Hawke Power Ex User manual

Power

POWER CONNECTOR

TERMINATION / HOOK UP

PROCEDURE

(AI365 Rev 5 – 01Mar16)

Hawke International

UK Office,

Oxford Street West,

Ashton-under-Lyne,

Lancashire.

OL7 0NA. UK

Sales: +44 (0) 161 830 6698

Technical: +44 (0) 161 830 6697

Fax: +44 (0) 161 830 6648

Power Termination Procedure (AI365 Rev 5 – 01Mar16)

CP / CR PROCEDURE

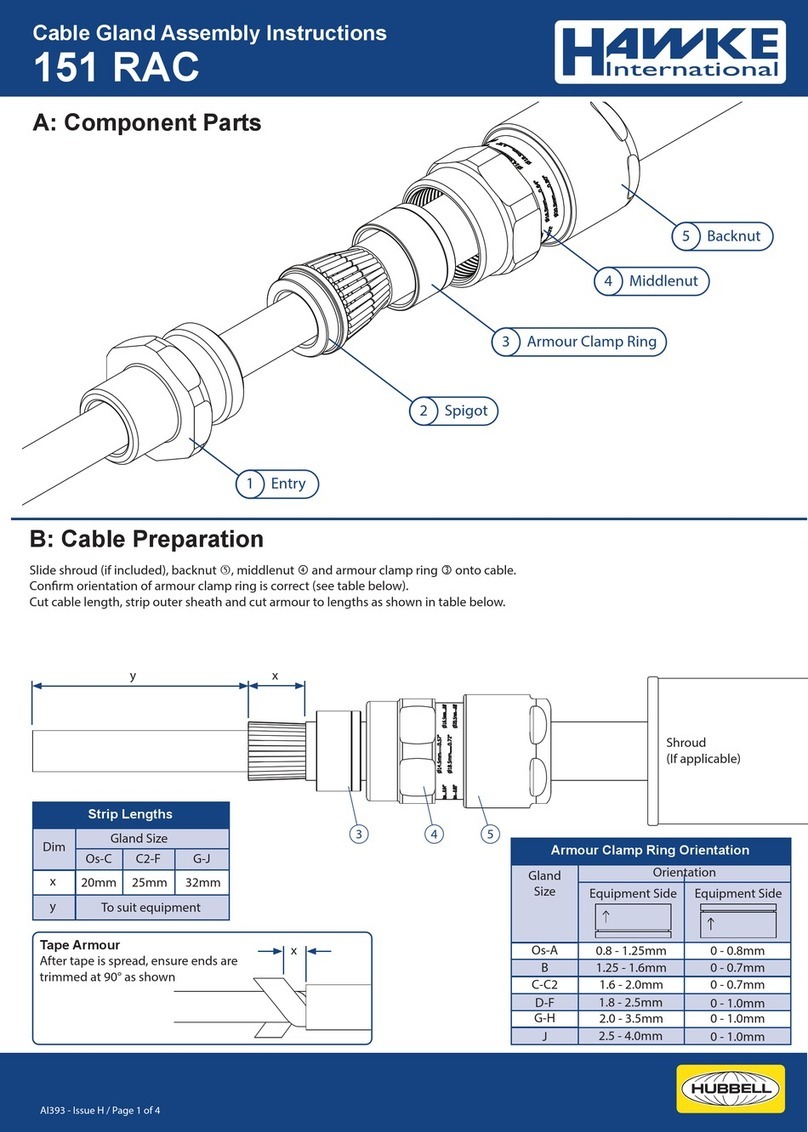

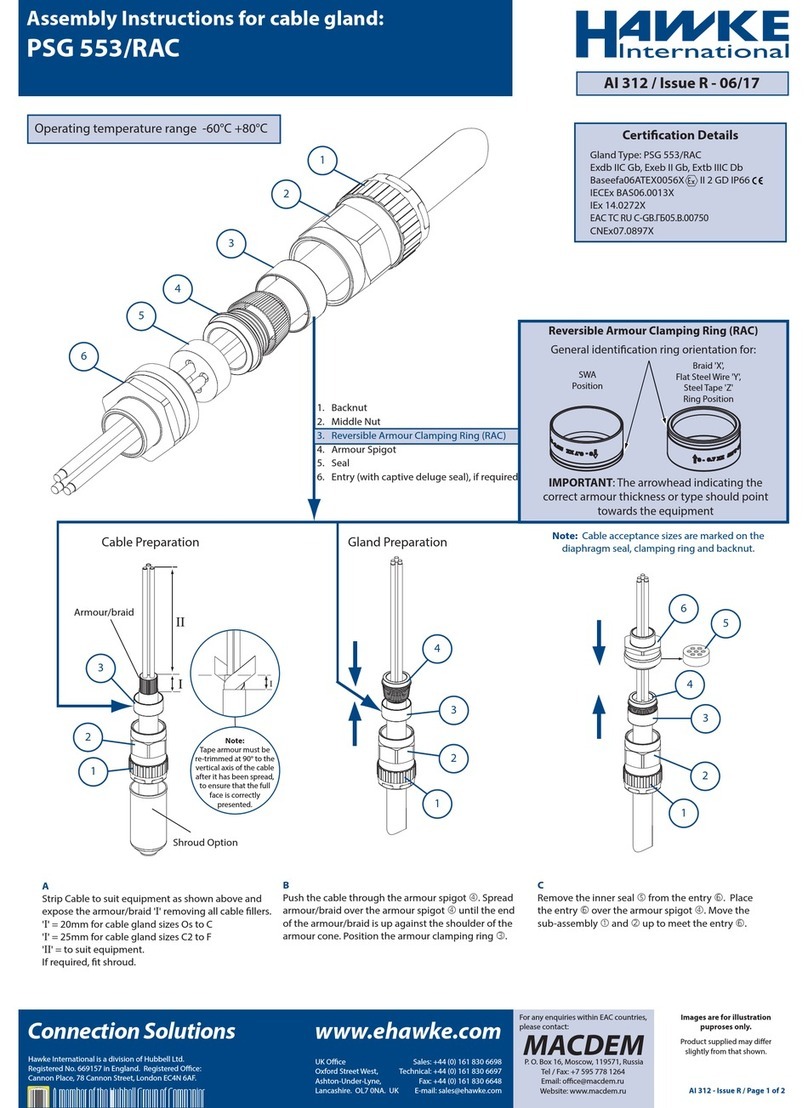

1) Terminate the cable into the Exd cable gland as per the

manufacturer’s instructions. Consider at this stage the

relative position of the phases.

2) Cut the conductors to the lengths shown.

(For earth conductors which are being terminated to the

earth ring (see step 6) but not carried through the

contact, cut back X = 100mm for all sizes, see 10 - 13)

3) Strip back the insulation as shown. (For all earth

conductors terminated via the internal earth ring, cut

back the insulation flush with the gland entry thread, see

10 - 13).

