HBK HBM Bruel & Kjaer U10M User manual

U10M, U10S

ENGLISH DEUTSCH FRANÇAIS ITALIANO

Mounting Instructions

Montageanleitung

Notice de montage

Istruzioni per il montaggio

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.: 7-2001.1385

DVS: A01385 06 YIC 09

05.2022

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

Sous réserve de modifications.

Les caractéristiques indiquées ne décrivent nos

produits que sous une forme générale. Elles

n'impliquent aucune garantie de qualité ou de

durabilité.

Con riserva di modifica.

Tutti i dati descrivono i nostri prodotti in forma

generica e non implicano alcuna garanzia di qualità o

di durata dei prodotti stessi.

保留变更的权利。

所有信息是对我品的性描。在性或者

性方它并提供何保。

U10M, U10S

ENGLISH DEUTSCH FRANÇAIS ITALIANO

Mounting Instructions

U10M, U10S

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety instructions 4................................................

2 Markings used 7....................................................

2.1 The markings used in this document 7.................................

3 Scope of supply and Options 8.......................................

4 General application instructions 11....................................

5 Structure and mode of operation 12....................................

5.1 Transducer 12.......................................................

5.2 SG covering agent 12.................................................

6 Conditions on site 13.................................................

6.1 Ambient temperature 13..............................................

6.2 Moisture and corrosion protection 13...................................

6.3 Deposits 13.........................................................

7 Mechanical installation 15............................................

7.1 Important precautions during installation 15..............................

7.2 General installation guidelines 15.......................................

7.3 Assembly with adapter 16.............................................

7.4 Mounting with PLS ramp disks 20......................................

7.5 Mounting with knuckle eyes 22.........................................

7.6 Assembly without adapter 27..........................................

7.7 Mounting with a fitted force application part 29...........................

8 Electrical connection 30..............................................

8.1 Connection in a six-wire configuration 30................................

8.2 Cable shortening or extension 31.......................................

8.3 Connection in a four-wire configuration 31...............................

8.4 EMC protection 31...................................................

9 TEDS transducer identification 32......................................

10 Versions and ordering numbers 33.....................................

11 Specifications (VDI/VDE2638) 36......................................

12 Dimensions 48......................................................

12.1 U10M with foot adapter 48............................................

12.2 U10M without foot adapter 50.........................................

3

U10M, U10S

TABLE OF CONTENTS

12.3 U10M with force application and foot adapter 51.........................

12.4 U10M with knuckle eyes 52............................................

12.5 PLS ramp disk dimensions 53..........................................

12.6 Installed dimensions of connection variants 54...........................

U10M, U10S

SAFETY INSTRUCTIONS

4

1 SAFETY INSTRUCTIONS

Intended use

The force transducers of the U10M/U10S type series are solely designed for measuring

static and dynamic tensile and/or compressive forces within the load limits stated in the

specifications for the respective maximum capacities. Any other use is not appropriate.

To ensure safe operation, the regulations in the mounting instructions, together with the

following safety rules and regulations, and the data specified in the technical data sheets,

must be complied with. It is also essential to observe the applicable legal and safety reg

ulations for the application concerned.

The force transducers are not intended for use as safety components. Please also refer

to the "Additional safety precautions" section. Proper and safe operation of force trans

ducers requires proper transportation, correct storage, setup and mounting, and careful

operation.

Load-carrying capacity limits

The information in the technical data sheets must be complied with when using force

transducers. The respective specified maximum loads in particular must never be

exceeded. The following limits set out in the technical data sheets must not be exceeded:

SForce limits

SLateral force limits

SBending moment limits

STorque limits

SBreaking forces

SPermissible dynamic loads

STemperature limits

SLimits of electrical loading capacity

Please note that when several force transducers are interconnected, the load/force

distribution is not always uniform.

Use as a machine element

Force transducers can be used as machine elements. When used in this manner, it must

be noted that, to favor greater sensitivity, the force transducers were not designed with

the safety factors usual in mechanical engineering. Please refer here to the section

"Load-carrying capacity limits", and to the specifications.

5

U10M, U10S

SAFETY INSTRUCTIONS

Accident prevention

The prevailing accident prevention regulations must be taken into account, even though

the nominal (rated) force values in the destructive range are well in excess of the full

scale value.

Additional safety precautions

Force transducers cannot (as passive transducers) implement any safety-relevant cut

offs. This requires additional components and constructive measures, for which the in

staller and operator of the plant is responsible.

In cases where a breakage or malfunction of the force transducer would cause injury to

persons or damage to equipment, the user must take appropriate additional safety mea

sures that meet at least the requirements of applicable safety and accident prevention

regulations (e.g. automatic emergency shutdown, overload protection, catch straps or

chains, or other fall protection).

