HB-THERM T24629-X User manual

Temperatur Control Technology

www.hb-therm.ch

M8086-EN 2020-02 1/6

2020-02

Page

Assembly Instructions

M8086-EN

Spare part Sonic transducer (O/ID T24629-X, T26326-X, T25242-X,

T25865-X)

Purpose

Replacement of Sonic transducer (BB 1, BB 2)

Precondition

WARNING!

Danger for unauthorized persons!

Conversion work may only be carried out by

specialist staff who have been trained accordingly.

Therefore:

–Keep unauthorized persons away from the work

area.

NOTE!

Knowledge of the Instruction Manual is a

precondition for carrying out conversion work on

the unit.

Procedure

DANGER!

Danger to life caused by electric current!

Touching conductive parts causes a direct danger

to life.

Therefore:

–For all work on the electrical system, for

maintenance, cleaning or repair work,

disconnect from the mains or disconnect all

phases of the external power supply and secure

them against being switched on again. Check

unit is isolated from power supply.

WARNING!

Danger of crushing due to rolling away or

tipping

With an uneven floor or when the castors are not

locked, there is a danger that the unit tips over or

rolls away causing crushing.

Therefore:

–Only install the unit on an even floor.

–Ensure that the castors are locked.

Assembly Instructions M8086-EN

M8086-EN 2020-02 2/6

1. Proceed as follows in order to cool down the unit and empty

the mould (mould evacuation):

Display menu page Functions.

Select the function Cooling and activate with the key.

If the function Mould evacuation is available, select it and

activate it with the key.

The activated function is indicated with the symbol.

Units HB-100X_4 and HB-100/140/160Z_4 without function

Mould evacuation: Loosen the drain connection (G) slowly until

the unit is depressurized.

2. Main switch off, remove the plug from the mains and empty

the unit.

3. Remove the cover from the unit (see Instruction Manual

Chapter Maintenance).

