OPERATION

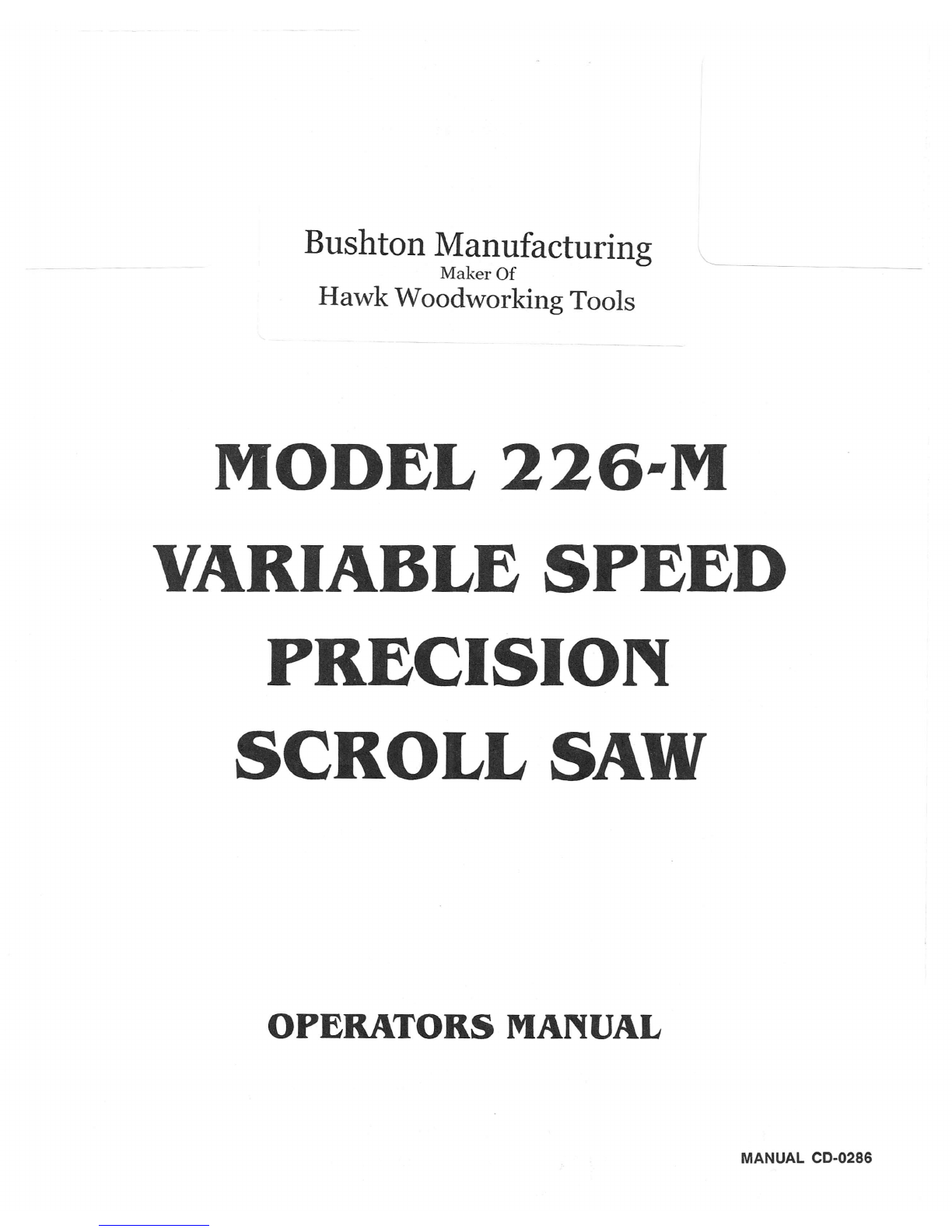

A. Blade installation in the blade holder

Place the blade holder in the oblong slot in the base

(right side of the saw base near the front.) Slide the

bottom of the blade (direction the teeth point) between

the two halves of the holder to the center screw. (Run

your finger across the teeth to determine the direction

the teeth point.) Center and secure using a 5/16 open

end wrench. (See Figure 1)