The electronics conditioning the measurement signal should be designed so that mea

surement signal failure does not subsequently cause damage.

General dangers of failing to follow the safety instructions

Force transducers are state-of-the-art and failsafe. There may be dangers involved if the

transducers are mounted, sited, installed and operated inappropriately, or by untrained

personnel. Every person involved with siting, starting-up, operating or repairing a force

transducer must have read and understood the mounting instructions and in particular

the technical safety instructions. The force transducers can be damaged or destroyed by

non-designated use of the force transducer or by non-compliance with the mounting and

operating instructions, these safety instructions or any other applicable safety regula

tions (BG safety and accident prevention regulations) when using the force transducers.

Force transducers can break, particularly if overloaded. The breakage of a force trans

ducer can also cause damage to property or injury to persons in the vicinity of the force

transducer.

If force transducers are not used according to their designated use, or if the safety in

structions or specifications in the mounting and operating instructions are ignored, it is

also possible that the force transducer may fail or malfunction, with the result that per

sons or property may be affected (due to the loads acting on or being monitored by the

force transducer).

The scope of supply and performance of the transducer covers only a small area of force

measurement technology, as measurements with (resistive) strain gage sensors presup

pose the use of electronic signal processing. In addition, equipment planners, installers

and operators should plan, implement and respond to the safety

engineering considerations of force measurement technology in such a way as to mini

mize residual dangers. Pertinent national and local regulations must be complied with.

U10M, U10S

SAFETY INSTRUCTIONS

6

Conversions and modifications

The design or safety engineering of the transducer must not be modified without our ex

press permission. Any modification shall exclude all liability on our part for any damage

resulting therefrom.

Maintenance

U10M/U10S force transducers are maintenance-free. We recommend having the force

transducer calibrated at regular intervals.

Disposal

In accordance with national and local environmental protection, material recovery and

recycling regulations, old transducers that can no longer be used must be disposed of

separately and not with normal household waste.

If you need more information about disposal, please

contact your local authorities or the dealer from whom you purchased the product.

Qualified personnel

Qualified personnel are persons entrusted with the setup, mounting, startup and opera

tion of the product, who have the appropriate qualifications for their function.

This includes people who meet at least one of the three following requirements:

1. Knowledge of the safety concepts of automation technology is a requirement and as

project personnel, you must be familiar with these concepts.

2. As automation plant operating personnel, you have been instructed how to handle the

machinery. You are familiar with the operation of the equipment and technologies

described in this documentation.

3. As commissioning engineers or service engineers, you have successfully completed

the training to repair the automation systems. You are also authorized to operate,

ground and label circuits and equipment in accordance with safety engineering stan

dards.

It is also essential to comply with the legal and safety requirements for the application

concerned during use. The same also applies to the use of accessories.

The force transducer may only be installed by qualified personnel, strictly in accordance

with the specifications and with the safety requirements and regulations.

7

U10M, U10S

MARKINGS USED

2 MARKINGS USED

2.1 The markings used in this document

Important instructions for your safety are specifically identified. It is essential to follow

these instructions in order to prevent accidents and damage to property.

Symbol Significance

WARNING This marking warns of a potentially dangerous situ

ation in which failure to comply with safety require

ments can result in death or serious physical injury.

CAUTION This marking warns of a potentially dangerous

situation in which failure to comply with safety

requirements can result in slight or moderate physical

injury.

NOTICE This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Important This marking draws your attention to important in

formation about the product or about handling the

product.

Tip This marking indicates application tips or other

information that is useful to you.

Information This marking draws your attention to information

about the product or about handling the product.

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

uThis marking indicates an action in a procedure

U10M, U10S

SCOPE OF SUPPLY AND OPTIONS

8

3 SCOPE OF SUPPLY AND OPTIONS

SForce transducer U10M (metric internal thread) or

U10S (UNF internal thread)

SU10M/U10S mounting instructions

SManufacturing certificate

SMachine handles for handling use on variants 225kN to 500kN

Accessories (not included in the scope of supply):

Cables/plugs Ordering number

Configurable cable, including mounted connectors for direct

connection to HBM amplifiers available upon request. K-CAB-F

Connection cable KAB157-3; IP67 (with bayonet locking);

