aci ACCESS series Installation instructions

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

Version: 4.0

I0000599

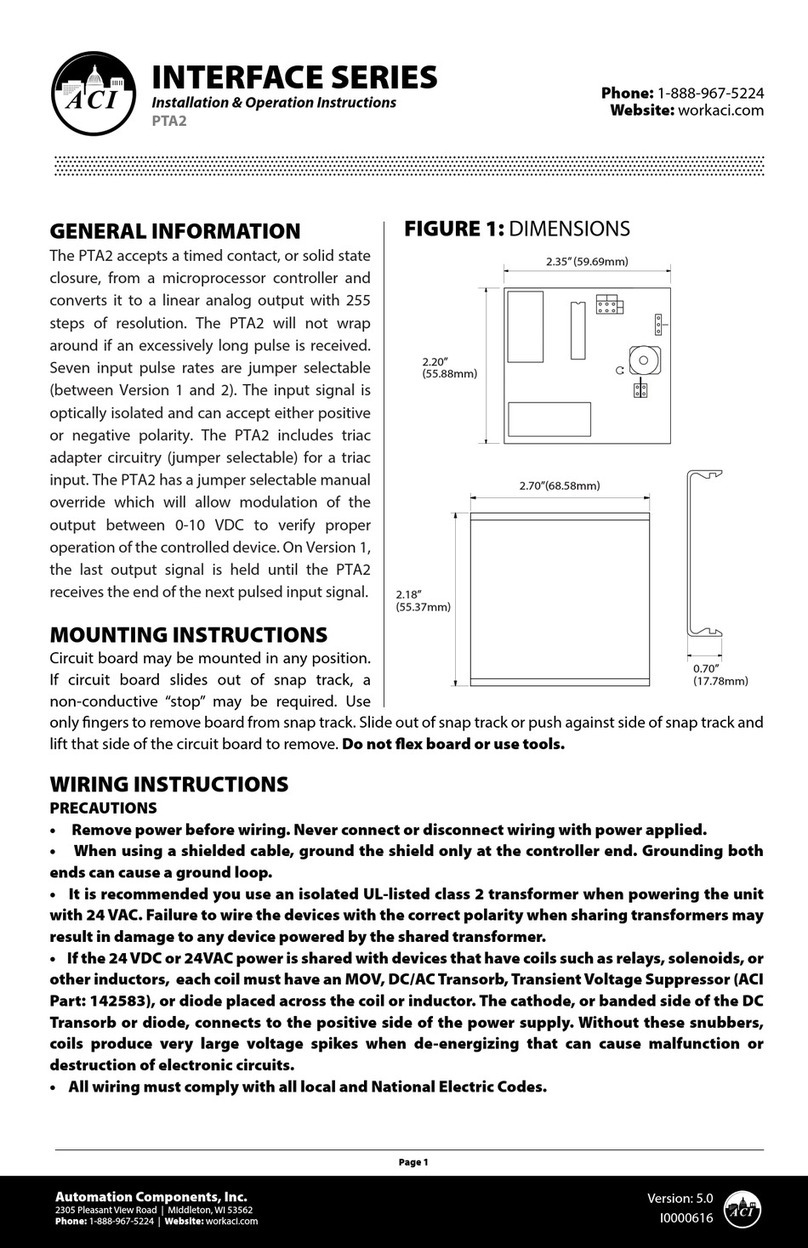

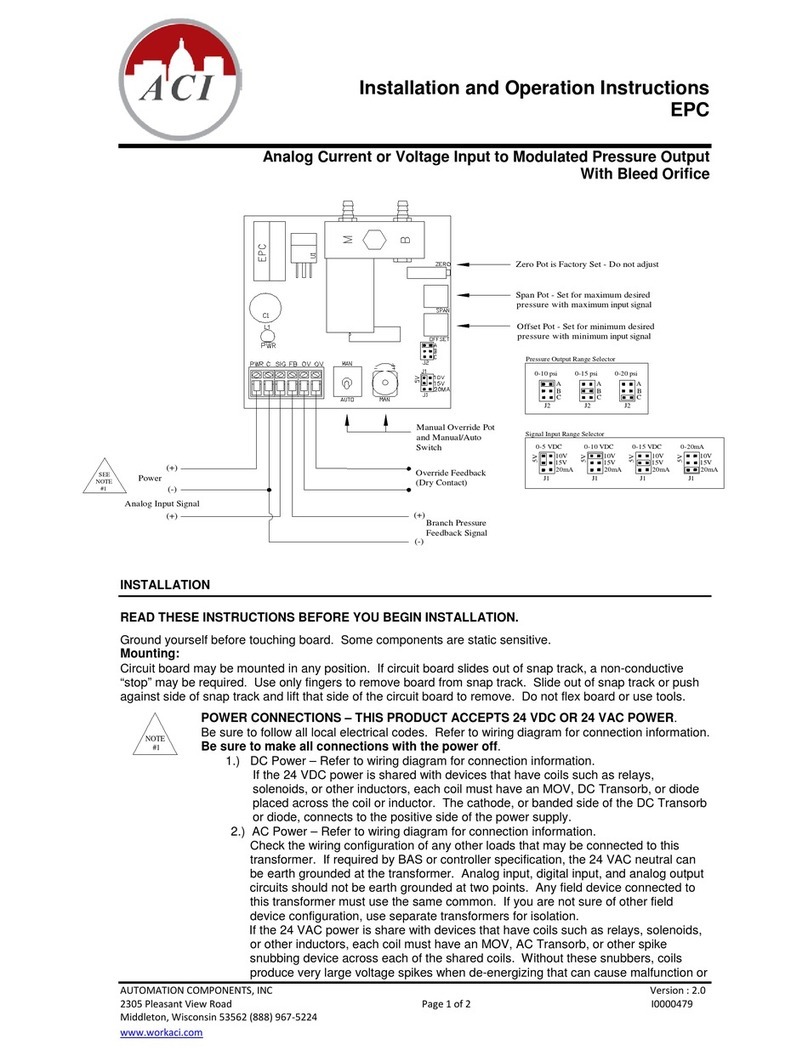

FIGURE 1: DIMENSIONS

INTERFACE SERIES

Installation & Operation Instructions

PXP2.3, PXP2.3FS, PXP2.3LG

Phone: 1-888-967-5224

Website: workaci.com

GENERAL INFORMATION

The PXP2.3 is an electric to pneumatic transducer which

converts an analog electrical input signal to a

proportional pneumatic output. The PXP2.3 will

automatically modulate its control valve(s) to regulate

the branch line pressure to the selected set point as

determined by the input signal. The PXP2.3 oers four

selectable input ranges which convert to a 0 to 15 psig

modulating output (See EPC product for 0 to 20 psig

outputs). A 0-5 VDC feedback signal indicating the

resultant branch line pressure is also provided. This

signal varies linearly with branch pressure (0 volts= 0

psig, 5 volts = 15 psig). The PXP2.3 incorporates two

valves and does not use air at set point. It’s branch

exhaust ow and response time are not limited by an

internal restrictor and are similar to its load rate. If power

fails to the PXP2.3, branch line pressure remains

constant if the branch line does not leak air. The

PXP2.3FS is equipped with a N.O. branch exhaust valve

which allows exhaust of branch air on power failure. A

manual override (jumper selectable), which controls the

output pressure, is provided for setup and

troubleshooting.

MOUNTING INSTRUCTIONS

Circuit board may be mounted in any position. If

circuit board slides out of snap track, a

non-conductive “stop” may be required. Use only

ngers to remove board from snap track. Slide

out of snap track or push against side of snap

track and lift that side of the circuit board to

remove. Do not flex board or use tools.

WIRING INSTRUCTIONS

PRECAUTIONS

• Remove power before wiring. Never

connect or disconnect wiring with power

applied.

• When using a shielded cable, ground the

shield only at the controller end. Grounding

both ends can cause a ground loop.

• It is recommended you use an isolated

UL-listed class 2 transformer when powering

the unit with 24 VAC. Failure to wire the

devices with the correct polarity when

3.25” (82.55mm)

2.18”

(55.37mm)

PXP

0.70”

(17.78mm)

2.18”

(55.37mm)

2.70”(68.58mm)

PXP With Gauge

3.65” (92.71mm)

2.70” (68.58mm)

2.20”

(55.92mm)

Ø1.64”

(41.66mm)

2.95” (74.90mm)

WIRING INSTRUCTIONS

(CONTINUED)

sharing transformers may result in damage to any

device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared with

devices that have coils such as relays, solenoids, or

other inductors, each coil must have an MOV,

DC/AC Transorb, Transient Voltage Suppressor

(ACI Part: 142583), or diode placed across the coil

or inductor. The cathode, or banded side of the DC

Transorb or diode, connects to the positive side of

the power supply. Without these snubbers, coils

produce very large voltage spikes when

de-energizing that can cause malfunction or