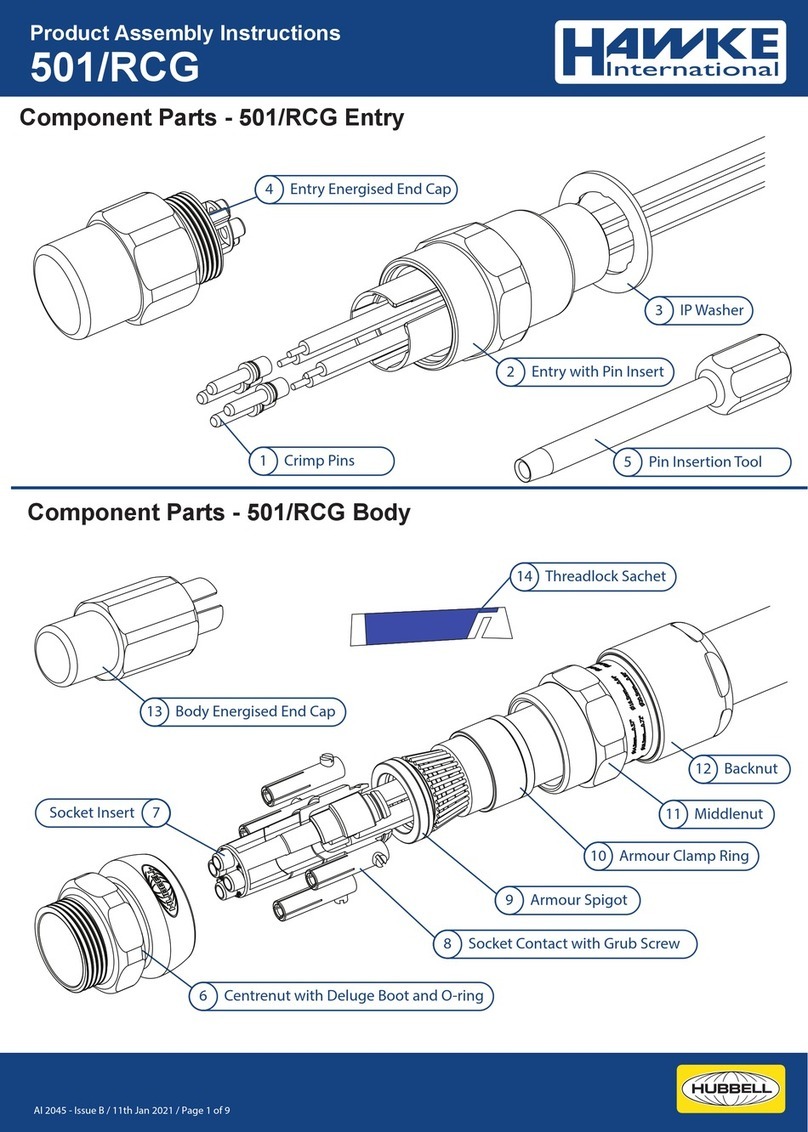

4) Unscrew the rear engaging nut from the CP / CR shell.

Remove the rear shell, spacer tube and insert from the

CP / CR shell.

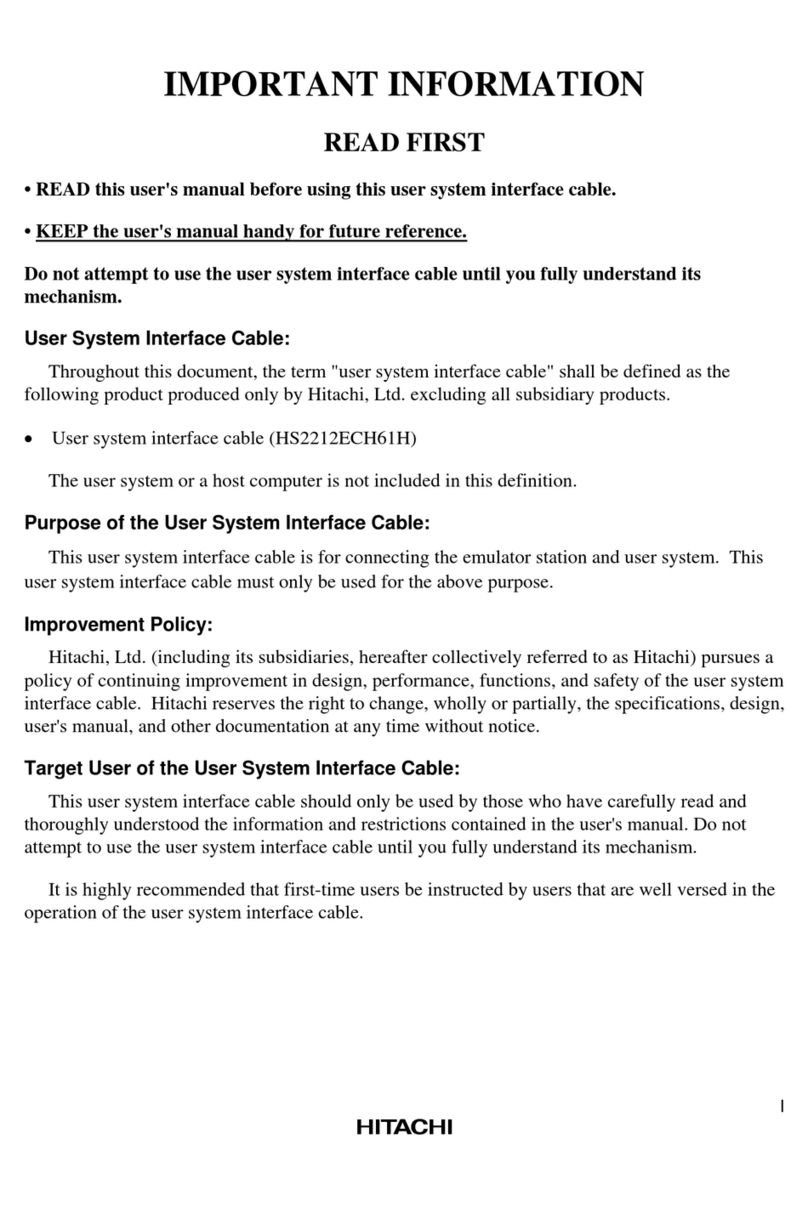

5) a) CONTACT SIZES 50 - 240mm².

