HAWKHAWK

ENTERPRISESENTERPRISES

ŸNEVER allow children to play around the

AS 500.

ŸStore the AS 500 in clean, dry environment. Do

not store outdoors. Do not allow water inside

the unit’s motor. If the motor becomes wet,

allow it to thoroughly dry before use.

ŸOperate the AS 500 on a flat surface. Do not

operate where unit could fall, or on slippery

surfaces. This increases the chance of injury,

fire, or electrical shock.

ŸDo not move or carry the AS 500 while it is

operang. When operang, the powerful

airflow can cause unpredictable movement.

ŸKeep all liquids from being drawn into the

AS 500. Never operate unit without factory

installed safety inlet and outlet grills in place.

ŸDo not use the AS 500 near combusble gas,

or hot air. Units could melt and cause a fire or

electrical hazard.

ŸDo not alter or modify your AS 500 in any way.

ŸUnplug before service or changing filters.

The HAWK AS 500 HEPA Air Scrubber is a portable

filtraon system that removes airborne parcles

including mold, pet dander, dust, pollen, drywall

dust, and other miscellaneous debris as small as

0.3 microns. The AS 500 ulizes up to 3 stages of

filtraon including a pre-filter, oponal 2nd stage,

and a HEPA filter. The AS 500 will create cleaner air

in any environment. The pre-filter and second

stage filter capture larger parcles and the HEPA

filter captures smaller parcles.

ŸNever use the AS 500 near water. Prevent risk

of serious injury from electrical shock.

ŸHandle the AS 500 carefully to avoid causing

damage or injury.

ŸUse only replacement parts authorized by

Hawk Modificaons or use of unauthorized

parts could create a hazard and will void your

warranty.

ŸDo not stack more than 2 units high in order to

avoid a pping hazard – falling equipment can

cause bodily harm.

Warnings!

ŸMake sure the air intake and outlet are free

from all materials and away from obstrucons

Any restricons may cause the AS 500 to

overheat and cause a shock or fire hazard.

ŸDo not repair the AS 500 unless you are

qualified.

qualified electrician or service person. Do not

the desired speed seng.

