HCFA TX2N-4AD4DA User manual

HCFA Corporation Limited

1

TX2N-4AD4DA Special Function Block

TX2N-4AD2DA Special Function Block

User’s Guide

1. Introduction

●TX2N-4AD4DA analog special function block has four input channels, four output

channels. The input channels receive analog signals and convert them into a digital value.

This is called an A/D conversion. The output channels take a digital value and output an

equivalent analog signal. This is known as a D/A conversion. TX2N-4AD4DA has a

maximum resolution of 12 bits.

●TX2N-4AD2DA analog special function block has four input channels, two output

channels. There’s no CH3, CH4 compared with TX2N-4AD4DA. The function and

performance of CH1, CH2 is same to the ones in TX2N-4AD4DA.

●In AD block, the selection of voltage or current based on input/output is by user wiring.

Analog ranges of -10 to 10V DC (resolution: 5mV), and/or 4 to 20mA, -20 to 20mA

(resolution: 20 µA) may be selected.

●In DA block, the selection of voltage or current based on input/ output is by user wiring.

Analog ranges of -10 to 10V DC (resolution: 5mV), and/ or 0 mA to 20 mA, 4 to 20mA

(resolution: 20 µA) may be selected.

●Data transfer between TX2N-4AD4DA(TX2N-4AD2DA)and main units is completed by

buffer memory exchange. There are altogether 64 buffer memories, 32 in 4AD, 32 in

4DA(each of 16 bits).

●The TX2N-4AD4DA draws 30mA from the 5V rail of the main unit or powered extension

unit.

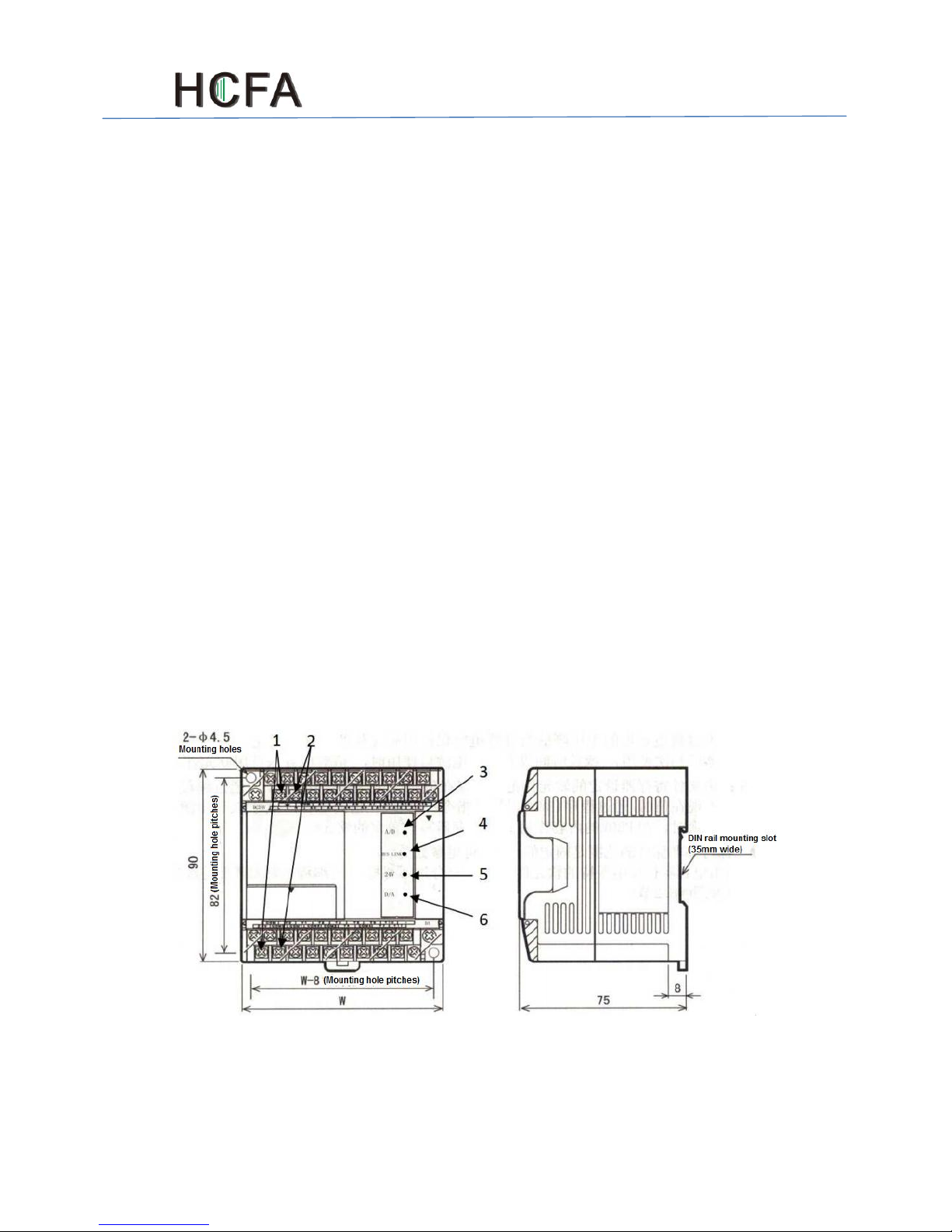

1.1 External Dimensions

1. 24V power supply terminal 2. 0V power supply terminal

3. A/D conversion indicator lamp 4. Bus power indicator lamp (LED)

5. 24V Power indicator lamp 6. D/A conversion indicator lamp

HCFA Corporation Limited

2

1.2 Connection with PLC

Various special function blocks controlled by FROM/TO instruction, such as analog input

