HBM HBM 100 User manual

WARRANTY

This HBM Machines product complies with the highest standards of

workmanship, durability and safety. HBM Machines guarantees original

buyers a faultless operation of its products for a one year period with respect

to material and construction.

This warranty is null and void in case of defects occurring due to

the following causes:

Normal wear

Lack of attention, ignorance, unsafe pworking procedures, lack of care

during transport or storage.

Lack of maintenance or maintenance carried out against the rules laid

down in this booklet

Use of the product for any work for which it was not intended;

exceeding the rated capacity. Transport without proper care

Shifting machinery without making use of proper lifting/ carrying gear

Failure to read and/ or understand the rules and guidelines explained

in these instructions.

Every use for which the product was not designed. These instructions

state very clearly all goals for which the product can be used. All other

work is prohibited!

Operation of the machinery by persons who have not or insufficiently

been educated or instructed in its operation or who do not or

insufficiently understand its operation.

Operation of the machinery by persons without sufficient experience,

in case of Their working without direct supervision by a teacher.

Operation of the machinery by persons under the influence of

medicines which impair one’s ability to react, or by persons under the

influence of alcohol or drugs.

Operation of the machinery by persons under the age of 16, or by

persons aged between 16 and 18 without direct supervision by a

teacher.

Repairs which are or have been made without prior written consent by

HBM Machines.

Any change or alteration made in the machinery by the customer

(owner).

Accidents or damage, caused by all causes from without, including

damage during transport, during storage on the clients’ premises,

damage caused by objects or persons falling on or knocking against

the machinery. Damages caused by acts of God are also excluded from

the warranty. Please note that the examples of external causes are not

comprehensive.

In no case shall HBM Machines be liable for the death or injuries of persons,

for damages to goods or to the machinery itself, which was caused by

operation of machinery supplied by HBM Machines.

MAKING USE OF WARRANTY

To use your right to warranty you should send the machinery or its

part tuo us, postage paid. Please include a proof of purchase and

explain your complaint to us.

In case our customer service finds a fault, we shall repair or replace

said machinery or its part. In case this proves impossible or

impractical, or cannot be don within a reasonable term, we will refund

your purchase price. The cost of returning the machinery or its part to

you shall be borne by HBM Mschines.

In case of our customer service ascertaining that there is no fault in

the machinery or its part, or when it is established that the fault or

damage arose because of events or causes not included in the

warranty (see list above) the client is bound to pay the fees for

transport and safe keeping.

PLEASE ACT RESPONSIBLY

It’s impossible to enumerate all possible uses for which a given product is

NOT suited. All these dangerous, ill-advised or hazardous uses have been

captured under the phrase Use of the product for any work for which it was

not intended. If you should be in doubt whether a specific use of the product

would be allowed or not, you are advised to:

Ask for advice from an expert user. This can’t do any harm. Who starts

operating a machine without having the necessary experience or

education may be taking a serious risk and will be held responsible for

all consequences!

Ask HBM Machines for advice.

Study the EC legislation with respect to machinery and safety

Read Books about the subject of proper use and design of machinery.

Please maintain your machine well. By doing so you can extend its

lifetime considerably. Regular maintenence will prevent premature wear and

promotes precision. Moreover, a well maintained machine will be safer than

an ill-maintained one.

Please note. Where machine/ machinery is

mentioned, this also includes tools.

© HBM Machines 2009. All Rights reserved.

SAFETY MEASURES

1. Only well trained personnel is allowed to operate this machine. In case you are

unfamiliar with this type of machine, please get educated before you start operating it!

2. All safety shields must remain intact and in place. Removal of safety shields is strictly

prohibited. You are responsible for keeping all safety measures in proper working

condition!

3. DO NOT STAND UNDER A SUSPENDED LOAD. KEEP HANDS AWAY FROM

MOVING PARTS! Do not lift unstable loads. DO NOT use the lift to permanently

support a load. Shift the load to a rigid, safe and fixed means of support.

4. You must prevent the machine from being inadvertently switched on.

5. Never force a machine. Never exceed the rated capacity!

8. RELEASE the cylinder pressure before you start any maintenance or repair job.

9. REGULARLY CHECK for damaged parts. Broken parts can be dangerous. Check if

operation is not impeded. Replace worn and damaged parts as soon as possible. Do not

operate machine before such parts have been replaced.

10. Never leave a working machine unattended. Shut off first. Release pressure!

11. Keep the workshop clean. Rubbish promotes accidents!

12. Never use machinery under hazardous conditions./ Make sure of proper lighting and

ventilation. Do not expose machinery to moisture, rain and snow. Don’t operate a

machine when you are tired, ill o rare using medicines which affect your reaction

abilities. Never operate a machine when under the influence of alcohol or drugs!

13. Keep children and visitors at a safe distance.

14. Workshops are danger areas for children. Please lock up after you leave. Prevent

children and laymen from entering the workshop without your consent. Use multiple

switches to prevent machines being switched on by the ignorant.

