HBS CPW 0604 User manual

CPW 0604

CNC Production Welder

Operating Manual

2013

ii

ii CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31)

CPW 0604 Operating Manual Issue 09/2013 Order No. BA CPW 0604

Translation of the Operating Manual

Customer Service in Germany:

HBS Bolzenschweiss-Systeme GmbH & Co. KG

Felix-Wankel-Strasse 18

85221 Dachau / Germany

Phone +49 8131 511-0

Fax +49 8131 511-100

E-mail [email protected]

Web www.hbs-info.com

Copyright:

The information contained herein may not be copied, reproduced, adapted,

merged, translated or used without the prior written consent of the copyright

owner.

Adaptations, errors and technical modifications reserved without prior notice.

©HBS Bolzenschweiss-Systeme GmbH & Co. KG

iii

CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31) iii

Dearcustomer,

ThankyouverymuchforpurchasingaCNCProductionWelderfromHBSBolzen-

schweiss-Systeme.

We from HBS wish you always successful working with this stud welding unit.

We ask you to observe the following points:

– Store the operating manual in a way that it can always be accessed by the

operator.

– Letthe operatorsign beforestarting upthat hehas readand completelyunder-

stoodtheoperatingmanual.

– This operating manual applies only to this stud welding unit.

– Protectthe studwelding unit from unauthorized use.

– Thestud welding unit must only be operatedby trainedpersonnel.

– Let an electrician check whether the wall sockets where you want to connect the

relatedstudweldingunit,areproperlyfusedandgrounded.

– Informourcustomerserviceincaseofmalfunction.

– In case of accident, inform a physician and the responsible official body.

THREATTOLIFE!

Persons fitted with a pace maker must not operate the stud

welding machine.

MAGNETICFIELDS!

During stud welding, strong electro-magnetic fields are

generated. Do not weld in the vicinity of the electrical

equipment which could be affected.

Safety instructions are a delicate subject. Anybody who handles a stud welding

unit, whether it is the welding gun or the power unit, should be familiar with them,

becauseimproper use of stud welding units canbe dangerous to life.

For your own sake you should know the safety instructions for operating your HBS

stud welding units inside out.

In addition to the protection of your health and the capital value of the enterprise, the

safety instructions are intended to clarify any responsibilities, which arise from

ownershipandoperationoftheequipment.

Thischapteroftheoperatingmanualoffersyouclearandeasytounderstandinformation

forthe safeoperation ofyour HBS stud welding unit.

iv

iv CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31)

Your CNC Production Welder may differ in some details from the captions in this

manual.This has noeffecton the operationof the weldingmachine.

Shouldyouhavequestionsaboutthismanualorincaseyouwanttoordersomemore

copies,please provide the order numberlisted inthe foot line.

Importantreminder:

Dataandinformationhereinwerecollectedwithgreatestcare.Althoughwedidourvery

besttocorrectlyupdateanyinformationuptothetimeofdelivery,thereisnoguarantee

inrespectoferrors.

If you should detect errors or mistakes right in this manual, please contact us:

HBS Bolzenschweiss-Systeme GmbH & Co. KG

Felix-Wankel-Strasse18

85221Dachau/Germany

Afeedback blank is provided in the appendix.

CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31) v

Table of ContentsTable of Contents

Table of ContentsTable of Contents

Table of Contents

Table of Contents

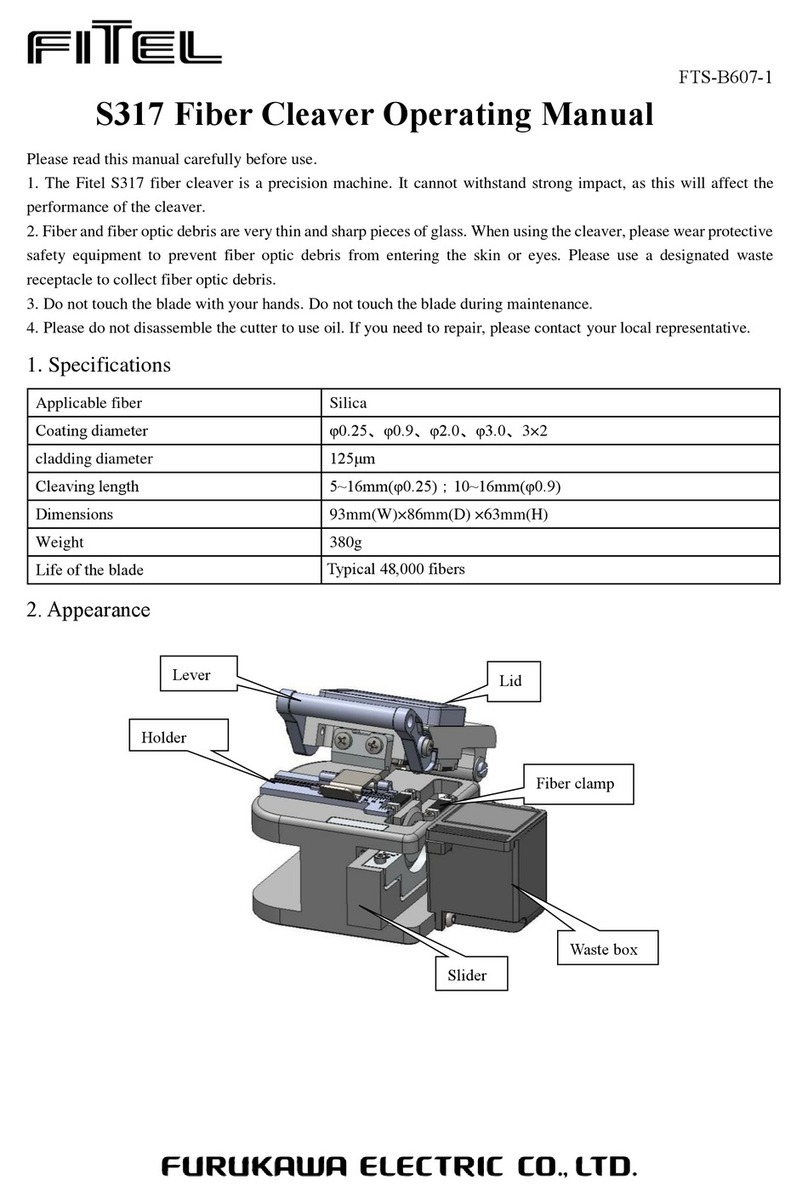

Important Data .................................................................................9

Data Delivery Condition ................................................................................ 9

1 General ........................................................................................... 11

1.1 Guide to this Operating Manual .................................................................. 12

1.2 Safety Symbols .......................................................................................... 13

1.3 General Safety Instructions ........................................................................ 14

1.4 IntendedUse .............................................................................................. 14

1.5 Transportation, Packaging, Storage ........................................................... 15

1.6 Accompanying Documents ........................................................................ 15

1.7 Markings ..................................................................................................... 16

2 Delivery........................................................................................... 18

3 Starting-up .....................................................................................19

3.1 Requirements of Workplace ...................................................................... 19

3.2 Requirements of Operating Personnel....................................................... 20

3.3 Requirements and Installation Instruction with HBS Base Frame .............. 21

3.4 Connecting the Welding Machine to the Primary Power Supply ................ 22

3.5 Connecting the Power Units to the CNC Production Welder ..................... 23

3.6 Connect Pneumatic Stud Switch(es) (PBW) to the Stud Welding Machine27

3.7 Pneumatic Diagram ................................................................................... 28

3.8 Change Working Place .............................................................................. 29

4 Function .........................................................................................30

4.1 Operating Elements ................................................................................... 30

4.1.1 Touch-PanelwithControl........................................................................................ 30

4.1.2 OperatingElements, Overview................................................................................ 30

4.2 MenuINITIALIZE ......................................................................................... 32

4.3 MenuSTARTMENU .................................................................................... 33

4.4 MenuAUTOMATIC...................................................................................... 34

4.4.1 DescriptionofOperating Elements ......................................................................... 35

4.4.2 AutomaticOptions ................................................................................................. 42

