Wheel Lifting Device AirgoLift

HAWEKA - AirgoLift

Table of Contents

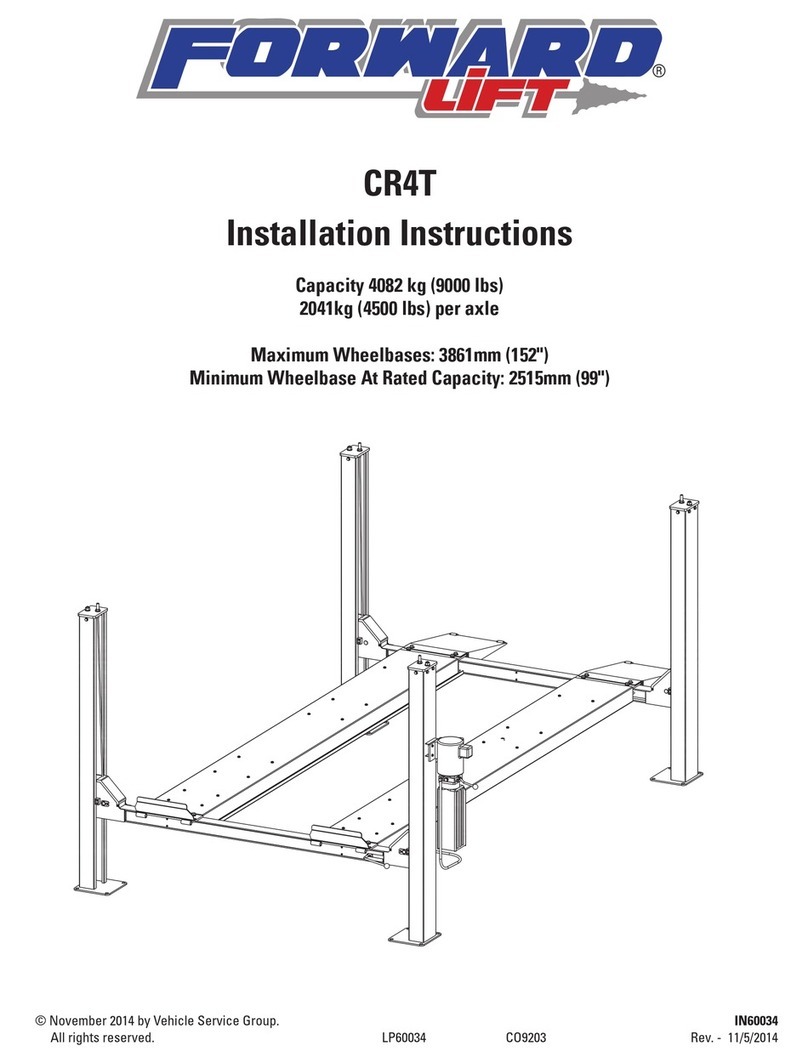

1. General Safety Instructions ..........................................................................................3

1.1 Explanation of symbols..............................................................................................3

2. Product Description ......................................................................................................4

2.1 Authorised intended use............................................................................................4

2.2 Transport weight and dimensions..............................................................................4

2.3 Technical Data...........................................................................................................5

