ACCESSORIES:

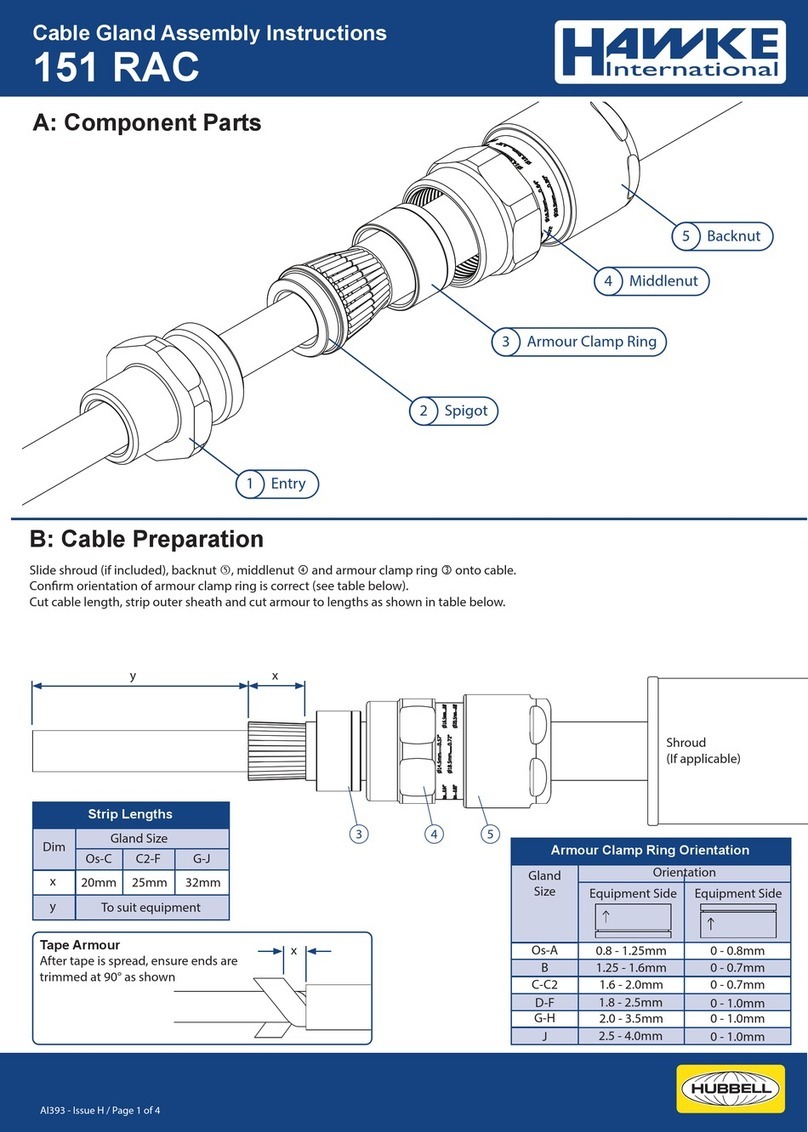

Before cable gland assembly or stripping of the cable gland

assembly, consideration should be given to any cable gland

accessories that may be required, such as: -

Shroud, to oer additional corrosion protection.

Locknut, to secure cable glands into position.

Sealing washer, to oer additional ingress protection of the

enclosure at the cable gland entry.

Earthtag, to provide an external armour/braid bonding point.

Serrated washer, to dampen any vibrations that may loosen the

locknut or cable gland assembly.

SCHEDULE OF LIMITATIONS:

1. The cable glands when used with braided cable types are only

suitable for use with xed apparatus, the cable for which must

be eectively clamped and cleated elsewhere.

2. This cable gland has an operating temperature range of -60°C

to +80°C.

3. A seal must be formed between the equipment and the cable

gland to maintain the appropriate degree of protection against

ingress of dust, solid objects and water.

AI 312 - Issue R / Page 2 of 2

EU Declaration of Conformity in accordance with European Directive 2014/34/EU

Manufacturer: Hawke International

Address: Oxford Street West, Ashton-under-Lyne, OL7 0NA, United Kingdom.

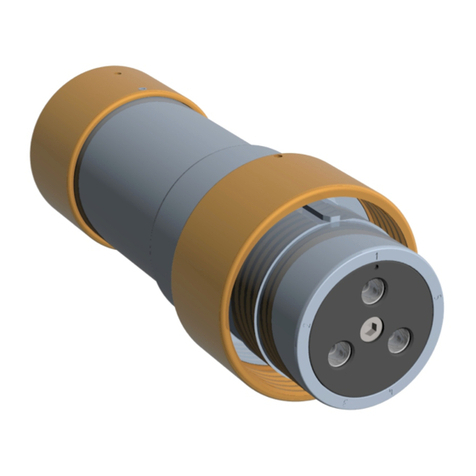

Equipment: Group II Compression Cable Glands Type: PSG 553/RAC

Provisions of the Directive fullled by the Equipment:

Group II Category 2GD Exeb IIC Gb, Exdb IIC Gb, Extb IIIC Db – IP66

Notied Body for EU-Type Examination: SGS-Baseefa 1180 Buxton UK

EU-type Examination Certicate: Baseefa06ATEX0056X

Notied Body for production: SGS-Baseefa 1180 Buxton UK

Harmonised Standards used:

EN60079-0:2012+A11:2013, EN60079-1:2014, EN60079-7:2015, EN60079-31:2014.

On behalf of the above named company, I declare that, on the date the

equipment accompanied by this declaration is placed on the market, the

equipment conforms with all technical and regulatory requirements of the above

listed directives.