units, high speed counting units, can be connected to TX2N programmable

controller(MPU) or the right of other expansion blocks or units. At most 8 special function

blocks can be connected to a MPU from No.0 to No.7 in sequence. As TX2N-4AD4DA is

the equivalent of 4AD, 4DA special function units(TX2N-4AD2DA is the equivalent of 4AD,

2DA special function units), if you want to connect these two special function units with

others at the same time, TX2N-4AD4DA(TX2N-4AD2DA)must be connected at last. At

most 6 special function blocks can be connected except TX2N-4AD4DA(TX2N-4AD2DA).

Please note that the serial number of AD follows the one of DA in TX2N-4AD4DA

(TX2N-4AD2DA).

For example, if 6 special function units has been connected before TX2N-4AD4DA

(TX2N-4AD2DA), DA number of TX2N-4AD4DA(TX2N-4AD2DA)is No.6, but AD

number is No.7.

TX2N-48MR-ES/UL TX2N-16EX TX2N-32ER TX2N-4AD-PT TX2N-4AD4DA

(TX2N-4AD2DA)

Special function Special function

blocks blocks

2. Wiring

1. The analog input and output are received through twisted pair shielded cable. This

cable should be wired away from power lines or any other lines which could induce

noise.

2. If a voltage ripple occurs during I/O, or there is electrically induced noise on the

external wiring, connect a smoothing capacitor of 0.1 to 0.47 µF, 25V.

3. If using current input, please connect the V+ and I+ terminal to each other.

4. If there is excessive voltage noise, connect the FG (frame ground) terminal with the

HCFA Corporation Limited

3

grounded terminal on 4AD.

5. Shorting voltage output terminal or connecting current output load to voltage output

terminal may damage the TX2N-4AD4DA(TX2N-4AD2DA)in D/A conversion.

6. Connect the ground terminal on the TX2N-4AD4DA (TX2N-4AD2DA)unit with the

grounded terminal on the main unit. Use 3-level grounding on the main unit, if

available.

3. Specification

3.1 Environment specification

Item Specification

Environment specifications Same as those on TX2N main unit

Dielectric withstand voltage 5000V AC, 1min (between all terminals and ground)

3.2 Power supply specification

Item Specification

Analog circuits 24V DC±10%,55mA (External power supply from the main unit)

Digital circuits 5V DC,30mA (Internal power supply from the main unit)