3m long, TPE outer sheath; 6 x 0.25mm2; free ends,

shielded, outside diameter 6.5mm

1-KAB157-3

Connection cable KAB158-3; IP54 (with screw locking); 3m

long, TPE outer sheath; 6 x 0.25mm2; free ends, shielded,

outside diameter 6.5mm

1-KAB158-3

Loose cable socket (bayonet locking) 3-3312.0382

Loose cable socket (screw locking) 3-3312.0354

Ground cable (400mm long) 1-EEK4

Ground cable (600mm long) 1-EEK6

Ground cable (800mm long) 1-EEK8

Knuckle eye, M16 external thread 1-Z4/20kN/ZGUW

Knuckle eye, M33x2 external thread 1-ZGAM33F

Knuckle eye, M42x2 external thread 1-ZGAM42F

Knuckle eye, M72x2 external thread 1-ZGAM72F

Knuckle eye, M16 internal thread 1-Z4/20kN/ZGOW

Knuckle eye, M33x2 internal thread 1-ZGIM33F

Knuckle eye, M42x2 internal thread 1-ZGIM42F

Knuckle eye, M72x2 internal thread 1-ZGIM72F

Ramp disk (pre-stress disk), M16 1-PLS/M16

Ramp disk (pre-stress disk), M33 1-PLS/M33

Ramp disk (pre-stress disk), M42 1-PLS/M42

9

U10M, U10S

SCOPE OF SUPPLY AND OPTIONS

Ordering numberCables/plugs

Ramp disk (pre-stress disk), M72 1-PLS/M72

Ramp disk (pre-stress disk), M120 1-PLS/M120

Equipment variants

All force transducers are available in different versions. The following options are avail

able:

1. Nominal (rated) force:

You can purchase nominal (rated) forces from 1.2 5kN to 1.2 5MN.

2. Double bridge design

The force transducer is also available with two electrically isolated measurement

bridge circuits.

3. Adjusted rated output

On request, we can adjust the rated output of your U10M to exactly match the nominal

rated output. In sensors with nominal (rated) forces 1.25kN, 2.5kN and 5kN, the out

put signal at nominal (rated) force is then 1mV/V, in all other force transducers it is

2mV/V. These values apply together with 100% calibration (standard). If you choose

the 200% calibration option, the output signal doubles. If you order the "adjusted rated

output" option, the output resistance is always adjusted as well, so that several sen

sors can be connected in parallel. (Exception: nominal (rated) force 1.25MN is not

suitable for parallel connection)

4. Calibration

On request, HBM can calibrate the force transducer to 200% nominal (rated) force.

The high mechanical reserves of the force transducer make this application possible

in measurement tasks with a limited oscillation bandwidth (see Specifications). But be

aware that when double the force is measured, the output signal also doubles.

5. TEDS transducer identification

You can purchase the force transducer with transducer identification ("TEDS"). TEDS

(Transducer Electronic Data Sheet) allows you to store the transducer data (rated out

puts) in a chip, that can be read out by a connected measuring device. Each measur

ing bridge has a separate TEDS in the double bridge variant. See also Page 32.

6. Without adapter

You can purchase the force transducer without an adapter. The force transducer can

then be directly screwed onto a structural element using the pitch circle, see Fig. 3.1.