destruction of electronic circuits.

• All wiring must comply with all local and

National Electric Codes.

The gauge port will accept a miniature 1/8”-27 FNPT back-ported pressure gauge to allow direct reading of

branch line pressure. The gauge should be sealed by Teon sealing tape, and should be tightened just

snug, using a backup wrench to hold the manifold. ADJUSTMENT OF INSTALLED GAUGES. If installation

requires adjustment of the gauge for proper reading of the face, turn the gauge no more than ½ turn in

either direction. O-rings in the bottom of the gauge port will allow this without leakage.

Warranty does not include malfunction due to clogged valve. Main air port is ltered with the supplied 80

– 100 micron integral-in-barb lter (except for the PXP2.3LG model). Periodically check the lter for

contamination and ow reduction. Replace if needed (Part # PN004).

The surface between the manifold and pressure transducer is a pressure seal. Minimize stress between the

circuit board and the manifold by holding the manifold in one hand while installing pneumatic tubing

onto the ttings, and use care when removing tubing to avoid damaging ttings or moving manifold.

This unit requires at least two cubic inches (minimum) of branch air line capacity to operate without

oscillation. Do not operate without main air supplied.

CHECKOUT

Select one of the four input signal combinations by moving the jumper shunt as shown in “Input Signal

Selector”.

Verify the MAN/AUTO jumper shunts are in the AUTO position (jumper over center pin and AUTO pin). In

AUTO, the manual override pot is inactive and the analog input signal is supplying the set-point. When in

the MAN position, the manual override pot in supplying the set point and the analog input signal is locked

out. Use a small bladed screwdriver to increase or decrease the pneumatic output.

Supply power and the LED power indicator

will light, but only measurement will verify

proper voltage. Apply minimum and

maximum input signals and measure

response. Response between the minimum

and maximum values will be linear,

therefore software algorithms are easy to

derive.

The feedback signal range on all selections is

0 to 5 VDC and is proportional to the output

pressure range of 0 – 15 psig.

The output and feedback signal will

continue to vary proportionally if the input

signal is increased beyond its upper limit (if

there is enough main air available).

However, do not exceed the listed maximum

input signal voltage by more than 25%.

The PXP2.3 incorporates two valves and is

not a constant bleed controller. Its branch

exhaust ow and response time is not limited by any internal restrictor and is similar to its load rate. The

PXP2.3 is ideal for long branch line runs, multiple actuators, and outside air dampers because of it’s 750

scim capacity.

Note: If power to the PXP2.3 is lost, it will maintain branch line pressure (assuming no branch line leaks). If

power to the PXP2.3FS (Fail-Safe) is lost, the branch line control valve will open and branch line pressure

will go to 0 psig.

