Hattersley Fig.1051 User manual

Installation and Operating Instructions

Constant Flow Regulator (CFR)

Fig.1051

General Notes

The Hattersley Fig.1051

• Can be used in variable volume heating

and chilled water systems.

• Has a double regulating feature allowing

the valve opening to be set with a 3mm

Allen key.

• Is operated by means of the handwheel

with position indicator or with

recordable set position.

• Has a linear control characteristic

across setting operating range.

• Has built in Differential Pressure

Control.

• HasamaximumworkingΔP=4bar

• Has built in pressure test points to verify

operational differential pressures.

Limit of Use

These valves have been categorised in accordance with the Pressure Equipment Directive

2014/68/EU.

The fluid to be transported is limited to group 2 liquids i.e. non-hazardous.

On no account must these valves be used on any group 1 liquids, group 1 gases, group 2

gases or unstable fluids.

Note: Valves are classified as SEP (sound engineering practice) and as such cannot be CE

marked and do not require a declaration of conformity.

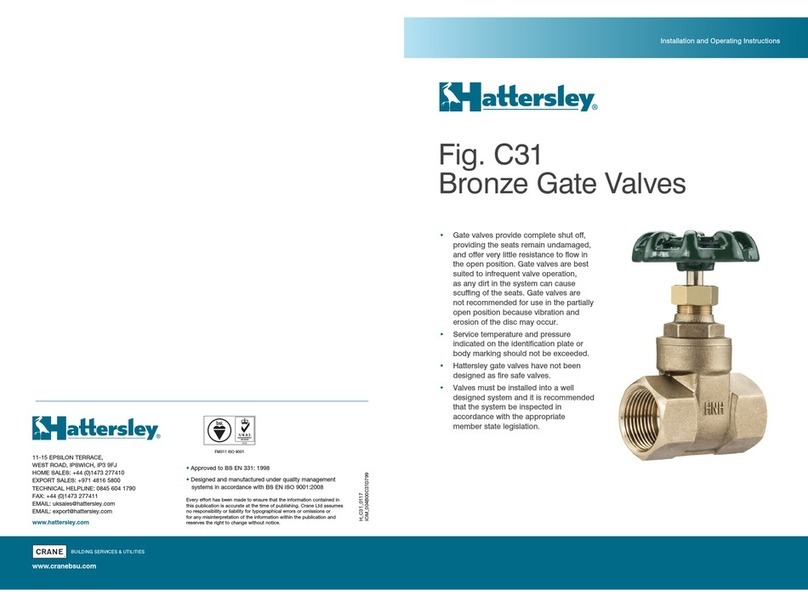

Fig.1DN25/DN32Style(left)andDN40/DN50Style(right)

Hattersley Constant Flow Regulator02

Installation and Operating Instructions

Installation

These instructions are issued as guidelines only and do not cover all installed conditions. If unsure

pleasecontactourTechnicalHelplineon01473277400,beforeinstallation.

• It is advised that the valve should be installed in a run of pipe of the same nominal size.

• Hattersley products are designed for installation and use within suitably designed systems

reflectingCIBSE,BSRIAandHVACguidelines.Particularcareshouldbetakenwithregardsto;

oAccessibilitytovalveforsetting/adjustment

oTubecutting–aftercuttingandthreading,theendmustbedeburredorreamed

before fitting to the valve.

oJointing–nothreadjointingmaterialsmustbeallowedtoprotrudeinsidethebore.

oBracketing/supports–thepipingsystemshallprovidesuitablesupportandmustbe

carefully aligned and at the correct distance between centres for the size and type

of valve.

• Orientation: The Fig. 1051 can be positioned in any orientation.

• Normallyinstalledonreturnpipework,i.e.aftertheequipmentitiscontrolling,butcanbe

installed in flow if required.

• Ensure direction of flow is correct - indicated by an arrow on the valve body.

• Fig.1051 operates between a minimum and maximum pressure drop across the valve -

seecommissioningsectiononpage4.