U10M, U10S

SCOPE OF SUPPLY AND OPTIONS

10

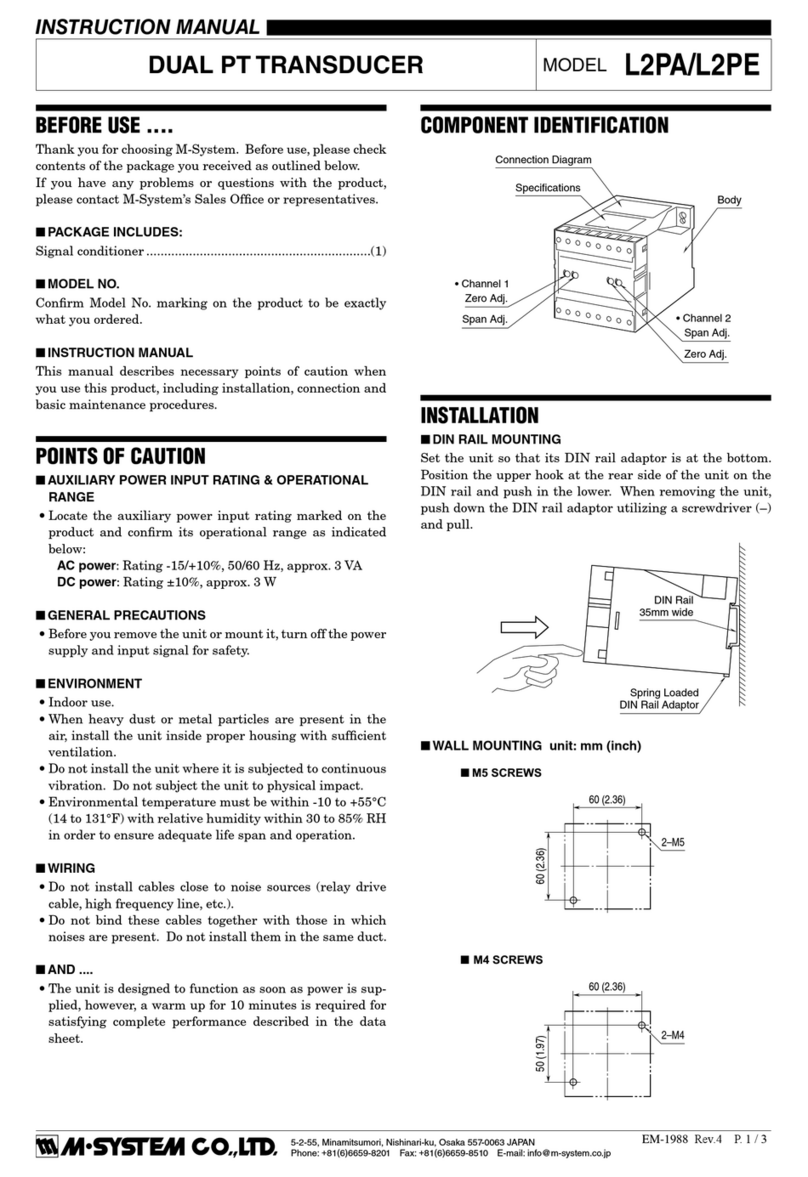

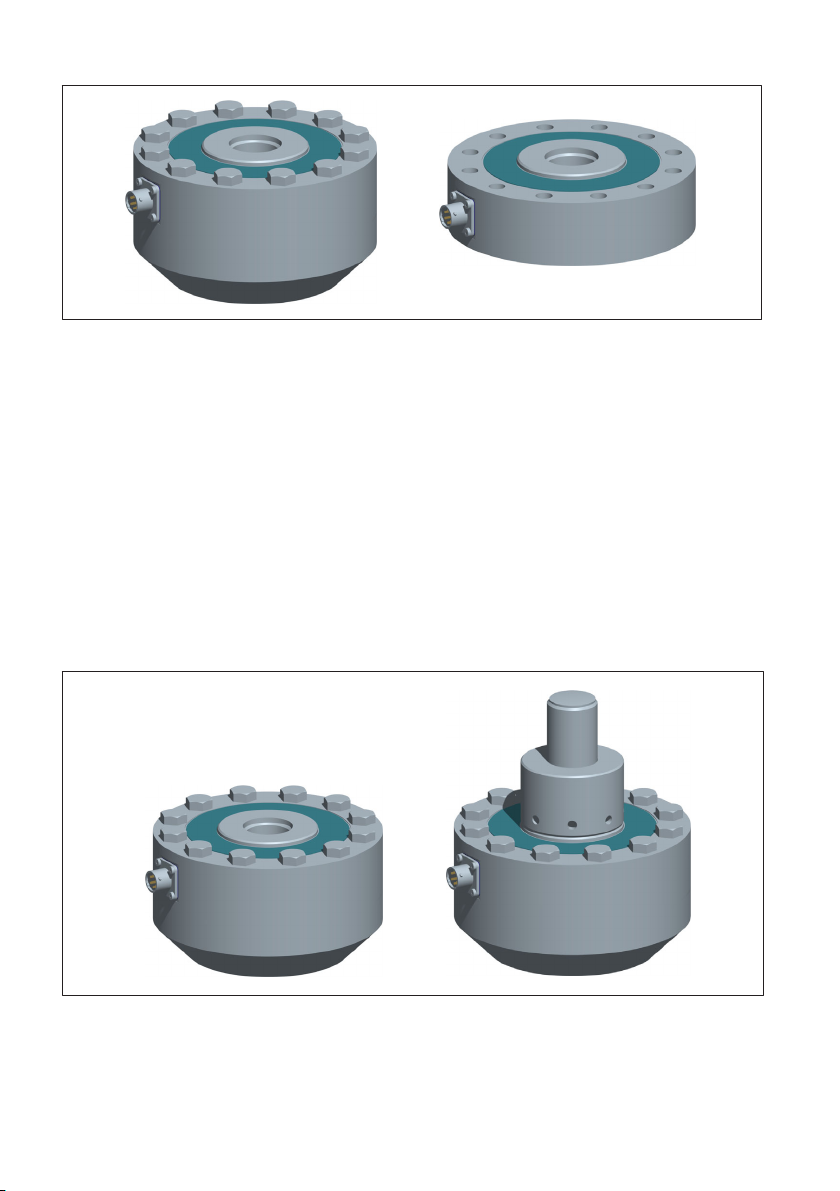

Fig. 3.1 U10M with adapter (left) and without adapter (right)

7. Plug protection

On request, we can fit plug protection, consisting of a rectangular tube (round tube for

nominal (rated) force 1.25MN), so that the plug is protected against

mechanical damage

8. Threaded connector or fixed cable

The standard version of the force transducer is

delivered with a bayonet connector. On request, a threaded connector or fixed cable

6m or 15m long can be provided instead.