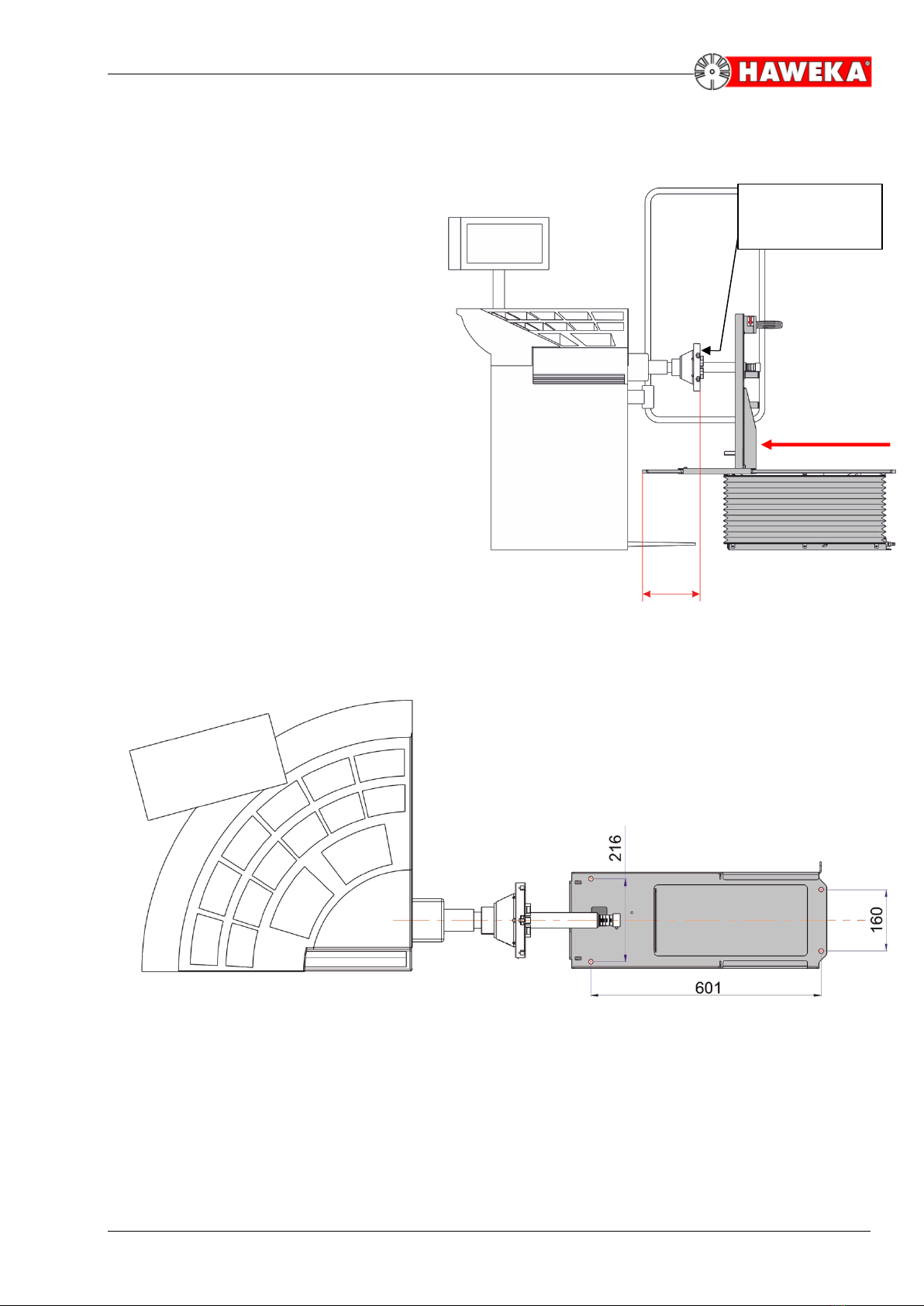

2.4 Dimensions................................................................................................................5

