HBM SP4M Series User manual

Mounting Instructions | Montageanleitung |

Notice de montage

English Deutsch Français

SP4M

Hottinger Baldwin Messtechnik GmbH

Im Tiefen See 45

D-64239 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbm.com

Mat.: 7-2001.2447

DVS: A2447-1.1 HBM: public

07.2016

EHottinger Baldwin Messtechnik GmbH.

Subject to modifications.

All product descriptions are for general information only.

They are not to be understood as a guarantee of quality or

durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allgemeiner

Form. Sie stellen keine Beschaffenheits- oder Haltbarkeits

garantie dar.

Sous réserve de modifications.

Les caractéristiques indiquées ne décrivent nos produits

que sous une forme générale. Elles n'impliquent aucune

garantie de qualité ou de durablilité.

Mounting Instructions | Montageanleitung |

Notice de montage

English Deutsch Français

SP4M

2A2447-1.1 HBM: public SP4M

English

1 Safety instructions 3........................................

2 Markings used 7............................................

2.1 Symbols on the product 7.....................................

2.2 Markings used in this document 7..............................

3 Mounting and Load application 9............................

4 Electrical connection 10......................................

4.1 Connecting in four‐wire and six‐wire configurations 10.............

4.2 Shortening the cable 11.......................................

4.3 Cable extensions 11..........................................

4.4 Parallel connection (option) 11..................................

4.5 EMC protection 11............................................

5 Specifications 13............................................

6 Dimensions 17..............................................

Safety instructions

SP4M A2447-1.1 HBM: public 3

1 Safety instructions

In cases where a breakage would cause injury to persons

or damage to equipment, the user must take appropriate

safety measures (such as safety devices to protect

against falls, collapses or overloads). For safe and

trouble‐free operation, load cells must not only be cor

rectly transported, stored, sited and mounted but must

also be carefully operated and maintained.

It is essential to comply with the relevant accident pre

vention regulations. In particular you should take into ac

count the limit loads quoted in the specifications.

Appropriate use

Load cells are designed for metrological applications.

Use for any additional purpose shall be deemed to be not

appropriate.

In the interests of safety, load cells should only be oper

ated as described in the Mounting Instructions. It is also

essential to comply with the legal and safety require

ments for the application concerned during use. The

same applies to the use of accessories.

Load cells can be used as machine elements (for con

tainer and silo weighing, for example). In these situa

tions, you must make sure that for greater sensitivity, the

load cells are not constructed with the customary safety

factors found in machine design. Load cells are not

safety elements within the meaning of appropriate use.

The layout of the electronics conditioning the measure

ment signal should be such that measurement signal fail

ure does not cause damage.

Safety instructions

4A2447-1.1 HBM: public SP4M

General dangers of failing to follow the safety

instructions

Load cells are state‐of‐the‐art and reliable. Load cells can

give rise to remaining dangers if they are inappropriately

installed and operated by untrained personnel.

Everyone involved with siting, starting up, maintaining or

repairing a load cell must have read and understood the

Mounting Instructions and in particular the technical

safety instructions.

Remaining dangers

The scope of supply and performance of the load cells

covers only a small area of weighing technology. In addi

tion, equipment planners, installers and operators should

plan, implement and respond to the safety engineering

considerations of the weighing technology in such a way

as to minimize remaining dangers. Prevailing regulations

must be complied with at all times. Reference must be

made to the remaining dangers associated with the

weighing technology.

Ambient conditions

In the context of your application, please note that be

cause of the alloy elements used, the high‐strength alu

minum alloy only has limited corrosion resistance if it

comes into contact with electrolytes or if there are high

and low pH values. With stainless steel single point load

cells, please note that acids and all materials which re

lease ions will also attack all grades of stainless steel and

their welded seams.

Should there be any corrosion, this could cause the load

cell to fail. If this is the case, the operator must take ap

propriate protective measures.

Safety instructions

SP4M A2447-1.1 HBM: public 5

Unauthorized conversions and modifications are

prohibited

Load cells must not be modified from the design or safety

engineering point of view except with our express agree

ment. Any modification shall exclude all liability on our

part for any damage resulting therefrom.

Qualified personnel

Load cells must only be installed by qualified personnel,

strictly in accordance with the specifications in conjunc

tion with the safety requirements and regulations listed

below. It is also essential to observe the appropriate legal

and safety regulations for the application concerned. The

same applies to the use of accessories.

Qualified personnel means persons entrusted with siting,

mounting, starting up and operating the product, who

possess the appropriate qualifications for their function.