4. Loosen the screws in the front panel and hinge it down.

Assembly Instructions M8086-EN

M8086-EN 2020-02 3/6

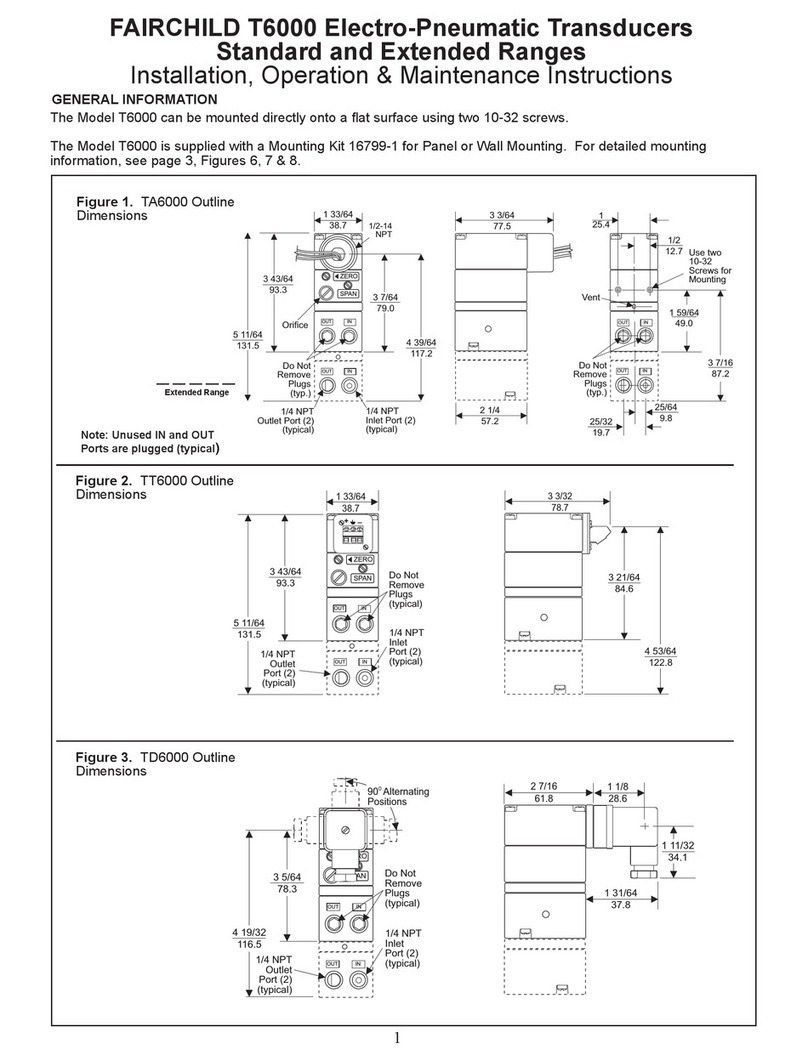

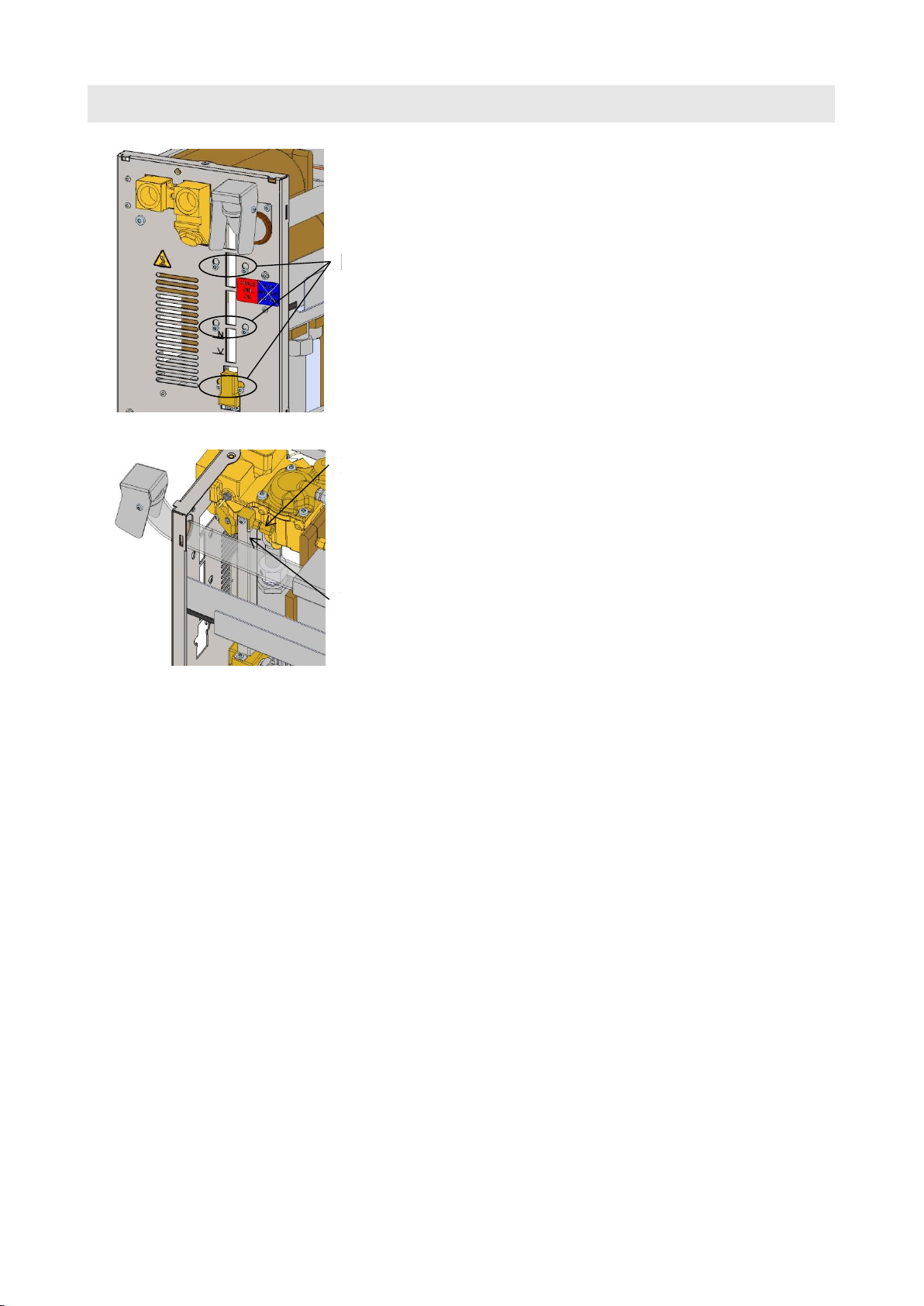

Fig. 1: Removing level indicator

Fig. 2: Pulling out level indicator

Only on T25865-1 and replacement sonic transducer BB 1

5. To enable accessibility to the transducer (BB 1), the level

indicator (10) must be removed. Proceed as follows:

Undo screws on pipe (Label 1 Fig. 2).

Remove 6x screws (Label 2 Fig. 1).

Pull out level indicator (Label 3 Fig. 2) so that accessibility to

the transducer (BB 1) is ensured.

6. Proceed as follows in order to remove the sound transducer

(BB 1, BB 2):

Remove the screws and mounting plate of the sound

transducer.

Remove sound transducer.

Remove O-ring.

Unplug cable of the sound transducer (BB 1, BB 2) on slot

X 53.1 or X 53.2.

7. Proceed as follows to assemble the new sound transducer

(BB 1, BB 2)

Clean installation space of sound transducer, especially groove

for O-ring.

Insert the new O-ring in the groove.

Fit the sound transducer with the mounting plate and screws

carefully.

Transfer the cable labelling of the old sound transducer to the

new sound transducer.

Insert the sound transducer into the corresponding slot at the

X 53.1 or X 53.2.