5. Operate unit unl area is clear of unwanted

contaminates or unl filters need to be

1. Place the AS 500 upright on a level and stable

2. Remove the dust cover.

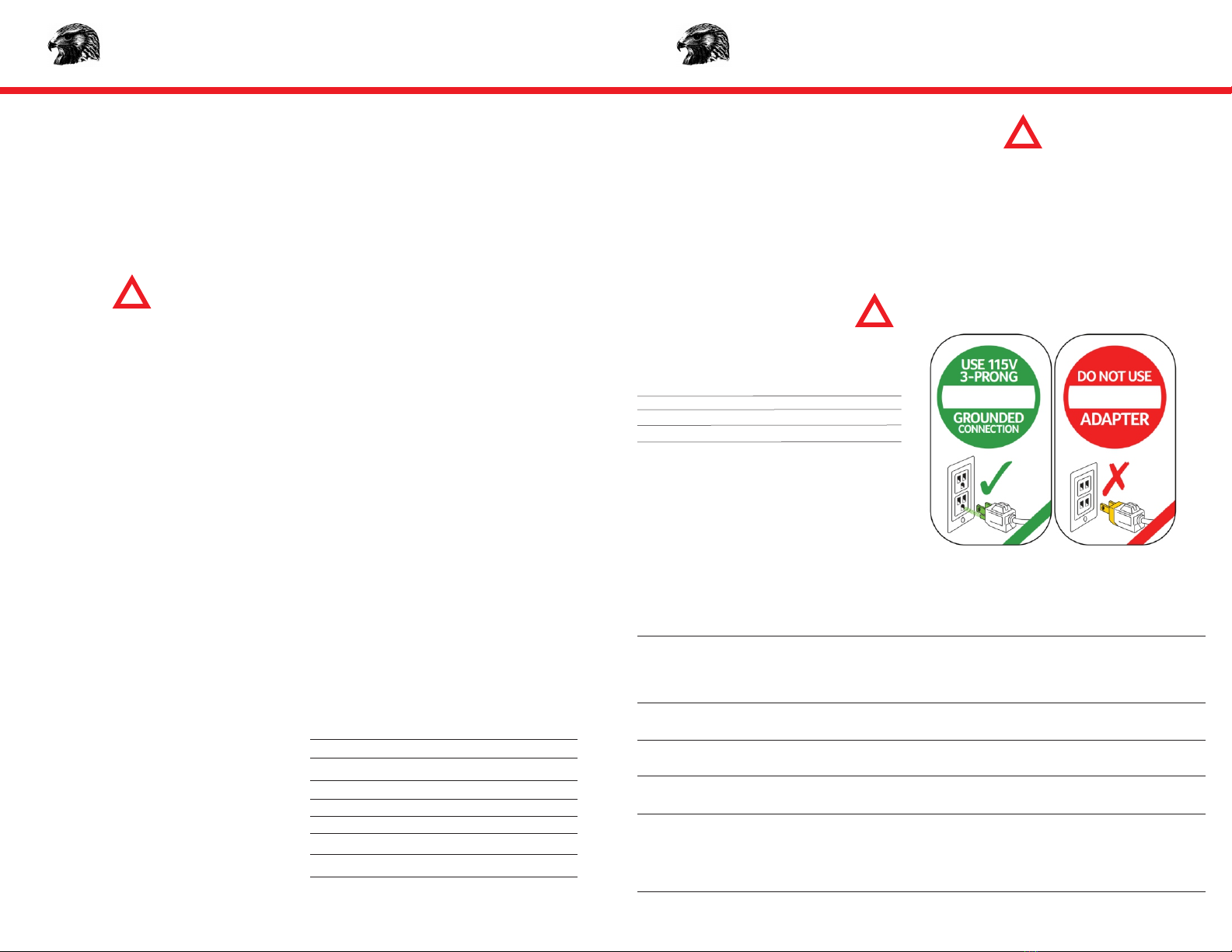

3. Plug the AS 500 into a grounded 115 volt

Operaon

grounded outlet with the correct voltage and

protected by a ground fault circuit interrupter.

amperage. For maximum protecon against

If you are unsure about the outlet, check with a

electrical shock, ALWAYS use a circuit that is

surface with the handle up.

use an adapter or extension cord.

4. To switch the unit on, locate the control panel

and turn the variable speed switch clockwise to

Pre-Filter G4

Prime-Filter H13 (Made in Germany)

light which illuminates when the HEPA filter

changing filters.

changed. The control panel has a filter change

needs to be changed. See instrucons for

Auxiliary/GFCI Outlet/Daisy Chain

You can interconnect (“daisy-chain”) up to three

AS 500 units to customize your air filtraon needs.

The GFCI will “trip” if it detects a sudden “ground

fault,” or overload and interrupt the electric

current. When the GFCI “trips,” unplug the unit

and look for potenal hazards such as standing

water, frayed cords, or anything that would cause a

dangerous electrical problem. If such a situaon

exists, plug the AS 500 into a different outlet and

then push the “reset” buon which is located

between the 2 outlets on the GFCI. If the unit will

not operate check the circuit breaker secon

below.

Power 115 Volts, 60 Hz

Current 2.5 amps

Air Flow 250-500 CFM

Unit Specificaons

Motor Rang .33 hp

Cerficaons C-ETL-US

grounded outlet

2) Open door by releasing sliding latches

Circuit Breaker Switch

Filters should be changed aer every remediaon

job and whenever the filter change indicator light

comes on. The unit should also be cleaned aer

each job to prevent cross-contaminaon.

AS 500 must be dry before installing clean filters.

1) Unplug the AS 500

outward, away from the AS 500 body.

The AS 500 is equipped with a circuit breaker

switch to protect the motor. The switch is located

directly above the GFCI outlet and cuts off power

to the unit when it detects an unsafe amount of

electricity passing through the unit. If the switch

“trips,” unplug the unit and look for potenal

hazards or anything that may be creang an

overload situaon. “Reset” breaker by pushing

buon in and connue normal operaon.

Changing Filters

Warning! Contaminated Hazard

To change filters:

3) Remove used filters and install new filters.

4) Latch door closed and plug the unit in a

Always wear NIOSH compliant protecve gear

when changing filters and dispose of used filters

according to your local regulaons.

• Circuit breaker or GFCI has tripped-push rest buon

AS 500 does not turn on • Switch not turned on. Turn on.

Troubleshoong

Problem Problem Cause / Soluon

• Excessive dirt built up on fan blade – wipe with a slightly damp cloth.

• No power to scrubber-make sure unit is plugged in; check power supply

AS 500 starts and then • Obstructed inlet/outlet – remove obstrucon

• Damaged housing/fan so fan will not spin – replace housing or fan wheel

• Faulty switch-replace

Motor makes noises but won’t • Damaged/faulty motor or motor sha – replace

shuts off • Faulty motor - replace

AS 500 vibrates • Motor sha is bent – replace motor. Fan blade is bent – replace

• Air intake restricted – remove restricon or bends/kinks inducng

turn on • Broken/loose wire to capacitor – ghten

• Motor sha set screw holding fan wheel is loose - ghten

• Damaged/faulty capacitor – replace

AS 500 change light illuminated • HEPA filter needs replacement - replace

DO NOT OPERATE MACHINE IN AN EXPLOSIVE

ENVIRONMENT!

Warning!

For the safe operaon of this machine follow the

instrucons given in this booklet and the training

provided. Failure to do so can result in personal

injury and/or damage to machine and property!

NOTE: In Canada, the use of a temporary adapter

is not permied by the Canadian Electrical Code.

HAWK ENTERPRISES 2902 Park Six Court, Elkhart, IN 46514 (574) 294-1910

www.hawkenterprises.com

HAWK ENTERPRISES 2902 Park Six Court, Elkhart, IN 46514 (574) 294-1910

www.hawkenterprises.com

HAWK AS 500 HEPA Air ScrubberHAWK AS 500 HEPA Air Scrubber

250-500 Variable CFM250-500 Variable CFM