Accident prevention

The prevailing accident prevention regulations must be

taken into account, even though the breaking load is well

in excess of the full scale value. Pay particular attention

to the following data from the specifications

Slimit load (EL)

Slimit load at max. Eccentricity

Slimit lateral loading (ELq)

Sbreaking load.

Load cells are precision measuring elements and must

be handled carefully during mounting and transportation.

Knocking or dropping the load cells can damage them.

Suitable retainers must be used during installation and

operation to protect the load cells against overloading.

Safety instructions

6A2447-1.1 HBM: public SP4M

No forces or moments must be directed via the spring

area during mounting.

Explosion‐proof version (option)

SWhen installing this version, it is essential to comply

with the relevant installation regulations.

SThere must be compliance with the installation condi

tions cited in the Declaration of Conformity and/or the

Type Examination Certificate.

SThe connection cable of the explosion‐proof single

point load cells features free ends (cable configuration

see chapter 4.1, page 10).

Markings used

SP4M A2447-1.1 HBM: public 7

2 Markings used

2.1 Symbols on the product

CE mark

The CE mark enables the manufacturer to guarantee that

the product complies with the requirements of the rel

evant EC directives (the declaration of conformity is

available at http://www.hbm.com/HBMdoc).

Statutory waste disposal mark

In accordance with national and local environmental

protection and material recovery and recycling regula

tions, old devices that can no longer be used must be

disposed of separately and not with normal household

garbage.

If you need more information about waste disposal,

please contact your local authorities or the dealer from

whom you purchased the product.

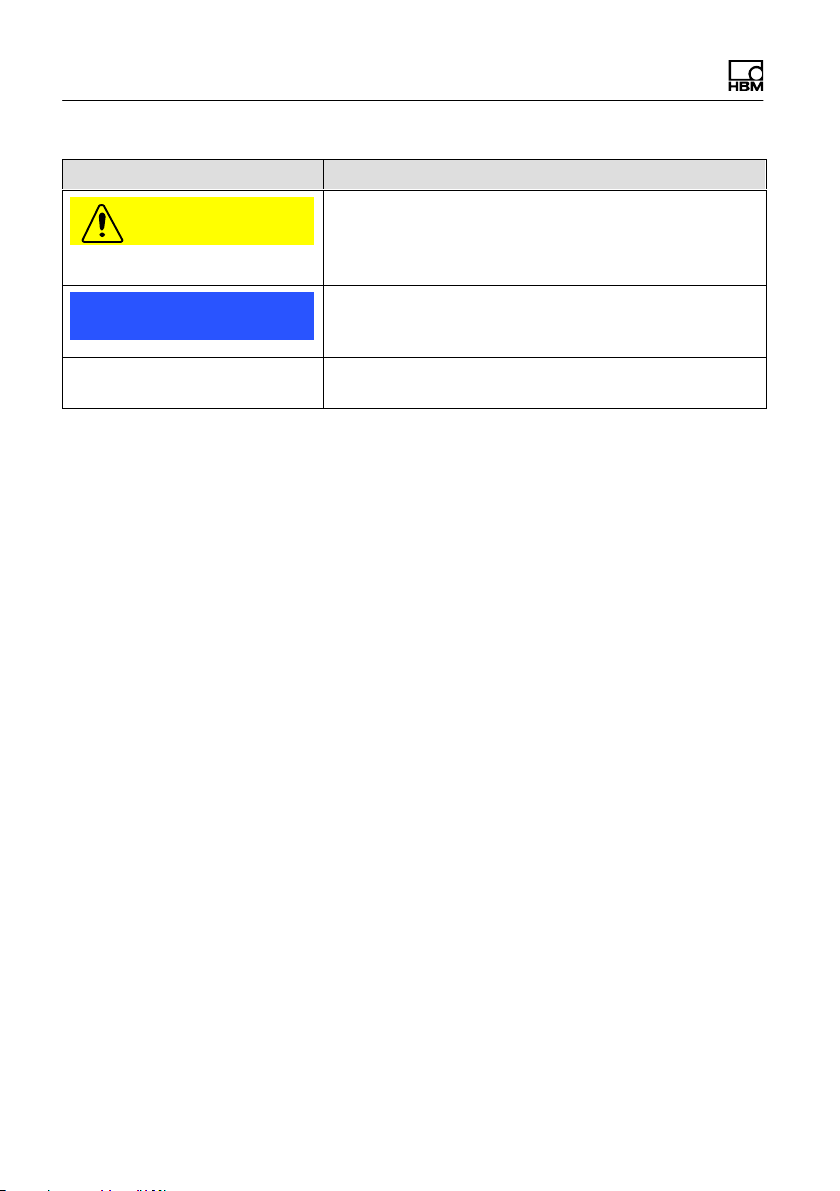

2.2 Markings used in this document

Important instructions for your safety are specifically

identified. It is essential to follow these instructions in

order to prevent accidents and damage to property.