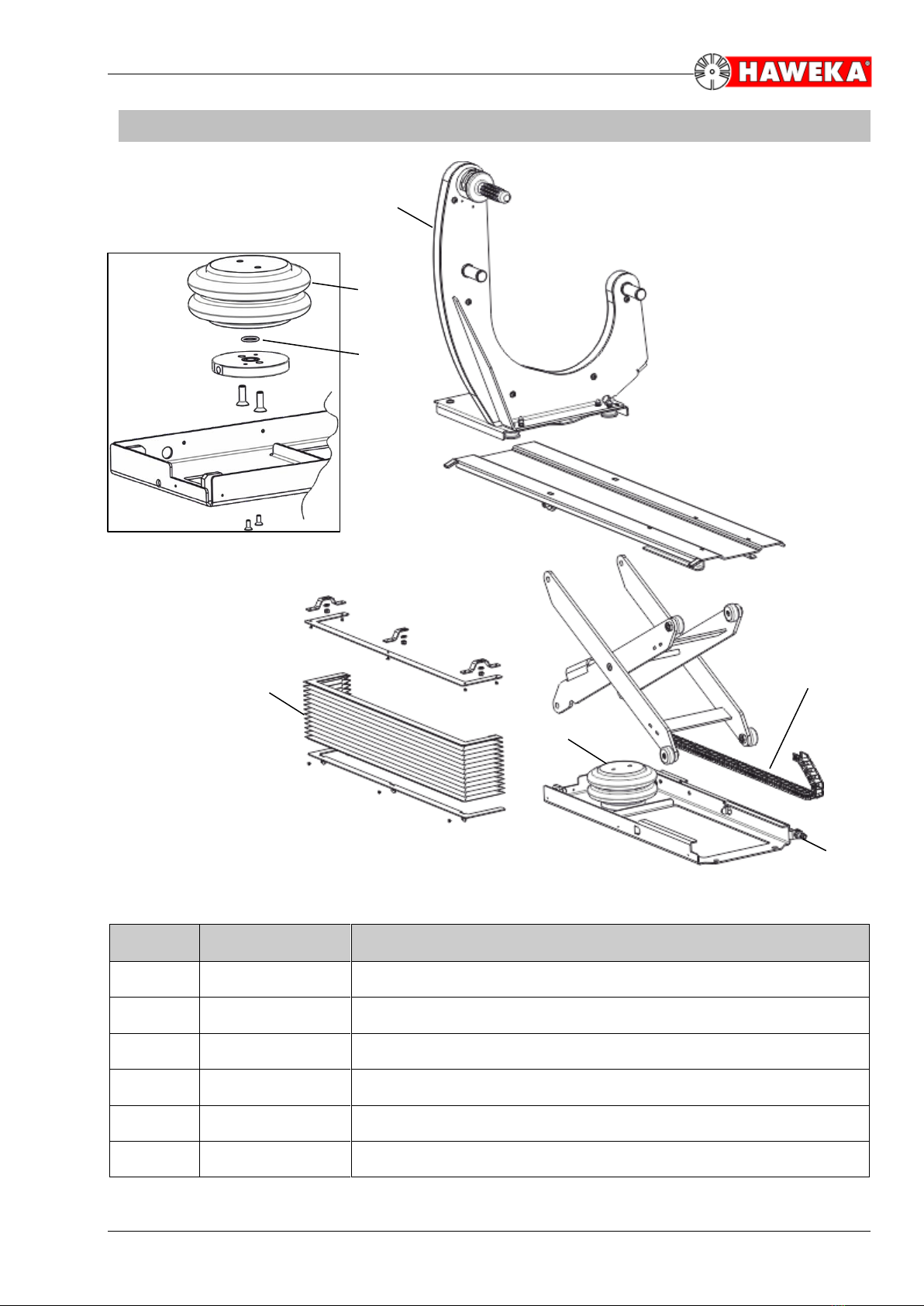

2.5 Description of device .................................................................................................6

