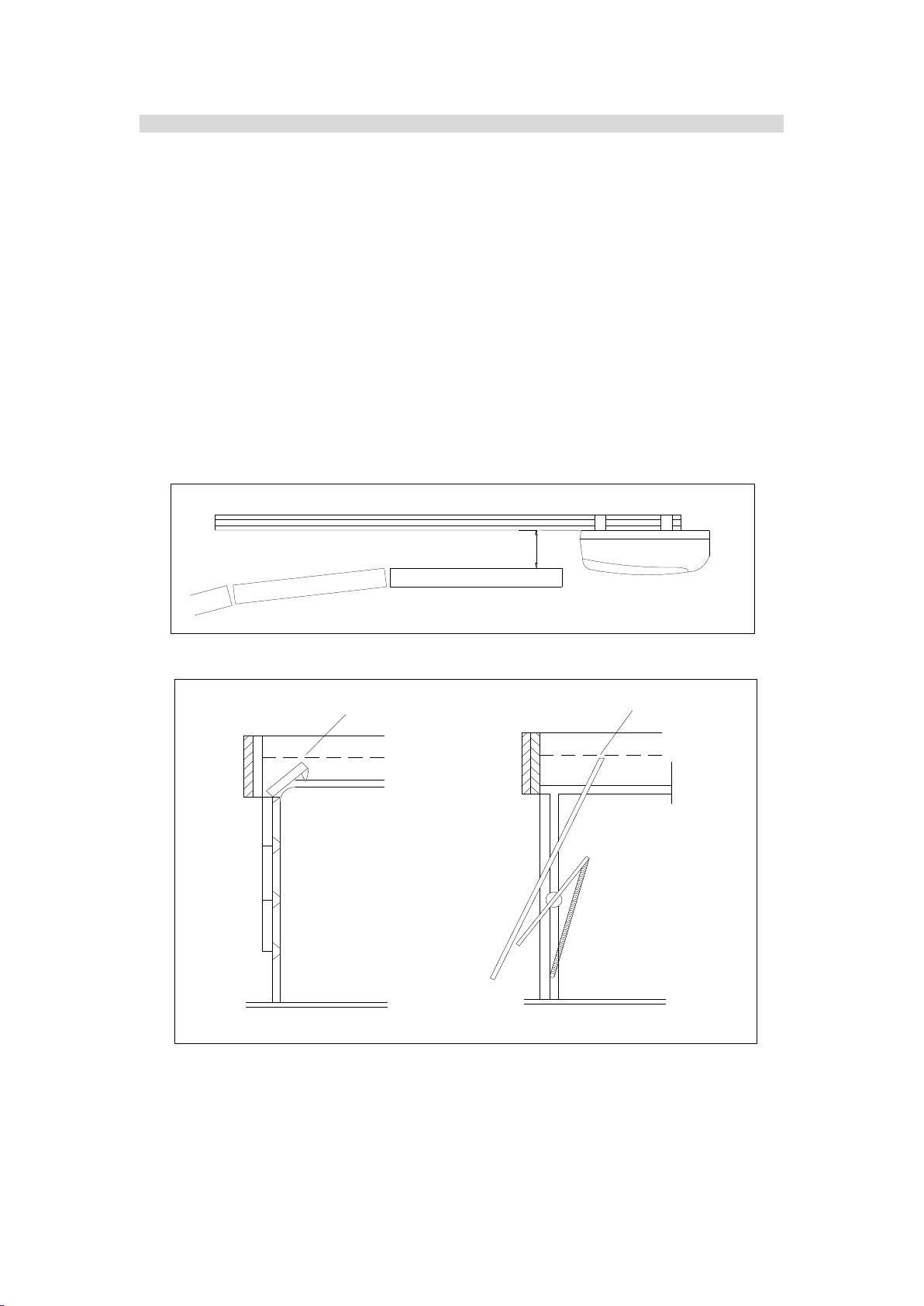

Our compliments for your excellent choice. The HATO 180C/200C electro-mechanical gear

motor has been produced for reliability and high quality.