Markings used

8A2447-1.1 HBM: public SP4M

Symbol Significance

CAUTION This marking warns of a potentially dangerous

situation in which failure to comply with safety

requirements can result in slight or moderate physical

injury.

Notice This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Emphasis

See….

Italics are used to emphasize and highlight text and

references to other chapters and external documents.

Mounting and Load application

SP4M A2447-1.1 HBM: public 9

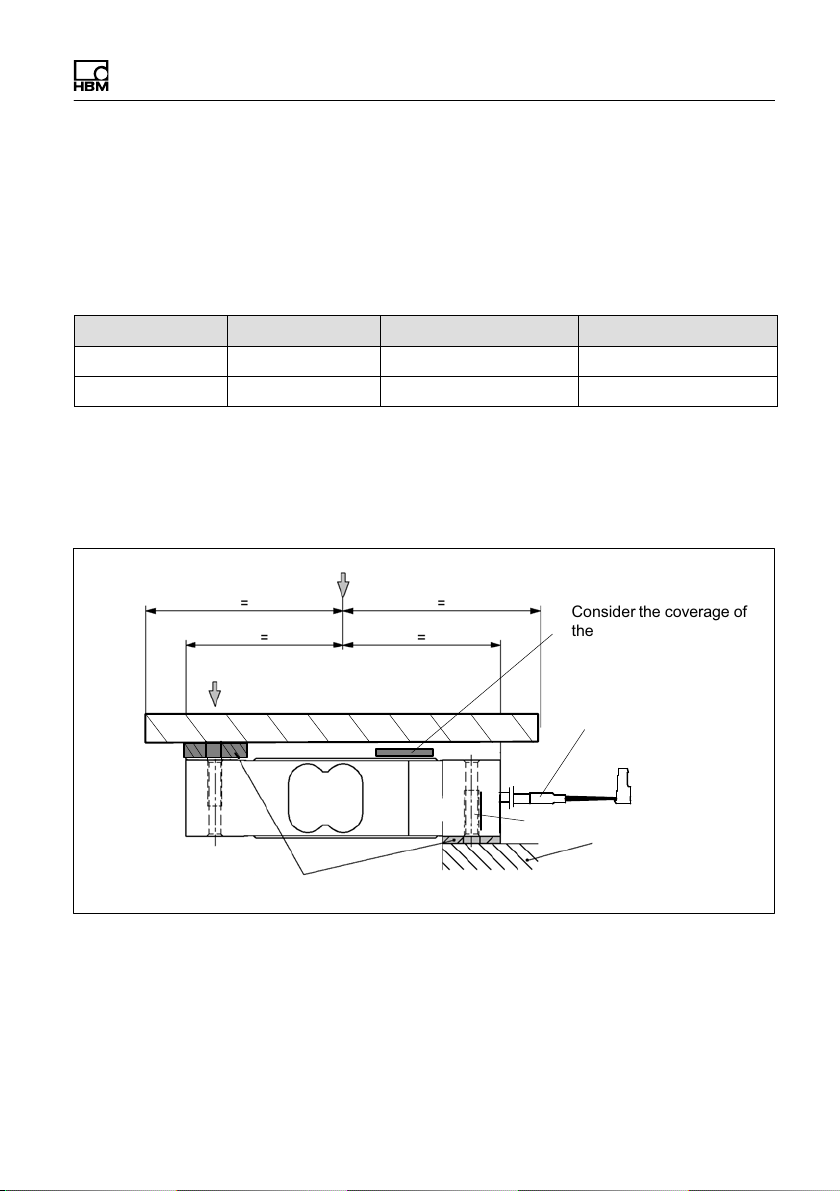

3 Mounting and Load application

The load cells are fixed at the mounting bores. For the

recommended screws and tightening torques refer to the

table below:

Max. capacity Thread Min. property class Tightening torque1)

1...36 kg M6 8.8 6 N@m

50...200 kg M6 10.9 14 N@m

1) Recommendedvalue for the stated property class. For screw dimensioning please refer to the

appropriate information given by the screw manufacturers.

Load must not be applied to the side where the cable

connection is located, as this would cause a force shunt.

ÈÈÈÈÈÈÈÈÈÈÈÈÈÈ

ÈÈÈÈÈÈÈÈÈÈÈÈÈÈ

Consider the coverage of

the ATEX versions (see

chapter 6 “Dimensions”,

page 17)

platform center

load application

connection cable

mounting bores

mounting

spacing washer

Electrical connection

10 A2447-1.1 HBM: public SP4M

4 Electrical connection

The following can be connected for measurement signal

conditioning:

Scarrier‐frequency amplifier

SDC amplifier

designed for strain gage measurement systems.