9. Force application part

On request, we can deliver the U10M with a force

application part mounted in the central thread, see Fig. 3.2 on Page 10.

Fig. 3.2 U10M without force application bolt (left) and with mounted force application

bolt (right); both pictures with foot adapter

11

U10M, U10S

GENERAL APPLICATION INSTRUCTIONS

4 GENERAL APPLICATION INSTRUCTIONS

The force transducers are suitable for measuring tensile and compressive forces. They

provide highly accurate static and dynamic force measurements and must therefore be

handled very carefully. Particular care must be taken when transporting and installing the

devices. Dropping or knocking the transducer may cause permanent damage.

U10M force transducers have a metric internal thread and U10S force transducers have

an internal thread to UNF standard.

The permissible limits for mechanical, electrical and thermal stress are listed in the Chap

ter "" on page 36. It is essential to take these limits into account when planning the mea

suring set-up, during installation and, ultimately, during operation.

U10M, U10S

STRUCTURE AND MODE OF OPERATION

12

5 STRUCTURE AND MODE OF OPERATION

5.1 Transducer

The measuring element is a loaded member made of steel (for nominal (rated) forces

from 12.5kN) or high-strength aluminum (for nominal (rated) forces up to 5kN), to which

strain gages (SG) are applied. The SG are arranged in each measuring circuit so that four

are extended and the other four shortened when a force acts on the transducer. Each

strain gage changes its ohmic resistance in proportion to its change in length and so mis

aligns the Wheatstone bridge. If bridge excitation voltage is present, the circuit produces

an output signal proportional to the change in resistance and thus also proportional to the

applied force. The arrangement of the SGs is selected so that parasitic forces or torques

and temperature effects are compensated as much as possible.

5.2 SG covering agent

To protect the SG, the force transducers have thin cover plates that are welded (steel

versions) or glued (aluminum versions) top and bottom. This procedure offers the SG a

high level of protection against environmental influences. In order to retain the protective

effect, these plates must not be damaged in any way.

13

U10M, U10S

CONDITIONS ON SITE

6 CONDITIONS ON SITE

Protect the transducer from weather conditions such as rain, snow, ice, and salt water.

6.1 Ambient temperature

The temperature effects on the zero signal and on the rated output are compensated.

To obtain optimum measurement results, the nominal (rated) temperature range must be

complied with. The arrangement of the SG results in extreme insensitivity to temperature

gradients, due to its construction. Nevertheless, constant or very slowly changing temper

atures are best. A radiation shield and all-round thermal insulation produce noticeable

improvements, but must not be allowed to set up a force shunt.

6.2 Moisture and corrosion protection

The force transducers are hermetically encapsulated and are therefore very insensitive to

moisture.

The protection class of the sensors depends on the choice of electrical connection. In the

standard version with a bayonet connector, the sensor achieves degree of protection

IP 67 as per DIN EN60259 (test conditions: 0.5 hours under a 1-meter water column).

This applies when the plug is connected.

Optionally, the force transducers are also available fitted with a fixed cable. In this ver

sion, all U10 achieve degree of protection IP68 with a nominal (rated) force equal to or

greater than 12.5kN. In the threaded connector version, the sensors achieve degree of

protection IP64.

The transducer must be protected against chemicals that could attack the steel (nominal

(rated) forces from 12.5kN) or aluminum (nominal (rated) forces up to 5kN).

With stainless steel force transducers, note that acids and all materials which release

ions will also attack stainless steels and their seam welds. Any resulting corrosion could

cause the force transducer to fail. In this case, appropriate protective measures must be

implemented.

We recommend protecting the transducer against long-term exposure to moisture and

weather conditions.

6.3 Deposits

Dust, dirt and other foreign matter must not be allowed to accumulate sufficiently to di

vert some of the measuring force onto the housing, thus distorting the measured value