15. BEWARE! Please wear anti slip footwear. If your hair is long, put it under your

clothes. If necessary or applicable, wear eye protection, ear

protection or a face mask. Normal spectacles will not protect

your eyes!

17. Never reach across or through machines, in particular when

in operation. Ensure a safe body posture.

19. Never try to adjust a working machine!

20. Please read and heed the safety stickers on the machine.

Keep them legible and replace them when necessary. Removing

such warning stickers is a crime and could lead to legal actions!

21. These instructions for use are not a substitute for proper

education.

22. In case you do not comply with any of the rules, guidelines

and warnings given here and on the machine, you are taking the risk of accidents, injury

and damages which may even result in death. You will be held responsible!

SPECIFICATIONS

Lifting capacity: 360 Kilogramm

Width: 480 mm.

Minimum height 220 mm.

Maximum height 780 mm.

Overall length 2215 mm.

INSTALLATION

Unpack the crate and check the contents. In case of missing or damaged

parts please call HBM Machines.

-- Mount the roll-on ramp (31) on the end of the support plateau (32)

-- Mount the front wheels (35 and 47) at the front side of the plateau (32).

Use the bolts (33), Rings (34) and nuts (38).

-- Mount the faceplate (39) using the bolts (33), Rings (34) and nuts (38).

PREPARATION FOR FIRST USE

--Leave the pump for at least an hour. The oil can now release its air

bubbles; the ait collects up top and can be expelled.

NOTICE

In case you don’t allow sufficient time for this your machine just will not

operate as it should. You can’te expel the air properly and you will end up

waiting some more!

-- The air is expelled by pumping it out. This is done by fully depressing the

exhaust pedal (10) followed by pumping action, some 15 to 20 strokes of the

lifting pedal (7)

-- Now try out operation without any load. Go to the highest point you can

reach and then let the lift down SLOWLY. The exhaust pedal is depressed

GENTLY so the lift comes down at its leisure.

WORKING PROCEDURE

WARNING

Please read and understand all warnings, notices and advice before you start

operating this lift. In case of non-compliance you are taking a risk of

accidents and injury. You will be responsible for the consequences!

-- The lift is to be put in a suitable place. You should check the surface

which must be horizontal and able to support the load. We advise you to put

the lift on a concrete surface.

-- You turn the adjusting bolt (30) down until the wheels (18) come off the

floor. Your lift is now entirely supported by its feet.

-- You may now roll your motorcycle up the ramp, onto the lift.

WARNING

Before you can raise the lift, please check that the motorcycle is carried

entirely by the lift –NOT by the ramp. No part of the motorcycle should be

carried by the ramp at any time!

BE CAREFUL

The ramp is designed only to help roll wheels onto the supporting structure.

You may only do this when the lift is in its lowest position.

-- You can now clamp the front wheel, limiting movement.

-- Using a guy rope fix the motorcycle immovably on the lift. Motion should

be restricted as far as possible.

-- You can now lift the motorcycle using the pedal (7)

-- Once you arrive at the preferred height you can stop further movement by

introducing the safety bar (48) into the hole in the frame. Further movement

is now impossible.

-- If you have finished your job, please check to see (1) if no tools are left

lying around and (2) whether the lift can descend without a hitch.

-- Only then can you take out the safety bar (48) and GENTLY depress the

exhaust pedal (10) to slowly lower the motorcycle.

NOTICE

The lowering speed depends on how much the exhaust pedal is depressed.

Please lower your motorcycle gently.

-- When the motorcycle has been fully lowered you can release the guy rope

and clamp, and roll if off the lift using the ramp.

MAINTENANCE AND CHECK-UPS

-- In case you’re storing the lift for an extended period, keep it in a dry place

to prevent rust from developing. The cylinder, ram and piston are

susceptible.

-- keep your lift clean. Oil and dirt are to be wiped off; don’t forget to

lubricate moving parts regularly.

-- Often check the ram for rust. Keep it slightly coated and clean by applying

machine oil on a clean rag.

-- Check the lift before use. In case of damage or doubt have it checked or

repaired. Please have repair done by qualified technicians only.

-- You should often check the oil level. In case of a dropping level you should

top up with the same oil. Never mix different oils. Use only hydraulics oil

since many kinds of oil will dissolve the gaskets!

-- In case of bad performance or difficult lowering, false air is usually the

cause. See under preparation for first use what to do, viz., expelling false air.

PARTS LIST

Nr

part

Nr.

part

1

Bolt M6x25

2

Ring M6

3

Wheel assembly

4

Detachable leg

5

Bolt M8x30

6

Half clamp

7

Lifting Pedal

8

Bolt M8x15

9

Hex nut M16

10

Exhaust Pedal

11

Containing Ring M16

12

Ring

13

Bolt M16x45

14

Bolt M16x90

15

Frame

16

Front wheels

17

R-lock

18

Foot bar of Hydraulics Cylinder

19

Spring

20

Pin

21

Hydraulical Pump

22

Steel wheel

23

Pin

24

Lifting Arm

25

Lifting Arm

26

Steel wheel

27

Hex nut M12

28

Container ring M12

29

Ring

30

Bolt M12x45

31

Ram

32

Plateau

33

Bolt M10x20

34

Ring

35

Right clamp part

36

Rubber

37

Bolt M6x16

38

Hex nut M10

39

Guy plate

40

Bearing

41

Bearing

42

Ring

43

Pressure plate

44

Handwheel

45

Handle

46

Bolt

47

Left clamp part

48

Hex nut

H.B.M. Machines B.V.

