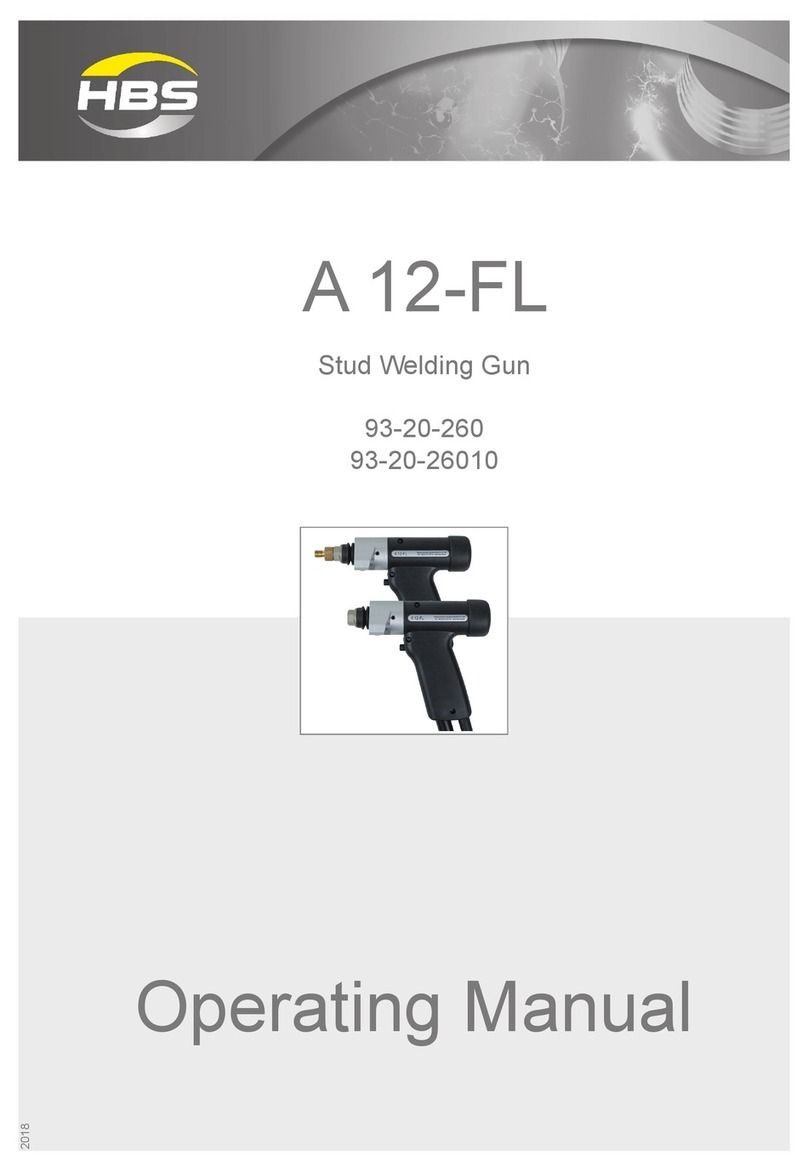

HBS CI 03 User manual

This manual suits for next models

1

Table of contents

Other HBS Welding System manuals

Popular Welding System manuals by other brands

Air Liquide

Air Liquide SAFMIG 330 TRS PLUS Safety instruction for use and maintenance

NewArc

NewArc R2500 instruction manual

Miller

Miller Gold SealTM Model 5000 owner's manual

Parkside

Parkside PISG 120 A1 Operation and safety notes

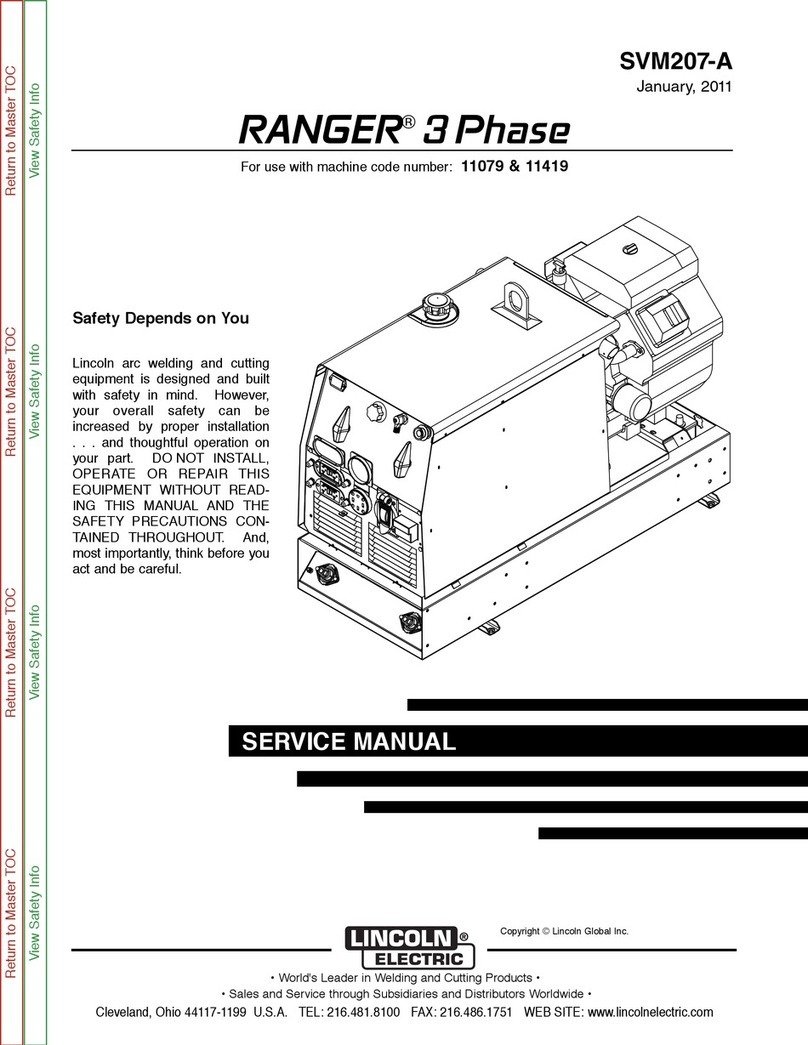

Lincoln Electric

Lincoln Electric RANGER 3PHASE SVM207-A Service manual

Amada

Amada TCW Operation manual

Campbell Hausfeld