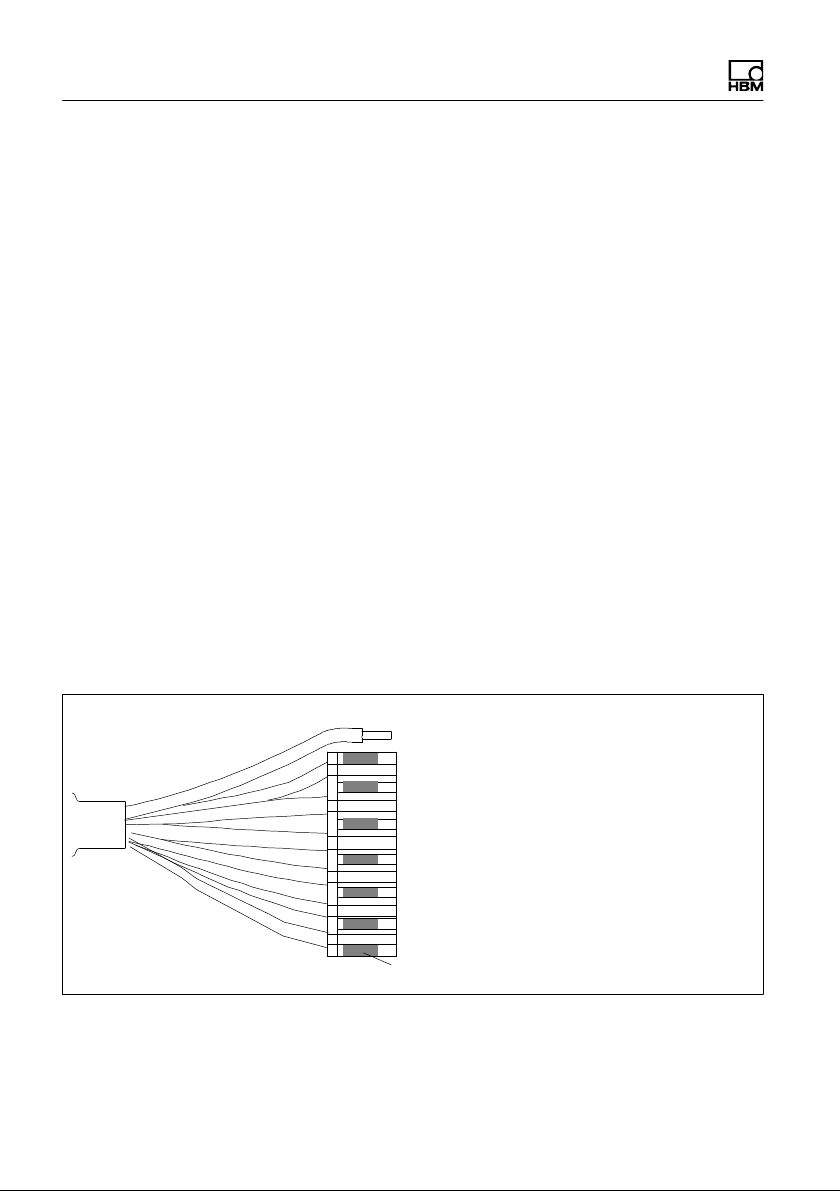

4.1 Connecting in four‐wire and six‐wire

configurations

When load cells in a six‐wire configuration are connected

to amplifiers with a four‐wire configuration, the sense

leads of the load cells must be connected to the corre

sponding excitation leads.

6‐wire cable connection (a choice of lengths: 1.5 m;

3 m; 6 m; 12 m)

4

Contact 1 (white) = Measurement signal (+)

Contact 3 (black) = Excitation (-)

Contact 6 (gray) = Signal (-)

Contact 4 (blue) = Excitation (+)

Contact 5 (green) = Signal (+)

Contact 2 (red) = Measurement signal (-)

12356

blue marking

Shield (yellow) = cable shield connected to

lead cell body

Fig. 4.1 Schematic diagram of a Pancon connector

(CE 100F26-6), 6-pin

Electrical connection

SP4M A2447-1.1 HBM: public 11

4.2 Shortening the cable

When the 6-wire configuration is used, the load cell's

6-wire cable can be cut off without impairing measure

ment accuracy.

4.3 Cable extensions

You must only use shielded, low‐capacitance measure

ment cables to extend the cables, making sure that there

is a proper connection with minimal contact resistance.

