HBK Z6 User manual

This manual suits for next models

5

Table of contents

Languages:

Other HBK Transducer manuals

Popular Transducer manuals by other brands

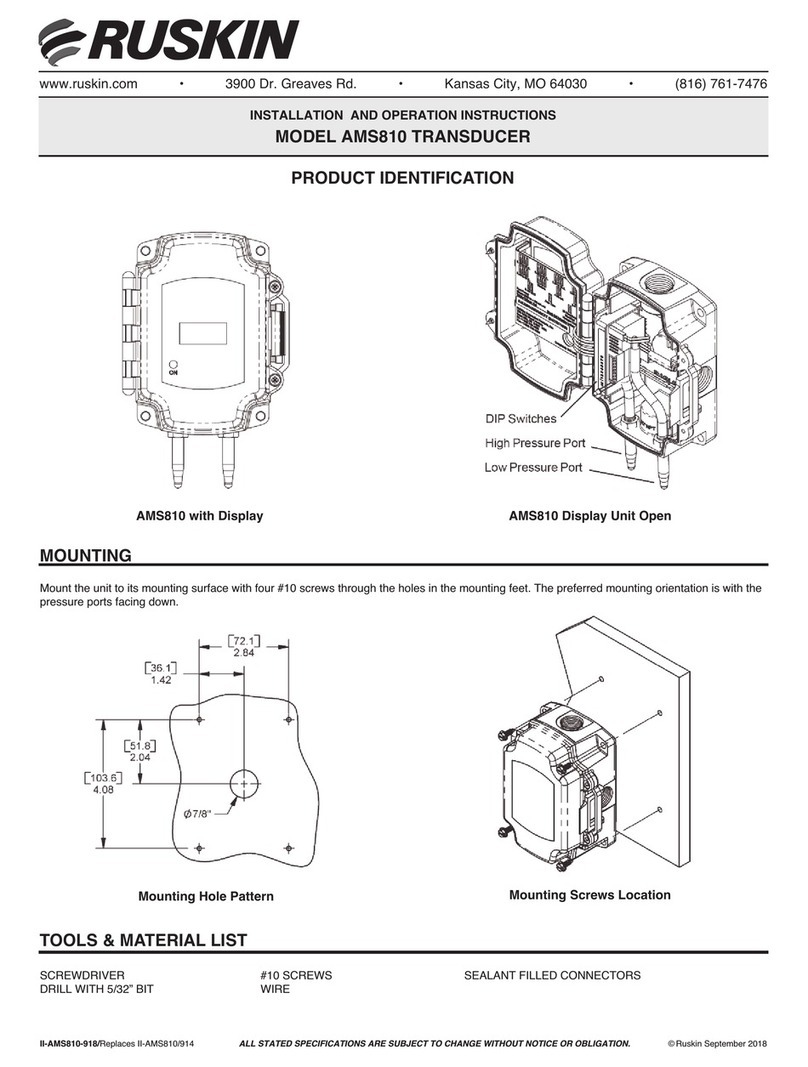

Ruskin

Ruskin AMS810 Installation and operation instructions

Balluff

Balluff Micropulse BTL5-A series user guide

