HBS KAH 412 LA User manual

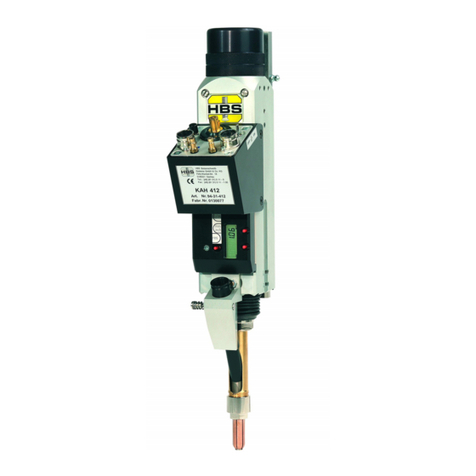

KAH 412 LA

Automatic Welding Head

94-37-412

Operating Manual

ii

ii KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08

KAH 412 LA Operating Manual, Issue 10/2008 Order No. BA 94-37-412

Customer Service in Germany:

HBS Bolzenschweiss-Systeme GmbH & Co. KG

Felix-Wankel-Strasse 18

85221 Dachau / Germany

Phone +49 (0) 8131 511-0

Fax +49 (0) 8131 511-100

E-mail post@hbs-info.com

Web www.hbs-info.com

Copyright:

The information contained herein may not be copied, reproduced, adapted,

merged, translated or used without the prior written consent of the copyright

owner.

Adaptations, errors and technical modifications reserved without prior notice.

© HBS Bolzenschweiss-Systeme GmbH & Co. KG

iii

KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08 iii

Dear customer,

Thank you very much for purchasing a power unit from HBS Bolzenschweiss-

Systeme.

We from HBS wish you always successful working with this stud welding unit.

We ask you to observe the following points:

– Store the operating manual in a way that it can always be accessed by the

operator.

– Let the operator sign before starting up that he has read and completely under-

stood the operating manual.

– This operating manual applies only to this stud welding unit.

– Protect the stud welding unit from unauthorized use.

– The stud welding unit must only be operated by trained personnel.

– Let an electrician check whether the wall sockets where you want to connect the

related stud welding unit, are properly fused and grounded.

– Inform our customer service in case of malfunction.

– In case of accident, inform a physician and the responsible official body.

THREAT TO LIFE!

Persons fitted with a pace maker must not operate the stud

welding machine.

MAGNETIC FIELDS!

During stud welding, strong electro-magnetic fields are

generated. Do not weld in the vicinity of the electrical

equipment which could be affected.

Safety instructions are a delicate subject. Anybody who handles a stud welding

unit, whether it is the welding gun or the power unit, should be familiar with them,

because improper use of stud welding units can be dangerous to life.

For your own sake you should know the safety instructions for operating your HBS

stud welding units inside out.

In addition to the protection of your health and the capital value of the enterprise, the

safety instructions are intended to clarify any responsibilities, which arise from

ownership and operation of the equipment.

This chapter of the operating manual offers you clear and easy to understand information

for the safe operation of your HBS stud welding unit.

iv

iv KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08

Your power unit may differ in some details from the captions in this manual. This has

no effect on the operation of the welding machine.

Should you have questions about this manual or in case you want to order some more

copies, please provide the order number listed in the foot line.

Important reminder:

Data and information herein were collected with greatest care. Although we did our very

best to correctly update any information up to the time of delivery, there is no guarantee

in respect of errors.

If you should detect errors or mistakes right in this manual, please contact us:

HBS Bolzenschweiss-Systeme GmbH & Co. KG

Felix-Wankel-Strasse 18

85221 Dachau / Germany

A feedback blank is provided in the appendix.

KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08 v

Table of Contents

1 General ............................................................................................. 9

1.1 Guide to this Operating Manual .................................................................. 10

1.2 Safety Symbols .......................................................................................... 11

1.3 General Safety Instructions ........................................................................ 12

1.4 Intended Use .............................................................................................. 12

1.5 Transportation, Packaging, Storage ........................................................... 13

1.6 Accompanying Documents ........................................................................ 13

1.7 Markings ..................................................................................................... 14

2 Delivery ........................................................................................... 15

3 Starting-up ..................................................................................... 16

3.1 Requirements of Workplace ...................................................................... 16

3.2 Connecting the Welding Head to the Power Unit ....................................... 17

3.3 Ground Connection .................................................................................... 19

3.4 Change Working Place .............................................................................. 19

4 Function ......................................................................................... 20

4.1 Components of the Welding Head ............................................................. 20

4.2 Adjusting the Working Position ................................................................... 21

4.3 Equipping the Welding Head for a Welding Fitting...................................... 22

4.4 Adjustments ............................................................................................... 24

5 Stud Welding Procedure .............................................................. 26

5.1 Safety Instructions ...................................................................................... 26

5.2 Functional Principle of Stud Welding .......................................................... 29

5.2.1 Contact Stud Welding ............................................................................................ 29

5.2.2 Gap Stud Welding .................................................................................................. 30

5.2.3 Drawn-Arc Stud Welding ........................................................................................ 31

5.2.4 Drawn-Arc Stud Welding with Shielding Gas .......................................................... 33

5.2.5 Short-Cycle Drawn-Arc Stud Welding with Shielding Gas ....................................... 34

5.2.6 Drawn-Arc Capacitor-Discharge Stud Welding ........................................................ 34

5.3 Welding Preparation ................................................................................... 35

5.4 High-strength Welds ................................................................................... 35

vi KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08

5.5 Determination of Welding Parameters ....................................................... 36

5.5.1 Standard Welding Parameters for Tip Ignition with Gap .......................................... 37

5.5.2 Standard Welding Parameters for Gap Stud Welding with

Drawn-Arc Ignition under Shielding Gas ................................................................. 38

5.6 Welding Procedure .................................................................................... 39

5.7 Checking the Quality of the Weld ............................................................... 39

5.7.1 Visual Inspection ................................................................................................... 40

5.7.2 Bending Test .......................................................................................................... 41

5.7.3 Arc Blow Effect ...................................................................................................... 43

5.8 Possible Malfunctions and Corrective Actions ............................................ 44

5.9 Welding Elements ...................................................................................... 45

6 Switching off the Power Unit ........................................................ 46

6.1 Temporary Switching off ............................................................................. 46

6.2 Disposal ..................................................................................................... 46

7 Care and Maintenance .................................................................. 47

7.1 Safety Instructions ...................................................................................... 47

7.2 Regular Maintenance Operations ............................................................... 48

7.3 Maintenance and Cleaning the Welding Head ............................................ 49

7.4 Removing the Equipment ........................................................................... 50

7.5 Detaching the Welding Head ...................................................................... 51

7.6 Dismounting and Cleaning the Welding Head ............................................ 52

7.7 Assembling the Welding Head ................................................................... 54

8 Appendix ........................................................................................ 56

8.1 Technical Data ............................................................................................ 56

8.2 Spare Parts ................................................................................................ 57

8.3 Accessories ............................................................................................... 64

8.4 Manual and Automatic Equipment Parts..................................................... 70

8.4.1 Manual Equipment Part.......................................................................................... 70

8.4.2 Automatic Equipment Part ..................................................................................... 71

8.5 Dimensional Drawing ................................................................................. 72

8.6 Environmentally Admissible Disposal ......................................................... 73

KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08 vii

Glossary ......................................................................................... 74

Regulations and Standards .......................................................... 75

Further Instructions - Tip Ignition ................................................. 77

Further Instructions - Arc Stud Welding ...................................... 78

Guarantee Clauses ........................................................................ 79

EU-Statement of Conformity ......................................................... 80

Confirmation .................................................................................. 81

Feedback ........................................................................................ 82

Service & Support ......................................................................... 83

Index ............................................................................................... 84

viii KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08

KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08 9

1 General

Persons addressed by this operating manual

This operating manual is written for operators, personnel of the end user, and authorized

service technicians. It provides you with all necessary information to operate the welding

head.