4.5 MenuMANUAL/CONTACT........................................................................ 43

4.5.1 Setting of the Contact Position............................................................................... 45

vi CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31)

Table of ContentsTable of Contents

Table of ContentsTable of Contents

Table of Contents

4.5.2 Positioning ofAxes in Manual Mode....................................................................... 47

4.5.3 Calibrationof contact signal ................................................................................... 49

4.5.4 Calibrationof Contact PositionZ ............................................................................ 50

4.5.5 CheckandDetermination of WeldingParameters .................................................. 51

4.5.6 FurtherFunctions................................................................................................... 56

4.6 MenuEQUIPMENT..................................................................................... 58

4.7 Menu SETUP CNC..................................................................................... 60

4.8 Menus PROGRAM EDIT / PROGRAM SELECT ....................................... 62

4.8.1 MenuPROGRAMSELECT .................................................................................... 63

4.8.2 Edita Program....................................................................................................... 69

4.8.3 Descriptionof the FunctionsinPROGRAM EDITOR .............................................. 75

4.9 MenuPROGRAM GRAPH........................................................................ 101

4.10 MenuPARAMETER CNC ......................................................................... 103

4.10.1 DescriptionofParameters.................................................................................... 105

4.10.2 Overview-ParametersXAxis............................................................................... 107

4.10.3 Overview-ParametersYAxis .............................................................................. 109

4.10.4 Overview-ParametersZU1Axis ...........................................................................111

4.11 Menu I/O Test ........................................................................................... 113

4.11.1 Overview................................................................................................................113

4.11.2 Functions..............................................................................................................114

4.12 MenuCONFIGURATION .......................................................................... 115

4.12.1 Setting the System Time ......................................................................................116

4.12.2 Setting the System Date.......................................................................................117

4.13 MenuSTANDARD VALUES...................................................................... 118

4.14 Menu SPARE PARTS............................................................................... 120

4.15 MenuSYSTEM ......................................................................................... 123

4.16 MenuCANSTATUS.................................................................................. 124

4.17 MenuSYSTEM-ADDRESS ...................................................................... 126

4.18 MenuSYSTEM-SETTING......................................................................... 128

4.19 MenuALERTMESSAGE .......................................................................... 130

4.20 MenuRS232............................................................................................. 139

4.21 Menu COUNTER...................................................................................... 140

4.22 Menu SAFETY DOOR.............................................................................. 141

4.23 Special Functions ..................................................................................... 143

5 Stud Welding Procedure.............................................................144

5.1 Safety Instructions.................................................................................... 144

5.2 Functional Principle of Stud Welding........................................................ 146

6 FTP Server ...................................................................................147

6.1 Structure of the Drive................................................................................ 147

CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31) vii

Table of ContentsTable of Contents

Table of ContentsTable of Contents

Table of Contents

6.2 Installing a Boot Project via FTP/USB ...................................................... 149

6.2.1 Installing a boot project from a USB memory stick............................................... 149

6.2.2 Procedure ............................................................................................................ 149

6.2.3 Installinga boot projectvia FTP ........................................................................... 153

7 Password .....................................................................................154

7.1 Defined Password Level .......................................................................... 154

8 Software .......................................................................................155

9 Switching off the CNC Production Welder ................................156

9.1 Temporary Switching off........................................................................... 156

9.2 Disposal ................................................................................................... 156

10 Care and Maintenance ................................................................157

10.1 Safety Instructions.................................................................................... 157

10.2 Maintenance Recommendations.............................................................. 157

10.3 Replacement of support battery of control system (all 12 months).......... 160

11 Appendix ......................................................................................161

11.1 Technical Data.......................................................................................... 161

11.2 EnvironmentallyAdmissible Disposal....................................................... 163

Glossary .......................................................................................164