………………………………….

A. Tindall

Technical Manager

F

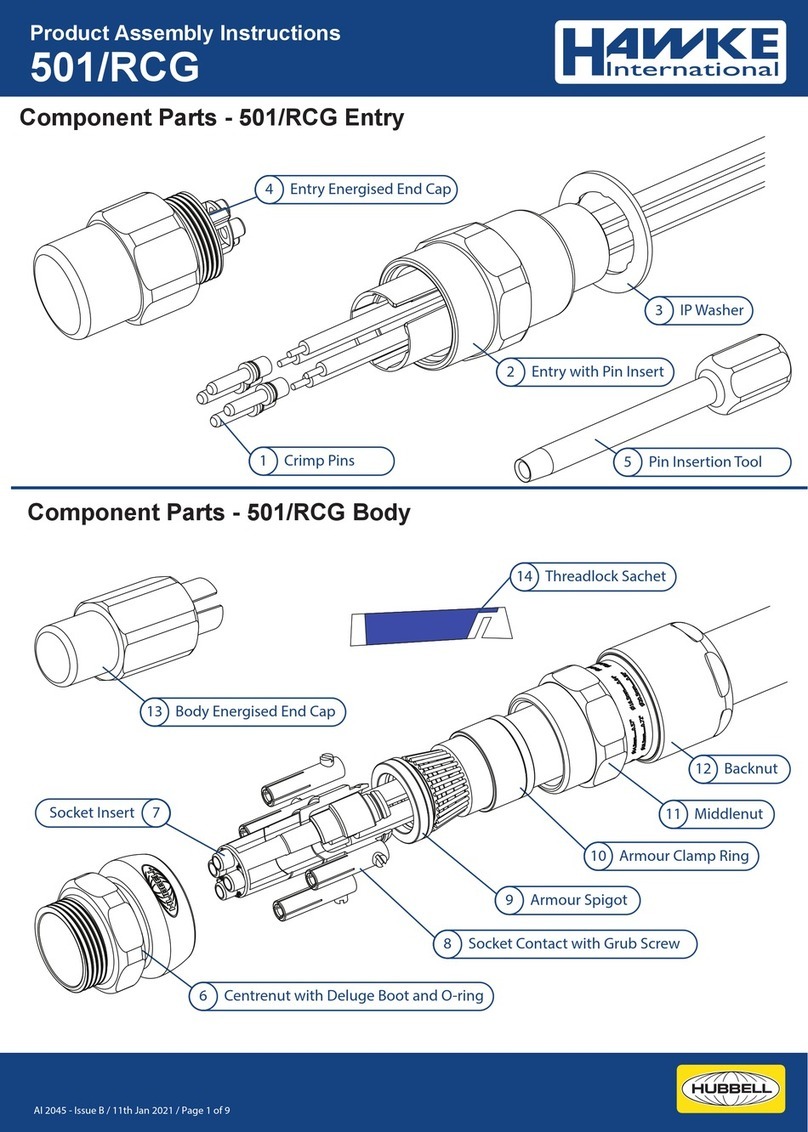

Select the correct punch tool to suit the

conductors sizes (see table) and cut out the

required number of holes in the seal

using the

indented positions as a guide. Remove the entry

and pass the individual conductors through

the appropriately sized punched holes in the seal

ensuring they are not twisted or kinked, and

slide the seal

down to the spigot

.

Replace entry

and re-assemble middle nut

onto the entry component

.

Tighten up the middle nut

until hand tight,

then using a wrench/spanner turn the nut

through a minimum of one full turn.

Hand tighten the backnut

to form a seal

around the cable, then tighten a further full turn

using a wrench/spanner. Ensure that the middle

nut

does not rotate when tightening the

backnut

. Ensure that the deluge seal is pulled

down into position, if tted.

Locate the shroud over the cable gland, if

applicable.

E

Unscrew the middle nut

and visually inspect that

the armour/braid has been successfully clamped

between the armour spigot

and the armour

clamping ring

. If armour/braid not clamped, repeat

assembly.

Note : If the equipment has a threaded entry, it may be

advisable to screw the cable gland into the equipment to

prevent twisting of the cable after Step E

D

Hold the entry

in position with a spanner/wrench to

prevent rotation. Hand tighten the middle nut

to the

entry

and turn a further ½ to ¾ of a turn with a

spanner/wrench.

IMPORTANT:Support the cable to prevent it from

twisting.

12.5

16.9

22.0

20.5

26.0

33.0

Outer Sheath

Min. Max.

0.8/1.25

1.25/1.6

1.6/2.0

0/0.8

0/0.7

0/0.7

Steel Wire Armour/

Tape/Braid

Orientation

2

Orientation

1

CABLE GLAND SELECTION TABLE

Male Entry

Thread Size

Metric

Size

Ref. NPT

Across

Flats

Across

Corners

Hexagon

Dimensions

A

B

C

M20

M25

M32

30.0

36.0

46.0

32.5

39.5

50.5

53.0

69.5

64.0

80

88

95

½" - ¾"

¾" - 1"

1" - 1¼"

Compressed

Length

Maximum

Length

CABLE GLAND SIZE FOR CONDUCTOR

Maximum No.

of Cores

A & B

7

4

3

1.5 2.5

Cores Cross Sectional Area mm²

4.0 6.0 10.0

---

------

---

---

---

---

---

A & B B & C C

B

C

B

PUNCH TOOL SIZE DETAILS

Punch Ref.

Core C.S.A. mm²

No.1 No.2 No.3

1.5 - 2.5 4.0 - 6.0 10.0

6

2

1

6

3

2

1

1

2

65

4