TOPVIEW SIDE VIEW

BASE

5/'6

OPEN

END WRENCH

f

TABLE

CENTER BLADE

IN HOLDER

FIGURE 1 BLADE HOLDER

1--7---

BLADE

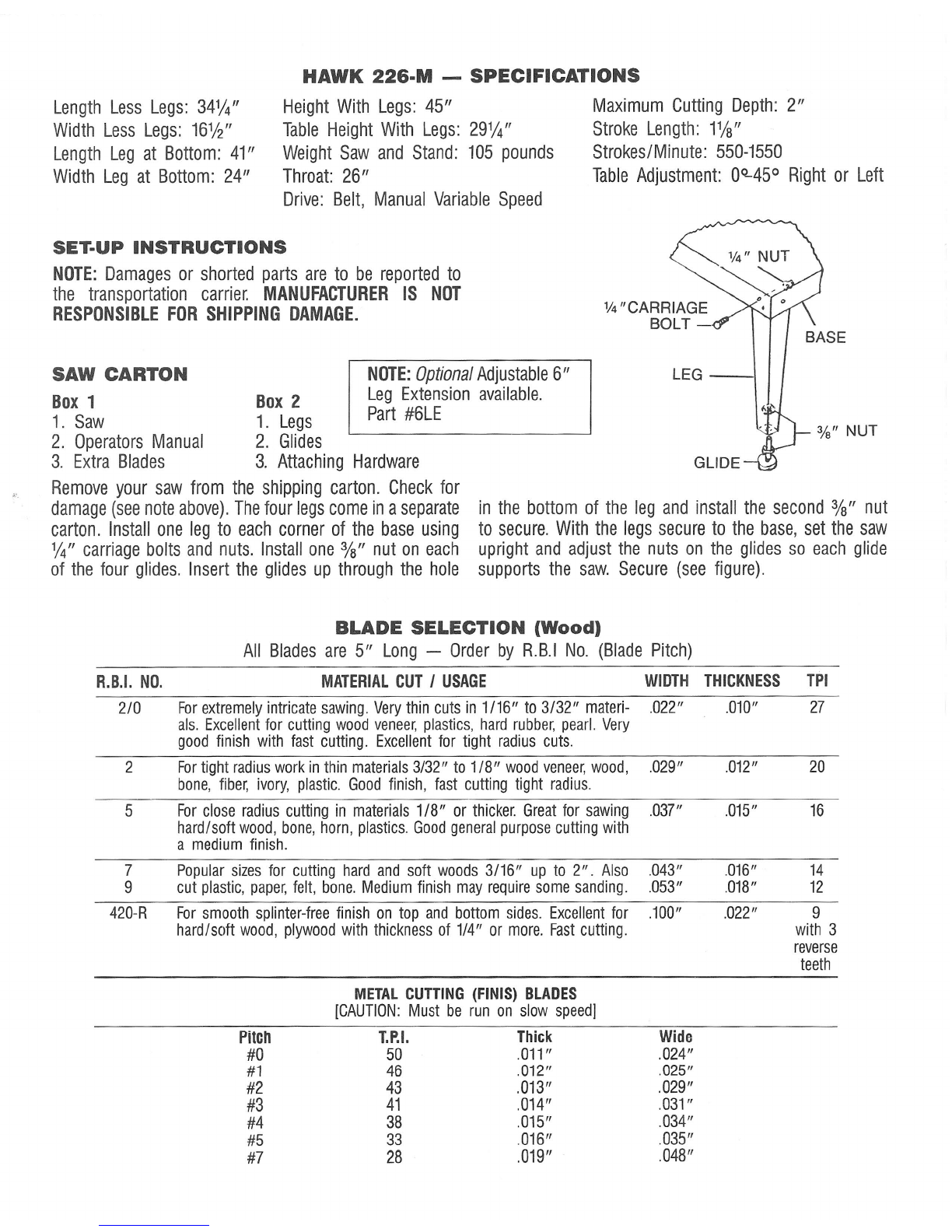

B. Blade installation in the saw (See Figure 2)

Place the quick change holder rod in the slot of the

upper arm behind the quick change blade holder. Slide

the blade up from the bottom thru the hole in the

center of the table. Pull the blade up until the holder

is at the bottom of the lower arm. Slide the blade and

holder back in the lower arm slot until the holder rests

in the V at the bottom of the lower arm between

the arm and clip.

Pull the upper arm down until the upper arm blade

holder assembly will slide over the blade (it may be

necessary to loosen the adjusting handle at the rear

of the saw to allow the upper arm to come down).

