HBM TTS User manual

Mounting Instructions | Montageanleitung |

Notice de montage

English Deutsch Français

TTS

Hottinger Baldwin Messtechnik GmbH

Im Tiefen See 45

D-64239 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbm.com

Mat.: 7-2001.1571

DVS: A1571-3.0 HBM: public

06.2016

EHottinger Baldwin Messtechnik GmbH.

Subject to modifications.

All product descriptions are for general information only.

They are not to be understood as a guarantee of quality or

durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allgemeiner

Form. Sie stellen keine Beschaffenheits- oder Haltbarkeits

garantie dar.

Sous réserve de modifications.

Les caractéristiques indiquées ne décrivent nos produits

que sous une forme générale. Elles n'impliquent aucune

garantie de qualité ou de durablilité.

Mounting Instructions | Montageanleitung |

Notice de montage

English Deutsch Français

TTS

2A1571-3.0 HBM: public TTS

English

1 Safety instructions 3........................................

2 Scope of supply 6..........................................

3 Application 7...............................................

4 Structure and mode of operation 8...........................

4.1 Mechanical construction 8....................................

4.2 Installation position 9.........................................

4.3 Conditions at the usage site 9.................................

5 Assembling the torque wrench 10............................

5.1 Fitting the square adapter on the measuring head 10..............

5.2 Fitting the lever 12............................................

5.2.1 One‐piece lever (nominal (rated) torque 100 N@m) 12..............

5.2.2 Two‐piece lever (nominal (rated) torque 200 N@m) 13..............

5.2.3 Three‐piece lever (nominal (rated) torque 500 N@m, 1 kN@m) 14....

5.2.4 Three‐piece lever (nominal (rated) torque 3 kN@m) 14.............

6 Electrical connection 16......................................

6.1 General instructions 16........................................

6.2 Connector pin assignment 17...................................

7 Maintenance 18..............................................

8 Dimensions 19..............................................

9 Accessories 21..............................................

10 Specifications 22............................................

Safety instructions

TTS A1571-3.0 HBM: public 3

1 Safety instructions

Use in accordance with the regulations

The TTS Transfer torque wrench may be used for torque

measurement and calibration tasks only. Use for any

additional purpose shall be deemed to be not in

accordance with the regulations.

In the interests of safety, the transducer should only be

operated as described in the Mounting Instructions. It is

also essential to observe the appropriate legal and safety

regulations for the application concerned during use. The

same applies to the use of accessories.

The transducer is not a safety element within the mean

ing of its use as intended. Proper and safe operation of

this transducer requires proper transportation, correct

storage, assembly and mounting and careful operation.

General dangers of failing to follow the safety

instructions

The transducer corresponds to the state of the art and is

fail‐safe. The transducer can give rise to remaining

dangers if it is inappropriately installed and operated by

untrained personnel.

Everyone involved with the installation, commissioning,

maintenance or repair of the transducer must have read

and understood the mounting instructions and in particu

lar the technical safety instructions.

Remaining dangers

The scope of supply and performance of the transducer

covers only a small area of torque measurement

technology. In addition, equipment planners, installers

and operators should plan, implement and respond to the

Safety instructions

4A1571-3.0 HBM: public TTS

safety engineering considerations of torque

measurement technology in such a way as to minimize

remaining dangers. Prevailing regulations must be

complied with at all times. Reference must be made to

remaining dangers connected with torque measurement

technology.

In these mounting instructions, remaining dangers are

pointed out using the following symbols:

Symbol Significance

CAUTION This marking warns of a potentially dangerous situa

tion in which failure to comply with safety require

ments can result in slight or moderate physical injury.

Notice This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

CE mark

The CE mark enables the manufacturer to guarantee that

the product complies with the requirements of the rele

vant EC directives (the declaration of conformity is avail

able at http://www.hbm.com/HBMdoc).

Statutory marking requirements for waste disposal

National and local regulations regarding the protection of

the environment and recycling of raw materials require

old equipment to be separated from regular domestic

waste for disposal.

For more detailed information on disposal, please contact

the local authorities or the dealer from whom you pur

chased the product.