FuehlerSysteme eNET International

FuehlerSysteme eNET International EM4/E operating manual

OHIO SEMITRONICS

OHIO SEMITRONICS PC5 Series OPERATION & CALIBRATION MANUAL

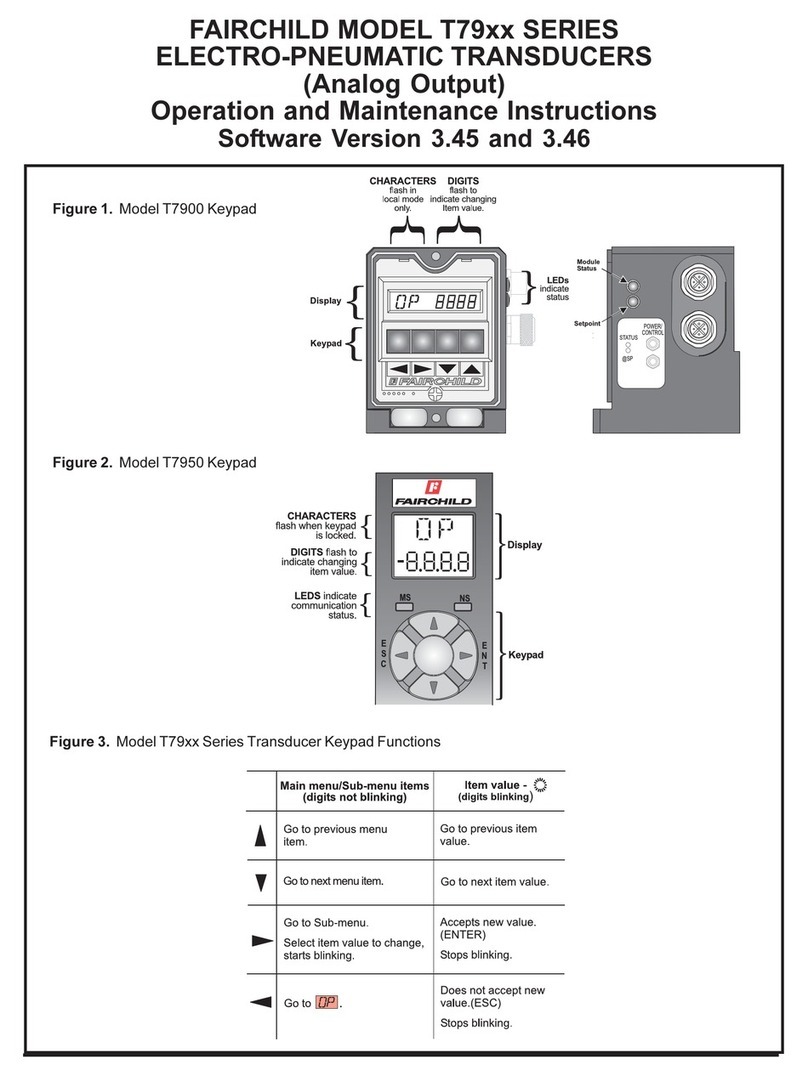

Fairchild

Fairchild T79 Series Maintenance and operating instructions