0

0

2

1

3

Assembly Instructions M8086-EN

M8086-EN 2020-02 4/6

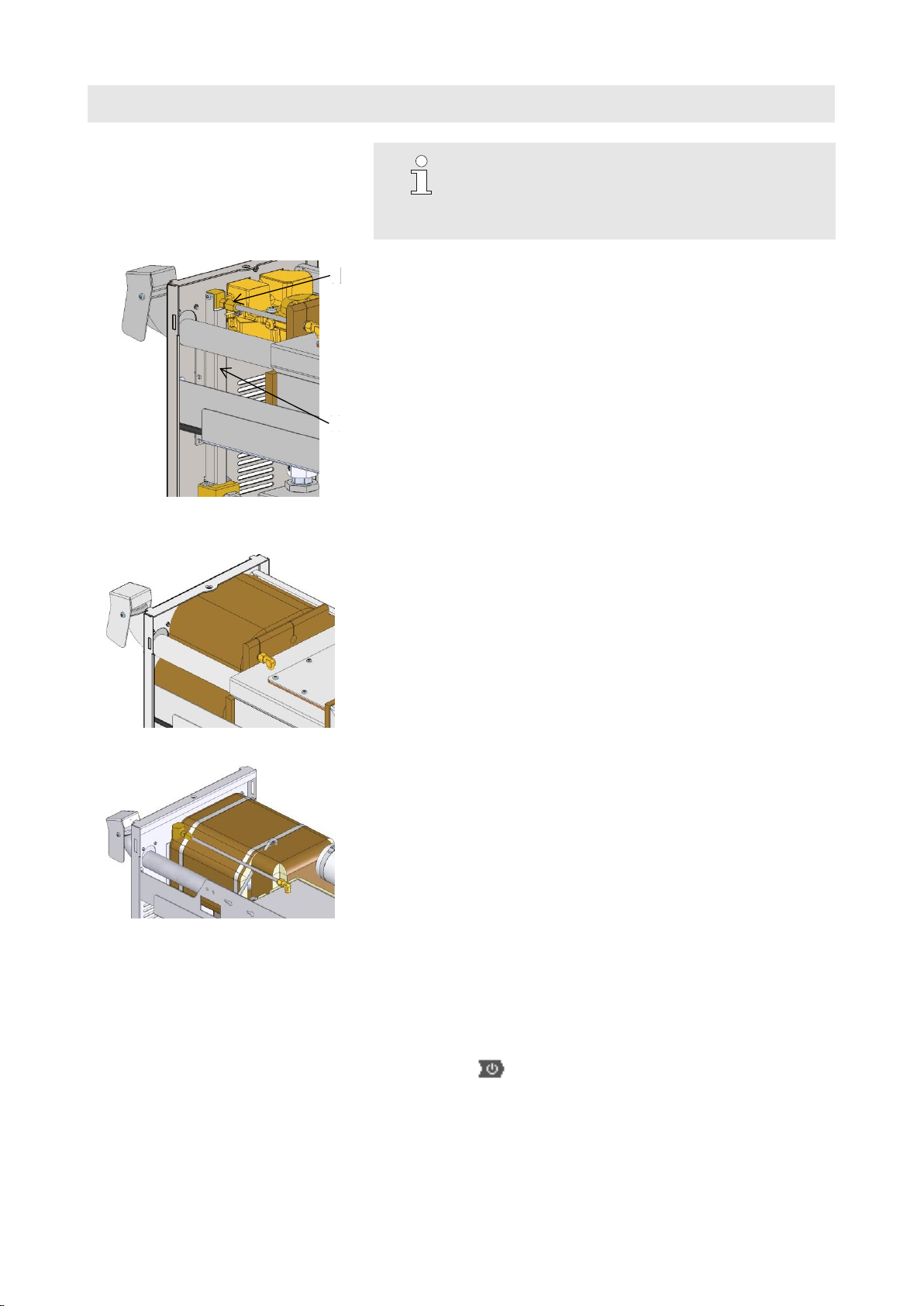

NOTICE!

The 2nd sound transducer should be cleaned, if the

demounted sound transducer is showing dirt on the

side touching the medium.

Fig. 3: Mount level indicator

Only on T25865-1 and replacement sonic transducer BB 1

8. To mount the level indicator, proceed as follows:

Push in level indicator (10) (Label 1 Fig. 3).

Mount 6x screws.

Tighten screws on pipe (Label 2 Fig. 3).