Regulations and Standards ........................................................165

Further Instructions - Arc Stud Welding ....................................167

Further Instructions - Tip Ignition............................................... 168

Guarantee Clauses ......................................................................169

EC Declaration of Conformity.....................................................170

Confirmation ................................................................................171

Feedback......................................................................................172

Service & Support .......................................................................173

Index .............................................................................................174

viii CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31)

Table of ContentsTable of Contents

Table of ContentsTable of Contents

Table of Contents

CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31) 9

Important Data

Data Delivery Condition

Project-No: __________________________

Serial Number: __________________________

Controlsystem:

Type: __________________________

SerialNo: __________________________

Runtime system: __________________________

Software: __________________________

Welding Head: __________________________

OrderNo: __________________________

SerialNo: __________________________

-equippedfor: __________________________

Stud length 1: VBZ PBZ Dia ________________

OrderNo:__________________ SerialNo: ________________

Stud length 2: VBZ PBZ Dia ________________

OrderNo:__________________ SerialNo: ________________

Stud length 3: VBZ PBZ Dia ________________

OrderNo:__________________ SerialNo: ________________

Power Unit: __________________________

OrderNo: __________________________

SerialNo: __________________________

Important Data

DataDeliveryCondition

10 CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31)

1 General

CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31) 11

1 General

Persons addressed by this operating manual

Thisoperatingmanual is written foroperators,personneloftheenduser,and authorized

servicetechnicians.Itprovides you withallnecessaryinformation to operate thepower

unit.

Required user qualification

Thepower unitmust onlybe operatedby qualifiedpersonnel.

Letthe CNCProduction Welder only be operated by persons who

– arequalifiedthroughasuitabletrainingaccordingtothecurrentstandards(see

appendix),

– areproperlyinstructed,

– are physically and intellectually suitable,

– can be expected to reliably fulfill the requested job.

What else must the owner observe?

Make sure that this operating manual is always in reach of the stud welding unit.

ReadtheentiremanualbeforeoperatingtheCNCProductionWelder.

Strictly observe the safety instructions.

Before starting up the power unit, let the operator sign the confirmation that he/

shehasreadandfullyunderstoodtheoperatingmanual(seeappendix).

Donotcommence stud weldinguntilyouhaveunderstoodalloperating

processes.

Contactus if thereare anydoubts on certainoperating procedures.

Protectthe power unitagainst unauthorized use.

Informourserviceincaseofmalfunction.

Basedonthisoperatingmanual,acompanyspecificworkorder,aswellasacompany

specificmaintenanceinstructionmustbedrawnup.Thecompanyspecificworkorder

must consider the special user conditions in your company.

Makesurethatoperatorsofthewelderareprovidedwithandwearpersonalprotective

equipment,e.g.protective goggles, gloves,shoes,ear protection etc.

Owners and operators make sure that the CNC Production Welder is only used as

directed.

Duringanyactivitysuch as transportation, set-up,(re-)assembly,production,

maintenanceetc.observetheinformationgiveninthisoperatingmanual.

1 General

12 CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31)

1.1 Guide to this Operating Manual

Thisoperatingmanualprovidesyouwiththefollowinginformation

"Delivery" in Chapter 2

"Starting-up" inChapter3

"FunctionalPrinciple" inChapter4

"Stud Welding Process" inChapter5

"FTPServer" inChapter 6

"Password" inChapter7

"Software" in Chapter8

"Switchingoff the PowerUnit" inChapter9

"CareandMaintenance" inChapter10

TechnicalDataandmuchmore inAppendix

THREAT TO LIFE and risk of serious health and material damage in

case of improper use of the power unit. Observe all notes in this

operating manual.

Note for qualified operators (see chapter 1).

All instructions contained in this manual must also be observed

by qualified operators.