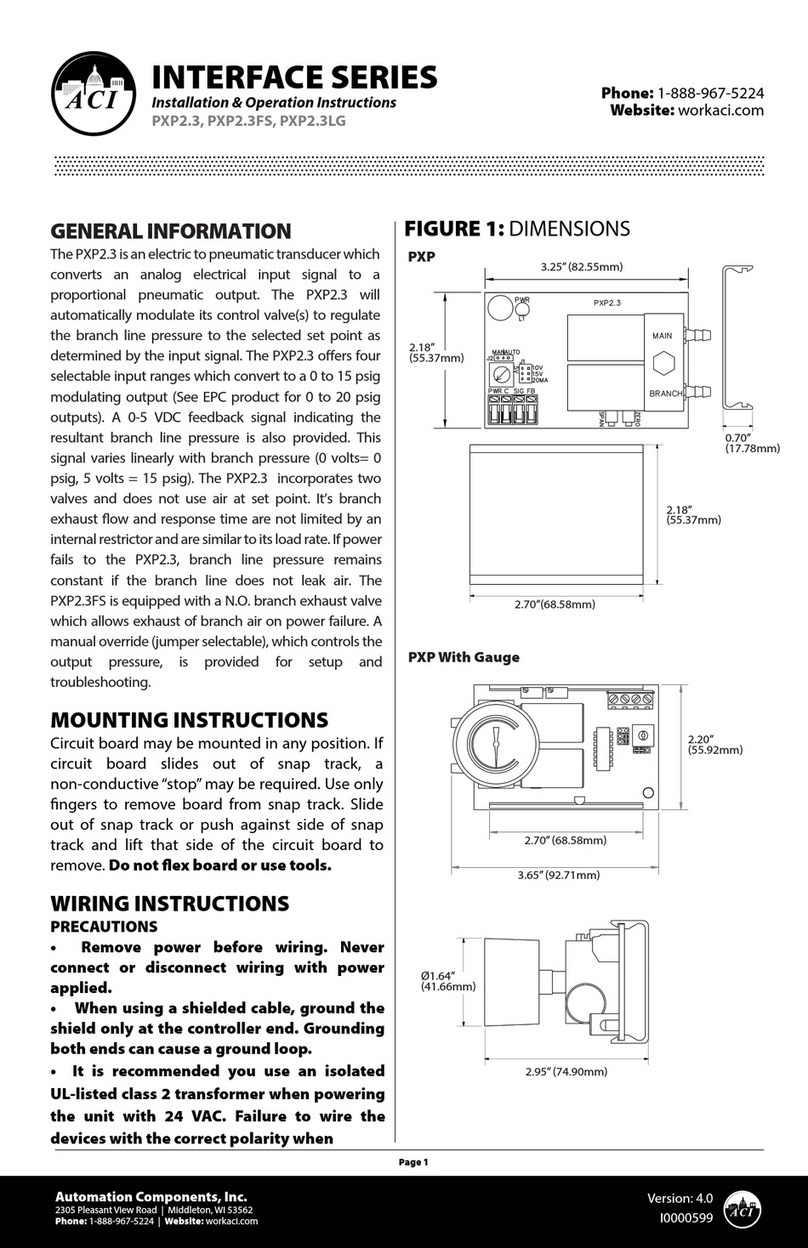

aci

aci ACCESS series Installation & operation instructions

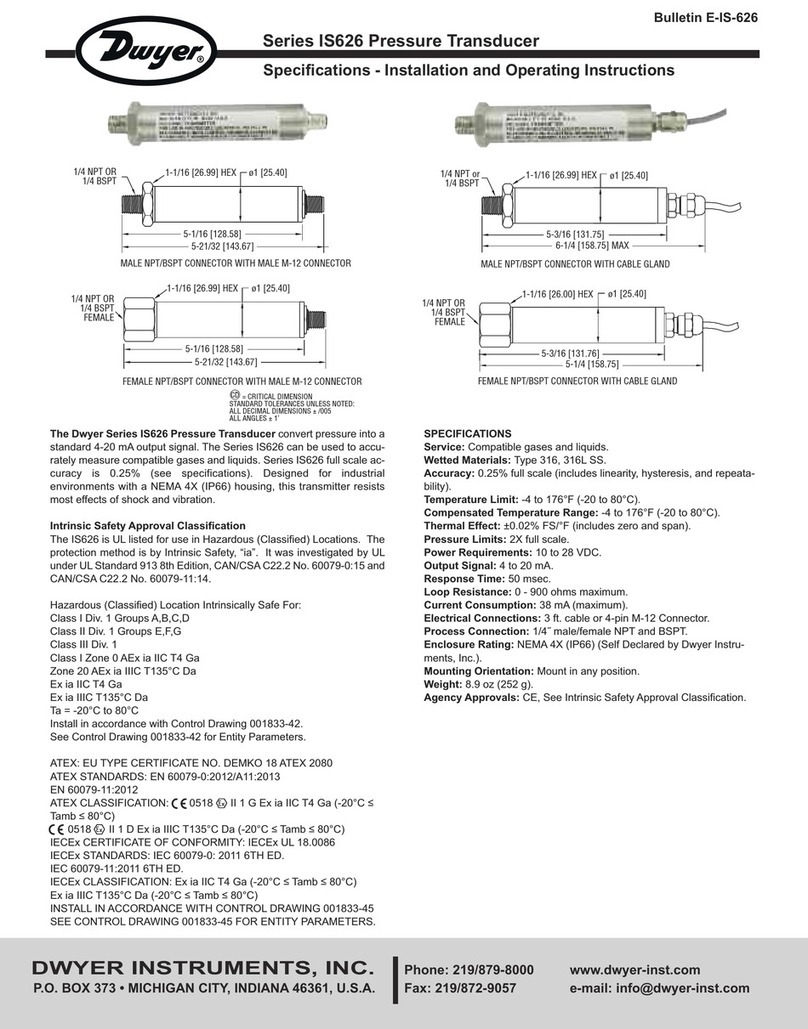

Dwyer Instruments

Dwyer Instruments IS626 Series Installation and operating instructions

Furuno

Furuno FI-5001 installation manual

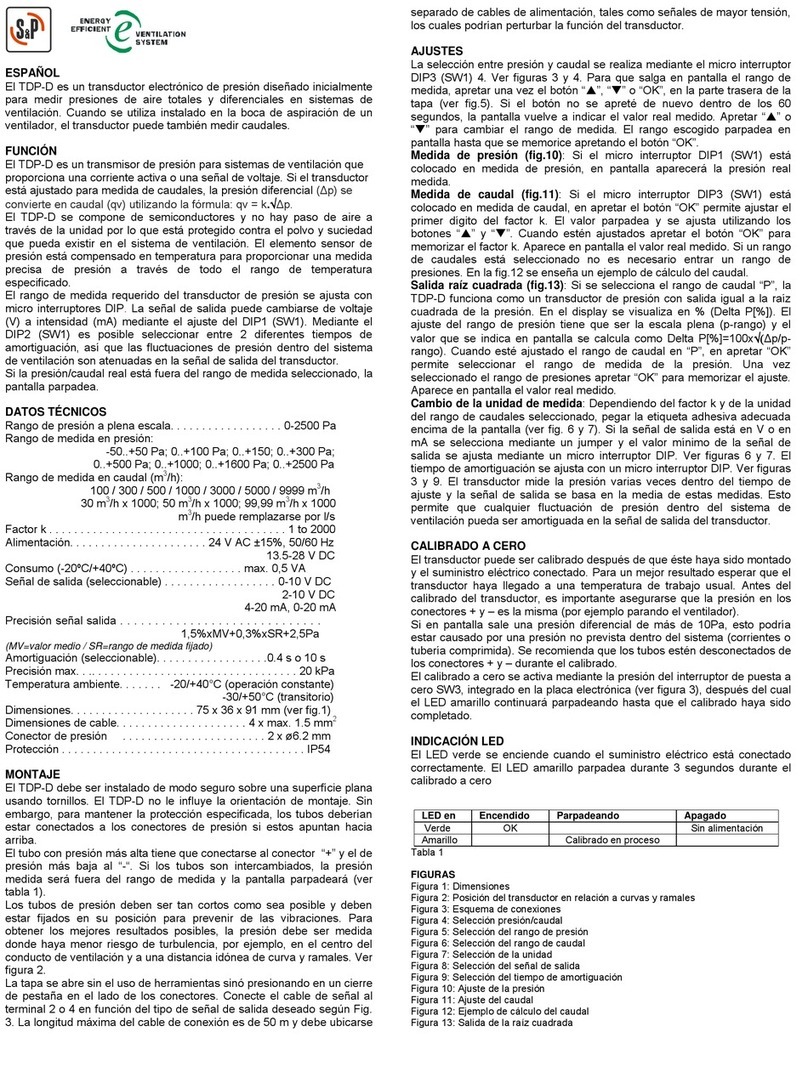

S&P

