441-622-015 Type 500X Page 3

1.4 Pneumatic Connections

1.4.1 The 1/4 NPT supply and output ports are marked “IN” and “OUT” respectively on the base of the unit. Clean all

pipe lines to remove contamination before installation. Apply pipe compound to male threads of the air line only.

Avoid getting compound in the air lines.

Clean dry instrument quality air must be used. To insure optimum performance supply pressure should be

regulated. To provide stable inlet pressure and prevent contamination of the internal section of the transducer the

use of an Instrument Air Filter Regulator is recommended.

The two unmarked ports on the base of the unit are gage ports but may be used as alternative output ports. Any

unused ports must be plugged.

The I/P transducer enclosure contains aluminum and is considered to constitute a potential risk of

ignition b impact or friction and must be taken into account during installation.

1.5 Electrical Connections

1.5.1 Electrical connections are made to the black and white leads extending out from the 1/2 NPT conduit fitting.

When the positive side of the input signal is connected to the black lead, the output pressure will increase as the

input signal increases. For reverse acting mode (increasing input signal decreases output pressure), connect

positive side of the input signal to the white lead.

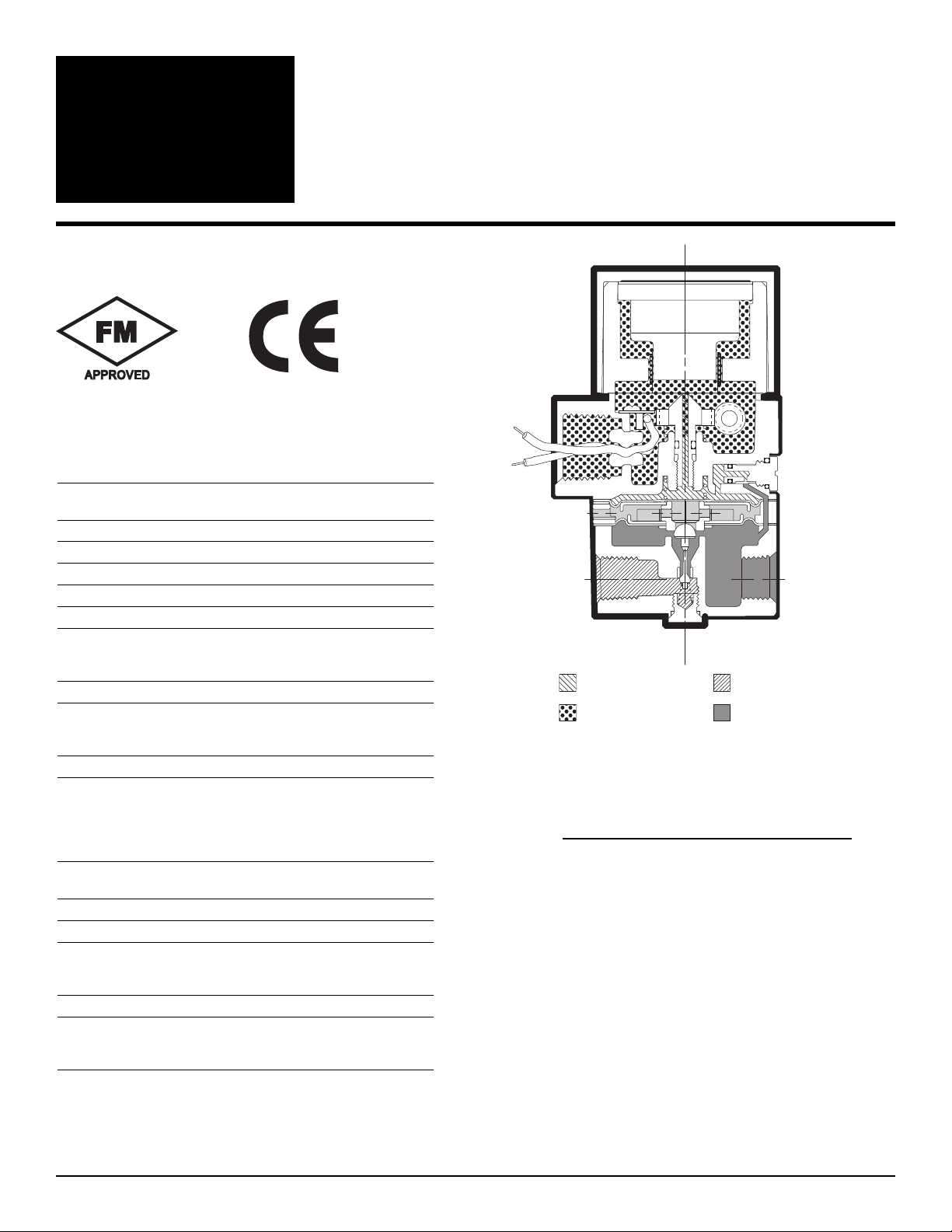

Fi ure 1 DIN 43650 Connector

2. OPERATION

2.1 Calibration

2.1.1 Zero and pan should always be checked after mounting. If unit is calibrated in a vertical position and then

mounted at an angle, readjustment of the zero is necessary. To calibrate use the following procedure:

1. Open protective covers to expose zero and span adjustment screws.

2. Connect the recommended air supply to the inlet of the transducer and an accurate pressure gage to the outlet.

3. Connect the electrical input and set the input signal to the minimum value of the range being used

(e.g. 4 mA for a 4-20 mA unit).