Safety instructions

TTS A1571-3.0 HBM: public 5

Conversions and modifications

The transducer must not be modified from the design or

safety engineering point of view except with our express

agreement. Any modification shall exclude all liability on

our part for any damage resulting therefrom.

Qualified personnel

The transducer must only to be installed and used by

qualified personnel, strictly in accordance with the

specifications and with safety requirements and

regulations. It is also essential to observe the appropriate

legal and safety regulations for the application concerned

during use. The same applies to the use of accessories.

Qualified personnel means persons entrusted with the

installation, fitting, commissioning and operation of the

product who possess the appropriate qualifications for

their function.

Scope of supply

6A1571-3.0 HBM: public TTS

2 Scope of supply

STransfer torque wrench (measuring head, lever, con

necting elements) in aluminum case

SSquare adapter with external square shaft for test

object (square size see specifications for the respec

tive nominal (rated) torque)

SConnecting cable, with Lemo® connector on trans

ducer side, 15‐pin Sub D connector on amplifier side,

length 3 m

SMounting Instructions

Application

TTS A1571-3.0 HBM: public 7

3 Application

The transfer torque wrench is used as a transfer stan

dard for calibrating torque wrench calibrating devices.

Generally, when a torque wrench calibrating device is

used, torque is generated by exerting force on the lever

of the torque wrench to be calibrated (e.g. the triggering

torque wrench to be used in the workshop). When cali

brating the torque wrench calibrating device, on the other

hand, a transfer torque wrench (the indicating torque

wrench) is inserted into the calibrating device instead of a

torque wrench in need of calibration. The torque is gener

ated in the same way as for normal use, so that the mea

surement conditions for the calibrating device are identi

cal. This is of particular importance with respect to the

parasitic loads acting at the same time as the actual cali

bration torque, namely lateral force and bending moment.

The design of the TTS transfer torque wrench is adapted

to German Calibration Service guideline DKD‐R 3‐8 1),

which regulates the calibration of torque wrench calibrat

ing devices.

To conform to the strict requirements regarding the trace

ability of a transfer standard, a transfer torque wrench

must be calibrated in an accredited calibration laboratory

(in Germany, this is a DKD laboratory). The DKD calibra

tion certificate in accordance with guideline DKD‐R 3‐7 2)

has to be ordered separately.

1) Guideline DKD‐R 3‐8 “Statische Kalibrierung von Kalibriereinrichtungen für Drehmoment

schraubwerkzeuge" (Static calibration of calibrating devices for torque tightening tools), pub

lished by the German Calibration Service.

2) Guideline DKD‐R 3‐7 “Statische Kalibrierung von anzeigenden Drehmomentschlüsseln“ (Static

calibration of indicating torque wrenches), published by the German Calibration Service.