S&P TDP-D quick start guide

Greystone Energy Systems

Greystone Energy Systems LP-S installation instructions

MKS

MKS Baratron 622A instruction manual

Airmar

Airmar P66 Owners and installation manual

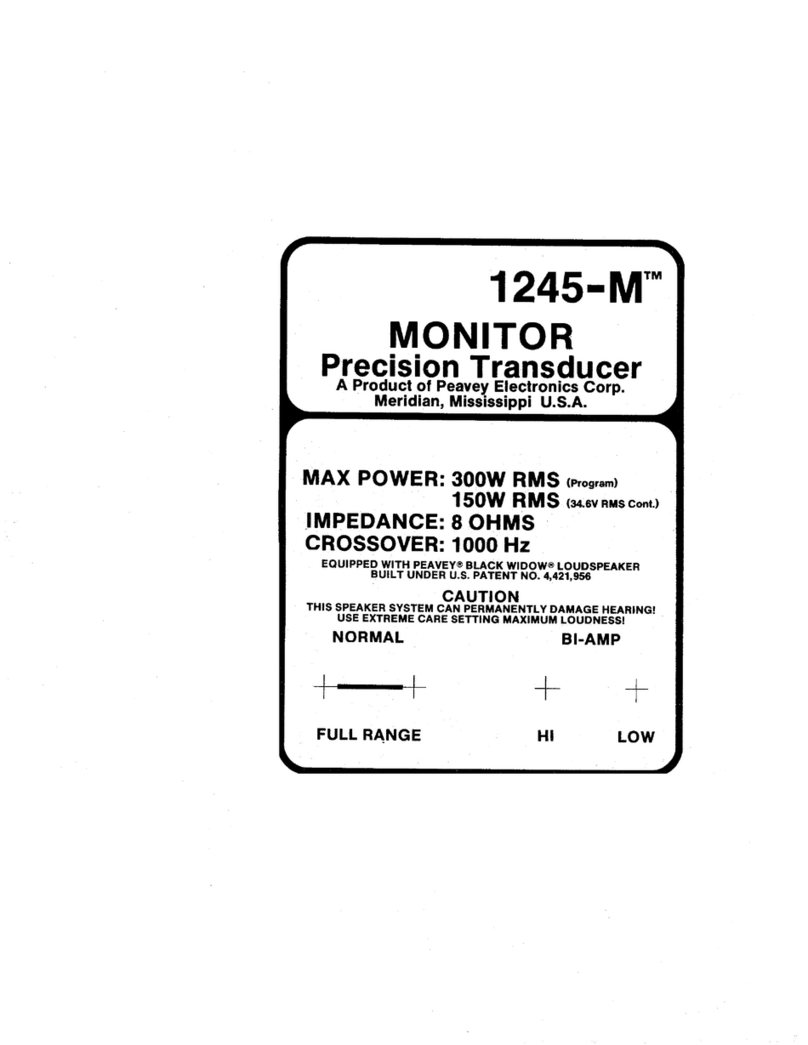

Peavey

Peavey 1245-M Specifications

TR-Electronic

