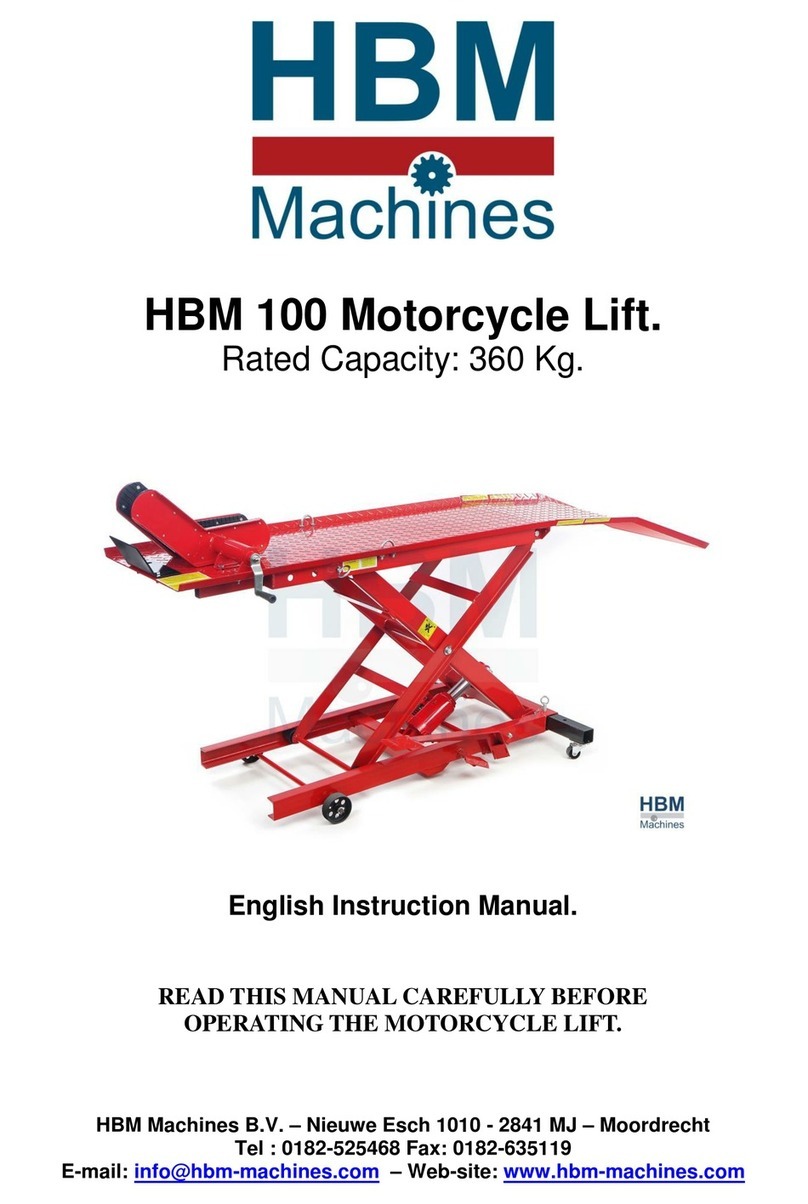

HBM HBM 300 User manual

WARRANTY

This HBM Machines product complies with the highest standards of workmanship,

durability and safety. HBM Machines guarantees original buyers a faultless operation of

its products for a one year period with respect to material and construction.

This warranty is null and void in case of defects occurring due to the following causes:

Normal wear

Lack of attention, ignorance, unsafe working procedures, lack of care during

transport or storage.

Lack of maintenance or maintenance carried out against the rules laid down in this

booklet

Use of the product for any work for which it was not intended; exceeding the rated

capacity. Transport without proper care

Shifting machinery without making use of proper lifting/ carrying gear

Failure to read and/ or understand the rules and guidelines explained in these

instructions.

Every use for which the product was not designed. These instructions state very

clearly all goals for which the product can be used. All other work is prohibited!

Operation of the machinery by persons who have not or insufficiently been educated

or instructed in its operation or who do not or insufficiently understand its

operation.