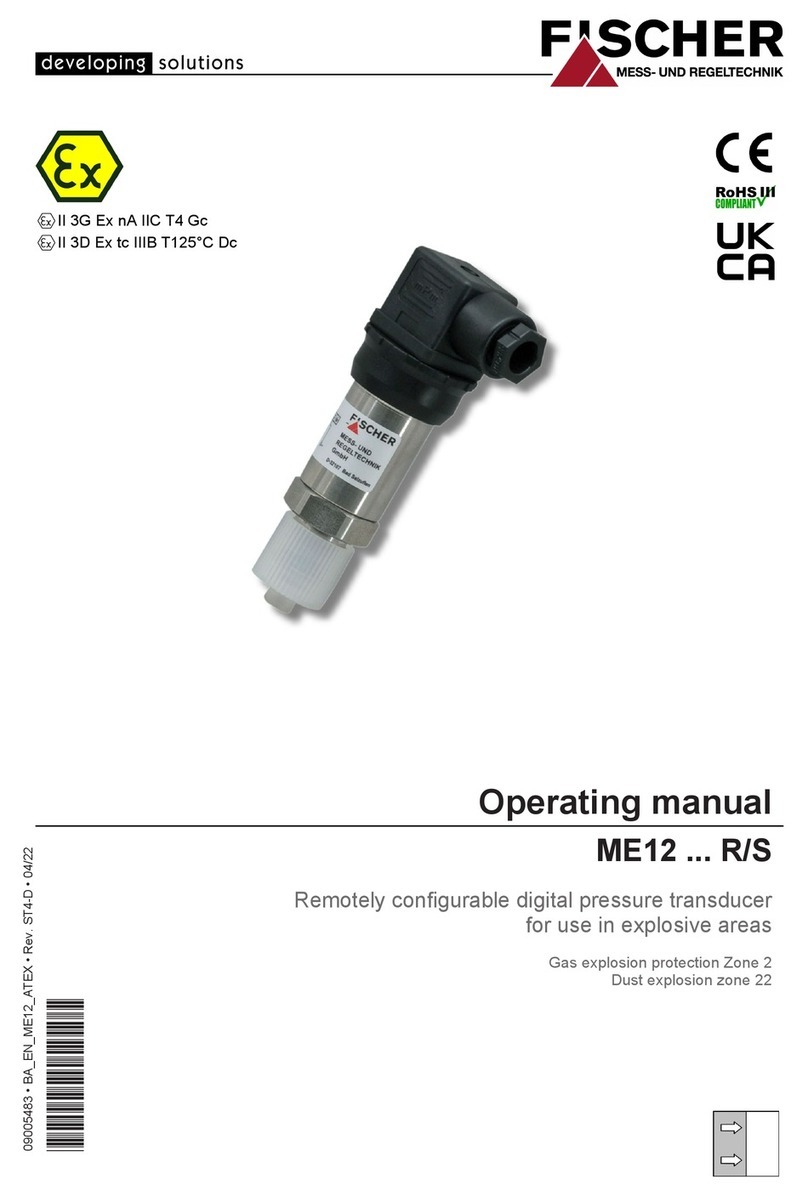

Fig. 4: Fitting insulation on 200T2

Fig. 5: Fitting insulation on 250T3

Only on oil units

9. Fit insulation as shown in Fig. 4 or Fig. 5.

10.Close and secure the front panel.

11.Reconnect mains plug and switch on main switch.

12.Press the key to switch on the unit and check it for leaks.

2

1

Assembly Instructions M8086-EN

M8086-EN 2020-02 5/6

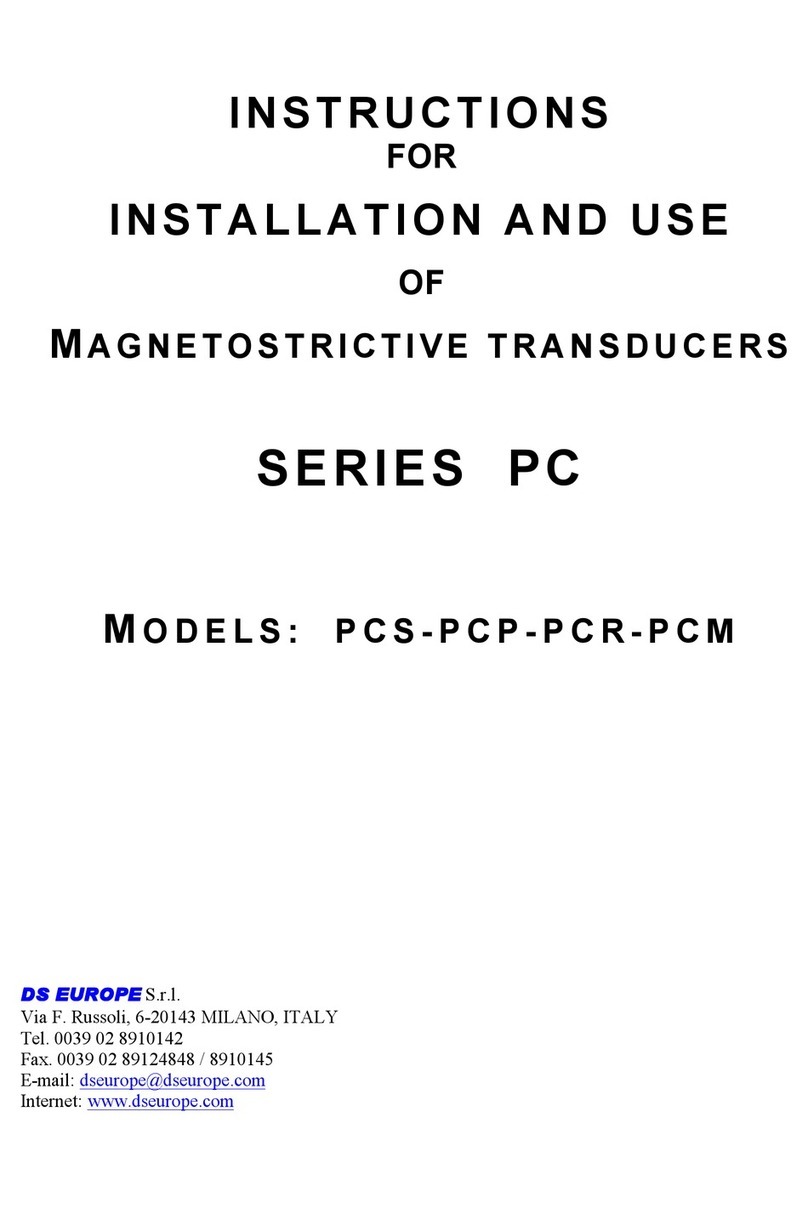

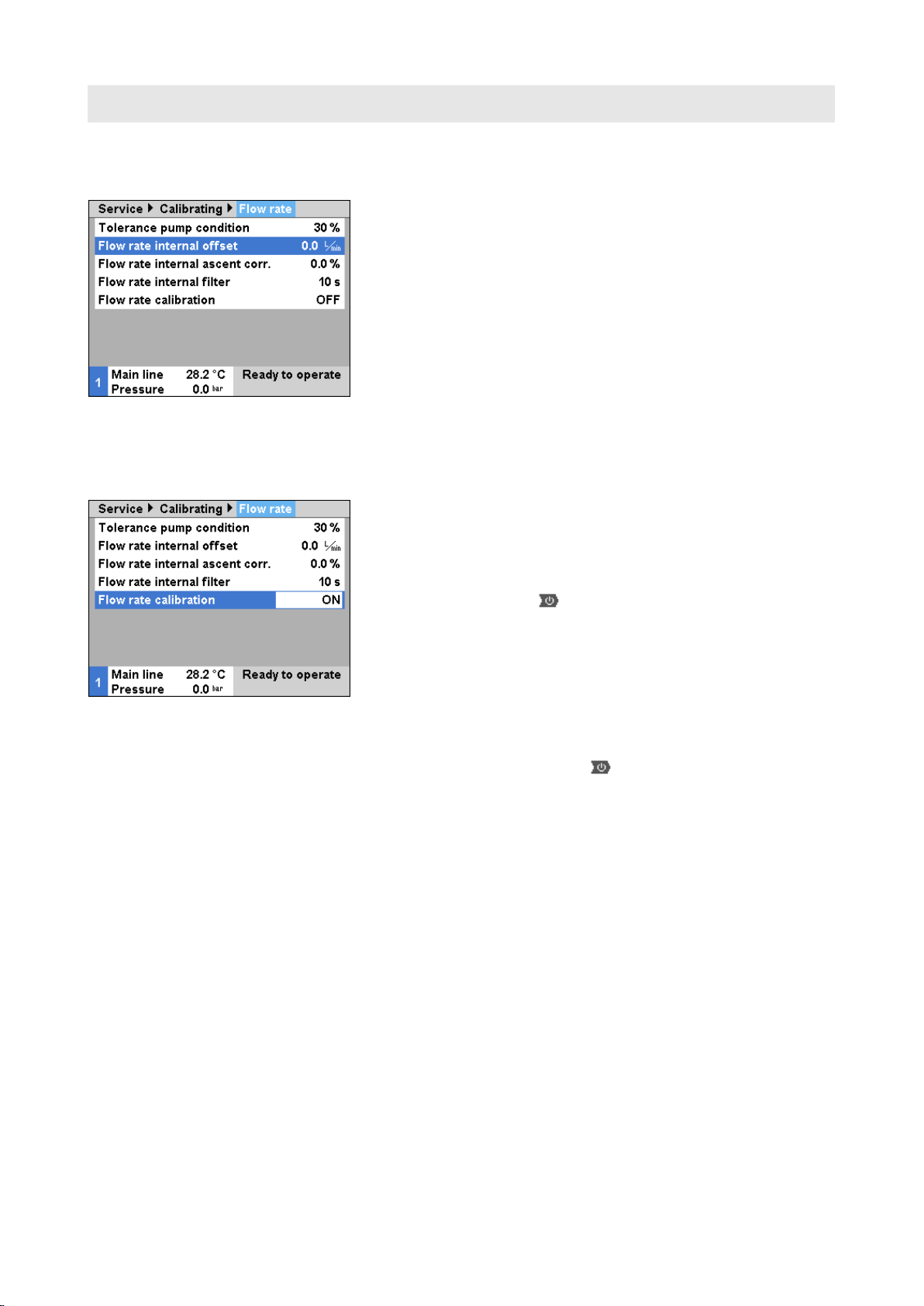

Fig. 6: Calibrating the flow rate

13.Flow rate calibration

(Software versions prior to SW51-1 0849B)

Operate unit in regular mode at 40 °C for at least 10 minutes.

Set Flow rate internal offset parameter in Service \ Calibrating \

Flow rate internally to "5 L/min".

Close shut-off valve between main or return line and wait for

1 minute.

Note current Flow rate.

Set Flow rate internal offset according to the following

calculation:

New Flow rate internal offset = 5 –current Flow rate

Open shut-off valve.

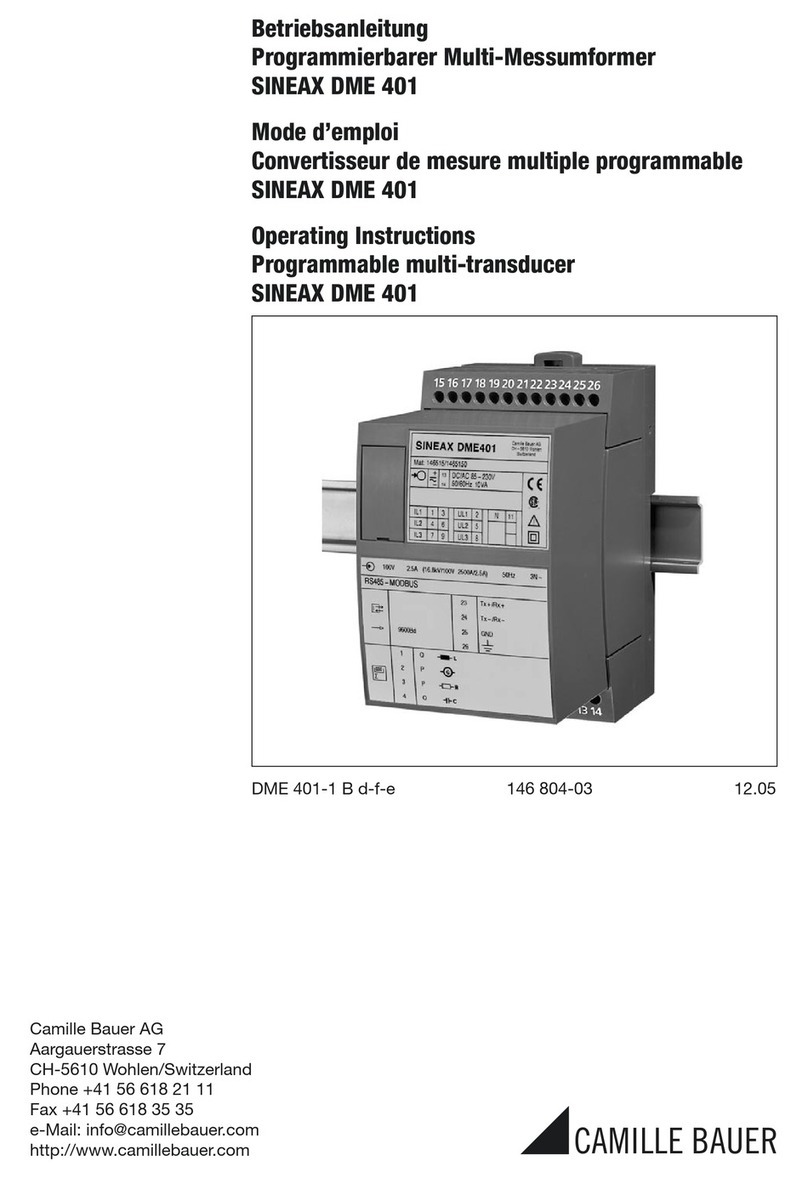

Fig. 7: Calibrating the flow rate

(From software version SW51-1 0849B onwards)

Operate unit in regular mode at 40 °C for at least 10 minutes.

Only for water units:

If available, set Pressure relief with unit OFF parameter in

Setting \ Miscellaneous to "OFF".

Switch off unit using button and wait at least 10 seconds.

Set Flow rate calibration parameter in Service \ Calibrating \

Flow rate internally to "ON".

The flow rate is calibrated automatically.

Only for water units:

If available, set Pressure relief with unit OFF parameter in

Setting \ Miscellaneous to "ON".

Switch on the unit using the key.

Assembly Instructions M8086-EN

M8086-EN 2020-02 6/6

14.Check flow rate calibration:

After calibration, run the unit for at least 5 minutes at 40 °C in

normal mode.

Close shut-off valve between feed and return lines.

Flow rate switches to 0 L/min and alarm indication ‚Flow rate

zero’is given.

NOTE!

The alarm message ‚Flow rate zero’ is delayed in

time.

If this is not the case, repeat the flow rate calibration.

ATTENTION!

Risk of incorrect calibration!

False calibrations can lead to faults witch the unit.

Therefore:

–Check the calibrations.

15.Switch the unit off by press the key.

16.Main switch off.

17.Close the unit correctly again.

Parts list

Pos

Description

O/ID

O/ID

T24629-1

T24629-2

T26326-1

T26326-3

T25242-2

T25865-1

T25865-3

Pcs

Pcs

Pcs

Pcs

Pcs

Pcs

Pcs

01

Sonic transducer water up to 160 °C, 1 m

T27045-1

1

-

-

-

-

-

-

02

Sonic transducer water up to 160 °C, 1,45 m

T27045-3

-

1

-

-

-

-

-

03

Sonic transducer water up to 180 °C, 1 m

T26310-1

-

-

1

-

-

-

-

04

Sonic transducer water up to 180 °C, 1,45 m

T26310-3

-

-

-

1

-

-

-

05

Sonic transducer oil up to 200 °C, 1 m

T26328-1

-

-

-

-

1

-

-

06

Sonic transducer oil up to 200 °C, 1 m

T26082-1

-

-

-

-

-

1

-

07

Sonic transducer oil up to 250 °C, 1,45 m

T26082-3

-

-

-

-

-

-

1

08

Socket 27x14x9 PEEK

T26080

-

-

-

-

-

1

1

09

O-Ring FPM 17x2 mm

T23523

-

-

-

-

1

-

-

10

O-Ring FFKM 17x2 mm

T25429

1

1

1

1

-

2

2

11

Assembly instructions German

M8086-DE

1

1

1

1

1

1

1

12

Assembly instructions English

M8086-EN

1

1

1

1

1

1

1

13

Assembly instructions French

M8086-FR

1

1

1

1

1

1

1

This manual suits for next models

2

Other HB-THERM Transducer manuals

Popular Transducer manuals by other brands

Mianyang Weibo Electronic

Mianyang Weibo Electronic WBI122S01 user manual

APAR

APAR AR553 User instruction

DaytonAudio

DaytonAudio HDN-8 user manual

Licht

Licht MFC-400/I-VAC Technical manual

Camille Bauer

Camille Bauer Gossen MetraWatt SINEAX DME 401 operating instructions

Krell Industries

Krell Industries LAT series owner's manual