Remove the screws from the front of the contacts

only and push the crimp lugs out of the insert.

b) CONTACT SIZES 300 – 630mm².

Remove the screw from the plastic housing and

remove the contact from inside.

CP / CR SHELL

INSERT

SPACER TUBE

REAR SHELL

ENGAGING NUT

REMOVE CONTACT

SCREWS

CRIMP LUGS

HOUSING SCREW

CONTACT

X mm

Y mm

CONTACT SIZE X mm (± 1.5mm)

50mm² 147

70mm² 147

95mm² 147

120mm² 146

150mm² 146

185mm² (ExP 40 & 50) 149

185mm² (ExP 75) 159

240mm² (ExP 40 & 50) 149

240mm² (ExP 75) 159

300mm² 167

400mm² 172

500mm² 188

630mm² 188

CONTACT SIZE Y mm (± 1.5mm)

50mm² 30

70mm² 30

95mm² 32

120mm² 32

150mm² 32

185mm² 40

240mm² 45

300mm² 50

400mm² 57

500mm² 62

630mm² 67

IMPORTANT NOTE

Hawke International does not recommend the use of their Power Connectors in applications where rigid PVC / SWA / PVC

power cabling (typically to BS 6346 standards) is used in portable / semi-portable applications.

In addition, Hawke recommends that barrier type glands are fitted to flexible power and loose filled control cabling entering the

connectors to maintain the Exd protection concept and to reduce the potential for core movements within the cable being

transferred to the connector’s internal components.

Power Termination Procedure (AI365 Rev 5 – 01Mar16)

6) Remove the internal earth ring from the rear shell sub

assembly by backing off the 2 grub screws on the flats. If

internal earthing is not required, the internal earth ring

assembly along with the fixing grub screws should be

discarded.