Operation of the machinery by persons without sufficient experience, in case of

Their working without direct supervision by a teacher.

Operation of the machinery by persons under the influence of medicines which

impair one’s ability to react, or by persons under the influence of alcohol or drugs.

Operation of the machinery by persons under the age of 16, or by persons aged

between 16 and 18 without direct supervision by a teacher.

Repairs which are or have been made without prior written consent by HBM

Machines.

Any change or alteration made in the machinery by the customer (owner).

Accidents or damage, caused by all causes from without, including damage during

transport, during storage on the clients’ premises, damage caused by objects or

persons falling on or knocking against the machinery. Damages caused by acts of

God are also excluded from the warranty. Please note that the examples of external

causes are not comprehensive.

In no case shall HBM Machines be liable for the death or injuries of persons, for damages

to goods or to the machinery itself, which was caused by operation of machinery supplied

by HBM Machines.

MAKING USE OF WARRANTY

To use your right to warranty you should send the machinery or its part tuo us,

postage paid. Please include a proof of purchase and explain your complaint to us.

In case our customer service finds a fault, we shall repair or replace said machinery

or its part. In case this proves impossible or impractical, or cannot be don within a

reasonable term, we will refund your purchase price. The cost of returning the

machinery or its part to you shall be borne by HBM Machines.

In case of our customer service ascertaining that there is no fault in the machinery

or its part, or when it is established that the fault or damage arose because of events

or causes not included in the warranty (see list above) the client is bound to pay the

fees for transport and safe keeping.

PLEASE ACT RESPONSIBLY

It’s impossible to enumerate all possible uses for which a given product is NOT suited. All

these dangerous, ill-advised or hazardous uses have been captured under the phrase Use

of the product for any work for which it was not intended. If you should be in doubt whether

a specific use of the product would be allowed or not, you are advised to:

Ask for advice from an expert user. This can’t do any harm. Who starts operating a

machine without having the necessary experience or education may be taking a

serious risk and will be held responsible for all consequences!

Ask HBM Machines for advice.

Study the EC legislation with respect to machinery and safety

Read Books about the subject of proper use and design of machinery.

Please maintain your machine well. By doing so you can extend its lifetime considerably.

Regular maintenance will prevent premature wear and promotes precision. Moreover, a

well maintained machine will be safer than an ill-maintained one.

Please note –where machines or machinery is mentioned, the text also applies to

tools.

© HBM Machines 2009. All Rights reserved.

SAFETY MEASURES

1. Only well trained personnel is allowed to operate this machine. In case you are unfamiliar with this type of

machine, please get educated before you start operating it!

2. All safety shields must remain intact and in place. Removal of safety shields is strictly prohibited. You are

responsible for keeping all safety measures in proper working condition!

3. DO NOT STAND UNDER A SUSPENDED LOAD. KEEP HANDS AWAY FROM MOVING PARTS! Do not lift

unstable loads. DO NOT use the lift to permanently support a load. Shift the load to a rigid, safe and fixed means of

support.

4. You must prevent the machine from being inadvertently switched on.

5. Never force a machine. Never exceed the rated capacity!

8. RELEASE the cylinder pressure before you start any maintenance or repair job.

9. REGULARLY CHECK for damaged parts. Broken parts can be dangerous. Check if operation is not impeded.

Replace worn and damaged parts as soon as possible. Do not operate machine before such parts have been replaced.

10. Never leave a working machine unattended. Shut off first. Release pressure!

11. Keep the workshop clean. Rubbish promotes accidents!

12. Never use machinery under hazardous conditions./ Make sure of proper lighting and ventilation. Do not expose

machinery to moisture, rain and snow. Don’t operate a machine when you are tired, ill o rare using medicines

which affect your reaction abilities. Never operate a machine when under the influence of alcohol or drugs!

13. Keep children and visitors at a safe distance.

14. Workshops are danger areas for children. Please lock up after you leave. Prevent children and laymen from

entering the workshop without your consent. Use multiple switches to prevent machines being switched on by the

ignorant.