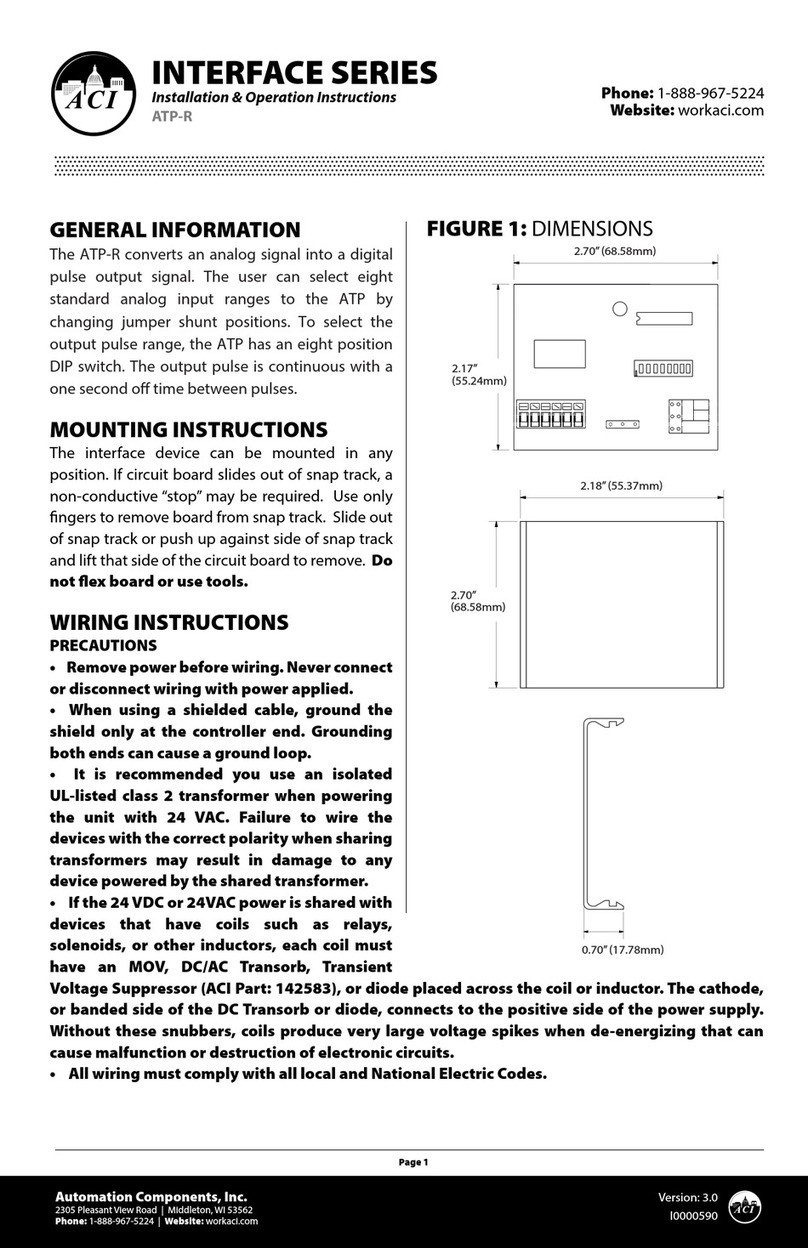

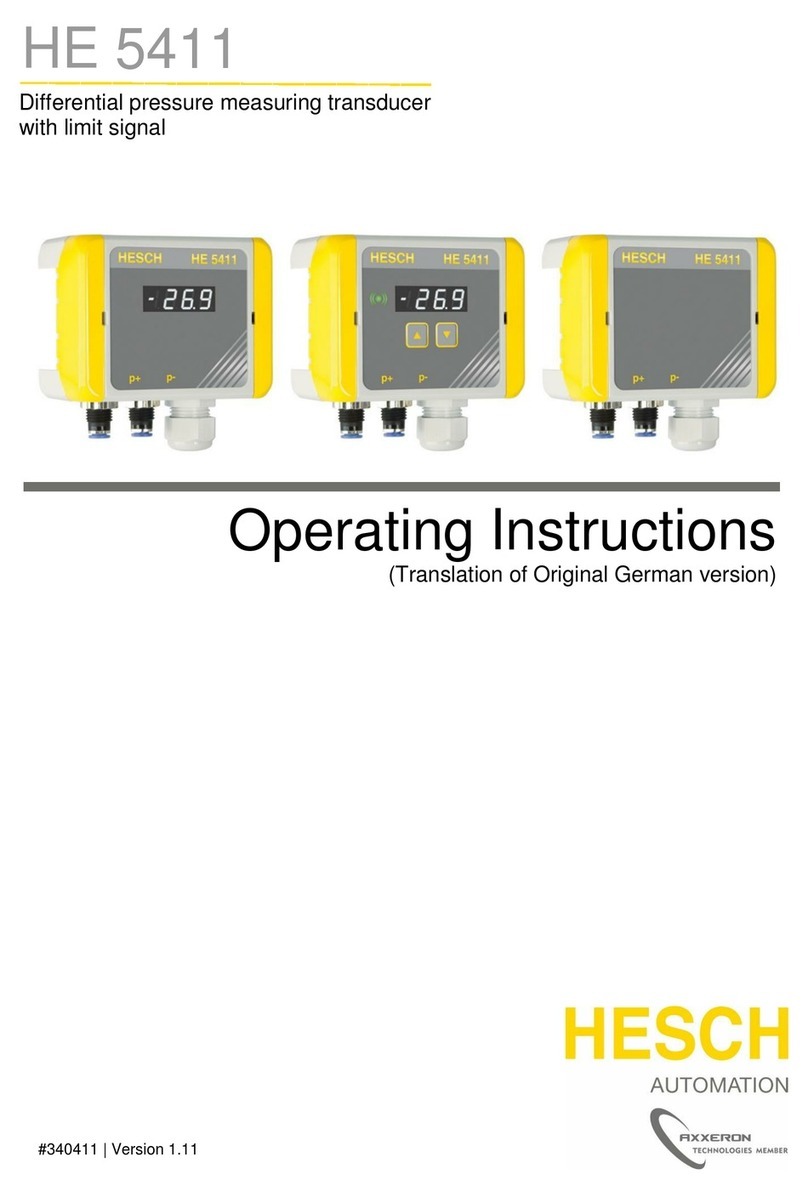

FIGURE 3: SHUNT SWITCHES

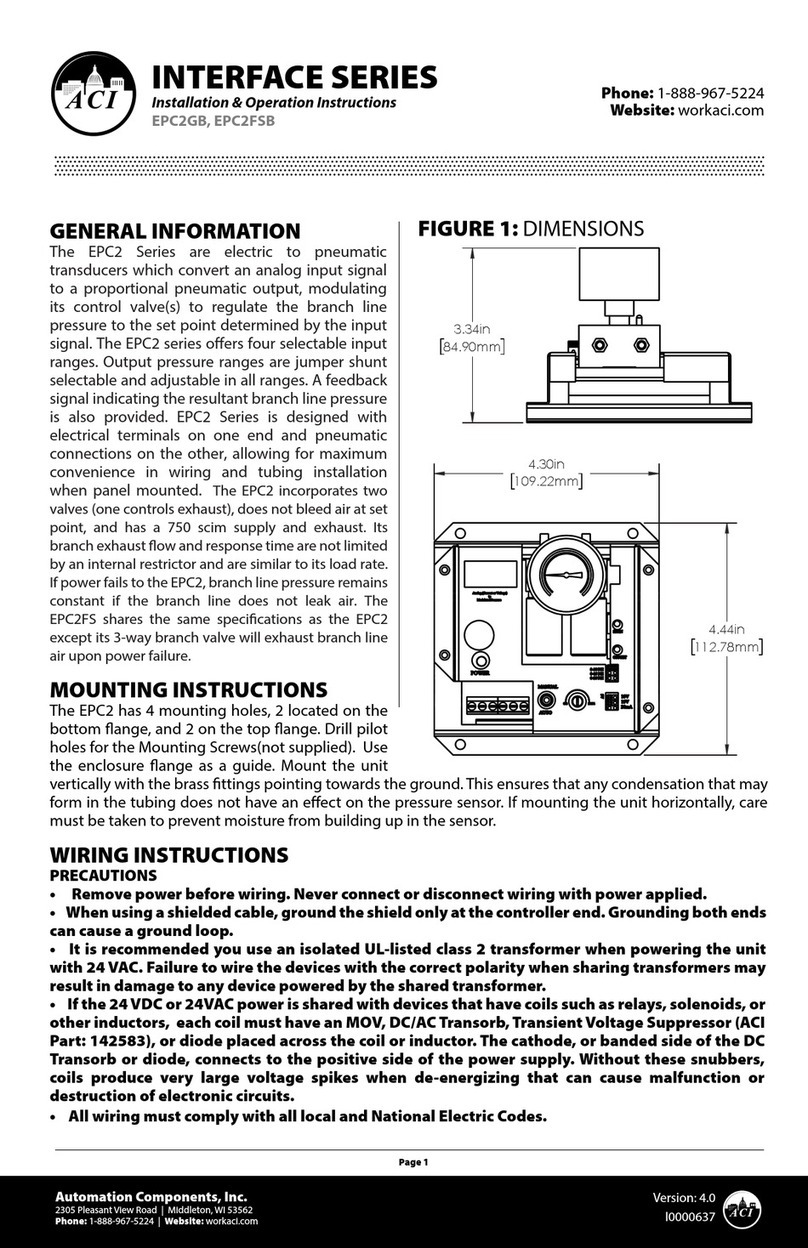

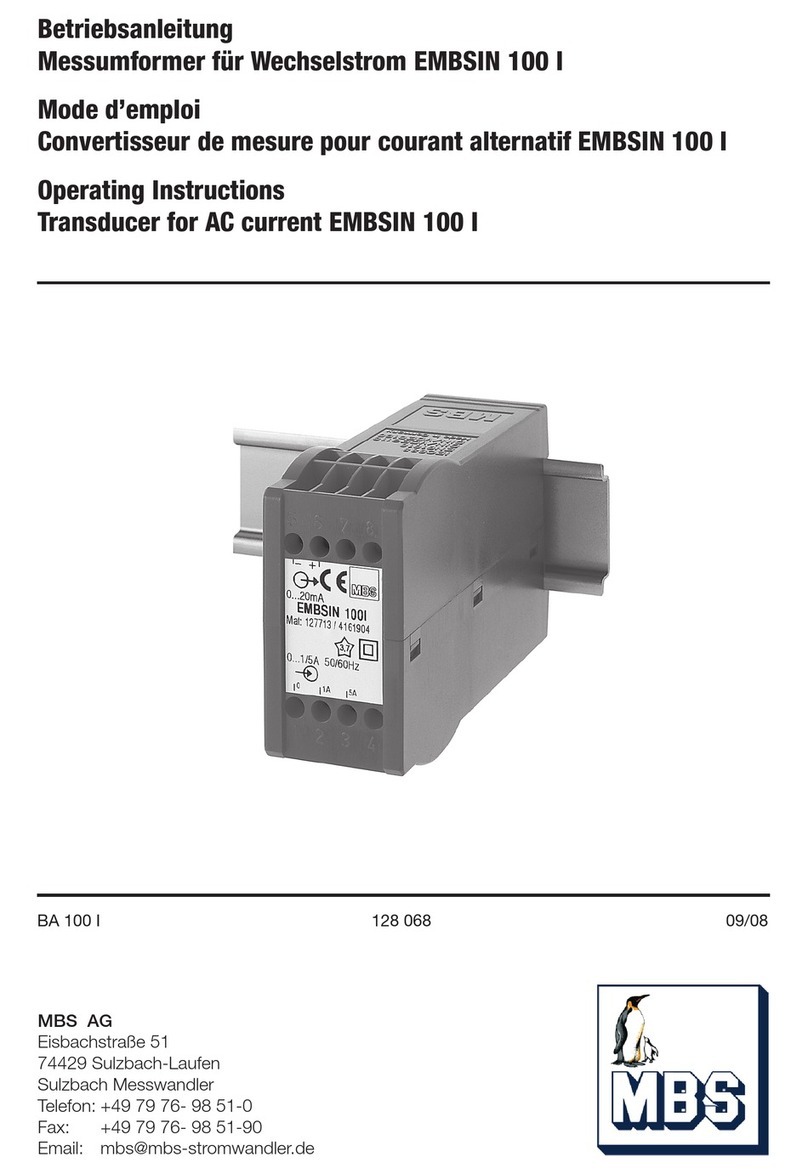

FIGURE 2: WIRING

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

Version: 4.0

I0000599

GENERAL INFORMATION

The PXP2.3 is an electric to pneumatic transducer which

converts an analog electrical input signal to a

proportional pneumatic output. The PXP2.3 will

automatically modulate its control valve(s) to regulate

the branch line pressure to the selected set point as

determined by the input signal. The PXP2.3 oers four

selectable input ranges which convert to a 0 to 15 psig

modulating output (See EPC product for 0 to 20 psig

outputs). A 0-5 VDC feedback signal indicating the

resultant branch line pressure is also provided. This

signal varies linearly with branch pressure (0 volts= 0

psig, 5 volts = 15 psig). The PXP2.3 incorporates two

valves and does not use air at set point. It’s branch

exhaust ow and response time are not limited by an

internal restrictor and are similar to its load rate. If power

fails to the PXP2.3, branch line pressure remains

constant if the branch line does not leak air. The

PXP2.3FS is equipped with a N.O. branch exhaust valve

which allows exhaust of branch air on power failure. A

manual override (jumper selectable), which controls the

output pressure, is provided for setup and

troubleshooting.

MOUNTING INSTRUCTIONS

Circuit board may be mounted in any position. If

circuit board slides out of snap track, a

non-conductive “stop” may be required. Use only

ngers to remove board from snap track. Slide

out of snap track or push against side of snap

track and lift that side of the circuit board to

remove. Do not flex board or use tools.

WIRING INSTRUCTIONS

PRECAUTIONS

• Remove power before wiring. Never

connect or disconnect wiring with power

applied.

• When using a shielded cable, ground the

shield only at the controller end. Grounding

both ends can cause a ground loop.