3. Installation and Commissioning....................................................................................7

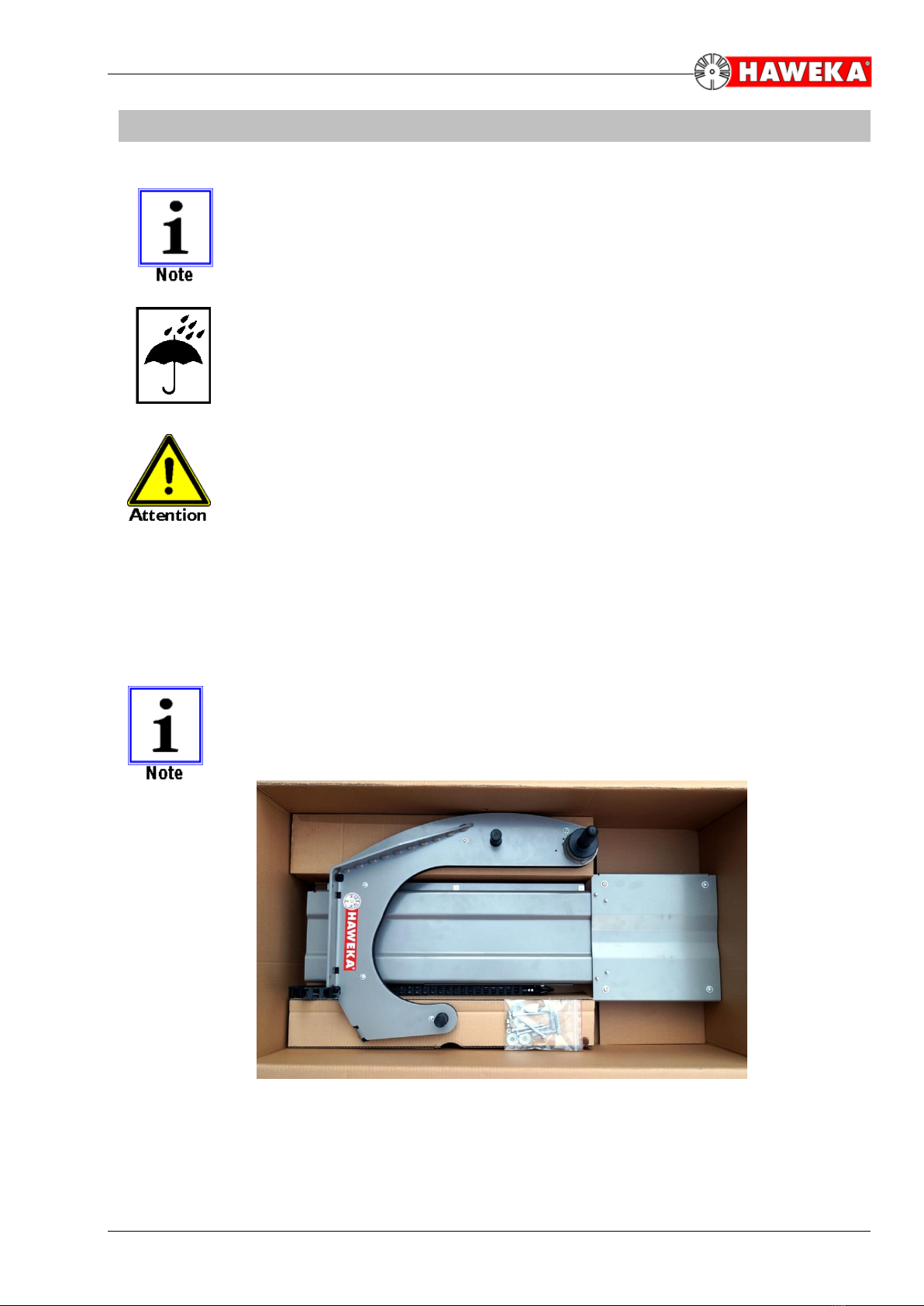

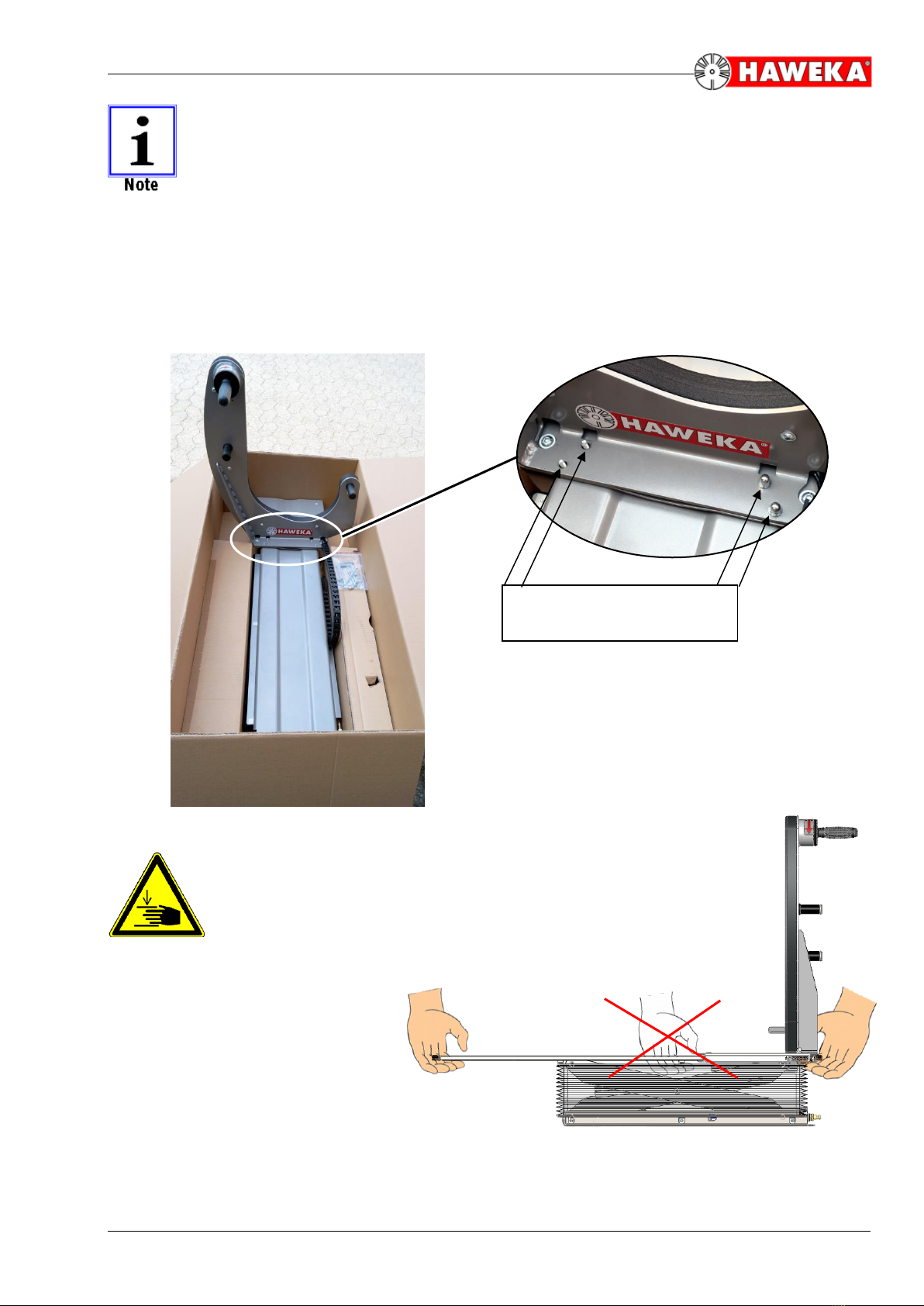

3.1 Assembly of the AirgoLifts.........................................................................................7

3.2 Function check...........................................................................................................9

