9

Improper connection of the equipment

grounding conductor can result in a risk of

electric shock. The conductor with insula-

tion having an outer surface that is green

with or without yellow stripes is the equip-

ment grounding conductor. If repair or

replacement of the electric cord or plug is

necessary, do not connect the equipment-

grounding conductor to a live terminal.

If power cord is worn or cut, or damaged

in any way, have it replaced immediately

by a qualified electrician.

If the grounding instructions are not com-

pletely understood, or if you are in doubt

as to whether the tool is properly

grounded check with a qualified electri-

cian or service personnel.

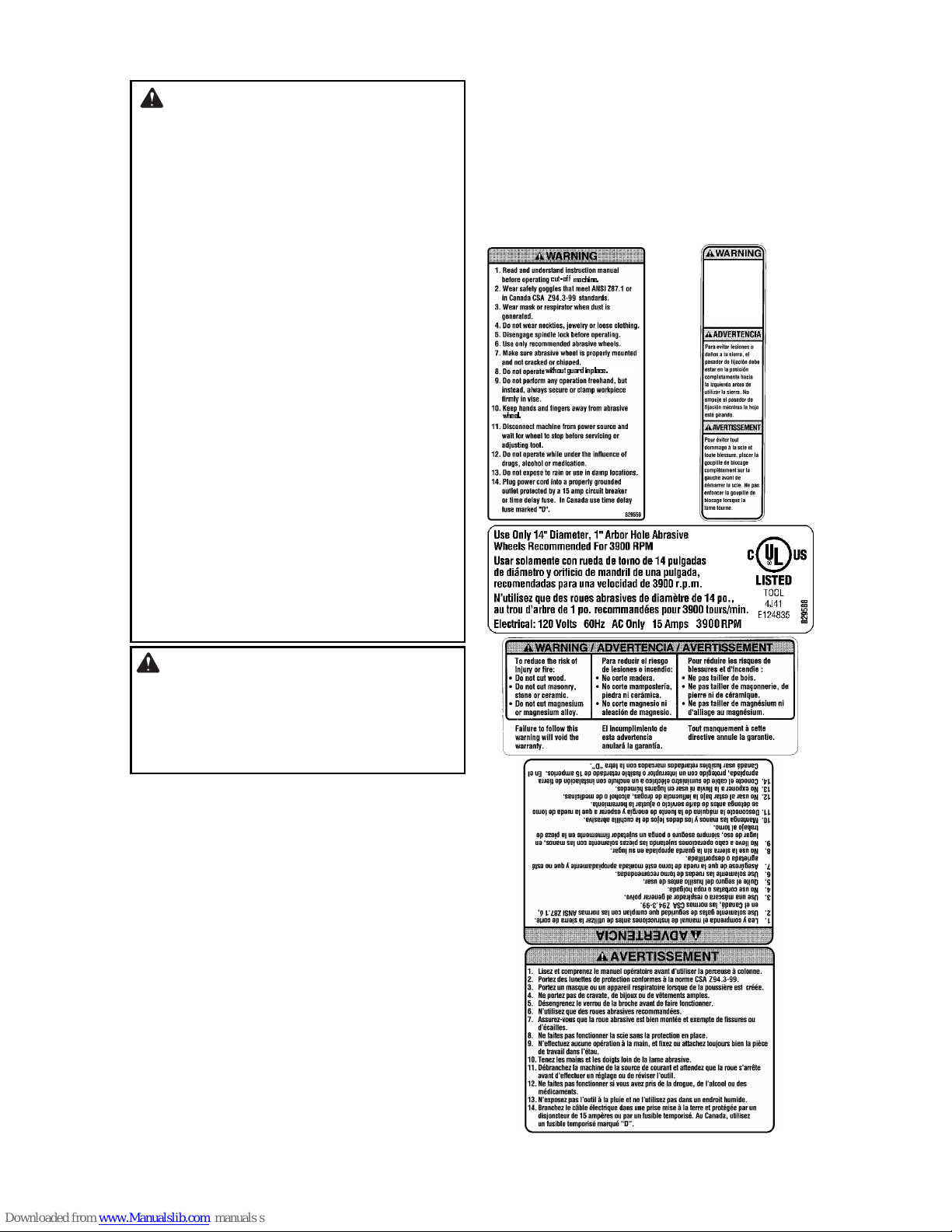

WARNING: Do not permit fin-

gers to touch the terminals of plug

when installing or removing the

plug from the outlet to avoid injury

or possible death from electrical

shock.

WARNING: If not properly

grounded, this tool can cause an

electrical shock, particularly when

used in damp locations, in proximity

to plumbing, or out of doors. If an

electrical shock occurs there is the

potential of a secondary hazard,

such as your hands contacting the

cut-off wheel.

Motor Safety Protection

IMPORTANT: To avoid motor damage,

this motor should be blown out or vacu-

umed frequently to keep dust from inter-

fering with normal motor ventilation.

1. Connect this tool to a power source

with the appropriate voltage for your

model and a 15-amp branch circuit with

a 15-amp time delay fuse or circuit

breaker. Using the wrong size fuse can

damage the motor.

2. If the motor won’t start, turn the switch

off immediately and unplug the tool.

Check the abrasive wheel to make sure

it turns freely. If the wheel is free, try to

start the motor again. If the motor still

does not start, refer to the "Motor Trou-

bleshooting Chart".

3. If the motor suddenly stalls while cut-

ting, release the trigger switch, unplug

the tool, and free the abrasive wheel

from the workpiece. The motor may

now be restarted and the cut finished.

4. Fuses may "blow" or circuit breakers may

trip frequently for the following reasons:

a. Motor Is Overloaded-Overloading can

occur if you feed too rapidly or make

too many start/stops in a short time.

b. Line voltages should not be more than

10% above or below the nameplate

voltage. For heavy loads, however, the

voltage at motor terminals must equal

the voltage specified for your model.

c. Improper or dull abrasive wheel is

used.

5. Most motor troubles may be traced to

loose or incorrect connections, overload,

low voltage (such as small size wire in

the supply circuit) or to overly long sup-

ply circuit wire. Always check the con-

nections, the load and the supply circuit

whenever motor doesn’t work well.

Check wire sizes and length with the

Wire Size Chart shown on next page.

Wire Sizes

NOTE: Make sure the proper extension

cord is used and is in good condition.

Use only 3-wire extension cords that have

3-prong grounding plugs and 3-pole

receptacles that accept the tool’s plug.

The use of any extension cord will cause

some loss of power. To keep this to a min-

imum and to prevent overheating and

motor burn-out, use the table at right to

determine the minimum wire size

(A.W.G.) extension cord.

Extension Cord

Length Gauge

(A.W.G.)

0-25

25-50

14

12