The welding process and the sequence of procedures to carry

out a weld are described in chapter 5.

1 General

1.1Guide tothis Operating Manual

CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31) 13

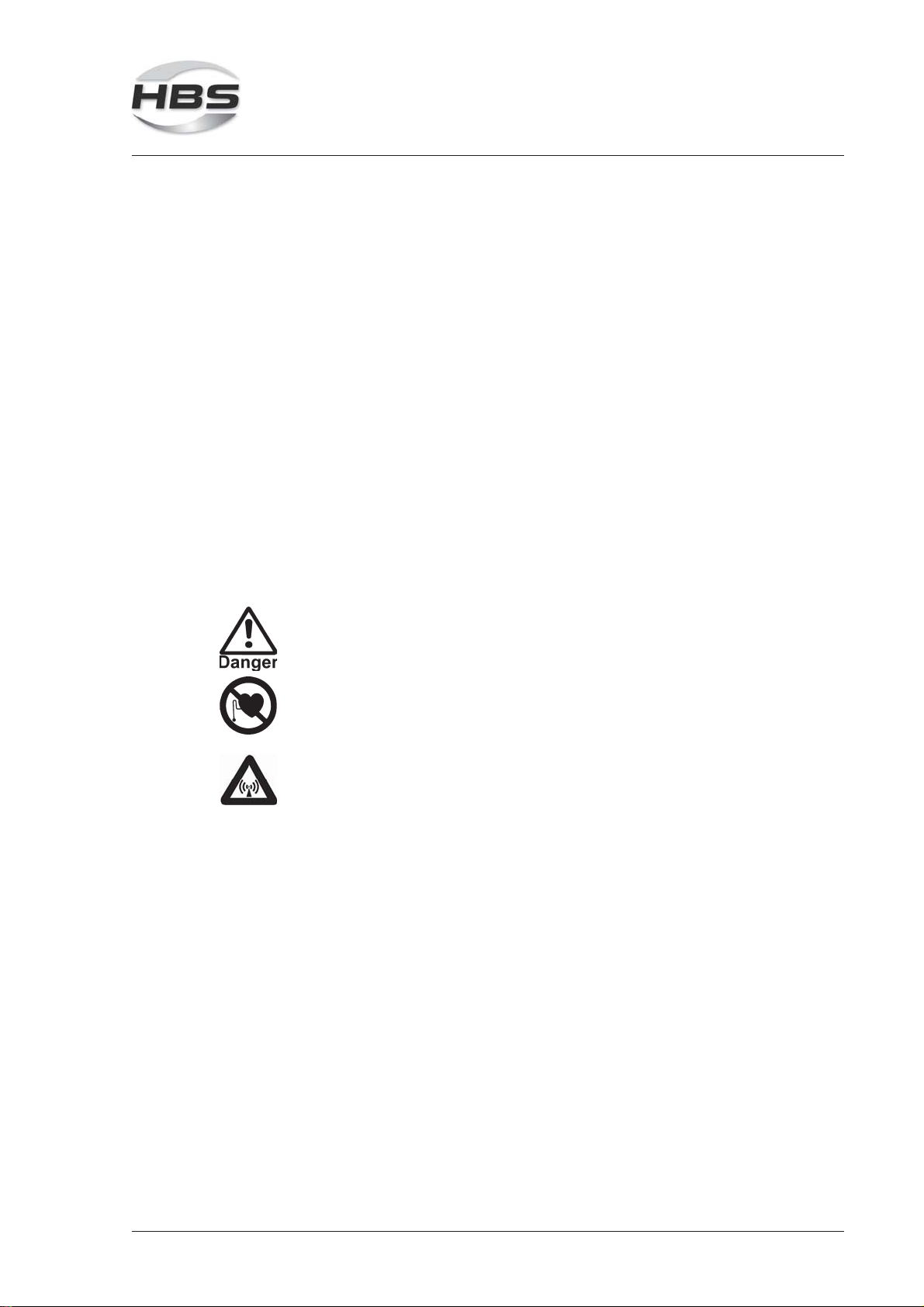

1.2 Safety Symbols

Symbols and markings used in this operating manual mean:

Threat to life or risk of personal injury

Risk of material damage

Ban for persons fitted with a pace maker

Warning of dangerous electrical voltage

Warning of electromagnetic fields

Warning of hot surfaces

Warning of hand injury

Warning of danger of crushing

Wear protective clothes

Wear protective goggles

Wear ear protection

Observe operating manual

Additional tips for operation and service safety

Prompt

– List

1 General

1.2 Safety Symbols

14 CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31)

1.3 General Safety Instructions

Improper operation of the CNC Production Welder is

LIFE-THREATENING!

Threat to life

– by electric shock and arc

– by toxic vapors and airborne particles

– by red-hot metal spatters (fire risk)

– by blow-up of explosive gases and materials

– by strong magnetic fields for persons fitted with a pace maker

In addition, through improper use damage to the stud welding unit

and to material can be caused. For details, see chapters 1, 3 and 5.

1.4 Intended Use

Warning: Unauthorized interference with the stud welding unit

as well as unauthorized alteration of the stud welding unit are

prohibited and result in complete cancellation of any guarantee

and liability claims against HBS.

Operation of the CNC Production Welder is only allowed with

HBS components and accessories, this clause is also part of

”use as directed”.

TheCNCProductionWelderisintendedtoweldweldingelementsaccordingtocurrent

standards (see chapter 5 and appendix). Any other use is regarded as not used as

directed.Themanufacturerisnotliablefordamagesresultingfromthestudweldingunit

not used as directed. Any risk is carried by the user.

TheCNCProductionWelderisdesignedaccordingtospecificstandardsandaccident

prevention regulations. Basics are European Union guidelines and in Germany valid

standards.Pleasenotethatinyourcountryadditionalstandardsandsafetyconditions

(especiallyrulesforaccidentprevention)maydifferfromthestandardsmentionedinthis

operating manual. The CNC Production Welder was manufactured to the latest

developmentsintechnologyandisregardedassafetooperate(placeofoperationsee

section 11.1).

Observing the operating manual of the used components is also part of the ”use as

directed”.

1 General

1.3GeneralSafetyInstructions

CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31) 15

1.5 Transportation, Packaging, Storage

HBSdelivers productsin aspecific transportpackage.

Savethe undamaged packing. Ship andtransport thedevice only inits original

packing.

Right before delivery, the CNC Production Welder is once again checked for proper

functioning and a control mark is attached. When receiving the delivery, check

everythingfordamagesandcompleteness.Ifdamagesoccurredduringtransportation

or components are missing, inform the manufacturer or the haulier immediately (see

page ii).

ProperfunctioningoftheCNCProductionWeldercanonlybecheckedbeforestarting-

upbyvisualinspection(visibledamage).

Thefollowing itemsare to be observed if the power unit is not tobe putinto operation

immediatelyafterdelivery.

– The CNC Production Welder must be stored in a secure place.

– TheCNCProductionWeldermustbeprotectedagainsthumidity,dust,metallicdirt.

– Storagetemperature: -5 °C to +50 °C

– Relativehumidity: 0% to 50% at +40 °C

0% to 90% at +20 °C

Ifyou resellthe CNCProduction Welder, please provide us with the name and

postal address of the new owner so that we can advise them of any changes to

theoperatingmanual.

1.6 Accompanying Documents

In addition to this operating manual, you must observe the operating manual of the

components like welding head, power unit(s), stud feeding units etc., as well as

applicableaccidentpreventionandsafetyinstructions.

1 General

1.5Transportation,Packaging,Storage

16 CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31)

1.7 Markings

There are various markings and safety symbols attached to your CNC Production

Welder(see section 1.2and 11.1).

Make sure that all markings remain clearly visible.