15. BEWARE! Please wear anti slip footwear. If your hair is long, put it under your clothes. If necessary or

applicable, wear eye protection, ear protection or a face mask. Normal

spectacles will not protect your eyes!

17. Never reach across or through machines, in particular when in

operation. Ensure a safe body posture.

19. Never try to adjust a working machine!

20. Please read and heed the safety stickers on the machine. Keep them legible

and replace them when necessary. Removing such warning stickers is a crime

and could lead to legal actions!

21. These instructions for use are not a substitute for proper education.

22. In case you do not comply with any of the rules, guidelines and

warnings given here and on the machine, you are taking the risk of accidents, injury and damages which may even

result in death. You will be held responsible!

ON DELIVERY

Please check if the product arrives (1) without damage and (2) complete –see the parts list

or packing list. If you notice the case/ crate has sustained real damage contact the

haulage company and (if possible) do not accept your delivery. In case your product arrives

in damaged condition (whatever the cause) but the packing case is intact, contact HBM

Machines. In case of doubt, ring HBM Machines. In case of obvious damage, always take

photographs –a proof of your statement about damage may be required.

IN CASE OF COMPLAINTS RE DAMAGE, ACT WITH DUE DILIGENCE!

In case a claim is made after too long a time interval, this will not be entertained (unless

you can provide a reasonable explanation for the delay).

UNPACKING AND ASSEMBLY (also read HOISTING and LIFTING, below))

1. Read the Instructions for Use in full before assembling, commissioning and using this

product. If you have any question after having read these instructions, please ask HBM

Machines for advice. Then follow the instructions.

2. Please note that Instructions for Use contain sufficient information about the product,

enabling normal operation according to its intended use.

3. Please note that products are meant to be used by experienced users only. In case you

fail to meet this requirement, please get educated or acquire more experience before

using our product.

4. Please note –the user/ owner of this product is fully responsible for any damage or

accident caused by a lack of knowledge or experience in the use of such a product!

5. This product should be installed in a place free from shocks, vibrations etc. Keep the

installation site clean, well ventilated (use a dust extractor if necessary) and well lit.

6. Follow the rules for assembly. Keep the instructions for use near the site where the

product is used, which makes consulting them easier.

7. After a product has been installed in its intended site, please check if measures taken/

adjustments made, intended for transport, lifting and hoisting only, must be undone or

rectified before using the product.

HOISTING AND LIFTING

1. Heavy products are here defined as products weighing over 25 kilograms, the

accepted limit for a weight that can be comfortably lifted and shifted by hand. If you

(attempt to) lift or shift loads heavier than 25 kilograms without proper lifting or

hoisting machinery, you do so at your own risk and you will be responsible for all

consequences. This also applies to products under 25 kilograms when shifted by

any means (by hand or using lifting or hoisting machinery).

2. Heavy products are always delivered in a packing crate or with a pallet or base that

can be moved using e.g. a fork lift, chain hoist, etc.. of sufficient capacity. This is for

good reasons. After arrival the new owner is expected to use proper appliances and

machines of sufficient capacity to move the product. This is not just to prevent

damage to the product, but also for reasons of personal safety.

3. In case of damage, injury or death resulting from moving and/or lifting heavy

products as defined under 1 without use of proper lifting or hoisting appliances, or

use of such devices without sufficient capacity, as defined under 2, the client will be

entirely responsible.

4. In case of hoisting heavy products using aids (fork lift, chain hoist, etc.) the rules as

given below MUST BE COMPLIED WITH. If not, the client/ owner/ user will be

entirely responsible.

SAFETY RULES FOR LIFTING AND MOVING HEAVY LOADS

1. NEVER stand under or near a load that is suspended or being lifted. Keep spectators

at a safe distance. In particular keep children away!

2. When lifting a load, follow the manufacturer’s guidelines concerning the points

where hooks, straps, bars, chains etc. are to be attached, and also concerning the

protection of the product from damage (e.g. to the paint) resulting from the use of

hoisting and lifting devices. If you don’t comply, you will be responsible for all

consequences.

3. Follow the manufacturer’s advice about fixing and securing movable parts or any

other measures to be taken during transport and lifting. If you don’t comply, you will

be responsible for all consequences.

4. Handle lifted or suspended loads with due caution. Keep them well balanced. Do not

move loads suddenly. Prevent swinging a load. Use approved straps, chains, hooks,

etc. Check hoisting materials for wear on a regular basis and replace them when

necessary. Do not knock against other objects. Let down on the floor gently. Let a

heavy load down only on a floor able to carry its weight.

5. Loads must be lifted/ shifted/ moved only by people having sufficient education and

experience. If you don’t comply, you will be responsible for all consequences.

6. It is strictly forbidden for persons to be lifted/ moved/ carried along with a load.

SPECIFICATIONS

Capacity 1000lb

Width 680mm

Minimum Height 175mm

Maximum Height 750mm

Air Inlet Fitting 1/4inch NPT

Air Pressure 120-200PSI

ASSEMBLY

Unpack the lift and check contents with list below. Should there be any damaged or

missing parts, contact your

supplier immediately.

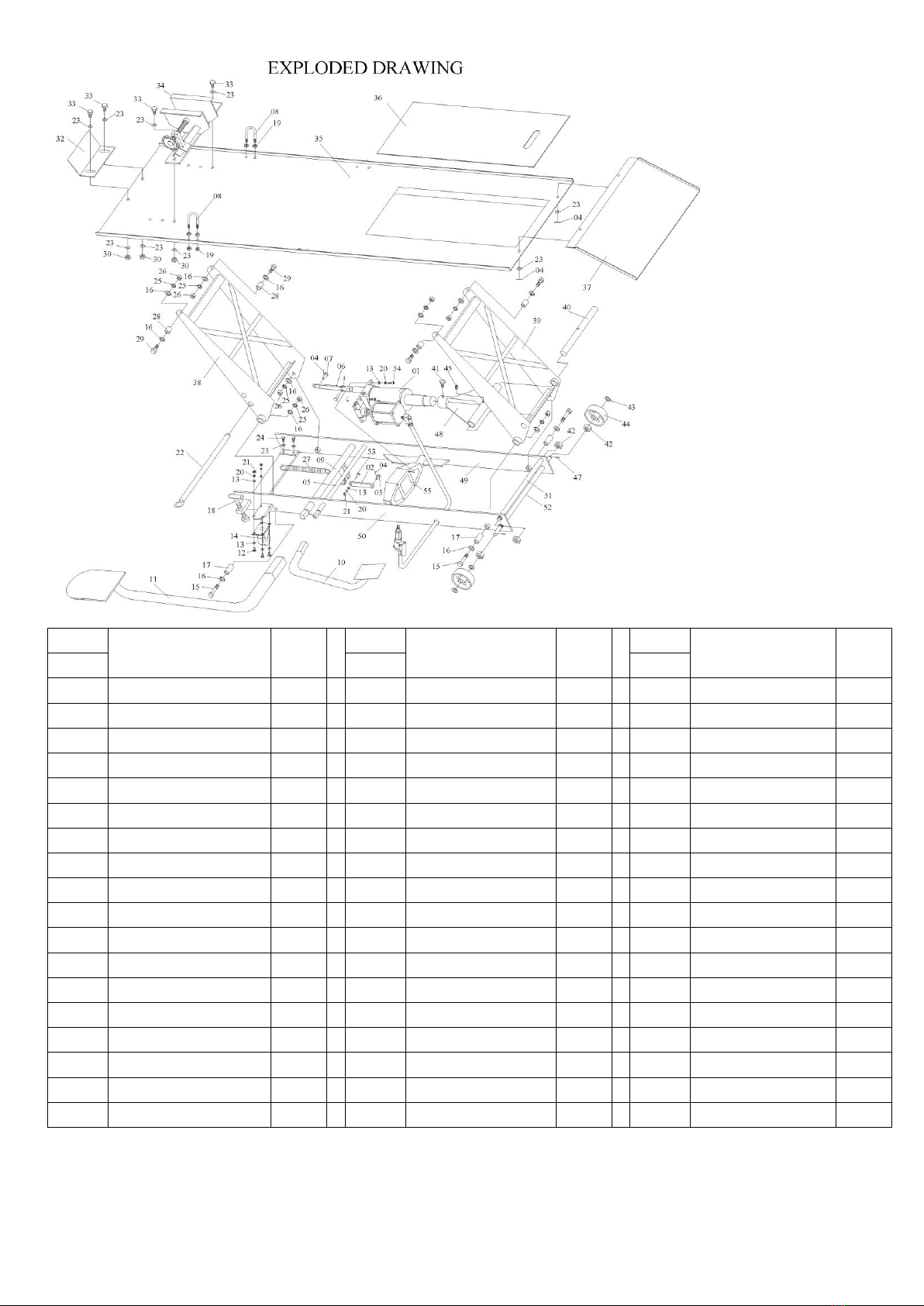

Packing List

·Main Assembly

·Sliding Plate

·Leading Plate

·Vice

·Lift Foot Pedal

·Release Foot Pedal

·Locking Bar

·Bolts, Washers, Nuts, Cotter Pins

ASSEMBLY

Place the sliding plate(36) to the platform(35) to cover the rear wheel removal aperture.

Attach leading plate(37) to end of platform using washers(23) and R-pins(04).

Fit the front wheel vice assembly(34) to the front of the platform using bolts(33),

washers(23) and nuts(30).

Fit the baffle plate (32) using bolts (33), washers (23) and nuts (30).

Fit the lift foot pedal(11) to the pump piston spindle(09)and fit the release foot pedal(10) to

the release valve spindle(05).

BEFORE FIRST USE

Leave the pump for one hour to allow the oil to settle before purging the system.

NOTE: Failure to allow sufficient time for the oil to settle could result in air remaining in

the oil. In this event, the pump will not purge completely first time and a second purge will

be required.

Connect the quick coupler-male into the air supply hose quick coupler-female and fully

press the release foot pedal (10), then turn on the air valve(P37) letting the pump work for

20 seconds to eliminate any air in the hydraulic system.

Test the lift without load by raising it to full height and then lowering it. Depress release

foot pedal (10) slowly to control the rate of descent.

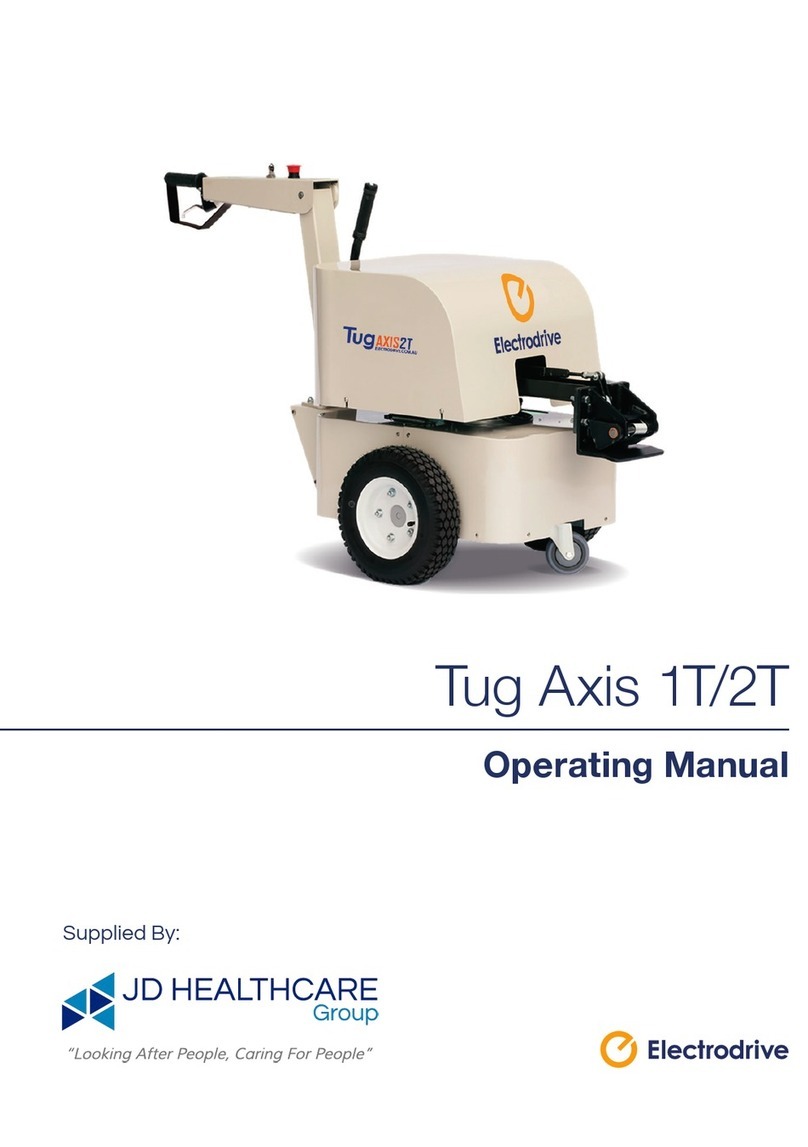

OPERATING INSTRUCTIONS

WARNING! Ensure that you read, understand and apply the safety instructions and

warnings before use.

WARNING! Do not attempt to overload the lift.

Position the lift in a suitable area, checking that the surface on which the lift will stand is

solid and flat.

Turn the adjusting screw assy(18) down to raise the castors off the ground to prevent the

lift from moving.

Wheel the motorcycle up the leading plate and onto the platform..

NOTE: There is a choice of mounting holes for the vice to cater for various sizes of

motorcycle.

Clamp front wheel in vice to prevent any movement of the motorcycle.

Strap the motorcycle securely to the platform.

Connect the quick coupler-male into the air supply hose quick coupler-female, then turn

on the air valve to raise the lift. When air source is not available, pump the lift foot

pedal(11) to raise the lift.

When the platform has been raised to the working height, turn off the air valve (or stop

pumping) and pass the locking bar (22) through the holes in the front lifting arm(38) so

that the lift cannot be inadvertently lowered.

When work is done, check under the lift to ensure that there are no obstructions and that

it is safe to lower the unit. Remove the locking bar and then SLOWLY press the release foot

pedal to GENTLY lower the lift.

NOTE: The speed of lowering is controlled by the release valve. The more the valve is

opened the more rapidly the lift descends. Ensure the decent is slow and controlled.

When the lift is fully lowered, unstrap the motorcycle, open the vice jaws and remove the

cycle from the lift.

MAINTENANCE

When not in use, the lift must be stowed in the lowest position in a dry location to

minimize ram and piston corrosion.

Keep the lift clean and wipe off any oil or grease. Lubricate all moving parts.

Periodically check the ram and piston for signs of corrosion. Clean exposed areas with a

clean oiled cloth.

Before each use check all parts. If any part of the lift is damaged or suspect, remove the lift

from service and take necessary action to repair.

Check the hydraulic oil level. If not adequate, remove the filler plug(P33) on the pump and

add hydraulic oil as necessary.

DO NOT use brake fluid or any other improper fluid. Only a good quality hydraulic jack oil

can be used.

When lift efficiency drops, purge away air from the hydraulic system as described

PUMP

PARTS LIST FOR PUMP

PARTS

DESCRRIPTION

Q'TY

PARTS

DESCRIPTION

Q'TY

NO.

NO.

P01

BASE

1

P24

AIR MOTOR

1

P02

STEEL BALL

3

P25

AIR HOSE

1

P03

SPRING

1

P26

AIR VALVE

1

P04

SCREW

2

P27

NYLONG RING

1

P05

"O"RING

1

P28

CYLINDER

1

P06

RELEASE WALVE

1

P29

O-RING

1

P07

SPRING

1

P30

NYLONG RING

1

P08

SCREW

1

P31

PISTON ROD

1

P09

UNION NUT

1

P32

NYLON RING

1

P10

SPRING

1

P33

TOP NUT

1

P11

STEEL BALL

1

P34

O-RING

1

P12

SCREW

1

P35

SPRING

1

P13

SCREW

1

P36

REGULATING

PLUG

1

P14

STELL BALL

1

P37

SEALING RING

1

P15

BALL CUP

1

P38

PUMP PISTON

1

P16

SPRING

1

P39

NUT

1

P17

SCREW

1

P40

UNION NUT

1

P18

"O"RING

1

P41

STEEL BALL

1

P19

SCREW

1

P42

SPRING

1

P20

SCREW

PROTECTOR

1

P43

STEEL BALL

1

P21

NYLON RING

1

P44

SPRING

1

P22

RESERVOIR

1

P45

SCREW

1

P23

FILLER PLUG

1

P46

SCREW

1

P47 NYLON\ RING 1

PARTS

DESCRRIPTION

QNTY

PARTS

DESCRIPTION

QNTY

PARTS

DESCRIPTION

QNTY

NO

NO

NO

01

Air pump

1

19

Nut M8

8

38

Front lifting arm

1

02

Link

1

20

Lock washer 6mm

13

39

Rear lifting arm

1

03

Pin

1

21

Nut M6

9

40

Lifting arm spindle

1

04

R-pin

5

22

Locking bar

1

41

Bolt M8x12

2

05

Release valve spindle

1

23

Washer 10mm

14

42

Nut M16

4

06

Link

1

24

Bolt M10x12

4

43

Washer 14mm

2

07

Pin

2

25

Lock washer 12mm

8

44

Front wheel

2

08

U-bolt

2

26

Nut M12

8

45

Set screw M8x10

1

09

Pump piston spindle

1

27

Spring

1

47

Cotter pin

2

10

Release foot pedal

1

28

Bush

4

48

Connection

1

11

Lift foot pedal

1

29

Bolt M12x65

4

49

Frame assy(RH)

1

12

Bolt M6x70

8

30

Nut M10

4

50

Frame assy(LH)

1

13

Washer 6mm

21

32

Baffle plate

1

51

Lifting arm top rod

1

14

Castor fork assy

2

33

Bolt M10x25

4

52

Front spindle

1

15

Bolt M12x70

4

34

Vise assy

1

53

Bolt M6x30

1

16

Washer 12mm

8

35

Platform

1

54

Bolt M6x25

4

17

Bush

4

36

Sliding plate

1

55

Pump base

1

18

Adjusting screw assy

2

37

Leading plate

1

HBM MACHINES B.V.

Grote Esch 1010 - NL 2841 MJ Moordrecht.

Tel. +31 / (0)1 82 / 52 54 68 - Fax. +31 / (0)1 82 / 63 51 19

EG –DECLARATION OF CONFORMITY

Certificate of Compliance

In Compliance with:

EG-Machinery Ruling 2006/42/EC

We hereby state that the machinery concerned, its layout and construction all comply with applicable EC

rulings concerning health and safety. Any change to this machinery without prior permission in writing

issued by ourselves will make any and every guarantee to said machinery NULLAND VOID.

Desccription and nature of the Machine: Motorcycle lift

Model and series: HBM 300 Pneumatic

Year of construction: 2011

Harmonised EC rulings which are applied: EN ISO 12100-1:3003

EN ISO 12100-2:2003

EN ISO 14121-1:2007

EN ISO 13857:2008

EN 349:1993+A1:2008

EN 982:1996+A1:2008

EN 849-1:1997+A1:2008

EN 1027:1995+A1:2008

EN 1494:2000+A1:2008

EN 1570:1998+A1:2004

Date and Place: 01-01-2011-NL2841MJMoordecht.

Signature/ Stamp: Herman Buitelaar

( Directer )

This manual suits for next models

2

Table of contents

Other HBM Lifting System manuals

Popular Lifting System manuals by other brands

Challenger Lifts

Challenger Lifts 44060 Installation, operation & maintenance manual

RITE-HITE

RITE-HITE Hydra-Rite RHH-4000 owner's manual

Terex

Terex Genie S-60 FE Service and repair manual

BraunAbility

BraunAbility A2 Series Service manual

Nußbaum Hebetechnik

Nußbaum Hebetechnik 4.40H Instructions and Documentation

Parkside

Parkside P-SA 1200 Operation and safety notes