Required user qualification

The welding head must only be operated by qualified personnel.

Let the welding head only be operated by persons who

– are qualified through a suitable training according to the current standards (see

appendix),

– are properly instructed,

– are physically and intellectually suitable,

– can be expected to reliably fulfill the requested job.

What else must the owner observe?

Make sure that this operating manual is always in reach of the welding head.

Read the entire manual before operating the power unit.

Strictly observe the safety instructions.

Before starting up the power unit, let the operator sign the confirmation that he/

she has read and fully understood the operating manual (see appendix).

Do not commence stud welding until you have understood all operating

processes.

Contact us if there are any doubts on certain operating procedures.

Protect the welding head against unauthorized use.

Inform our service in case of malfunction.

Based on this operating manual, a company specific work order, as well as a company

specific maintenance instruction must be drawn up. The company specific work order

must consider the special user conditions in your company.

Make sure that operators of the welder are provided with and wear personal protective

equipment, e.g. protective goggles, gloves, shoes, ear protection etc.

Owners and operators make sure that the welding head is only used as directed.

During any activity such as transportation, set-up, (re-)assembly, production,

maintenance etc. observe the information given in this operating manual.

10 KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08

1.1 Guide to this Operating Manual

This operating manual provides you with the following information

"Delivery" in Chapter 2

"Starting-up" in Chapter 3

"Functional Principle" in Chapter 4

"Stud Welding Process" in Chapter 5

"Switching off" in Chapter 6

"Care and Maintenance" in Chapter 7

Technical Data and much more in Appendix

THREAT TO LIFE and risk of serious health and material damage in

case of improper use of the welding head. Observe all notes in this

operating manual.

Note for qualified operators (see chapter 1).

All instructions contained in this manual must also be observed

by qualified operators.

The welding process and the sequence of procedures to carry

out a weld are described in chapter 5.

KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08 11

1.2 Safety Symbols

Symbols and markings used in this operating manual mean:

Threat to life or risk of personal injury

Risk of material damage

Ban for persons fitted with a pace maker

Warning of dangerous electrical voltage

Warning of electromagnetic fields

Wear protective clothes

Wear protective goggles

Wear ear protection

Additional tips for operation and service safety

Prompt

–List

12 KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08

1.3 General Safety Instructions

Improper operation of the welding head is LIFE-THREATENING!

Threat to life

– by electric shock and arc

– by toxic vapors and airborne particles

– by red-hot metal spatters (fire risk)

– by blow-up of explosive gases and materials

– by strong magnetic fields for persons fitted with a pace maker

In addition, through improper use damage to the stud welding unit

and to material can be caused. For details, see chapters 1, 3 and 5.

1.4 Intended Use

Warning: Unauthorized interference with the stud welding unit

as well as unauthorized alteration of the stud welding unit are

prohibited and result in complete cancellation of any guarantee

and liability claims against HBS.

Operation of the welding head is only allowed with HBS power

units, this clause is also part of ”use as directed”.

The welding head is intended to weld welding elements according to actual standards

(see chapter 5 and appendix). Any other use is regarded as not used as directed. The

manufacturer is not liable for damages resulting from the welding head not used as

directed. Any risk is carried by the user.

The welding head is designed according to specific standards and accident prevention

regulations. Basics are European Union guidelines and in Germany valid standards.

Please note that in your country additional standards and safety conditions (especially

rules for accident prevention) may differ from the standards mentioned in this operating

manual. The welding head was manufactured to the latest developments in technology

and is regarded as safe to operate (place of operation see section 8.1).