Type plate

Safetysymbols

Replace illegible or damaged markings

Before opening machine disconnect mains

Observe operating manual

Warning of dangerous electrical voltage

Secure the following safety symbols in the area of welding place:

1 General

1.7Markings

CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31) 17

Markings

1 General

1.7Markings

18 CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31)

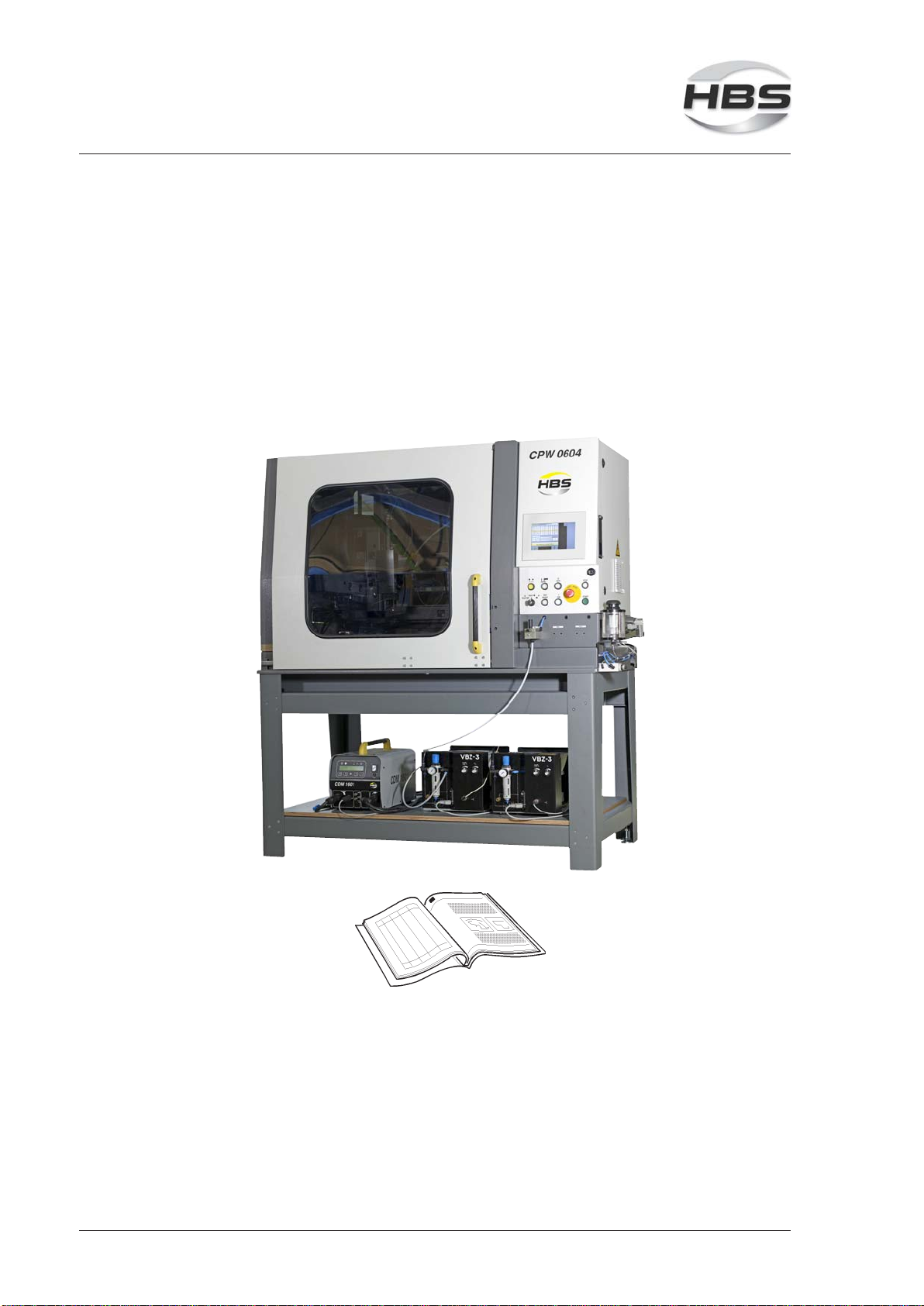

2 Delivery

Thebasicequipmentofyourpowerunit contains the following components:

No. of pieces Part Type OrderNo.