• It is recommended you use an isolated

UL-listed class 2 transformer when powering

the unit with 24 VAC. Failure to wire the

devices with the correct polarity when

WIRING INSTRUCTIONS

(CONTINUED)

sharing transformers may result in damage to any

device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared with

devices that have coils such as relays, solenoids, or

other inductors, each coil must have an MOV,

DC/AC Transorb, Transient Voltage Suppressor

(ACI Part: 142583), or diode placed across the coil

or inductor. The cathode, or banded side of the DC

Transorb or diode, connects to the positive side of

the power supply. Without these snubbers, coils

produce very large voltage spikes when

de-energizing that can cause malfunction or

destruction of electronic circuits.

• All wiring must comply with all local and

National Electric Codes.

The gauge port will accept a miniature 1/8”-27 FNPT back-ported pressure gauge to allow direct reading of

branch line pressure. The gauge should be sealed by Teon sealing tape, and should be tightened just

snug, using a backup wrench to hold the manifold. ADJUSTMENT OF INSTALLED GAUGES. If installation

requires adjustment of the gauge for proper reading of the face, turn the gauge no more than ½ turn in

either direction. O-rings in the bottom of the gauge port will allow this without leakage.

Warranty does not include malfunction due to clogged valve. Main air port is ltered with the supplied 80

– 100 micron integral-in-barb lter (except for the PXP2.3LG model). Periodically check the lter for

contamination and ow reduction. Replace if needed (Part # PN004).

The surface between the manifold and pressure transducer is a pressure seal. Minimize stress between the

circuit board and the manifold by holding the manifold in one hand while installing pneumatic tubing

onto the ttings, and use care when removing tubing to avoid damaging ttings or moving manifold.

This unit requires at least two cubic inches (minimum) of branch air line capacity to operate without