• CFR’sarenotdesignedasisolationvalves.Dedicatedisolationvalvesshouldbeinstalled

toisolateagainstsystempressure,i.e.formaintenanceetc.,whendisconnecting/draining

pipework.

• Careshouldbetakentonotexceedmaximumoperatingdifferentialpressure,toprevent

damage to the internal components.

• SystemsshouldbeinstalledwithstrainerstoprotecttheCFRandotherinstalleditems.

• StraightlengthsofpipeworkarenotrequiredforCFR’sbutsomestraightlengthsare

recommended to create a more stable flow pattern.

Flushing

Controlvalves,liketheCFR,aresizedtogivegoodcontroloverthe

systemwater,therefore,havebeendesignedwithasmallconvoluted

flow path. These water ways may not allow adequate water velocities

forflushingofthecoil,evenwhenfullyopen.Therefore,inlinewith

BSRIArecommendations,itisrecommendedthataflushingpoint

belocatedbetweenthecoilandtheCFR.Thisallowsthecoiltobe

flushedwithoutthewaterpassingthroughtheCFR.

PleaserefertoBSRIAGuideBG29–2012forguidance.

Product Title Here

03Hattersley Constant Flow Regulator 03

Valve Setting Indicator

Fig.1051 valves operate from closed to fully

openwith4completeturnsofthehandwheel.

The handwheel indicates the valve setting by means

of digits in the outer (left) and inner (right) windows.

The digit in the inner window indicates tenths of a turn.

Theexampletotherightshowsavalvesettingof4-0

turns (fully open).

Regulator

Flowregulationisachievedbyadjustingthevalvesettinguntiltherequiredflowrateisobtained.

The‘Microset’handwheelwillindicatethefinalvalvesetting.Seetable1onpage4forflowrate

setting.

Setting Facility

The valve setting at which the required flow rate is achieved may be retained as follows:

1.Removecapincentreofhandwheel

2.UsingtheAllenkeyprovidedtightenthecentrescrewuntilitstops.

Do not over-wench.

3.Replacecentrecapinhandwheel.

Thevalveisnowsetandbeadjustedandre-settotheoriginalsetpoint.

Pressure Temperature Rating

Temperature °C -10 to 120

Pressure (Bar) 16

Hattersley Constant Flow Regulator 04

Installation and Operating Instructions

Commissioning

TheFig.1051controlstheflowratedependingonitssetposition,therefore,removingtheneedto

measure the flow rate.

TheFig.1051maintainsaconstantdifferentialpressureacrossitsinternalseat,anyexcess

pressure being removed by the internal differential pressure controller. To ensure that sufficient

pressureisavailableforthedifferentialpressurecontrollertocontroltheflowratecorrectly,a

differential pressure reading should be taken using the test points provided.

Whentakingdifferentialpressurereadings,itisimportantthatthesystemisrunningatfullload,

i.e.withCFR’ssettodesignflowrate.Thisensuresthatdifferentialpressurereadingsarecarried

outinthemostunfavourableconditions,guaranteeingoptimumperformanceinnormalrunning

conditions.

ToensurethatallCFRsareworkingattherequireddifferentialpressure,itisnecessarytocheck

theleastfavoured/indexCFR.ByverifyingtheleastfavouredCFRissetcorrectlythenallother

CFRsmusthaveahigherdifferentialpressure.However,wewouldalsorecommendthata

selectionofotherCFRsaretestedalongthecircuittoverifythis.