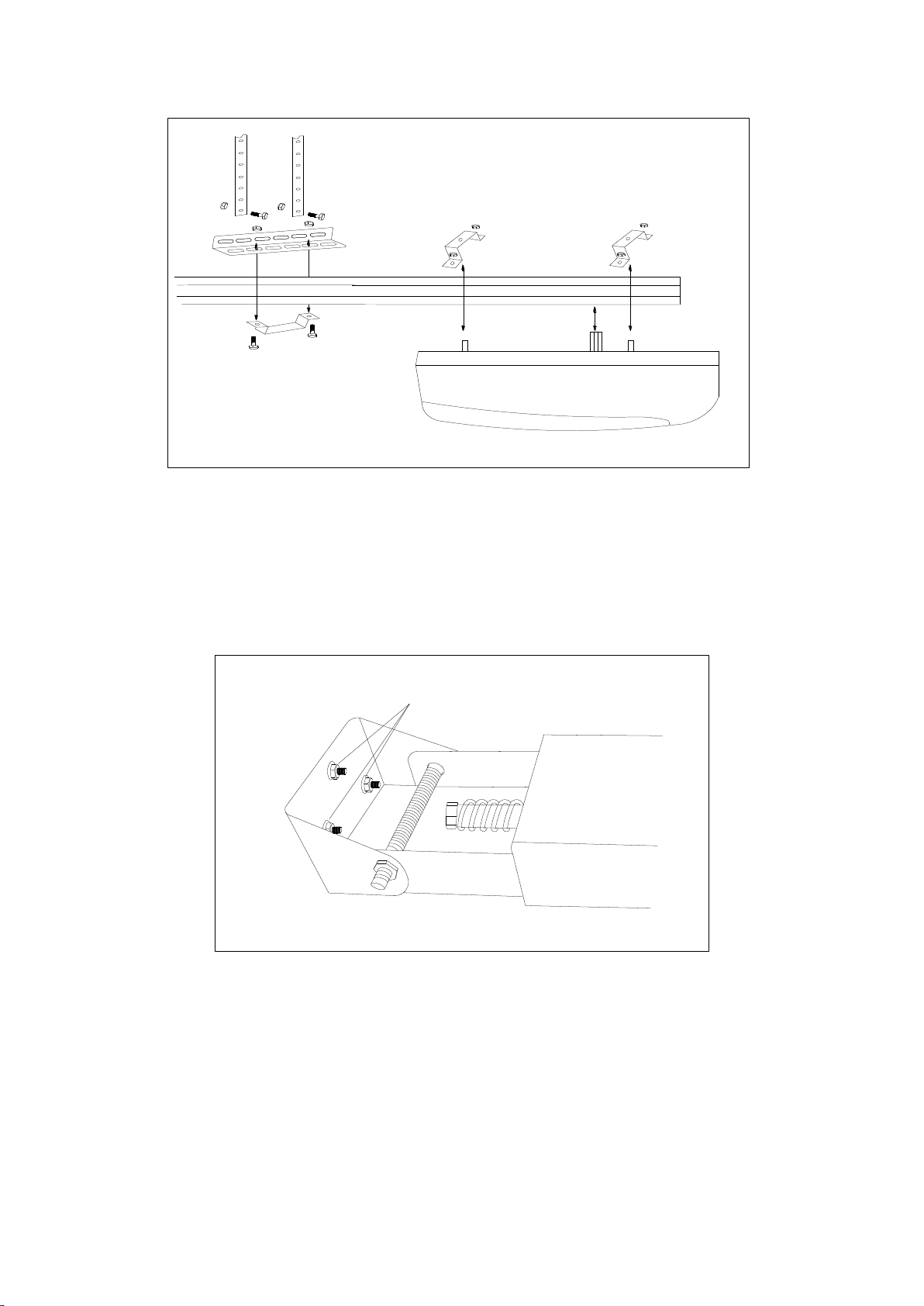

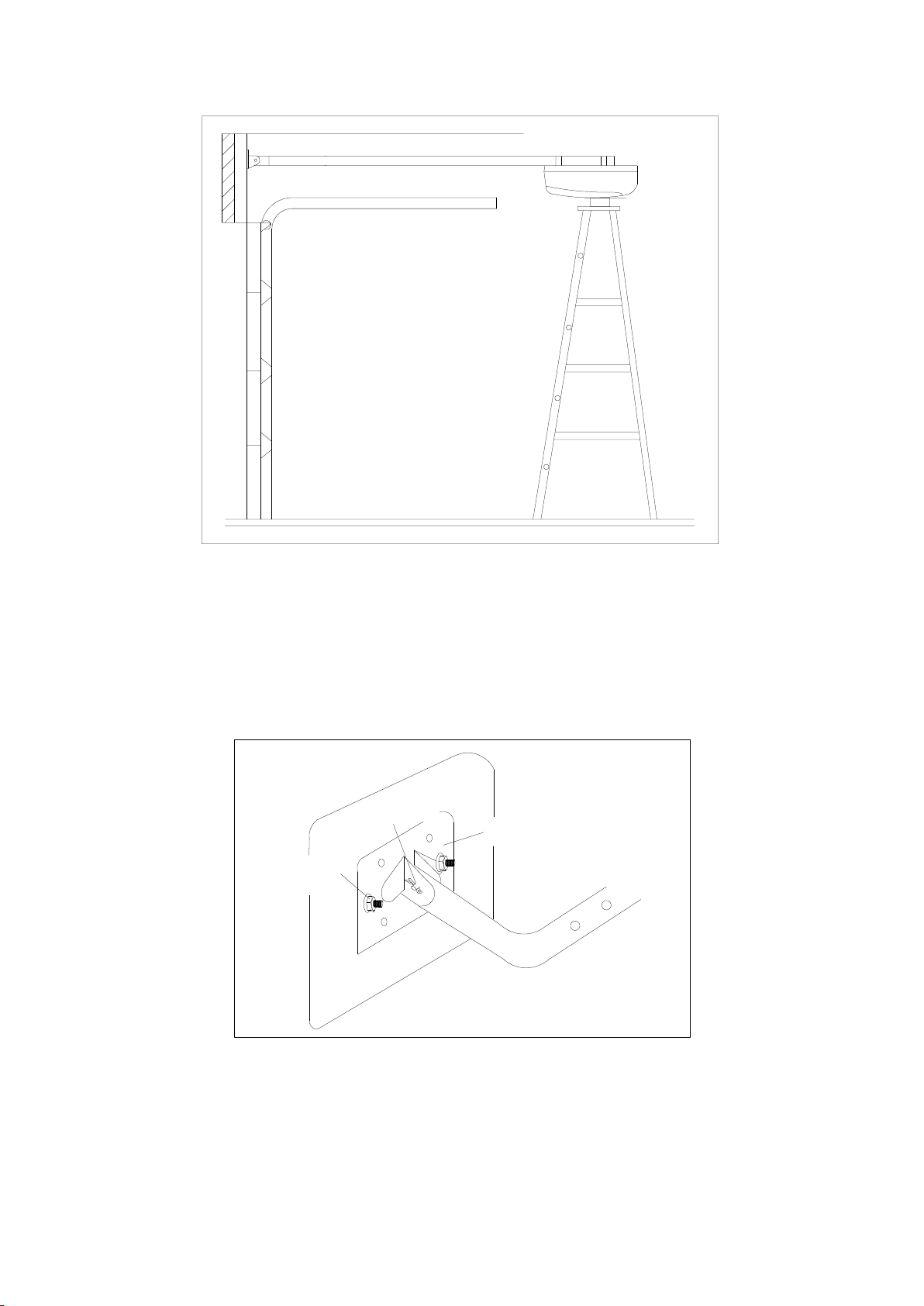

This Manual will offer information you may need to install your gear motor assuring long-lasting

performance and to safeguard your safety. HOWEVER CAUTION IS UNQUESTIONABLY

INDISPENSABLE AND NOTHING IS BETTER THAN PREVENTING ACCIDENTS.

CONFORMITY DECLARATION:

It’s in accordance with Machine Directive 2006/42/WE and following modify.

It’s in accordance with the following directive CE:

Electromagnetic compatibility Directive 2014/30/UE and following modify.

Low tension Directive 2014/35/UE and following modify.

Radio directive RED 2014/53/UE

Have been applied the following harmonized norms:

EN ISO 12100:2012; EN 60204-1:2010; EN 60335-2-95:2015, EN 301 489-3 V1.4.1:2006; UNI

EN 12453:2002, where applicable EN 12445:2002

Current declaration are available on website

1.Safety instructions

Carefully read and follow all safety precaution, warnings before attempting to install and use

this garage door operator, incorrect installation can lead to severe injury.

The installation should be carried out by a qualified technician.

To avoid electrical shock, disconnect the power cord from the mains power outlet before

doing any repairs or removing the cover.

The door operator must be grounded.

Before installation of the door operator, the door should be carefully checked for being

kept well balance. The door must be in good working order. Open and close the door

manually, make sure the door can be moved smoothly.

No one or vehicle is allowed to enter or leave the garage while the remoter is being

installed, do not allow children to play near the door.

Locate any fixed control: within sight of door but away from all moving parts of the door

and at a height of more than 1.5m above the ground to avoid children reaching it.

Keep remote controls away from children, to prevent the door operator from being

activated involuntarily.

When opening or closing the door, do not attempt to walk or drive through the door.

The door should only be operated when it can be observed to avoid accidents.

Install and adjust the manual release so that the handle hangs less than 1.5m above the

floor.

Our company reserves the right to change the design and specification without prior

notification.