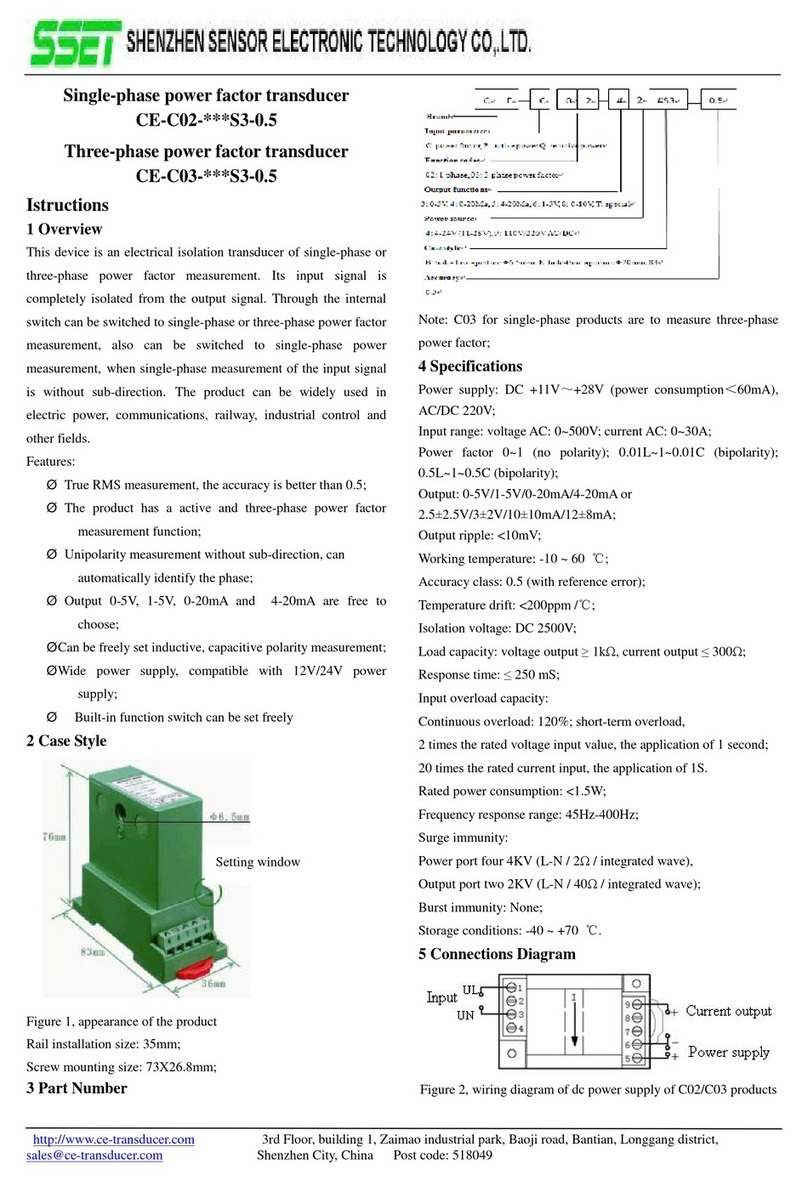

(force shunt). The relevant areas are marked in Fig. 6.1.

U10M, U10S

CONDITIONS ON SITE

14

The gap must remain free

Fig. 6.1 Deposits must not be allowed to form where marked.

15

U10M, U10S

MECHANICAL INSTALLATION

7 MECHANICAL INSTALLATION

7.1 Important precautions during installation

SHandle the transducer with care.

SComply with the requirements for the force application parts as specified in Sec

tion 7.3 and Section 7.6.

SWelding currents must not be allowed to flow over the transducer. If there is a risk

that this might happen, you must provide a suitable low-ohm connection to electrically

bypass the transducer. HBM provides the highly flexible EEK ground cable for this

purpose, for example. It can be screwed on above and below the transducer.

SMake sure that the transducer cannot be overloaded.

WARNING

There is a danger of the transducer breaking if it is overloaded. This can cause danger for

the operating personnel of the system in which the transducer is installed.

Implement appropriate safety measures to avoid overloads (see Specifications in

Chapter 11, page 36) or to protect against resulting dangers.

7.2 General installation guidelines

The forces to be measured must act on the transducer as accurately as possible in the

direction of measurement. Torques and bending moments, eccentric loading and lateral

forces may produce measurement errors and destroy the transducer, if limit values are

exceeded.