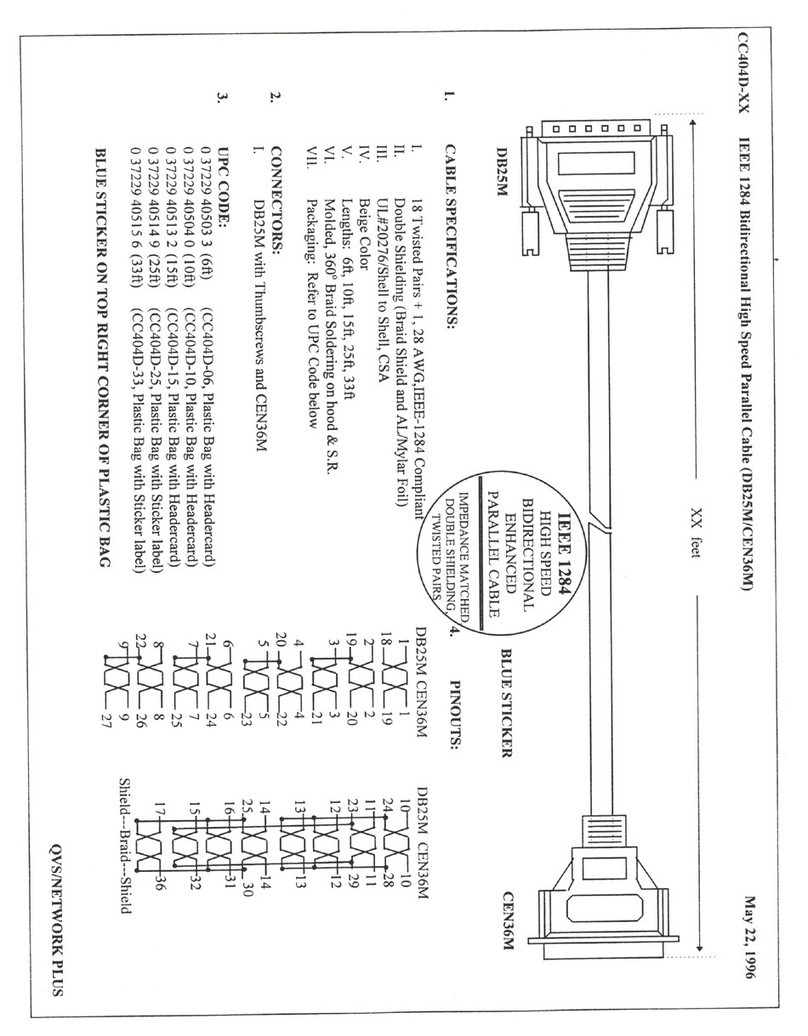

7) Crimp the lugs or contacts onto the conductors

(excluding internal earth wire if being used) using

suitable crimp tool. (Hawke recommend Elpress crimp

tools). Contact sizes of 185mm² and larger should be

adjacently double crimped as shown.

8) Feed the conductors through the rear shell assembly and

screw this onto the cable gland entry thread ensuring

the sealing washer is present.

9) Measure the distance from the front of the rear shell to

the end of the crimp lug (50 – 240mm²) or contact (300 -

630mm²). It should be as shown. If not, remove the rear

shell and add or remove the spacer washers supplied to

get the required length. At least 1 washer must be

present to maintain IP rating.

Internal earth procedure (skip to step 13 if not used or

you have single phase connector).

10) Slide the internal earth ring down over the conductors

with the lug going over the bare earth wire.

11) Position the internal earth ring inside the rear shell and

tighten the grub screws into the groove on the earth

ring. Excessive force could distort rear shell.

CRIMP HERE

REAR SHELL ASSEMBLY

1.5mm SEALING / SPACER WASHER

GRUB SCREWS

INTERNAL EARTH

RING

GRUB SCREWS

INTERNAL EARTH RING

EARTH WIRE

Z mm

CONTACT SIZE Z mm

50mm² 111 +0/-4

70mm² 111 +0/-4

95mm² 111 +0/-4

120mm² 111 +0/-4

150mm² 111 +0/-4

185mm² (ExP 40 & 50) 111 +0/-4

185mm² (ExP 75) 121 +0/-4

240mm² (ExP 40 & 50) 111 +0/-4

240mm² (ExP 75) 121 +0/-4

300mm² SKT 161 ±1

300mm² PIN 151 ±1

400mm² SKT 161 ±1

400mm² PIN 151 ±1

500mm² SKT 171 ±1

500mm² PIN 161 ±1

630mm² SKT 171 ±1

630mm² PIN 161 ±1

Power Termination Procedure (AI365 Rev 5 – 01Mar16)