The cable of a six‐wire load cell can be extended with a

cable of the same type.

4.4 Parallel connection (option)

Only single point load cells with an aligned output (nomi

nal (rated) sensitivity and output resistance) are suitable

for parallel connection. Many of HBM's single point load

cell types are available with this option.

4.5 EMC protection

Electrical and magnetic fields often induce interference

voltages in the measuring circuit. Therefore:

SUse shielded, low‐capacitance measurement cables

only (HBM cables fulfill both conditions)

SDo not route the measurement cables parallel to

power lines and control circuits.

If this is not possible, protect the measurement cable,

in rigid steel conduits, for example

Electrical connection

12 A2447-1.1 HBM: public SP4M

SAvoid stray fields from transformers, motors and con

tact switches

To ensure the best EMC protection, the load cell, to

gether with the connection cable and the subsequent

electronics, should be placed in a shielded housing.

Exception

Load cells with shielded, round cables are EMC‐tested in

accordance with EC directives and identified by CE certi

fication. But you must make sure that the shield of the

connection cable is connected to the shielding housing of

the electronics.

Specifications

SP4M A2447-1.1 HBM: public 13

5 Specifications

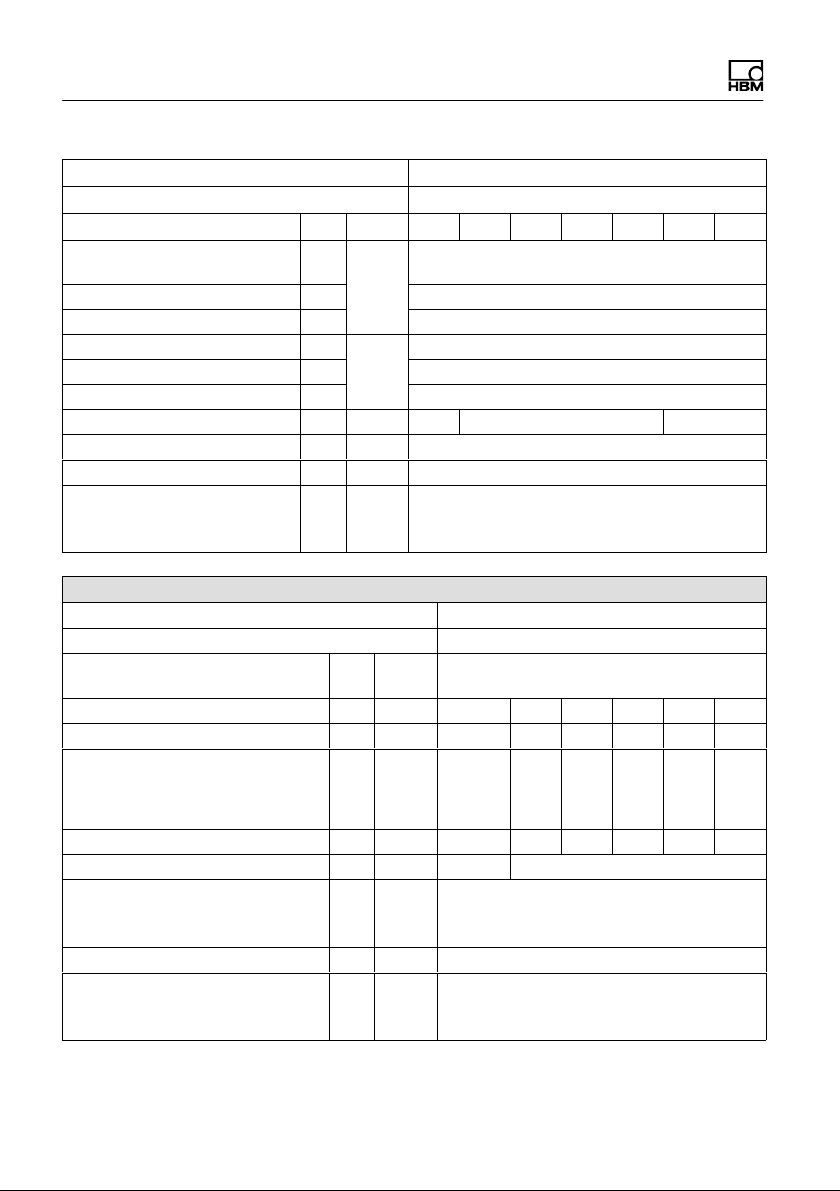

SP4M-C3MR, Capacity 1 … 20 kg

Type SP4M...