oscillation. Do not operate without main air supplied.

PWR

L1

Man Auto

J2 J1

10V

15V

20mA

5V

PWR CSIG FB

MAIN

BRANCH

Span

Zero

80 - 100 Micron

Filter in Barb

Selector for

Manual Override

24VAC/DC

Power Supply

Manual

Override

Pot

Analog

Signal

Input

(+) (+)

(+)

(-) (-)

(-)

CHECKOUT

Select one of the four input signal combinations by moving the jumper shunt as shown in “Input Signal

Selector”.

Verify the MAN/AUTO jumper shunts are in the AUTO position (jumper over center pin and AUTO pin). In

AUTO, the manual override pot is inactive and the analog input signal is supplying the set-point. When in

the MAN position, the manual override pot in supplying the set point and the analog input signal is locked

out. Use a small bladed screwdriver to increase or decrease the pneumatic output.

Supply power and the LED power indicator

will light, but only measurement will verify

proper voltage. Apply minimum and

maximum input signals and measure

response. Response between the minimum

and maximum values will be linear,

therefore software algorithms are easy to

derive.

The feedback signal range on all selections is

0 to 5 VDC and is proportional to the output

pressure range of 0 – 15 psig.

The output and feedback signal will

continue to vary proportionally if the input

signal is increased beyond its upper limit (if

there is enough main air available).

However, do not exceed the listed maximum

input signal voltage by more than 25%.

The PXP2.3 incorporates two valves and is

not a constant bleed controller. Its branch

exhaust ow and response time is not limited by any internal restrictor and is similar to its load rate. The

PXP2.3 is ideal for long branch line runs, multiple actuators, and outside air dampers because of it’s 750

scim capacity.

Note: If power to the PXP2.3 is lost, it will maintain branch line pressure (assuming no branch line leaks). If

power to the PXP2.3FS (Fail-Safe) is lost, the branch line control valve will open and branch line pressure

will go to 0 psig.