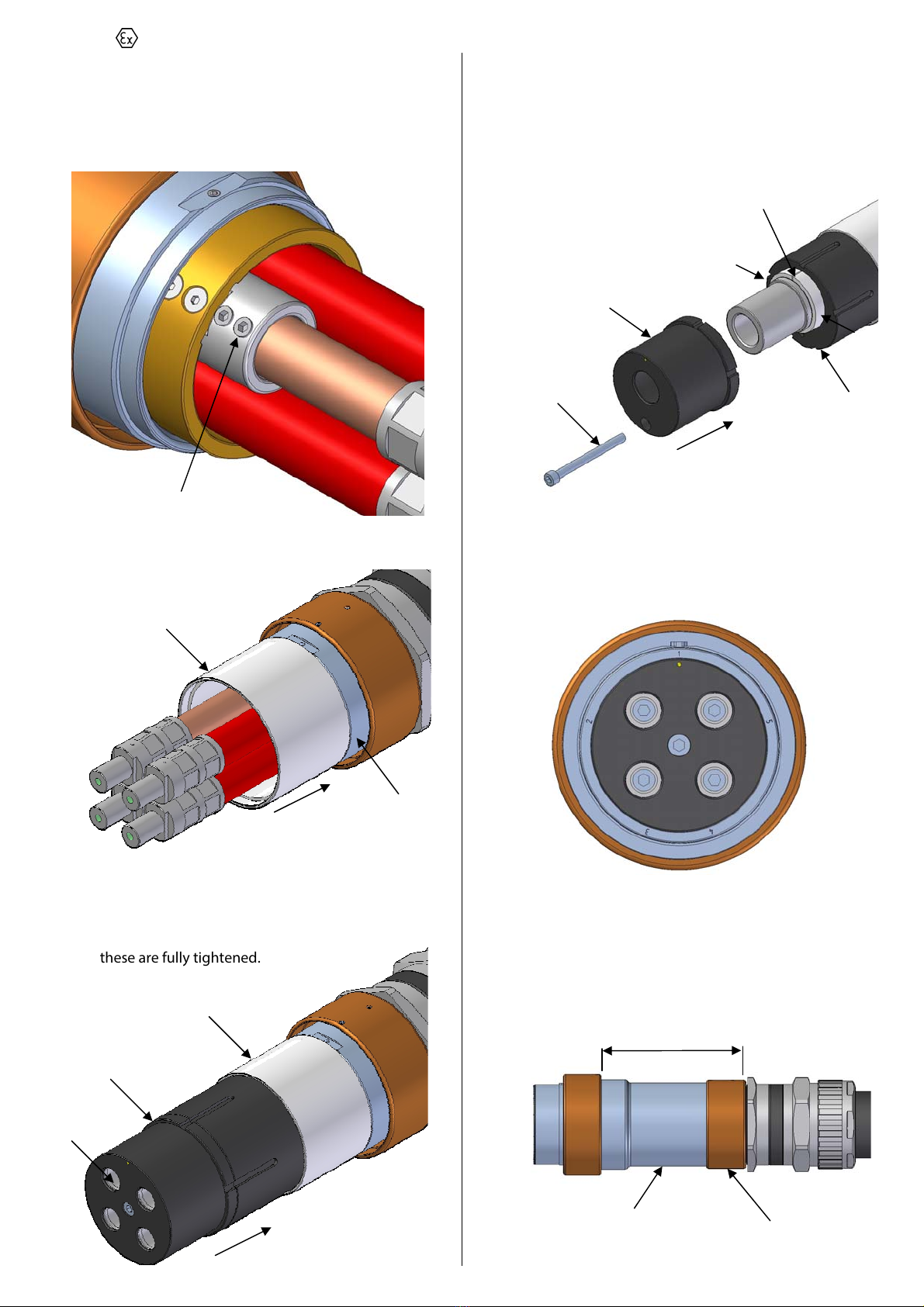

12) Tighten the 2 grub screws on the internal earth lug into

the earth conductor as tight as possible so that the earth

wire is sufficiently clamped. If earth is to be carried

through to a contact, crimp contact prior to tightening

grub screws.

13) Slide the spacer tube over the conductors and onto the

rear shell.

14) a) CONTACT SIZES 50 - 240mm².

Push the insert assembly fully onto the crimp lugs.

The insert should push inside the spacer tube. Refit

the 4 screws into the ends of the contacts. Ensure

these are fully tightened.

b) CONTACT SIZES 300 – 630mm².

Push the rear retainer over the contact. Place the

split tube around the contact. Slide the front contact

retainer over the contact and split tube. Slide the

rear contact retainer over the rear of the contact and

tighten the screw fully.

15) Slide the CP / CR shell over the insert and line the yellow

dot on the insert up with the required keying position 1

to 5 marked on the CP / CR shell.

16) Screw the rear engaging nut fully onto the CP / CR shell.

Measure the distance between the front of the rear

engaging nut to the back of the engaging nut which

should be no greater than the distance shown.

GRUB SCREWS

SPACER TUBE

REAR SHELL

SPACER TUBE

INSERT ASSEMBLY

REFIT SCREWS

REAR RETAINER

FRONT RETAINER

SPLIT TUBE

SCREW

Should be tight fit, Dictated by

spacer washers from step 9.