4. Observe the output pressure. If necessary adjust zero screw until reaching minimum output pressure setting.

Turn zero screw counter clockwise to increase pressure, clockwise to decrease pressure.

If unable to achieve output during calibration process, turn zero adjustment screw counter

clockwise for up to 30 revolutions, until output pressure rises.

5. Increase electrical input signal to its maximum value (e.g. 20 mA for a 4-20 mA unit).

6. Observe the output pressure. If necessary adjust the span screw until reaching maximum output pressure setting.

For I/P (current) input models turn span screw counter clockwise to increase pressure,

clockwise to decrease pressure. For E/P (voltage) input models turn span screw clockwise

to increase pressure, counter clockwise to decrease pressure.

7. The Zero and pan adjustments are interactive. After adjusting the span it will be necessary to recheck the zero.

Repeat steps 3-6 until both end points are at the required values.

8. For reverse acting performance interchange the black and white electrical signal leads and carry out the same

procedure as described above. Adjust the zero screw with minimum input (4mA) to get maximum output then

adjust span screw with maximum input (20mA) to get minimum output. Repeat as necessary.

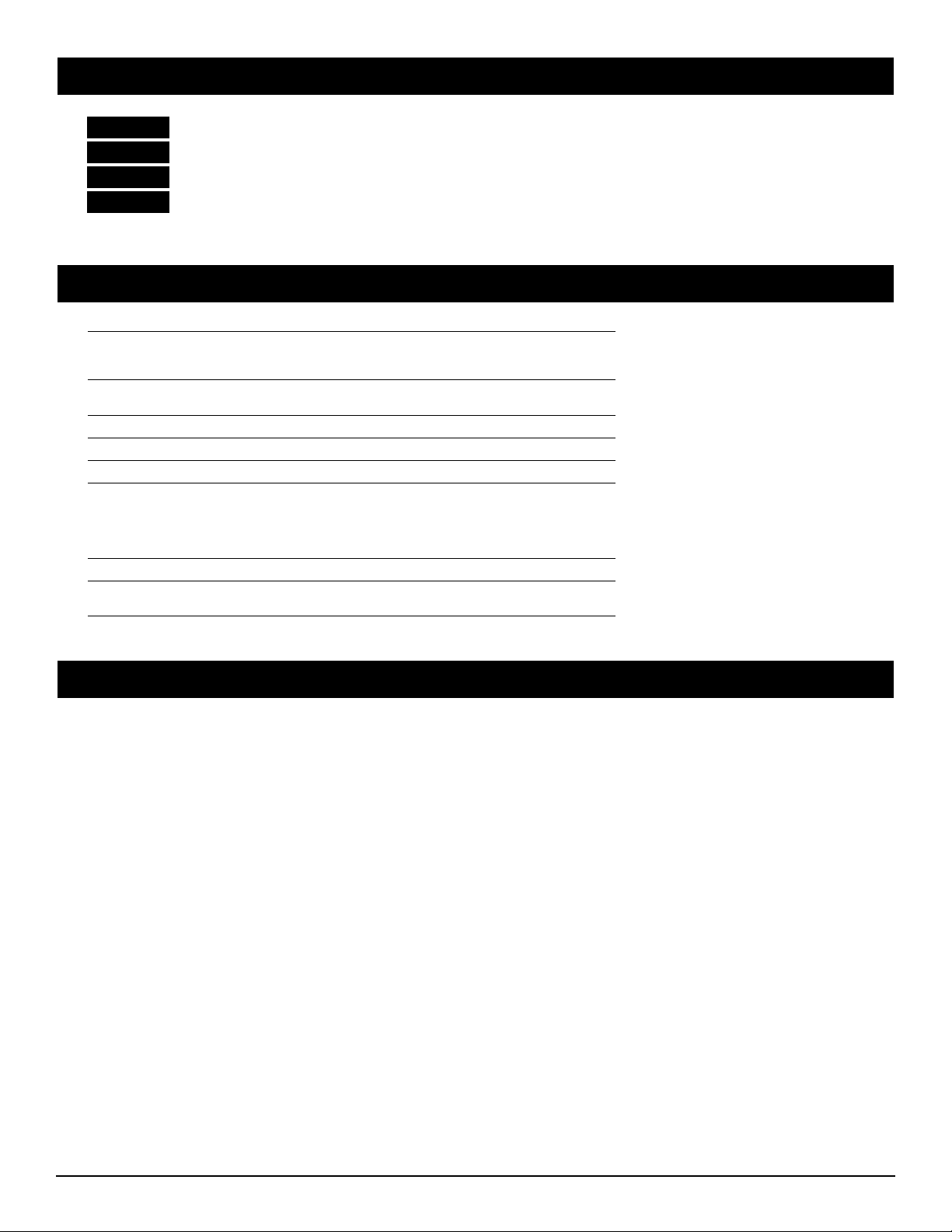

Fi ure 2 Electrical Schematic

WARNING

NOTE

NOTE

Notes:

1. For 4-20 mA and 10- mA use J1 as positive input.

2. For 10-50 mA change R4 to 100 Ohms.

3. For 1-9 VDC and 0-10 VDC remove R2, use J5 as

positive input.