J1

0-20mA

J1

0-10V

J1

0-15V

J1

0-5V

INPUT SIGNAL SELECTOR

J1 SHUNT POSITIONS

Branch Pressure

Feedback Output

Blue Manifold for Failsafe Model

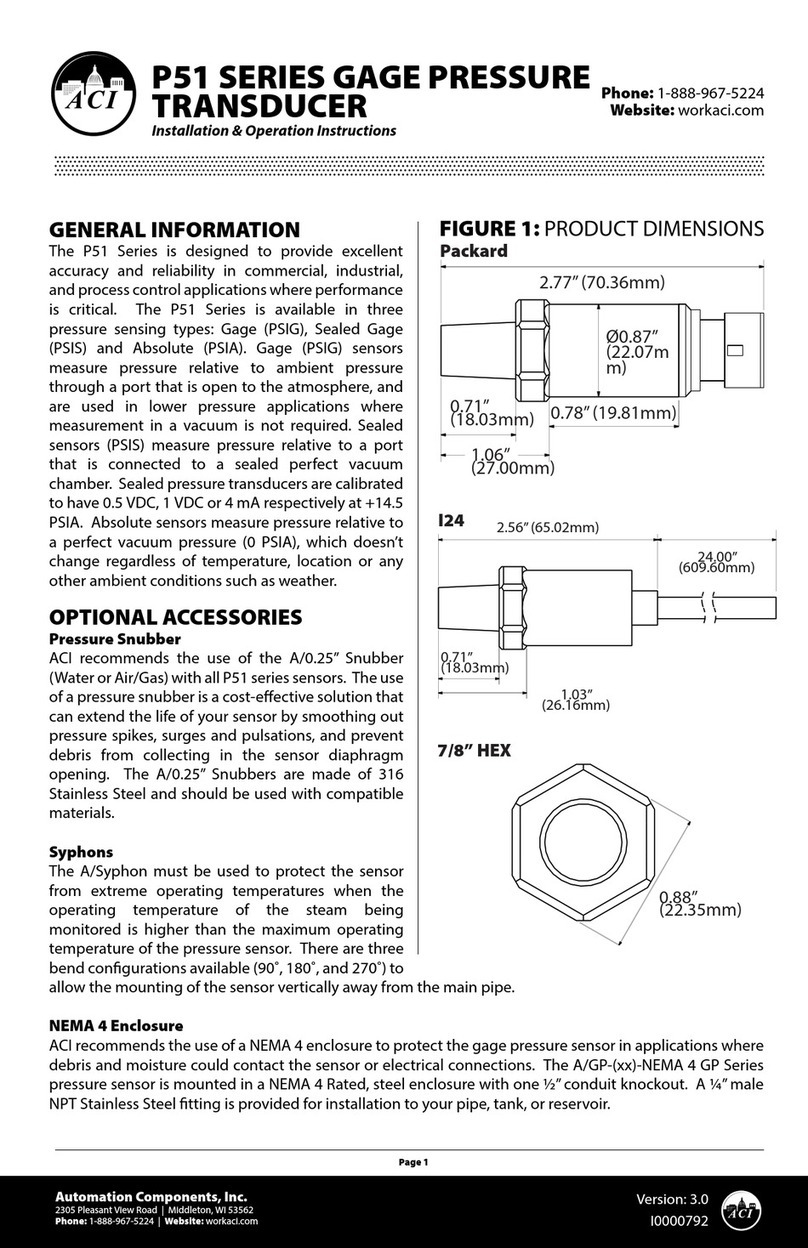

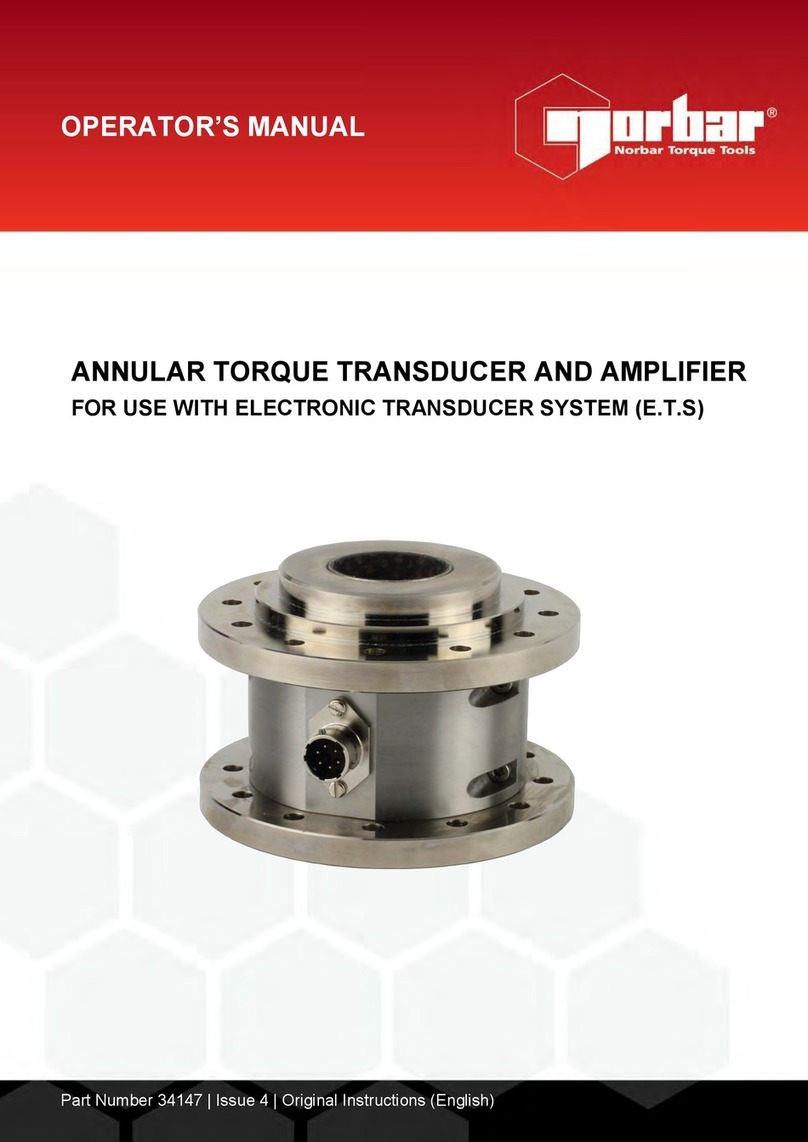

FIGURE 4: PNEUMATIC TUBING

INSTALLATION

GENERAL INFORMATION

The PXP2.3 is an electric to pneumatic transducer which

converts an analog electrical input signal to a

proportional pneumatic output. The PXP2.3 will

automatically modulate its control valve(s) to regulate

the branch line pressure to the selected set point as

determined by the input signal. The PXP2.3 oers four

selectable input ranges which convert to a 0 to 15 psig

modulating output (See EPC product for 0 to 20 psig

outputs). A 0-5 VDC feedback signal indicating the

resultant branch line pressure is also provided. This

signal varies linearly with branch pressure (0 volts= 0

psig, 5 volts = 15 psig). The PXP2.3 incorporates two

valves and does not use air at set point. It’s branch

exhaust ow and response time are not limited by an

internal restrictor and are similar to its load rate. If power

fails to the PXP2.3, branch line pressure remains

constant if the branch line does not leak air. The

PXP2.3FS is equipped with a N.O. branch exhaust valve

which allows exhaust of branch air on power failure. A

manual override (jumper selectable), which controls the

output pressure, is provided for setup and

troubleshooting.

MOUNTING INSTRUCTIONS

Circuit board may be mounted in any position. If

circuit board slides out of snap track, a

non-conductive “stop” may be required. Use only

ngers to remove board from snap track. Slide

out of snap track or push against side of snap

track and lift that side of the circuit board to

remove. Do not flex board or use tools.

WIRING INSTRUCTIONS

PRECAUTIONS

• Remove power before wiring. Never

connect or disconnect wiring with power

applied.

• When using a shielded cable, ground the

shield only at the controller end. Grounding

both ends can cause a ground loop.

• It is recommended you use an isolated

UL-listed class 2 transformer when powering

the unit with 24 VAC. Failure to wire the

devices with the correct polarity when

WARRANTY

The PXP Series is covered by ACI’s Two (2) Year Limited Warranty, which is located in the front of ACI’S SENSORS &

TRANSMITTERS CATALOG or can be found on ACI’s website: www.workaci.com.

W.E.E.E. DIRECTIVE

At the end of their useful life the packaging and product should be disposed of via a suitable recycling

centre. Do not dispose of with household waste. Do not burn.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

Version: 4.0

I0000599

WIRING INSTRUCTIONS

(CONTINUED)

sharing transformers may result in damage to any

device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared with

devices that have coils such as relays, solenoids, or

other inductors, each coil must have an MOV,

DC/AC Transorb, Transient Voltage Suppressor

(ACI Part: 142583), or diode placed across the coil

or inductor. The cathode, or banded side of the DC

Transorb or diode, connects to the positive side of

the power supply. Without these snubbers, coils