1 Weldingmachine CPW0604 Project-depending

1 Projectdirectory CPW0604 BA CPW 0604

(Operatingmanualanddocumentation)

Note:Yourmachinemaydifferfrom thepicture,dependingontheequipmentcompo-

nents.

2 Delivery

CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31) 19

3 Starting-up

Inthischapteryoulearnwhattoobserveduringsetting-upandstarting-upoftheCNC

ProductionWelder.

3.1 Requirements of Workplace

Vapors and airborne particles may occur during stud welding

operations. Especially with surface treated materials, toxic

vapors may be produced.

Ensure that a fume extraction is available and that the room is adequately

ventilatedaccordingtoaccidentpreventionregulations.

If possible, do not weld in rooms which are lower than 3 meters.

Specialregulationsapplyforconfinedrooms,accordingtoaccidentprevention

regulationsoftheofficialbodies(seeappendix).

Weld only in adequate distance from combustible articles or liquids.

Before you start welding, remove any combustible articles or liquids in vicinity of

theworkplace.

Make sure that a fire extinguisher is within reach.

Never weld in rooms exposed to risk of explosion.

Do not set-up the product in the vicinity of any apparatus or equipment which is

sensitivetoweldingspatters.

Do not set-up the product in the vicinity of any apparatus or equipment which is

sensitiveto magnetic fields.

Set-uptheCNCProductionWelder:

– ona stable, clean, and levelsurface

– so that no-one is influenced or injured by welding spatters

– so that all cables and primary lines are protected from being damaged

– so that nobody will trip or fall over the cables or connection lines.

Ensure that air is able to circulate freely through the housing.

If heat is built-up inside the housing caused by bad air circulati-

on, the stud welding unit will be seriously damaged.

3 Starting-up

3.1RequirementsofWorkplace

20 CPW 0604 BA CPW 0604 Issue 10.09.13 (From Software-Release 0.0.1.31)

Secure the following safety symbols in the area of welding place:

THREAT TO LIFE for persons fitted with a pace maker

Strong electro-magnetic fields occur in the vicinity of the stud welding

unit during welding. Such fields may affect the proper function of a

pace maker. Thus persons equipped with a pace maker must not

operate the stud welding unit and must not stay in its vicinity during

welding.

During the actual welding process, you must expect red-hot welding

spatters, possibly liquid spatters, a flash, and a loud bang > 90 dB (A).

Alert any colleagues who are occupied in the vicinity of the welder.

Wear your personal protective equipment according to current

standards (see appendix).

3.2 Requirements of Operating Personnel

At first read the general instructions in chapter 1 before you start working.

Instructanyconcernedpersonsbeforeeachoperation.

Thestudweldingunit must onlybeoperatedby qualified personnel.

Let the stud welding unit only be operated by persons,

– whoaretrainedaccordingtoapplicable standardsforstudwelding,

– whoareproperlyinstructed,

– whoare suitable fromintellectual and physicalpoint of view,

– who can be expected to carry out the delegated jobs reliably.

Wear suitable protective clothing , e.g. protective glasses, safety shoes, protecti-

vegloves,earprotection.

THREAT TO LIFE by electrical shock and electric arc

When operating the stud welding unit, you must not wear any

metallic jewellery on your body, especially on hands, also wrist

watches etc. are concerned. Any electrically conductive and

electro-magnetically sensitive parts must be removed from your

body before the work starts to avoid any danger or possible

damages caused by electrical voltage or electromagnetic fields.

3 Starting-up

3.2RequirementsofOperatingPersonnel

Table of contents

Other HBS Welding System manuals