Structure and mode of operation

8A1571-3.0 HBM: public TTS

4 Structure and mode of operation

4.1 Mechanical construction

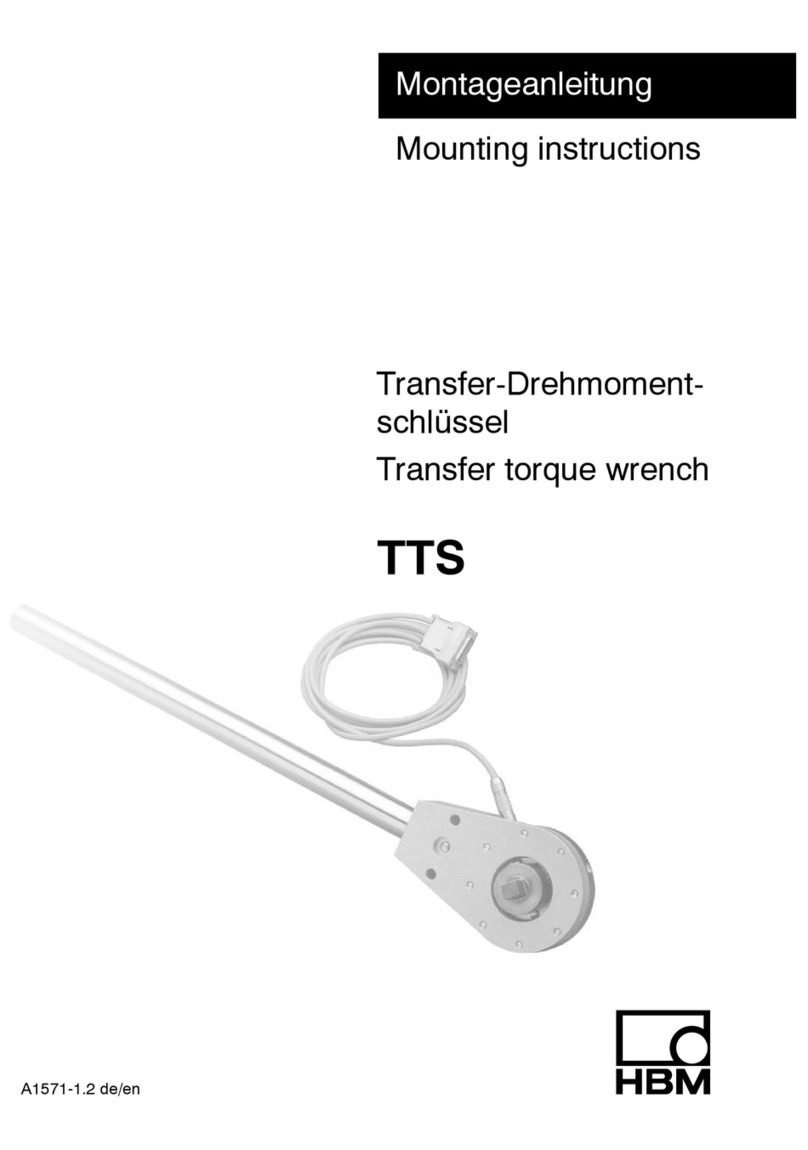

The transfer torque wrench comprises a measuring head

and a lever. A measuring body and an interchangeable

square adapter are integrated in the measuring head.

The supplied connecting cable is connected with the

transducer via a six‐pin Lemo®socket.

Measuring head

Lever

Lemo®socket

Knurled screw

Square adapter

Fig. 4.1 Mechanical construction

CAUTION

The hexagon‐socket screws on the measuring head are

marked with a locking varnish and must not be loosened!

Structure and mode of operation

TTS A1571-3.0 HBM: public 9

4.2 Installation position

The transfer torque wrench can be mounted in any

position. With a clockwise torque, a positive output signal

is produced in conjunction with HBM measuring

amplifiers.

4.3 Conditions at the usage site

The transfer torque wrench is protected to IP22

according to EN 60529.

Transducers must be protected against coarse dirt parti

cles, dust, oil, solvents and humidity.

During operation, the prevailing safety regulations for the

security of personnel must be observed.

Assembling the torque wrench

10 A1571-3.0 HBM: public TTS

5 Assembling the torque wrench

The transfer torque wrench is taken apart and delivered

in a carrying case. The measuring head, the square

adapter, the knurled screw, the lever and the connecting

cable are all separate. Depending on the nominal (rated)

torque, there are one, two or three parts to the lever.

CAUTION

If you want to use a different square adapter from the

accessories program, instead of the one supplied, you

must keep to its maximum permissible torque (see Sec

tion 9, Page 21).