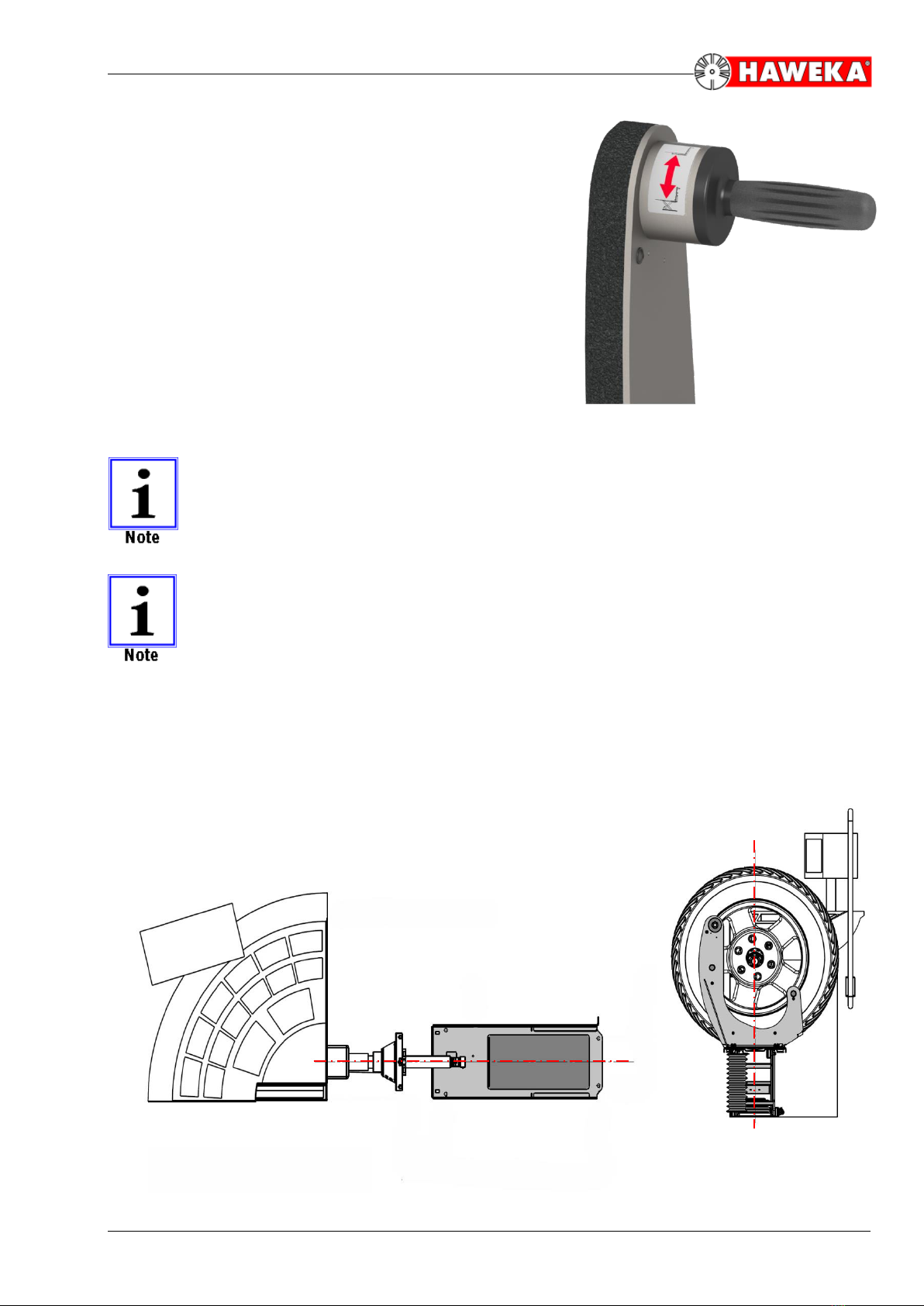

3.3 Position in front of the wheel balancer.....................................................................10

4. Application and Operation ..........................................................................................12

5. Maintenance and Care ...............................................................................................13

5.1 General Care...........................................................................................................13

5.2 Setting the Lifting Speed..........................................................................................13

6. Troubleshooting and their Causes..............................................................................14

7. Spare Parts.................................................................................................................15