Accuracy class1) C3 Multi Range (MR)

Number of load cell verification

intervals

nLC 3000

Maximum capacity2) Emax kg 1 3 5 7 10 15 20

Minimum load cell verification

interval

vmin g 0.1 0.2 0.5 0.5 1 1 2

Temperature coefficient of zero

signal

TC0% of Cn

/10 K

"0.0140

"0.0093

"0.0140

"0.0100

"0.0140

"0.0093

"0.0140

Ratio of minimum verification

interval

Y 10,000 15,000 10,000 14,000 10,000 15,000 10,000

Maximum platform size mm 300 300 450 450

Nominal sensitivity

Maximum capacity 1 kg

Maximum capacities 3 kg...200 kg

CnmV/V 1.8 +0.27 -0.18 (Option 6: A1 = 1.8 mV/V±0.1 %)

2.0±0.2 (Option 6: A = 2mV/V±0.1 %)

Zero signal mV/V 0"0.1

Temperature coefficient of

sensitivity3)

Temperature range +20 °C ... +40 °C

-10 °C ... +20 °C

TCS% of

Cn/10 K "0.0170

"0.0110

Non-linearity3) dlin

% of Cn

"0.0166

Relative reversibility error3) dhy "0.0166

Minimum dead load output return

(MDLOR)

"0.0166

Off-center load error4, as per OIML

R76

"0.0233

Input resistance RLC W300...500

Output resistance R0300...500 (Option 6: A = 410 W"0.2 W)

Reference voltage Uref

V

5

Nominal (rated) range of the

excitation voltage

BU1 ... 12

Max. excitation voltage 15

Insulation resistance at 100 VDC Ris GW>2

Specifications

14 A2447-1.1 HBM: public SP4M

Type SP4M...

Accuracy class1) C3 Multi Range (MR)

Maximum capacity2) 2015107531kgEmax

Nominal (rated) range of the

ambient temperature

BT

°C

-10 ... +40

Operating temperature range Btu -10 ... +50

Storage temperature range Btl -25 ... +70

Limit load EL% of

Emax

150

Limit lateral loading, static Elq 300

Breaking load Ed300

Rated displacement at Emax, approx. snom mm < 0.5 < 0.3 < 0.25

Weight, approx. m kg 0.45

Degree of protection5IP67

Material: Measuring body

Application protection

Cable sheath

Aluminum

Silicone rubber

PVC

SP4M-C3MR, Capacity 1 … 20 kg

Type SP4M...

Accuracy class1) C3 Multi Range (MR)

Number of load cell verification

intervals

nLC 3000

Maximum capacity2) Emax kg 30 50 75 100 150 200

Minimum load cell verification interval vmin g 2 5 5 10 10 20

Temperature coefficient of zero signal

TC0% of Cn

/10 K

"0.0093

"0.0140

"0.0093

"0.0140

"0.0093

"0.0140

Ratio of minimum verification interval Y 15,000 10,000 15,000 10,000 15,000 10,000