U10M, U10S

MECHANICAL INSTALLATION

16

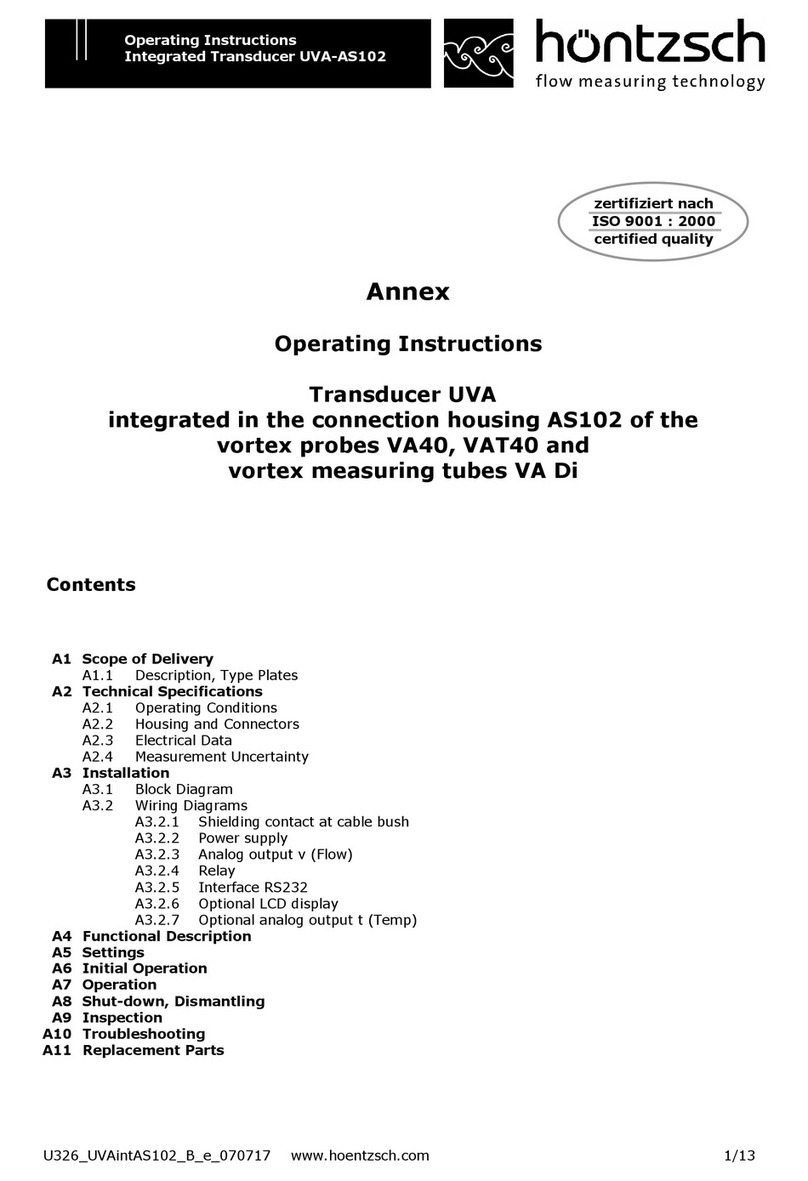

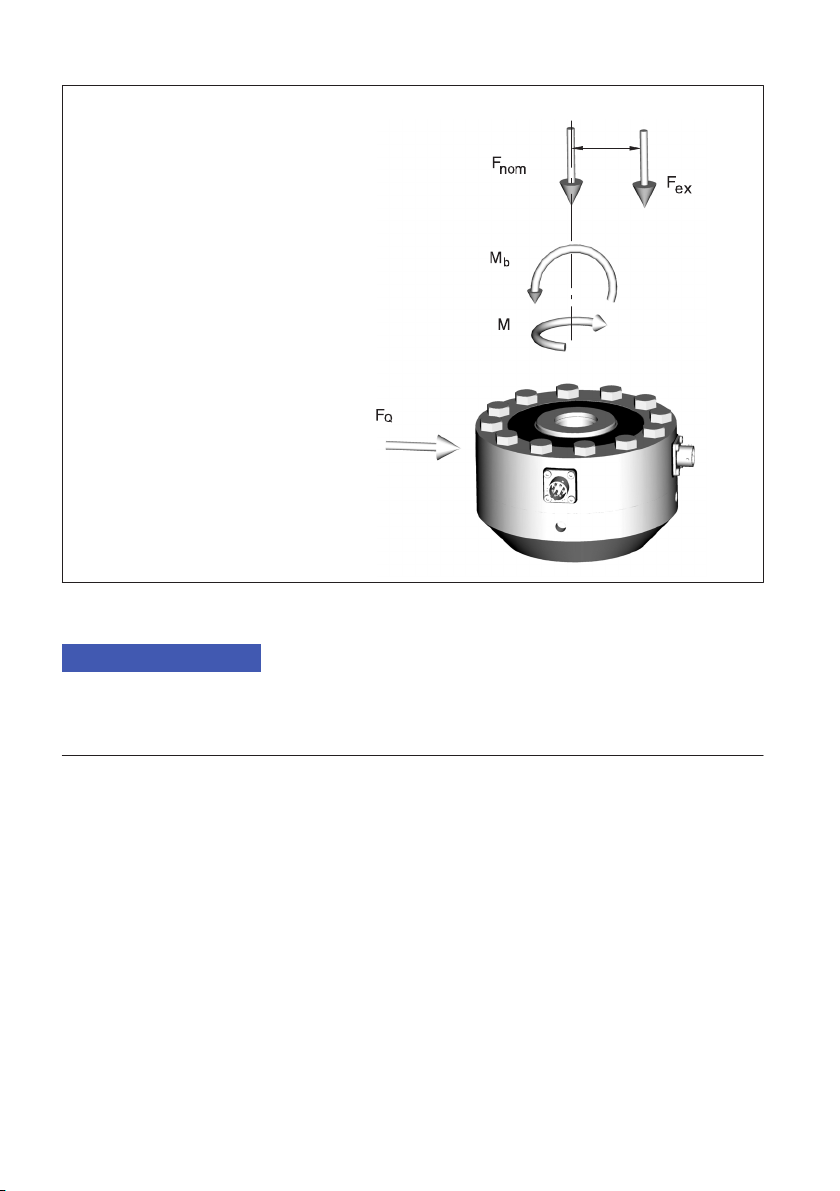

de

Fnom: Force in direction of measurement

Fex: Force parallel to direction of measurement, but

outside center of force transducer

FQ: Force vertical to direction of measurement

Mb: Bending moment

Md: Torque

d

Fig. 7.1 Parasitic forces and moments

Notice

When installing and operating the transducers, please note the maximum parasitic forces -

lateral forces, bending and torsional moments, see Chapter 11, page 36 - and the maximum

permissible load-carrying capacity of the force application parts used.

7.3 Assembly with adapter

The U10 can be directly mounted onto the structural

elements in this mounting variant. The internal threads on the force transducer and

adapter can be used for this purpose. The transducer can then measure axial forces in

both the tensile and pressure directions. Alternating loads are also correctly recorded if the

transducer is mounted without axial play. The transducer can be used without restrictions

with the full oscillation bandwidth.

The customer's own structural elements (threaded bolts) must meet the following condi

tions:

SThe upper and lower force application parts must be aligned as accurately as possible

in one axis. Installation is facilitated by centering aids at top and bottom. The center

17

U10M, U10S

MECHANICAL INSTALLATION

ing diameter corresponds to dimension P, the admissible centering depth is 3mm

(see Page 48ff).

SThe anti-screw-through device attached to the internal thread of the adapter must not

be removed.

SThe (customer-side) external thread must comply with a thread tolerance of 6g for

metric threads and 3A for UN/UNF threads.

SThe threads must be cleaned of any deposits and soaked with graphite-free grease

before being screwed in.

SThe following applies for steel force transducers (nominal (rated) forces from

12.5kN): To achieve the full endurance strength, a material with sufficient

tensile strength (min. Rp,0.2 = 900 N/mm2) and hardness (min. 40HRC) must be used.

We recommend the use of threads rolled after heat treatment for measurement

ranges between 225kN and 500kN.

If the customer fits their own force application parts in the U10, and these have a differ

ent coefficient of thermal expansion from that of the measuring bodies (e.g. a steel

thread in an aluminum measuring body), and if these are fitted tilted or uncentered, ther