Grote Esch 1010 - NL 2841 MJ Moordrecht.

Tel. +31 / (0)1 82 / 52 54 68 - Fax. +31 / (0)1 82 / 63 51 19

EG –DECLARATION OF CONFORMITY

Certificate of Compliance

In Compliance with:

EG-Machinery Ruling 2006/42/EC

We hereby state that the machinery concerned, its layout and construction all comply with

applicable EC rulings concerning health and safety. Any change to this machinery without prior

permission in writing issued by ourselves will make any and every guarantee to said machinery

NULL AND VOID.

Desccription and nature of the Machine: Motorcycle Lift

Model and series: HBM 100

Serial Number:

Year of construction: 2011

Harmonised EC rulings which are applied: EN 1570:1998+A2:2009.

Date and Place: NL 2741 PA Waddinxveen.

01-08-2009.

Signature/ Stamp: Herman Buitelaar

( Manager )

Table of contents

Other HBM Lifting System manuals

Popular Lifting System manuals by other brands

Challenger Lifts

Challenger Lifts CL10 Installation, operation & maintenance manual

Liko

Liko Likorall 200 Service manual

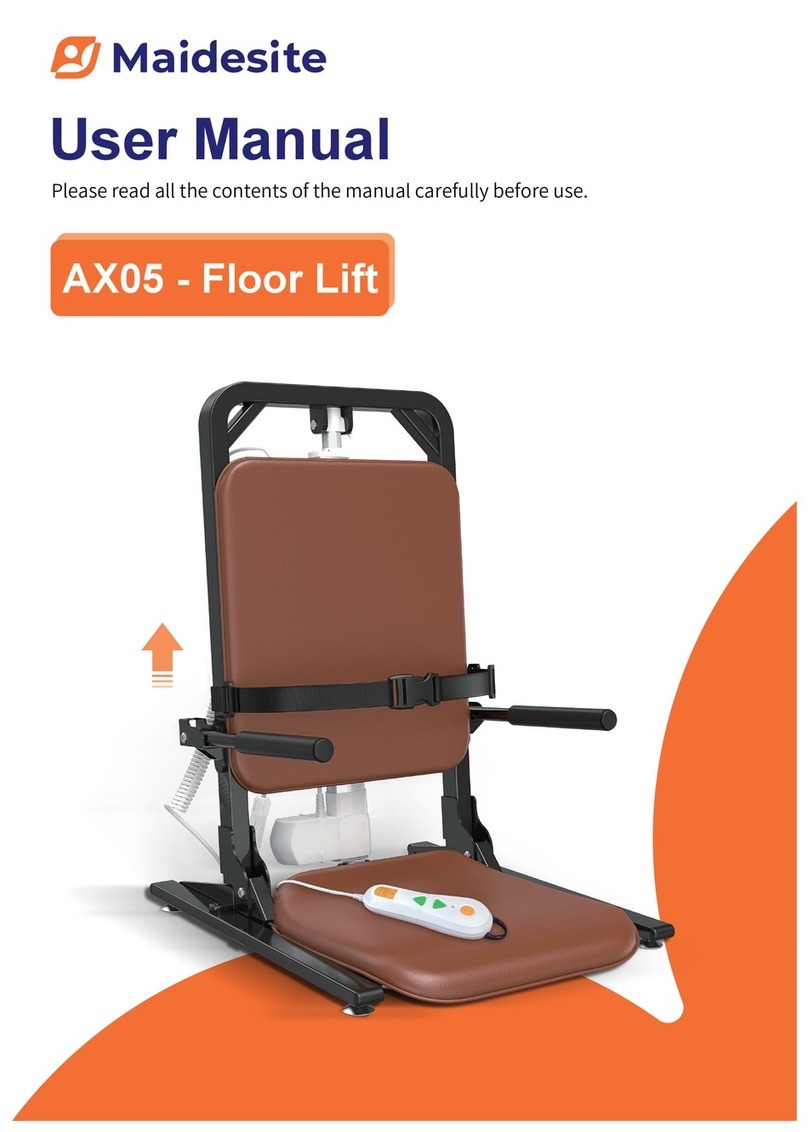

Maidesite

Maidesite AX05 user manual

REID LIFTING

REID LIFTING PORTA GANTRY Series Assembly & Operation guide

Sealey

Sealey MC454 instructions

AUTOPSTENHOJ

AUTOPSTENHOJ Masterlift 2.35 Combi installation instructions