Campbell Hausfeld WF1800 Operating instructions & parts manual

stayer

stayer PLUS120GE operating instructions

Miller

Miller TRAVEL MAASTER SPT-1C owner's manual

Miller

Miller SRH 2000 CHANTIER owner's manual

ESAB

ESAB A6 Mastertrac Tandem instruction manual

Eastwood

Eastwood MP140i instructions

widos

widos 2500 / OD 315 Working Instructions Translation

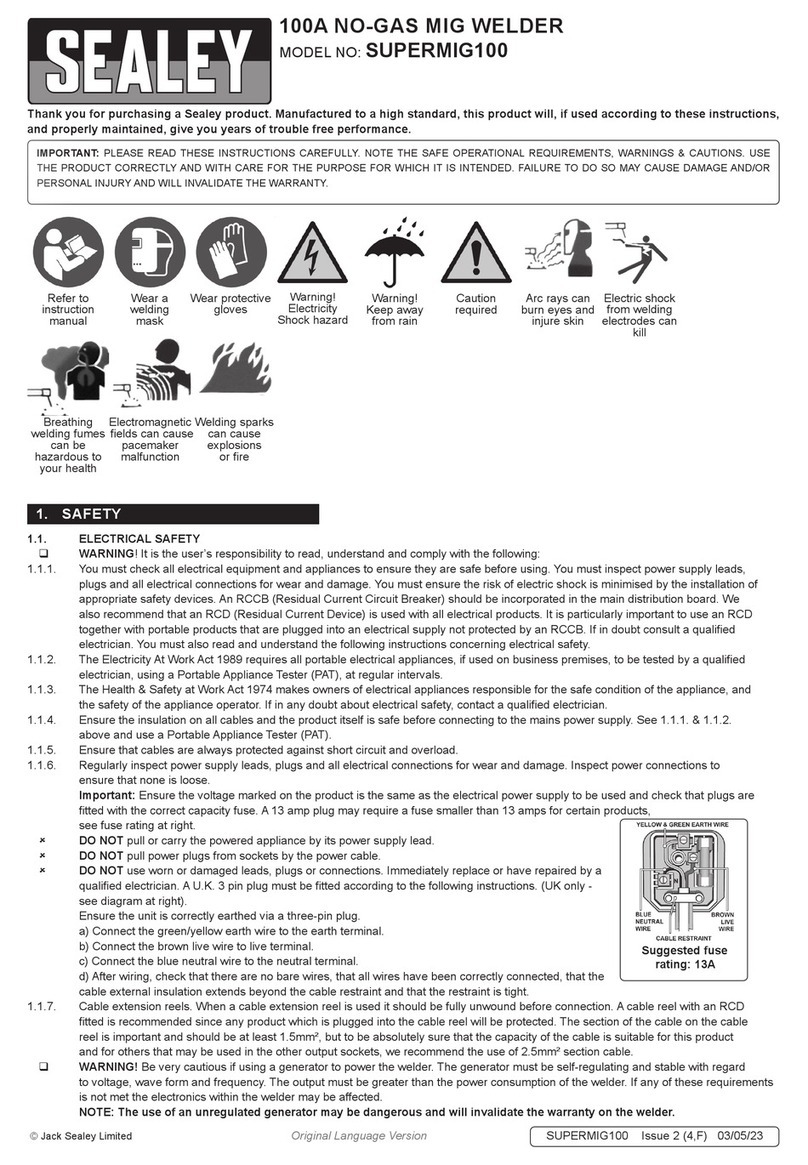

Sealey

Sealey SUPERMIG100 quick start guide

Chicago Electric

Chicago Electric 61205 Owner's manual & safety instructions

Top Gun

Top Gun SYN 2500 PULSE user manual

Mosa

Mosa MS 200 S Use and maintenance manual

Magmaweld

Magmaweld ID 500M PULSE user manual