mal stress may be produced during temperature variations that may adversely affect the

temperature dependence of the zero point due to irregular deformation. In this case, to

ensure precise measurements we recommend centering using centering dimension “P”,

and using a nut that ensures a right angle for locking (e.g. by grinding the nut).

Alternatively, the connecting part could be designed so that it is fitted without locking

using centering dimension P. This is possible whenever the connecting structural ele

ments can be mounted using the "Pre-stressing with defined tightening torque" method

(see table Tab. 7.1, page 19). This is the case for all nominal (rated) forces up to and

including 25 kN.

U10M, U10S

MECHANICAL INSTALLATION

18

A

0,03 A

0,02

16,5 f7

76

23

22,1

25

39

SR60

M16

22

11

M16 M16

A

16,5 f7

11

1x45°

min. 22

2:1

A

Fig. 7.2 Adapter dimensions

You do not need to pay attention to this information if measurement takes place at uni

form temperatures or taring is possible before changes in temperature. Likewise, large

nominal (rated) forces above 25 kN are not affected.

The screwed-in force application parts must be sufficiently pre-stressed to meet the

stated specifications and the full endurance strength of the threads. This is implemented

with a locknut screwed onto the customer-side structural element. We recommend using

one of the methods described below.

1. Pre-stressing with defined tightening torque

Force transducers with a nominal force up to and including 25kN can be mounted

using this method.

SScrew the force application part into the transducer or adapter as far as the retainer.

SUnscrew force application part two revolutions.

SPre-stress force application part with defined tightening torque.

Nominal (rated) force Tightening torque MAThread reach

in kN in N@min lb@inch in mm in inch

1.25 17 150 26.4 1.04

2.5 35 310 26.4 1.04

5 68 600 26.4 1.04

This manual suits for next models

1

Table of contents

Languages:

Other HBK Transducer manuals

Popular Transducer manuals by other brands

Woodward

Woodward UMT 1 manual

Philips

Philips Avalon CTS M2720A Service guide

Veris

Veris Hawkeye H421SP installation guide

NK TECHNOLOGIES

NK TECHNOLOGIES AT-TH Series instructions

S+S Regeltechnik

S+S Regeltechnik AERASGARD RCO2-W-A Operating Instructions, Mounting & Installation

Carrier

Carrier 48NP installation instructions