TR-Electronic LMR-70-300 ANA-I+JUSTAGE manual

Garmin

Garmin Panoptix PS21-TR installation instructions

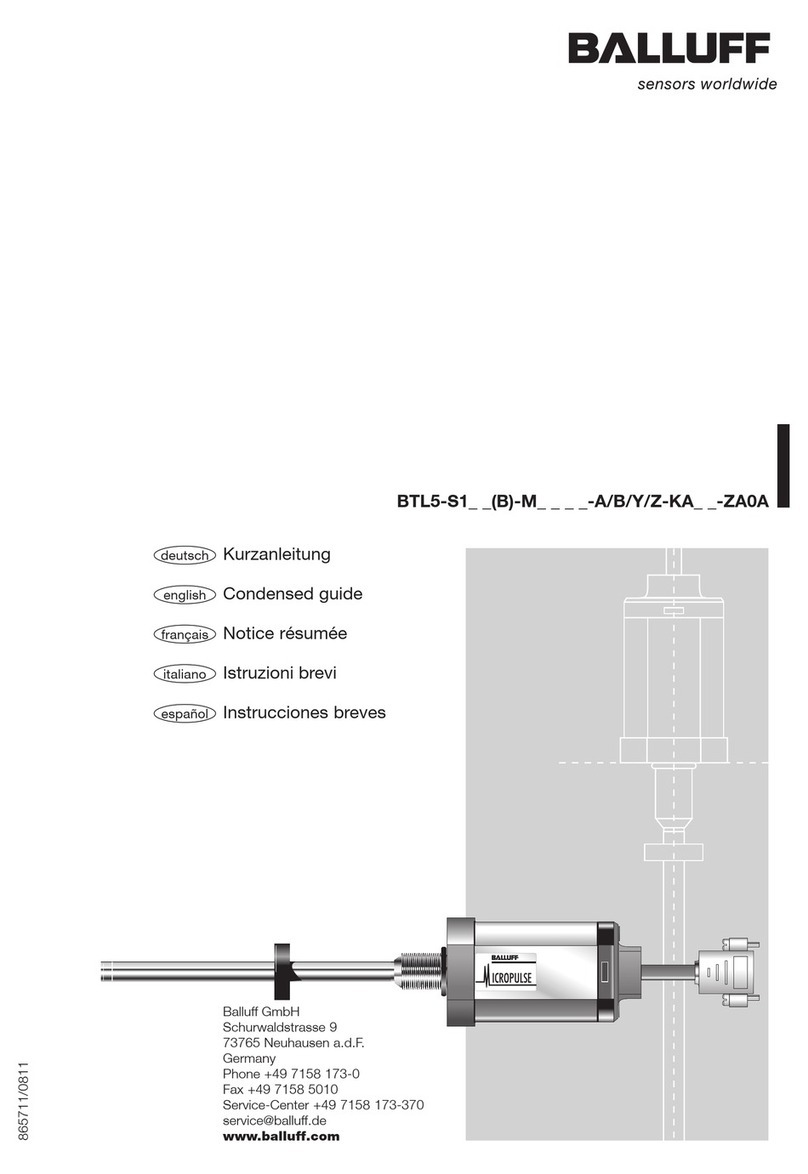

Balluff

Balluff BTL5-S1 Series Condensed guide

controlair

controlair 500-AA Installation, operation and maintenance instructions

Simrad

Simrad 200-7G - REV A datasheet