produce very large voltage spikes when

de-energizing that can cause malfunction or

destruction of electronic circuits.

• All wiring must comply with all local and

National Electric Codes.

The gauge port will accept a miniature 1/8”-27 FNPT back-ported pressure gauge to allow direct reading of

branch line pressure. The gauge should be sealed by Teon sealing tape, and should be tightened just

snug, using a backup wrench to hold the manifold. ADJUSTMENT OF INSTALLED GAUGES. If installation

requires adjustment of the gauge for proper reading of the face, turn the gauge no more than ½ turn in

either direction. O-rings in the bottom of the gauge port will allow this without leakage.

Warranty does not include malfunction due to clogged valve. Main air port is ltered with the supplied 80

– 100 micron integral-in-barb lter (except for the PXP2.3LG model). Periodically check the lter for

contamination and ow reduction. Replace if needed (Part # PN004).

The surface between the manifold and pressure transducer is a pressure seal. Minimize stress between the

circuit board and the manifold by holding the manifold in one hand while installing pneumatic tubing

onto the ttings, and use care when removing tubing to avoid damaging ttings or moving manifold.

This unit requires at least two cubic inches (minimum) of branch air line capacity to operate without

oscillation. Do not operate without main air supplied.

Min Tubing Length:

25 ft [7.62 m]

CHECKOUT

Select one of the four input signal combinations by moving the jumper shunt as shown in “Input Signal

Selector”.

Verify the MAN/AUTO jumper shunts are in the AUTO position (jumper over center pin and AUTO pin). In

AUTO, the manual override pot is inactive and the analog input signal is supplying the set-point. When in

the MAN position, the manual override pot in supplying the set point and the analog input signal is locked

out. Use a small bladed screwdriver to increase or decrease the pneumatic output.

Supply power and the LED power indicator

will light, but only measurement will verify

proper voltage. Apply minimum and

maximum input signals and measure

response. Response between the minimum

and maximum values will be linear,

therefore software algorithms are easy to

derive.

The feedback signal range on all selections is

0 to 5 VDC and is proportional to the output

pressure range of 0 – 15 psig.

The output and feedback signal will

continue to vary proportionally if the input

signal is increased beyond its upper limit (if

there is enough main air available).

However, do not exceed the listed maximum

input signal voltage by more than 25%.

The PXP2.3 incorporates two valves and is

not a constant bleed controller. Its branch

exhaust ow and response time is not limited by any internal restrictor and is similar to its load rate. The

PXP2.3 is ideal for long branch line runs, multiple actuators, and outside air dampers because of it’s 750

scim capacity.

Note: If power to the PXP2.3 is lost, it will maintain branch line pressure (assuming no branch line leaks). If

power to the PXP2.3FS (Fail-Safe) is lost, the branch line control valve will open and branch line pressure

will go to 0 psig.