Differential Pressure Requirements

Ateach%settingoptionallsizesrequireaspecificconstantΔP(DifferentialPressure)toensure

theCFRiswithinitsworkingrange:

Table 1 - CFR Flow Rate Setting Table

H/W

Setting

%

Opening

FLOW RATE l/s

DN25 DN32 DN40 DN50

ΔP

Across

Test

Points

Activation

ΔP

Overall

(kPa)

Flow

Rate

l/s

ΔP

Across

Test

Points

Activation

ΔP

Overall

(kPa)

Flow

Rate

l/s

Activation

ΔP

Overall

Across

Test

Points

(kPa)

Flow

Rate

l/s

Activation

ΔP

Overall

Across

Test

Points

(kPa)

Flow

Rate

l/s

4.0 100.0 10 25 0.48 30 40 0.90 35 2.40 35 3.20

3.5 87.5 10 25 0.42 30 40 0.79 35 1.90 35 2.80

3.0 75.0 10 20 0.36 30 35 0.68 30 1.50 30 2.40

2.5 62.5 10 20 0.30 30 35 0.56 30 1.20 30 2.00

2.0 50.0 10 20 0.24 30 30 0.45 25 0.90 30 1.60

1.5 37.5 10 20 0.18 30 30 0.34 25 0.70 30 1.20

1.0 25.0 10 20 0.12 30 25 0.23 20 0.50 25 0.80

0.5 12.5 10 20 0.06 30 25 0.11 20 0.30 25 0.40

0.0 0.0 0 0 0.00 0 0 0.00 0 0.00 0 0.00

Forflowratesbetweensettings,interpolationofpositioncanbeused.

PleasenotethatDN25andDN32testpointsmeasurethedifferentialpressureacrosstheseat,

not overall pressure drop.

PleasenotefortheDN40andDN50thetestpointsmeasuretheoveralldifferentialpressuredrop

across the valve only.

The pump speed should be set to ensure that the required differential pressure is always

available.BysettingthedifferentialpressureacrosstheleastfavouredCFRtothevaluestated

intheabovetable,itensuresthatminimumpumpenergyisused,therefore,reducingsystem

running costs and CO2 emissions:

DN25 & DN32

To set pump speed to achieve this: whilst measuring ΔP (across test points), increase

pump speed until a constant ΔP is achieved, however please note that the typical ΔP

value, as shown in the table above, can differ but in itself is not critical to operation.

DN40 & DN50

To set pump speed to achieve this: whilst measuring ΔP (across test points), increase

pump speed until a value greater than the minimum stated in the above table is achieved.

As the measured ΔP is the total pressure drop across the PICV, the measured value will

continue to rise as pump speed is increased. Any value above the minimum requirement

will increase running costs, therefore, reducing system efficiency.

Theoptimumsettingisachievedwhenthereissufficient,butnotexcessive,pumppressure

available.

Flow rate verification should be carried out using separate Flow Measurement Devices (FMD)

wherefitted.InlinewithCIBSE&BSRIArecommendations,werecommendthatasaminimum

requirement,FMDsareinstalledinallbranches.

Installation and Operating Instructions

Hattersley Constant Flow Regulator5

Product Title Here

2

www.cranebsu.com

H_FIG.1051_1117

IOM_200054-000R01_v1

Every effort has been made to ensure that the information contained in

this publication is accurate at the time of publishing. Crane Ltd assumes

no responsibility or liability for typographical errors or omissions or

for any misinterpretation of the information within the publication and

reserves the right to change without notice.

• Designed and manufactured under quality management

systemsinaccordancewithBSENISO9001-2008

FM311ISO9001

POBOX719,IPSWICH,IP19DU

HOMESALES:+44(0)1473277410

EXPORTSALES:+44(0)1473277450

TECHNICALHELPLINE:08456041790

FAX:+44(0)1473277411

EMAIL: [email protected]

EMAIL: [email protected]

www.hattersley.com

Table of contents

Other Hattersley Control Unit manuals

Popular Control Unit manuals by other brands

HomeMatic

HomeMatic HM-PB-2-WM Installation and operating manual

LiteOn

LiteOn WN4501L user manual

BYOC

BYOC Crown Jewel Hard Clipper instructions

PHOENIX DIGITAL

PHOENIX DIGITAL OCM-DPR-1 Installation and user manual

DeZurik

DeZurik VPB V-PORT instruction manual

A.R.I.

A.R.I. D-070-P Installation operation & maintenance