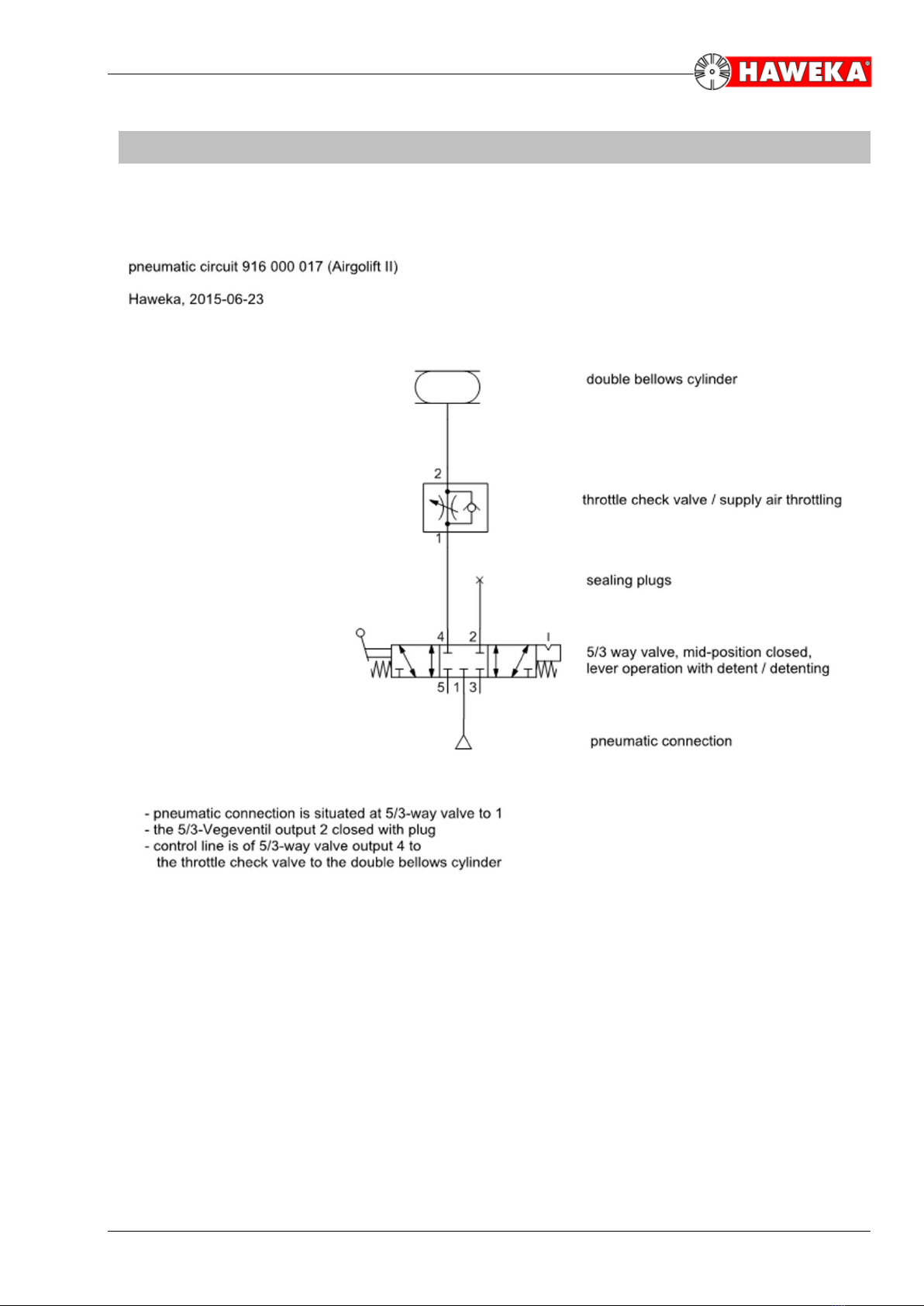

8. Pneumatic Diagram....................................................................................................17

9. EC Declaration of Conformity.....................................................................................18

Last updated: November 2019

Subject to technical modifications.

Version 2.0

Figures: HAWEKA AG / D-30938 Burgwedel

Reproduction in any form is not permitted.