Air Compressor

PRODUCT SPECIFICATIONS

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 4

Version: 4.0

I0000599

24 VAC (+/-10%), 50 or 60Hz, 24 VDC (+10%/- 5%)

160 mA maximum, 200 mA on fail safe models

0-5 VDC @ 10,000 | 0-10 VDC @ 10,000 | 0-15 VDC @ 10,000 | 0-20 mA @

250

0-5 VDC = Output Span

Field Calibration Possible: 0 to 15 psig (0-103.421 kPa) maximum

Maximum: 25 psig (172.369 kPa) | Minimum: 18 psig (124.106 kPa)

PXP2.3FS: 750 SCIM (12.29 Liters), 750 SCIM (12.29 Liters) | PXP2.3GFS: 750

SCIM (12.29 Liters), 750 SCIM (12.29 Liters) | PXP2.3LG: 1400 SCIM (22.94 Liters),

1400 SCIM (22.94 Liters)

1% full scale @ room temperature | 2% full scale across operating temperature

range

MAN function = output can be varied | AUTO function = output is controlled

from input signal

Supply valves @ 20 psig (138 kPa) main/15 psig (103 kPa) out, 750 scim (1400 on

LG model)

Branch Line requires 2 in or 33.78 cm (min.). Branch line min. of 25 feet of 1/4”

O.D poly tubing

Furnished with integral-in-barb 80-100 micron lter (Part # PN004) except for

PXP2LG which is furnished with external 5 micron in-line lter (PN021)

90° Pluggable Screw Terminal Blocks

16 (1.31 mm) to 26 AWG (0.129 mm)

0.5 Nm (Minimum); 0.6 Nm (Maximum)

1/4" O.D. nominal (1/8” I.D.) polyethylene

Removeable brass barbed ttings for Main and Branch in machined aluminum

manifold

Plugged 1/8-27-FNPT gauge port | Gauge installed at additional cost

0-30 psig (0-200 kPa)

35 to 120°F (1.7 to 48.9°C)

10 to 95% non-condensing

-20 to 150°F (-28.9 to 65.5°C)

NON-SPECIFIC INFORMATION

Supply Voltage:

Supply Current:

Input Signal Source (@

Impedance):

Feedback Signal Output Range:

Output Pressure Range:

Air Supply Pressure:

Air Consumption:

Output Pressure Accuracy:

Manual / Auto Override:

Air Flow:

Filtering:

Connections:

Wire Size:

Terminal Block Torque Rating:

Connections | Pneumatic

Tubing Size-Type:

Pneumatic Fitting:

Gauge Pressure Range (Gauge

Models):

Operating Temperature Range:

Operating Humidity Rage:

Storage Temperature:

Other manuals for ACCESS series

16

This manual suits for next models

4

Other aci Transducer manuals

Popular Transducer manuals by other brands

MKS

MKS HPS Products 999 Quattro Series Operation and maintenance manual

Axxeron

Axxeron HESCH HE 5411 operating instructions

BECKWITH ELECTRIC

BECKWITH ELECTRIC M-0214 Instruction book

norbar

norbar PNEUTORQUE PT 1 Operator's manual

Lumel

Lumel P41 User Manual & Quick Start

Knick

Knick VariTrans P 41000 Series user manual

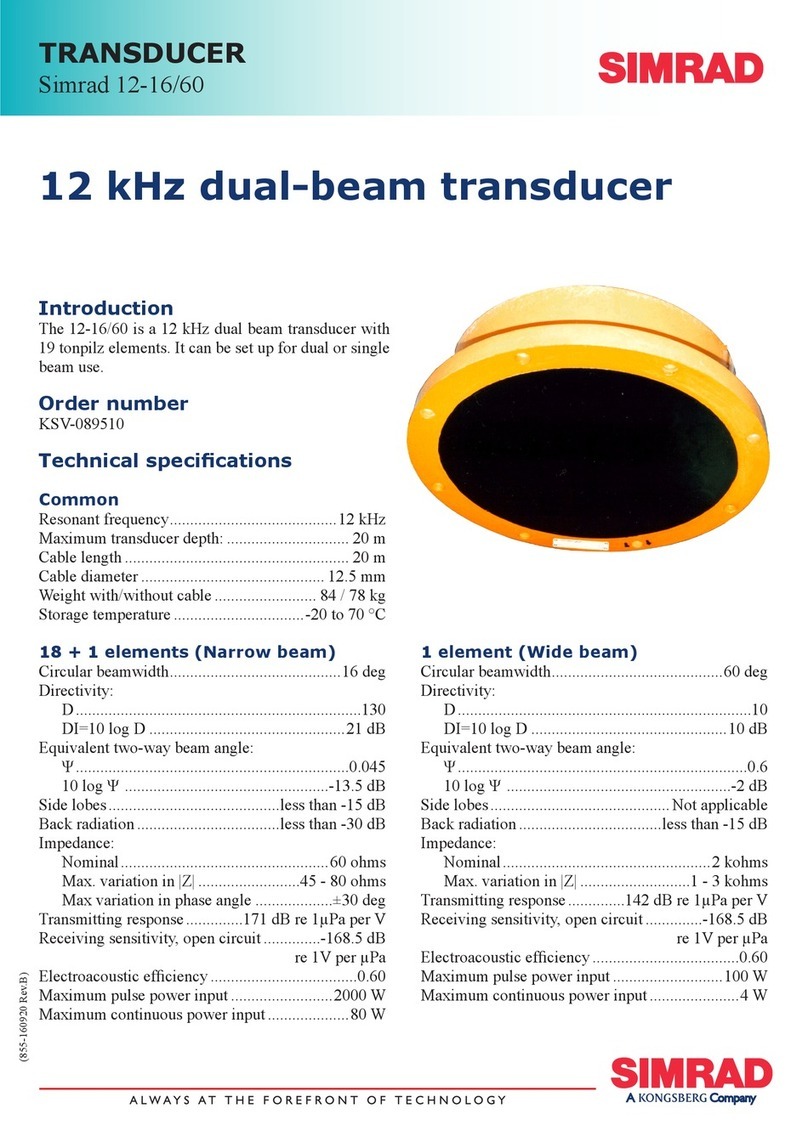

Simrad

Simrad 12-16/60 datasheet

Signaltec

Signaltec TPS II installation manual

ADInstruments

ADInstruments MLT844 quick start guide

novotechnik

novotechnik Z-TF1-PO1 user manual

LEI accessories

LEI accessories FISHSTRIKE HS-WS Installation and operation instructions

LEI accessories

LEI accessories PD-N installation manual