Center the blade in the blade holder and slide upward

to the screw. (See Figures 1, 2 & 3)

----------1.- QUICK CHANGE

,..--•.••••••~-. HOLDER ROD

PLACE BLADE INLINE

WITH SCREW

LOOSEN TO INSTALL BLADE FIGURE 2

Using the Allen wrench supplied, left side in the rub-

ber grommet, secure the blade at the top.

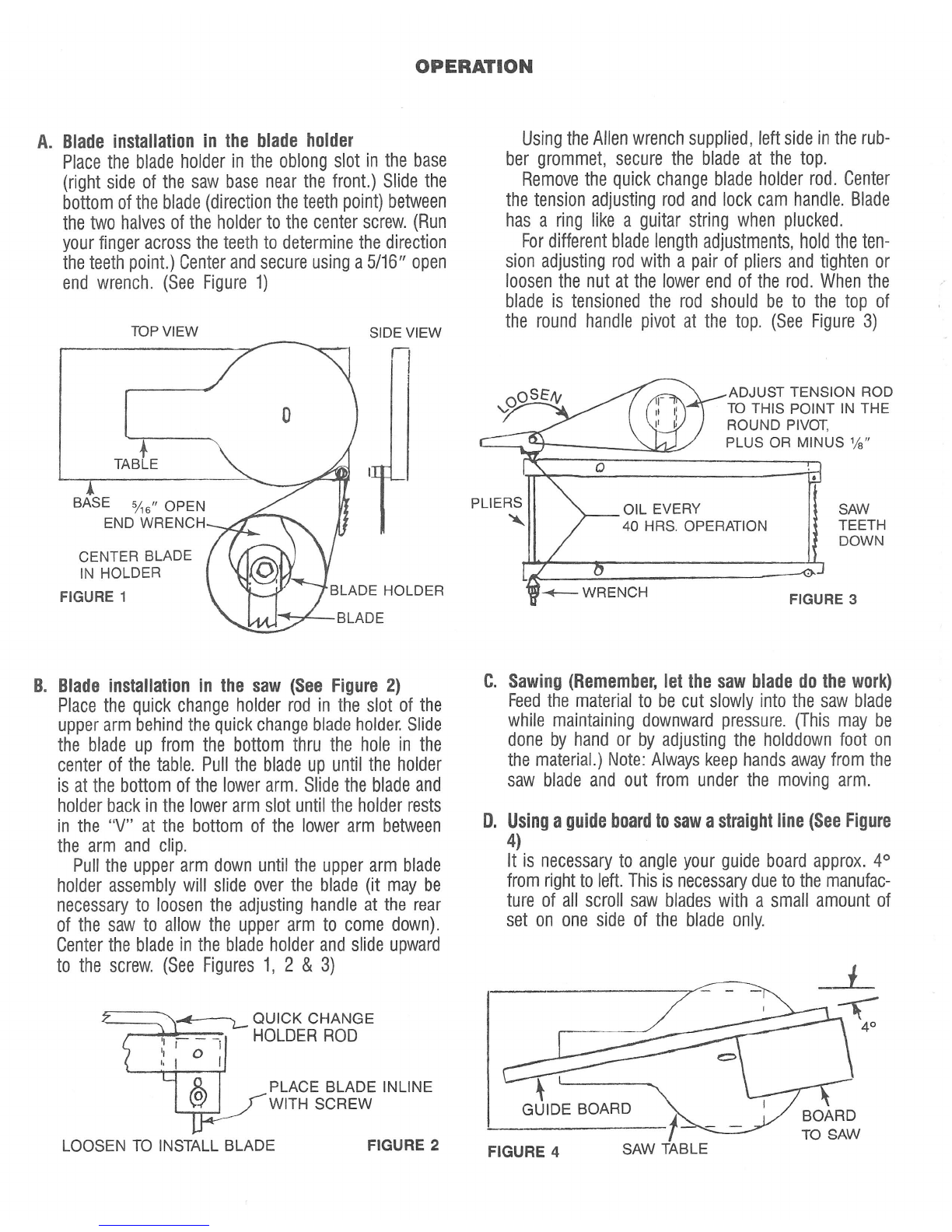

Remove the quick change blade holder rod. Center

the tension adjusting rod and lock cam handle. Blade

has a ring like a guitar string when plucked.