REAR ENGAGING NUT

CP / CR SHELL

Ex32P

–

Ex63P = 154.5mm

Ex75P = 164.5mm

Power Termination Procedure (AI365 Rev 5 – 01Mar16)

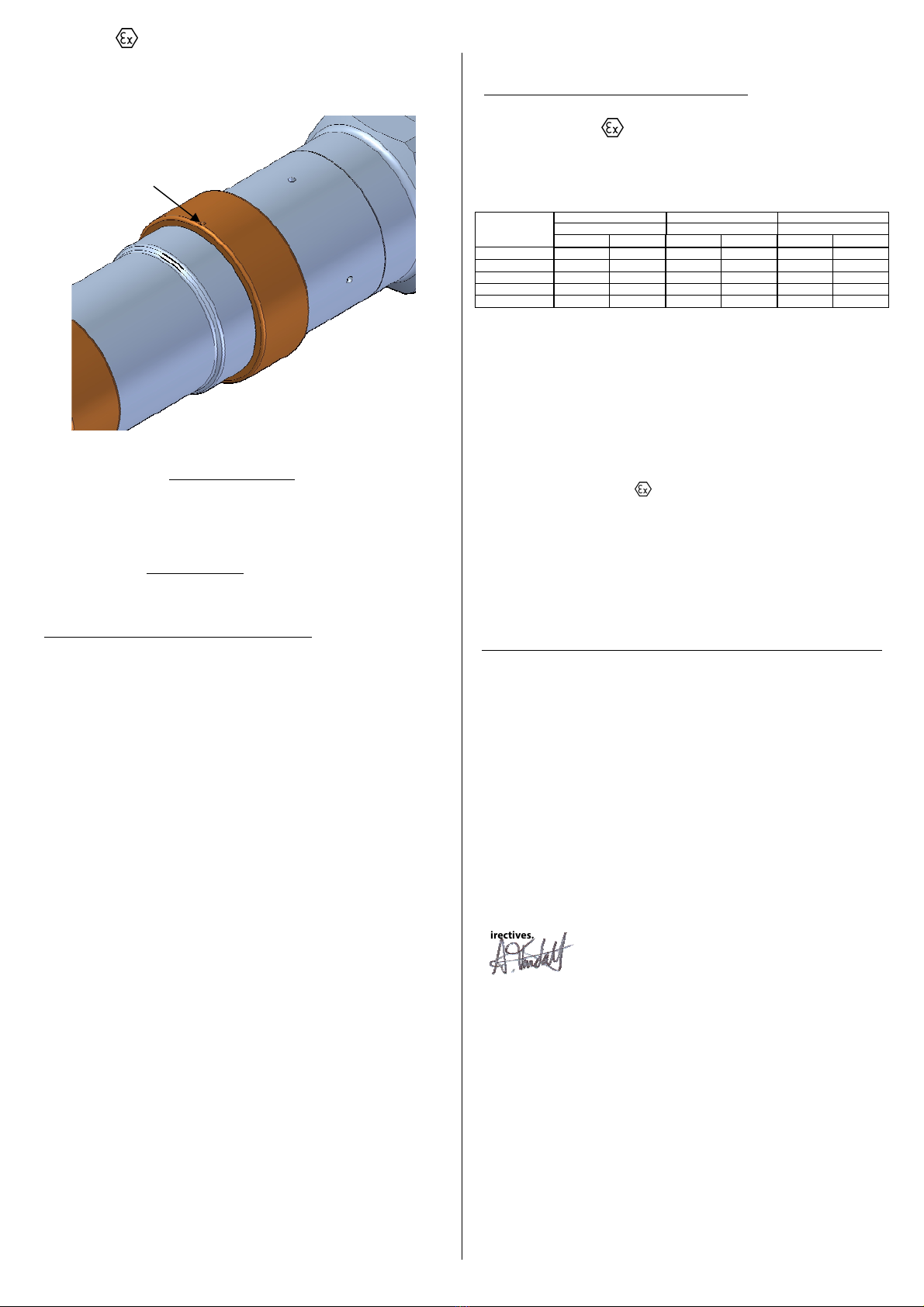

17) Tighten down the 2 grub screws on the rear engaging

nut.

18) Terminate the equipotential external earth to the ring

terminal crimp provided if applicable. Remove the

button head screw, spring washer and crimp from the

rear engaging nut. Crimp the external earth wire into the

crimp and reassemble.

19) Refit the protective or flameproof cap if applicable.

20) The connector is now ready for installation. Please refer

to the hook up procedure.

HOOK UP PROCEDURE

Before commencing hook up, a visual inspection should be

carried out on the cable / gland / connector assembly. The

assembly should be checked to ensure that all of the

assembly components are tight. If the assembly components

have loosened during transportation / cable installation, they

should be retightened in accordance with the relevant

assembly instruction sheets without twisting the cable in the

cable gland / connector assembly. No hazardous gases

should be present.