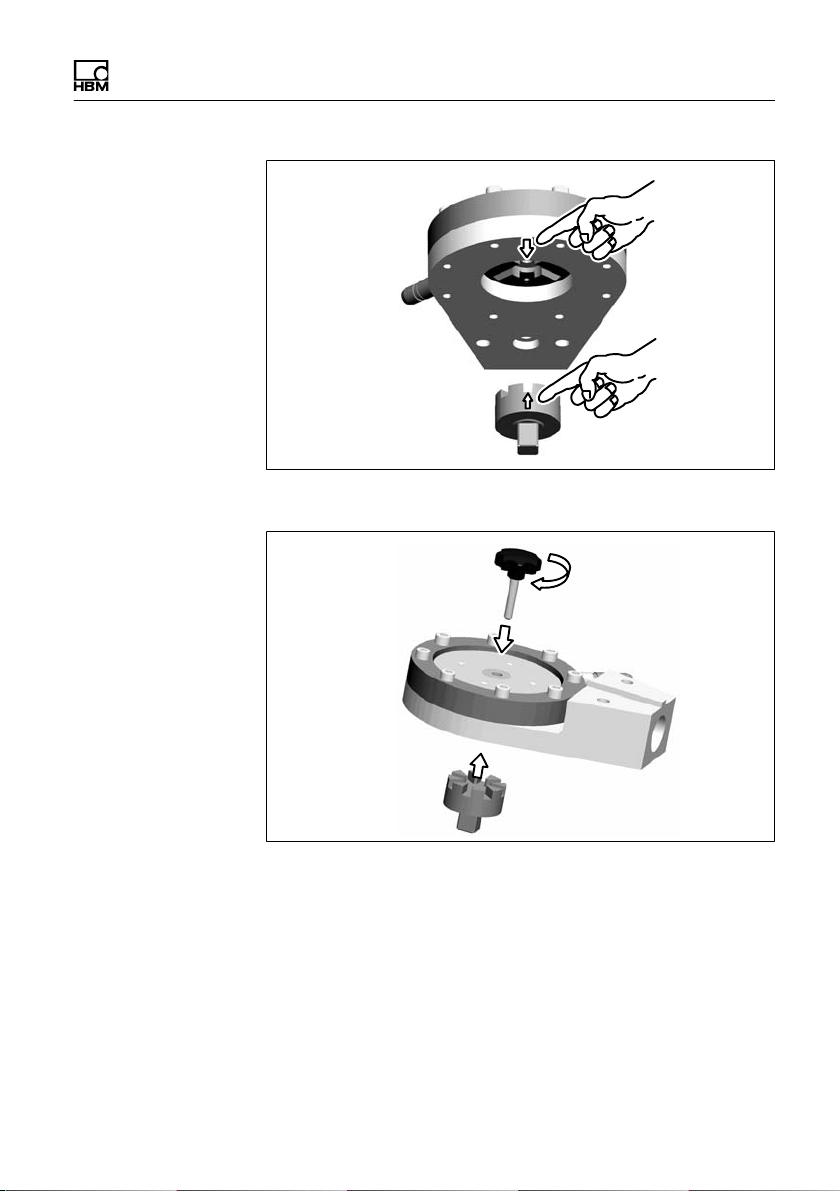

5.1 Fitting the square adapter on the

measuring head

Notice

We recommend that the square adapter is always

installed in the same angular position. The later transfer

torque wrenches have arrows on the measuring head

and on the square adapter for ease of positioning (see

Fig. 5.1). The points of the arrows should point to one

another.

Assembling the torque wrench

TTS A1571-3.0 HBM: public 11

Fig. 5.1 Positional markings

Knurled screw

Measuring

head

Square adapter

Fig. 5.2 Fitting the square adapter on the measuring head

Position the square adapter in accordance with the arrow

markings (see Fig. 5.1) on the measuring head; insert the

knurled screw into the central hole in the measuring head

and screw the square adapter in tight.

Assembling the torque wrench

12 A1571-3.0 HBM: public TTS

Information

By keeping to the same angular position, any symmetry

deviation will not affect the reproducibility of the mea

surement results.

5.2 Fitting the lever

Depending on the nominal (rated) torque, there are one,

two or three parts to the lever. To make assembly easier,

apply a little oil to the mating surfaces of the individual

components.

5.2.1 One‐piece lever (nominal (rated) torque

100 N@m)

SPress down the spring bolts of the lever.

SPush the lever as far as it will go into the receiving

hole in the measuring head.

STurn the lever from side to side until you hear the

spring bolts engage.

Spring bolt

Measuring head

Fig. 5.3 One‐piece lever

Assembling the torque wrench

TTS A1571-3.0 HBM: public 13

5.2.2 Two‐piece lever (nominal (rated) torque

200 N@m)

SFirst join the parts of the lever together by pushing the

longer piece into the shorter one.

SFit the lever and the measuring head, as described in

sub‐section 5.2.1.

Spring bolt

Spring bolt

Fig. 5.4 Two‐piece lever

Assembling the torque wrench

14 A1571-3.0 HBM: public TTS

5.2.3 Three‐piece lever (nominal (rated) torque

500 N@m, 1 kN@m)

SFirst attach the connection bolt of the lever with the

two supplied hexagon‐socket screws (a./f. 5) in the

measuring head.

SPush the center piece over the connection bolt and

tighten the knurled screw.

SNow push the end piece into the center piece and turn

the knurled screw tight.

Connection bolt

Center piece

End piece

Fig. 5.5 Three‐piece lever (500 N@m, 1 kN@m)

5.2.4 Three‐piece lever (nominal (rated) torque

3 kN@m)

SFirst attach the connection bolt of the lever with two of

the supplied hexagon‐socket screws (a./f. 5) in the

measuring head. Make sure you get the right end, as

shown in Fig. 5.7.

SPush the center piece over the connection bolt and

tighten the fastening screws.

Assembling the torque wrench

TTS A1571-3.0 HBM: public 15

SNow push the end piece into the center piece and turn

the fastening screws tight.

Center piece

End piece

Connection

bolt

Fig. 5.6 Three‐piece lever (3 kN@m)

Measuring

head end

20 mm

Lever end

70 mm

Fig. 5.7 Detailed view of end orientation on the connection

bolt

Electrical connection

16 A1571-3.0 HBM: public TTS

6 Electrical connection

6.1 General instructions

Electric and magnetic fields often cause interference

voltages in the measuring circuit. This interference

comes primarily from power lines lying parallel to the

measuring leads, but it can also come from nearby

contactors or electric motors. Interference voltage can

also be coupled galvanically, especially by grounding the

measurement chain at a number of points.

Please follow the below instructions:

SUse only shielded and low‐capacitance measurement

cables for six wire circuit from HBM.

SDo not position the measurement cables parallel to

power lines or control circuits. If this is not possible

(e.g. in cable shafts), protect the measurement cable

with armoured steel tubing, for example and keep it a

minimum distance of 50cm away from the other

cables. Power lines or control circuits should be

twisted together (15 twists per meter).

SGuard against stray fields from transformers, motors

and contactors.

SDo not ground the transducer, the amplifier and the

indicator more than once. All the measurement chain

devices must be connected to the same grounded

conductor.

Grounding concept (Greenline)

The cable shield of the connection cable is connected to

the measuring head of the transducer. This encloses the

measurement system in a Faraday cage. Any electro

Electrical connection

TTS A1571-3.0 HBM: public 17

magnetic interference active here does not affect the

measurement signal.

In the event of interference due to potential differences

(equalization currents) the zero operating voltage and the

housing ground should be isolated from one another at

the amplifier and a potential equalization line should be

run between the housing and the amplifier housing

(flexible stranded wire, 10 mm2conductor cross‐section).

6.2 Connector pin assignment

The transfer torque wrench comes supplied with a

ready‐made 6‐wire connection cable (six‐wire circuit).

The pin assignment for the HBM amplifier can be found

in the following table:

Top view

1

8

9

15

Pin Wire color Connection

1 yellow Shielding connected to enclosure

ground

5 black Excitation voltage (-UB)

6 blue Excitation voltage (+UB)

8 white Measurement signal (+UA)

12 gray Sensor circuit (-)

13 green Sensor circuit (+)

15 red Measurement signal (-UA)

Extension cables should be of the shielded, low‐capaci

tance type. HBM provides the 1‐KAB254‐10 cable

(ready‐made) and the KAB8/00‐2/2/2 cable (by the

meter, can also be supplied with fitted connecting plug)

specifically for this purpose.

Maintenance

18 A1571-3.0 HBM: public TTS

7 Maintenance

The transfer torque wrench is maintenance free.

Other manuals for TTS

2

Table of contents

Languages:

Other HBM Power Tools manuals

Popular Power Tools manuals by other brands

Pro's Kit

Pro's Kit Pro'sKt SS-621 Series user manual

FLORABEST

FLORABEST FBK 4 C2 instructions

master mechanic

master mechanic 181683 owner's manual

SPX FLOW

SPX FLOW Power Team PTPH-100T operating instructions

Far Tools

Far Tools DPB 16E Original manual translation

Far Tools

Far Tools PM 550T Original manual translation