The welding head KAH 412 can be connected to the HBS power unit ARC 500 Automa-

tic, ARC 800 Automatic, ARC 1550 Automatic, IT 90 Automatic, IT 1001 Automatic,

IT1002 Automatic, CDM 1601 Automatic, CDM 2401 Automatic, CDM 3201 Automatic

and SCD 3201 Automatic. For details please contact the HBS customer service

(address see page ii).

Check in any case the operating manual of the HBS power unit whether this

welding head can be used.

Observing the operating manual of the used power unit is also part of the ”use as

directed”.

KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08 13

1.5 Transportation, Packaging, Storage

HBS delivers products in a specific transport package.

Save the undamaged packing. Ship and transport the device only in its original

packing.

Right before delivery, the welding head is once again checked for proper functioning and

a control mark is attached. When receiving the delivery, check everything for damages

and completeness. If damages occurred during transportation or components are

missing, inform the manufacturer or the haulier immediately (see page ii).

Proper functioning of the welding head can only be checked before starting-up by visual

inspection (visible damage).

The following items are to be observed if the welding head is not to be put into operation

immediately after delivery.

– The welding head must be stored in a secure place

– The welding head must be protected against humidity, dust, metallic dirt.

– Storage temperature: -5 °C to +50 °C

– Relative humidity: 0% to 50% at +40 °C

0% to 90% at +20 °C

If you resell the welding head, please provide us with the name and postal

address of the new owner so that we can advise them of any changes to the

operating manual.

1.6 Accompanying Documents

In addition to this operating manual, you must observe the operating manual of the power

unit as well as applicable accident prevention and safety instructions.

14 KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08

1.7 Markings

There are various markings and safety symbols attached to your power unit (see

section 8.1).

Make sure that all markings remain clearly visible.

Type plate

The type plate contains the following data:

Manufacturer

Type

Order No./Serial No.

Primary voltage

Fuse

Power consumption

Cooling class

Protection class

Date

Safety symbols

Replace illegible or damaged markings

Before opening machine disconnect mains

Observe operating manual

Warning of dangerous electrical voltage

Secure the following safety symbols in the area of welding place:

KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08 15

2 Delivery

The basic equipment of your welding head contains the following components:

No. of pieces Part Type Order No.

1Welding head KAH 412 LA 94-37-412

equipped for one stud dimension

1Operating manual KAH 412 LA BA 94-37-412

16 KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08

3 Starting-up

In this chapter you learn what to observe during setting-up and starting-up of the welding

head.

3.1 Requirements of Workplace

The welding head corresponds with protection class IP 20. It

must not be used in humid conditions!

Vapors and airborne particles may occur during stud welding

operations. Especially with surface treated materials, toxic

vapors may be produced.

Ensure that a fume extraction is available and that the room is adequately

ventilated according to accident prevention regulations.

If possible, do not weld in rooms which are lower than 3 meters.

Special regulations apply for confined rooms, according to accident prevention

regulations of the official bodies (see appendix).

Weld only in adequate distance from combustible articles or liquids.

Before you start welding, remove any combustible articles or liquids in vicinity of

the workplace.

Make sure that a fire extinguisher is within reach.

Never weld in rooms exposed to risk of explosion.

Do not set-up the product in the vicinity of any apparatus or equipment which is

sensitive to welding spatters or magnetic fields.

Set-up the welding head:

– on a stable, clean, and level surface

– so that no-one is influenced or injured by welding spatters

– so that all cables and primary lines are protected from being damaged

– so that nobody will trip or fall over the cables or connection lines.

Ensure that air is able to circulate freely through the housing.

If heat is built-up inside the housing caused by bad air circulati-

on, the stud welding unit will be seriously damaged.

KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08 17

Secure the following safety symbols in the area of welding place:

THREAT TO LIFE to persons fitted with a pace maker

Strong electro-magnetic fields occur in the vicinity of the stud welding

unit during welding. Such fields may affect the proper function of a

pace maker. Thus persons equipped with a pace maker must not

operate the stud welding unit and must not stay in its vicinity during

welding.