Fordifferent blade length adjustments, hold the ten-

sion adjusting rod with a pair of pliers and tighten or

loosen the nut at the lower end of the rod. When the

blade is tensioned the rod should be to the top of

the round handle pivot at the top. (See Figure 3)

ADJUST TENSION ROD

TO THIS POINT IN THE

ROUND PIVOT,

PLUS OR MINUS %

SAW

TEETH

DOWN

FIGURE 3

C. Sawing (Remember, let the saw blade do the work)

Feedthe material to be cut slowly into the saw blade

while maintaining downward pressure. (This may be

done by hand or by adjusting the holddown foot on

the material.) Note: Always keep hands away from the

saw blade and out from under the moving arm.

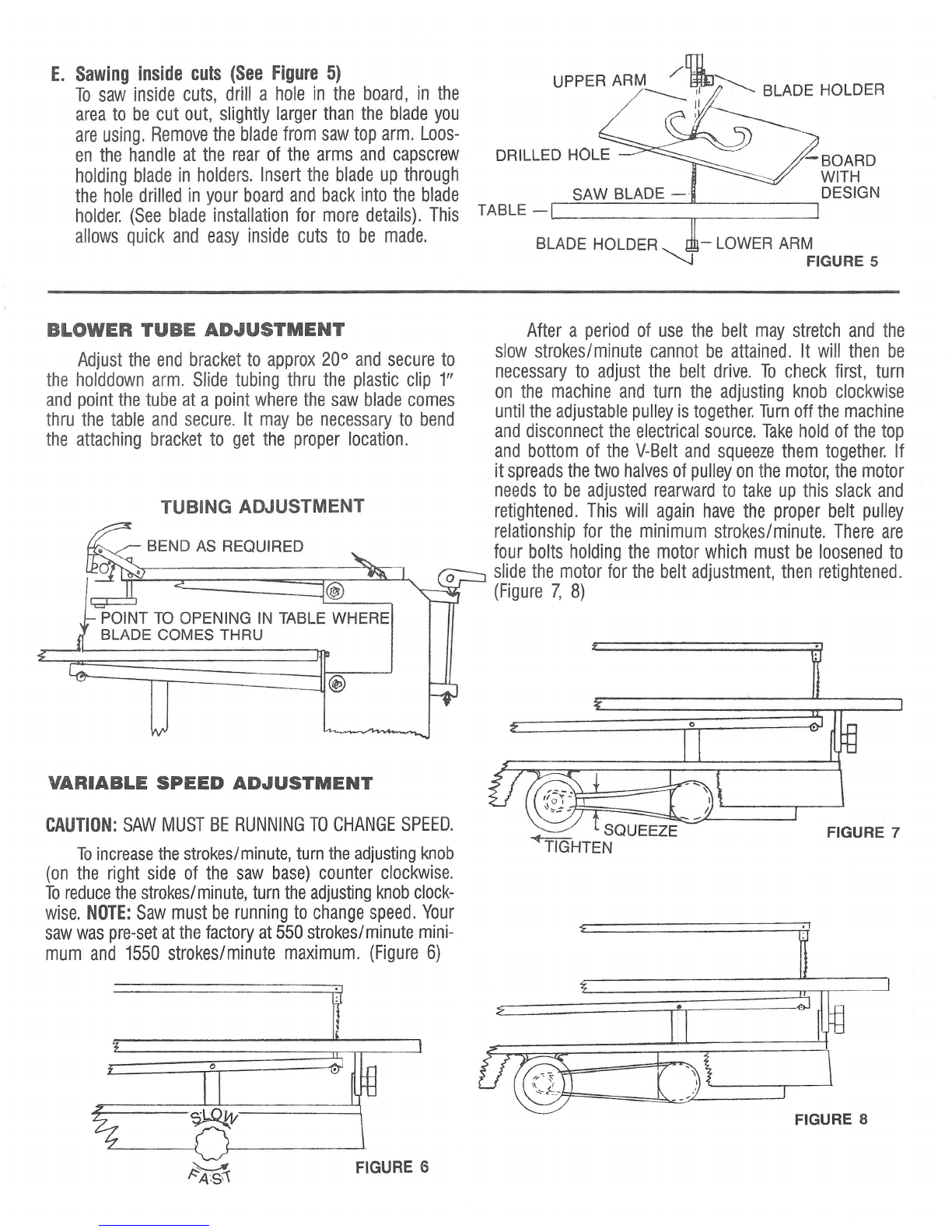

D. Using a guide board to saw a straight line (See Figure

4

It is necessary to angle your guide board approx. 4°

from right to left. This is necessary due to the manufac-

ture of all scroll saw blades with a small amount of

set on one side of the blade only.

BOARD

TO SAW

FIGURE 4