Maximum platform size mm 450 450 600 600

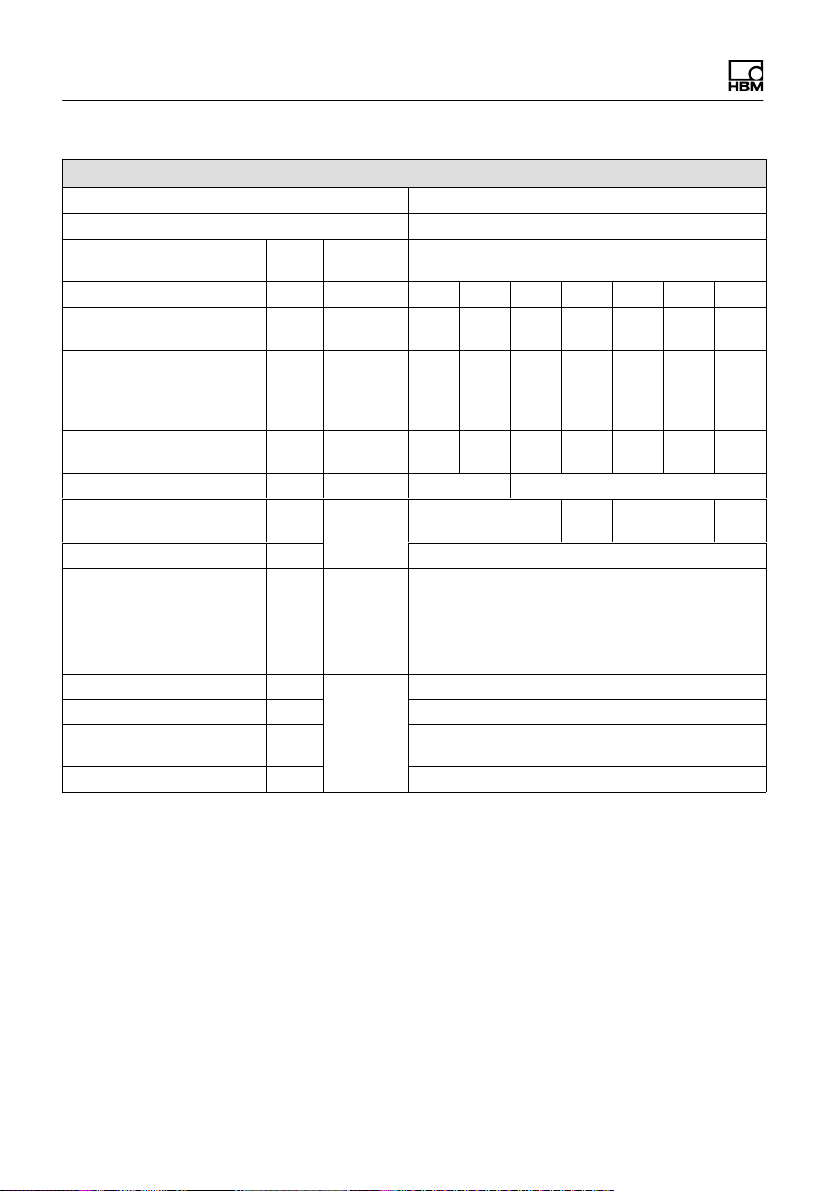

Nominal sensitivity

Maximum capacity 1 kg

Maximum capacities 3 kg...200 kg

CnmV/V 1.8 +0.27 -0.18 (Option 6: A1 = 1.8 mV/V±0.1 %)

2.0±0.2 (Option 6: A = 2mV/V±0.1 %)

Zero signal mV/V 0"0.1

Temperature coefficient of sensitivity3)

Temperature range +20 °C ... +40 °C

-10 °C ... +20 °C

TCS% of

Cn/10 K "0.0170

"0.0110

Specifications

SP4M A2447-1.1 HBM: public 15

Type SP4M...

Accuracy class1) C3 Multi Range (MR)

Maximum capacity2) 200150100755030kgEmax

Non-linearity3dlin

% of Cn

"0.0166

Relative reversibility error3) dhy "0.0166

Minimum dead load output return

(MDLOR)

"0.0166

Off-center load error4, as per OIML R76 "0.0233

Input resistance RLC W300...500

Output resistance R0300...500 (Option 6: A = 410 W"0.2 W)

Reference voltage Uref

V

5

Nominal (rated) range of the

excitation voltage

BU1 ... 12

Max. excitation voltage 15

Insulation resistance at 100 VDC Ris GW>2

Nominal (rated) range of the

ambient temperature

BT

°C

-10 ... +40

Operating temperature range Btu -10 ... +50

Storage temperature range Btl -25 ... +70

Limit load EL% of

Emax

150

Limit lateral loading, static Elq 300

Breaking load Ed300

Rated displacement at Emax, approx. snom mm < 0.25

Weight, approx. m kg 0.45

Degree of protection5) IP67

Material: Measuring body

Application protection

Cable sheath

Aluminum

Silicone rubber

PVC

1) As per OIML R60, with PLC = 0.7

2) Max. eccentric loading as per OIML R76.

3) If the values for non-linearity (dlin), relative reversibility error (dhy) and temperature coefficient of

sensitivity (TCS) are added together, they are within the cumulated error limit specified in OIML

R60.

4) As per OIML R76

5) As per EN 60 529 (IEC 529)

Specifications

16 A2447-1.1 HBM: public SP4M

SP4M-C6MR, Capacity 7 … 36 kg

Type SP4M…

Accuracy class1) C6 Multi Range (MR)

Number of load cell

verification intervals nLC 6000

Maximum capacity2) Emax kg 7 10 15 18 20 30 36

Minimum load cell

verification interval vmin g 0.5 0.5 1 1 1 2 2

Temperature coefficient

of zero signal TC0% of

Cn/10 K

"0.0100

"0.0070

"0.0093

"0.0077

"0.0070

"0.0093

"0.0077

Ratio of minimum verification

interval Y 14,000 20,000 15,000 18,000 20,000 15,000 18,000

Max. platform size mm 300 x 300 450 x 450

Nominal sensitivity CnmV/V 2.0 ±0.2 1.8

±0.18 2.0 ±0.2 2.4

±0.24

Zero signal 0"0.10

Temperature coefficient of

sensitivity3)

Temperature range:

+20 ... +40 °C

-10 ... +20 °C

TCS% of

Cn/10 K ±0.0087

±0.0058

Relative reversibility error 3) dhy

% of Cn

±0.0083

Non-linearity 3) dlin ±0.0083

Minimum dead load output

return (MDLOR) ±0.0083

Off-center load error4) ±0.0116

1) As per OIML R60, with PLC = 0.7

2) Max. eccentric loading as per OIML R76.