1) Turn off the power to the connectors.

2) Ensure the connectors are both set to the same keying

position number, are of the same insert type and phase

orientation.

3) Engage the CP connector with the BR / CR connector and

align the key on the CP connector to the keyway on the

BR / CR connector.

4) Engage the two connectors by screwing the engaging

nut clockwise onto the BR/CR shell. If the engaging nut

will not screw on more than half a turn, then the

connectors are set to different keying positions.

GRUB SCREWS

EARTH

CAP

KEYING POSITION INDICATORS

CP KEY

BR / CR KEYWAY

ENGAGING NUT SHOULD COVER BR / CR

SHELL THREAD WHEN FULLY MATED

Power Termination Procedure (AI365 Rev 5 – 01Mar16)

5) Fully tighten the engaging nut with strap wrench if

necessary and then tighten the grub screw on the

engaging nut.

6) To disconnect, turn off the power (no hazardous gases

should be present), slacken the tightened grub screw,

turn the engaging nut anti-clockwise and remove the

connector. If power is to be put through the connectors

whilst demated, then a flameproof cap (available

separately) must be fitted.

SCHEDULE OF LIMITATIONS

These connectors must be electrically isolated before

any attempt is made to remove the covers or join or

separate the two halves.

When separated the metal flameproof caps (not the

acetal environmental caps) shall be fitted and locked

before any associated supply cables are re-energised.

The cable entry devices selected for use with the in-line

connectors shall provide a mechanical cable retention

facility appropriate to the cable type and conditions of

service.

When used in dust environments the cable entry threads

shall be sealed in accordance with the installation code

of practice to ensure that an ingress protection level of

IP6X is maintained.

Flameproof joints are not intended to be repaired.

TECHNICAL SPECIFICATION

All Hawke Power connectors have a maximum

working voltage of 750VAC.

Other voltage ratings available on special request.

CONNECTOR

SIZE

UPPER AMBIENT = 40°C UPPER AMBIENT = 50°C UPPER AMBIENT = 60°C

TEMP CLASS TEMP CLASS TEMP CLASS

T6 T5 T6 T5 T6 T5

32 20.5W 27.5W 15.75W 26W 7.5W 15.75W

40 22.5W 30.5W 17.5W 28W 8.7W 17.5W

50 25.8W 35.3W 20W 32.25W 10W 20W

63 30.2W 41.5W 23.5W 37.7W 11.7W 23.5W

75 36.3W 49.5W 28.25W 45.25W 14W 28.25W

For determination of maximum current ratings please

refer to catalogue.

Do not exceed maximum dissipated wattage.

No maintenance or servicing is required on this product.

Certification: II2GD Exdb IIC T* Gb, Extb IIIC T85°C Db

Exd IIB+H2T* Gb, Extb IIIC T**°C Db

Tamb: -40°C to +60°C

Baseefa06ATEX0062X IECEx BAS06.0019X CSA 2633583

Inmetro IEx 14.0218X EAC RU C-GB.ГБ05.B.00750

IP Rating: IP66 / 67 (IP68 on request)

Deluge Rating: DTS01

EC Declaration of Conformity in accordance with European Directive 94/9/EC

(until 19th April 2016) and

EU Declaration of Conformity in accordance with European Directive 2014/34/EU

(from 20th April 2016)

Manufacturer: Hawke International

Address: Oxford Street West, Ashton-under-Lyne, OL7 0NA, United Kingdom

Equipment Type: Range of Connectors: PowerEx Ex 32 to Ex 75

Provisions of the Directive fulfilled by the Equipment:

Group II Category 2GD Exdb IIC Gb, Extb IIIC Db – IP66

Notified Body for EC-Type Examination: SGS-Baseefa 1180 Buxton UK

EC-type Examination Certificate: Baseefa06TEX0061X

Notified Body for production: SGS-Baseefa 1180 Buxton UK

Harmonised Standards used:

EN 60079-0:2012, EN60079-1:2014, EN60079-31:2014

On behalf of the above named company, I declare that, on the date the equipment

accompanied by this declaration is placed on the market, the equipment

conforms with all technical and regulatory requirements of the above listed

directives.

………………………………….

A. Tindall

Technical Manager

GRUB SCREW

Table of contents

Other Hawke Cables And Connectors manuals