During the actual welding process, you must expect red-hot welding

spatters, possibly liquid spatters, a flash, and a loud bang > 90 dB (A).

Alert any colleagues who are occupied in the vicinity of the welder.

Wear your personal protective equipment according to actual

standards (see appendix).

3.2 Connecting the Welding Head to the Power Unit

Switch off the power unit. In this way, you avoid any risk of

electrical shock.

Plug the connecting line of the welding head into the socket of the power unit.

Press-in the plug and twist firmly to the right.

The connection is not secured against working itself loose!

Check the plug connections regularly to ensure that they are

properly locked. In case of loose connection, heat may build up

in the plug and may destroy the entire plug connection.

18 KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08

Plug the control cable of the welding head into the appropriate connection of the

power unit.

Twist the retaining nut of the control cable plug clockwise to secure the connec-

tion.

The welding head cables must not be coiled during welding.

Coiled cables work as a coil and may negatively affect the

welding result. Before welding, lay out the cables lengthwise.

Take care to ensure good connection on the welding head

before you pin the pneumatic connections onto the power unit.

Plug-in the connectors of your air pressure supply into the appropriate bushings

at the front side of the power unit.

The power unit controls the air between booth bushings.

Air connection B (blue marking) and air connection A

(black marking) must not be interchanged (ends up in

failure during feeding and welding).

KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08 19

3.3 Ground Connection

Plug the ground cable in the connector of the power unit.

Press in the plug and twist firmly clockwise.

The connection is not secured against working itself loose!

Check the plug connections regularly to ensure that they are

properly locked. In case of loose connection, heat may build up

in the plug and may destroy the entire plug connection.

Remove any rust, paint, or contaminants from the workpiece in the areas where

you intend to connect the ground cables.

Connect the ground clamp to the workpiece as securely as possible.

Take care to ensure good contact and symmetrical connection.

The welding location must lie directly between the two ground

clamps.

3.4 Change Working Place

Switch off the power unit. In this way, you avoid any risk of

electrical shock.

When you move your workplace, disconnect the welding head and the ground

cable from the power unit. Proceed in reversed sequence as described in section

3.2 and 3.3.

After changing the workplace, check the welding head and the ground cables for

possible damage or missing components.

20 KAH 412 LA Order No. BA 94-37-412 Issue 23.10.08

4 Function

In this chapter you learn more about the design of the welding head and how

to use the various setting options.

4.1 Components of the Welding Head

The basic body of the welding head KAH 412 is made of an aluminum square.

All supply lines are plugged in the connection casing (welding current cable, control

cable, air pressure hoses).

At the front side of the welding head KAH 412 the slot tube is located, which may be

quickly replaced by means of the stop spring. Supplying the welding fittings to the chuck

(manually or automatically) is done through the slot tube with guide bushing. The plunger

cylinder, which is integrated in the piston and equipped with linear ball bearings with zero

backlash, transports the fitting pneumatically through the chuck in welding position.

Above the connection casing, the complete adjusting mechanism for lift-off and spring

force is positioned. The spring force is directly displayed on a scale.

Attaching the welding head KAH 412 in Z-direction is done with the quick-change prism

system, which is mounted on the backside. The fixture is performed pneumatically or

motor-driven, depending on customer’s needs.

This manual suits for next models

1

Table of contents

Other HBS Welding System manuals

Popular Welding System manuals by other brands

Welding Industries Malaysia

Welding Industries Malaysia WIM200 instruction manual

Lincoln Electric

Lincoln Electric PRO-CUT IM665 Operator's manual

Lincoln Electric

Lincoln Electric INVERTEC STT Series Service manual

Demiriz

Demiriz DCP-3 instruction manual

Hypertherm

Hypertherm HT4400 Quick setup

Miller

Miller DIVERSION 165 owner's manual