3) The values for non-linearity (dlin), relative reversibility error (dhy) and temperature coefficient of

sensitivity (TCS) are recommended values. If these values are added together, they are within the

cumulated error limit specified in OIML R60.

4) As per OIML R76

For more specifications, see table SP4M..., accuracy

class C3MR (page 13)

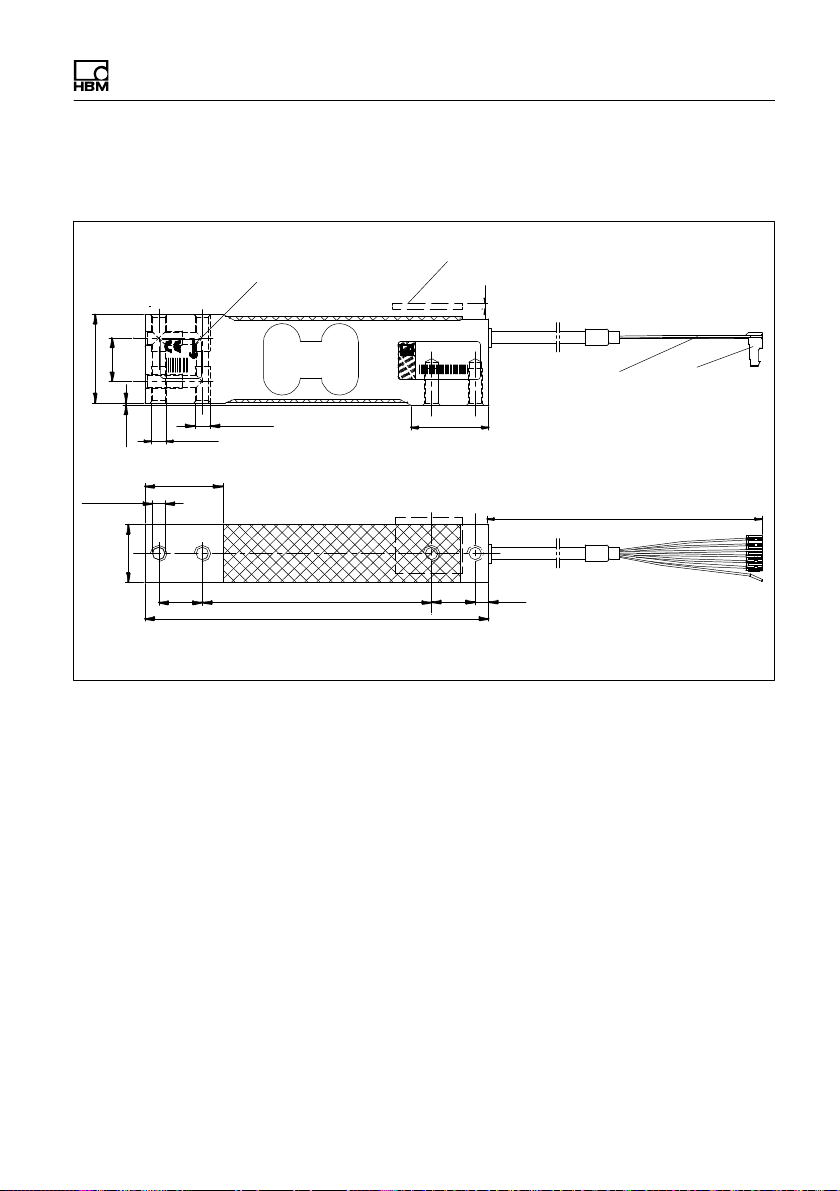

Dimensions

SP4M A2447-1.1 HBM: public 17

6 Dimensions

6‐M6x1‐6H,

16 deep Round cable 3000"50 mm

Cable and plug (see chapter 4

“Electrical connection”, page 10)

12345678 week

year

v

19.1

M6x0.5, 16 deep

M6x1‐6H

34

35

39

25.4*

19.1 99.6 19.1 6.1

150

Load direction

SP4C3‐MR 20kg

* SP4M.../1 kg: 18 mm

x4

Cover with ATEX, Zone 1 and 21;

Zone 2 and 22 (31 mm x 25 mm)

1+0.1

-0

Dimensions

18 A2447-1.1 HBM: public SP4M

This manual suits for next models

2

Table of contents

Languages: