Instruction Manual

D103551X012

EWNS Valve

March 2022

9

WARNING

To avoid personal injury or property damage caused by uncontrolled movement of the bonnet (key 10), loosen the bonnet

by following the instructions in the next step. Do not remove a stuck bonnet by pulling on it with equipment that can

stretch or store energy in any other manner. The sudden release of stored energy can cause uncontrolled movement of the

bonnet. If the cage sticks to the bonnet, proceed carefully with bonnet removal and support the cage so that it will not fall

unexpectedly from the bonnet.

Note

The following step also provides additional assurance that the valve body fluid pressure has been relieved.

7. Hex nuts (key 8) and washers (key 24) attach the bonnet (key 10) to the valve body (key 1). Loosen these nuts

approximately 3 mm (1/8 inch). Then loosen the body‐to‐bonnet gasketed joint by either rocking the bonnet or

prying between the bonnet and valve body. Work the prying tool around the bonnet until the bonnet loosens. If no

fluid leaks from the joint, proceed to step 9.

8. If leakage does occur from the joint, tighten the nuts (key 8) and verify that the process is properly shut down or the

valve is properly bypassed.

9. Unscrew the hex nuts (key 8), remove the washers (key 24), and carefully lift the bonnet (key 10) off the valve stem.

If the valve plug and stem assembly (key 4) starts to lift with the bonnet, use a deadblow hammer on the end of the

stem and tap it back down. Set the bonnet on a cardboard or wooden surface to prevent damage to the bonnet

gasket surface.

10. Remove the cage gasket (key 5). Lift the valve plug and stem assembly (key 4) out of the valve body and set it on a

protective surface. If the valve plug is to be reused, protect the valve plug seating surface to prevent scratches.

Install screws or bolts into the tapped holes in the top of the cage (key 2), and carefully lift the cage and seat ring

(key 3) assembly out of the valve body. Remove the other cage gasket (key 5).

CAUTION

Inspect the cage, bonnet, and body gasket surfaces. These surfaces must be in good condition, with all foreign material

removed. Small burrs less than approximately 0.076 mm (0.003 inches) in height (the thickness of a human hair) can be

ignored. Scratches or burrs that run across the serrations are not permitted under any conditions, since they will prevent

the gaskets from sealing properly.

11. Clean all gasket seating surfaces; refer to your process or safety engineer for appropriate cleaning tools. Clean in

the same direction as the surface serrations, not across them.

12. Cover the opening in the valve body to protect the gasket seating surface and to prevent foreign material from

getting into the valve body cavity.

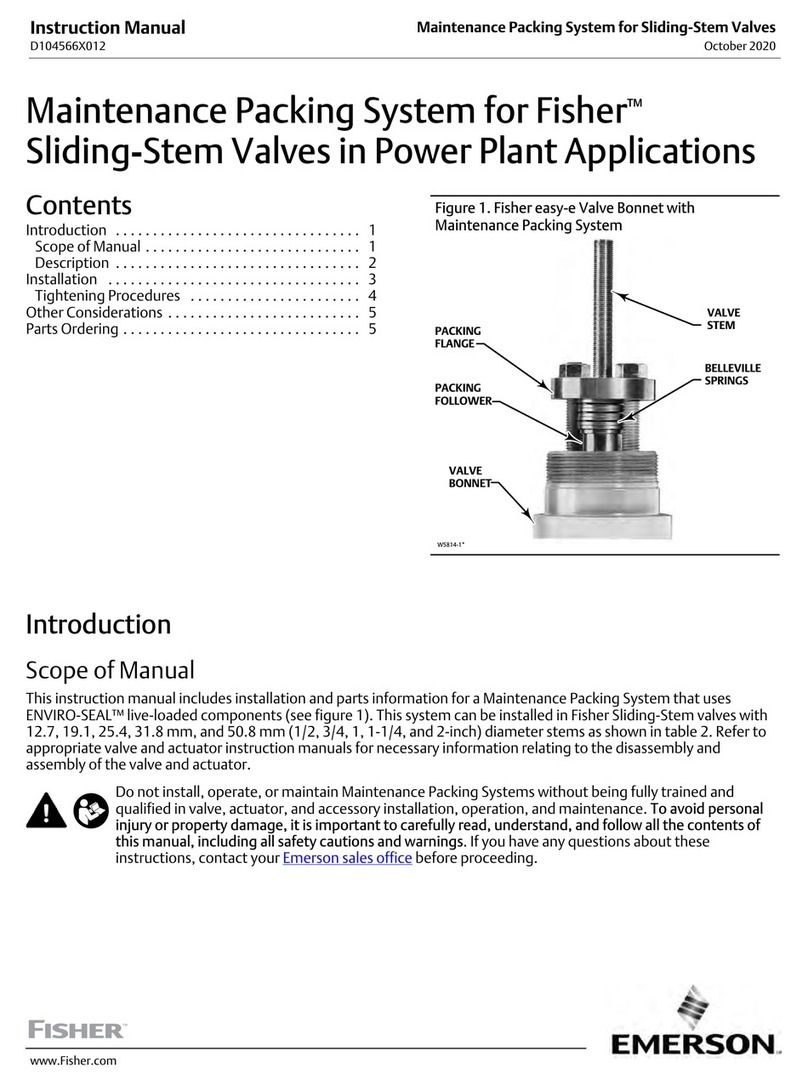

13. Remove the packing flange nuts (key 14), packing flange (key 9), qty 2 Belleville springs (key 20), indicator disk (key

19), packing follower (key 17), qty-4 load scale mounting screws (key 21), and load scale (key 22). Carefully push

out all the remaining packing parts from the valve side of the bonnet using a rounded rod or other tool that will not

scratch the packing box wall.

14. Clean the packing box and the following metal packing parts: packing follower (key 17), packing box ring (key 11).

15. Inspect the valve stem threads and packing box surfaces for any sharp edges that might cut the packing. Scratches

or burrs could cause packing box leakage or damage to the new packing. If the surface condition cannot be

improved by light sanding or honing with a tool similar to a small honing stone, replace the damaged parts.