3.3 Performance specification

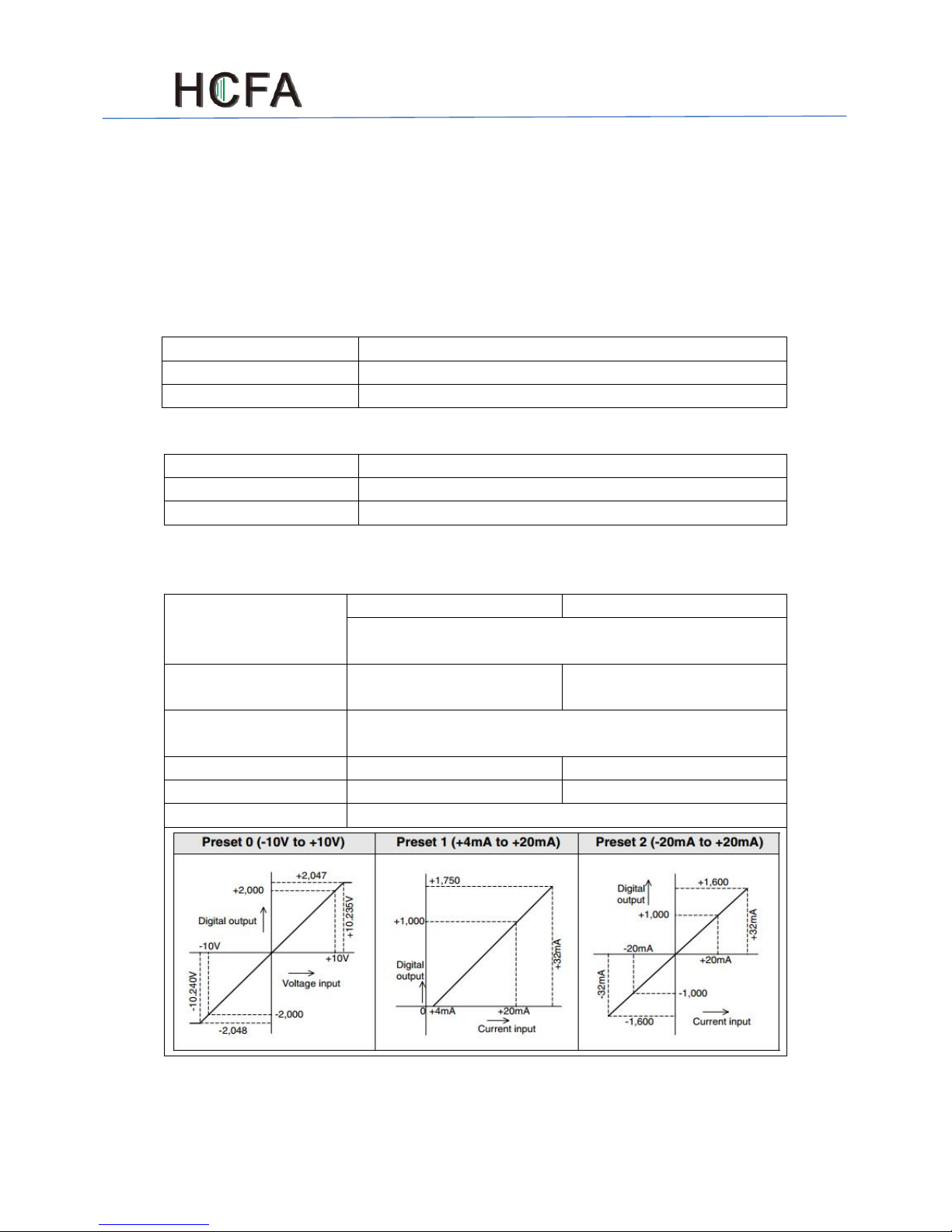

AD Analog Inputs

Items Voltage input Current input

Either voltage or current input can be selected with your choice of input terminal.

Up to four input points can be used at one time.

Analog input range DC -10V to 10V(Input resistance:200K

Ω)

DC -20mA to 20mA(Input resistance:250

Ω)

Digital output 12-bit conversion stored in 16-bit 2’s complement form Maximum value: +2047

Minimum value: -2048

Resolution 5mV(10V default range:1/2000) 20A(20mA default range:1/1000)

Overall accuracy ±1%(for the range of -10V to +10V) ±1%(for the range of -20mA to +20mA)

Conversion Speed 15ms/channel (Normal speed), 6ms/channel (High speed)

DA Analog output

HCFA Corporation Limited

4

Item Voltage output Current output

Analog output

range

DC -10V to 10V (External load resistance:

2KΩto 1MΩ)

DC 0mA to 20mA(External load resistance:500Ω)

Digital Input 16 bits, binary, with sign (Effective bits for numeric value:11 bits and sign bit (1 bit))

(Effective bits for numeric value: 11 bits and sign bit (1 bit)

Resolution 5mV(10V*1/2000) 20μA(20mA*1/1000)

Overall accuracy ±1%(for the range of -10V to +10V ) ±1% (for the range of -20mA to +20mA )

Conversion speed

TX2N-4AD4DA,DA has 4 channels(TX2N-4AD2DA ,DA has 2 channels)

2.1ms for each channel(Change in the number of channels used will not change the conversion speed)

Isolation

Photo-coupler isolation between analog and digital circuits.

DC/DC converter isolation of power from PLC main unit.

No isolation between analog channels

External power

supply

24V DC±10% 200mA

Number of

occupied I/O points

The analog block occupies 8 I/O points. (can be either inputs or outputs)

Power

consumption

5V, 30mA (Internal power supply from MPU or powered extension unit)

I/O Characteristics

(Default: Mode 0)

4. Allocation of buffer memory(BFM)

4.1 Allocation of AD buffer memory(BFM)

BFM Contents

*#0 Channel initialization Default = H0000

*#1 Channel 1 Contains the number of samples (1 to 4096) to be used for

an averaged result.

The default setting is 8- normal speed. High speed

operation can be selected with a value of 1.

*#2 Channel 2

*#3 Channel 3

*#4 Channel 4

#5 Channel 1 These buffer memories contain the averaged input values

for the number of samples entered for the channel in buffer

memories #1 to #4 respectively.

#6 Channel 2

#7 Channel 3

HCFA Corporation Limited

5

#8 Channel 4

#9 Channel 1 These buffer memories contain the present value currently

being read by each input channel.

#10 Channel 2

#11 Channel 3

#12 Channel 4

#13-#14 Reserved

#15 Selection of A/D conversion speed When set to 0, a normal speed is selected of 15ms/channel

When set to 1, a high speed is selected of 6ms/channel

●In buffer memory locations (BFMs) marked with an “*”, data can be written from the PLC

using the TO instruction.

●For buffer memories (BFMs) without “*” mark, data can be read by the PLC using the

FROM instruction.

●Before reading from the analog special function block, ensure that the appropriate

settings have been sent to the analog special function block. Otherwise, the previous

values held in the analog block will be used.

BFM b7 b6 b5 b4 b3 b2 b1 b0

#16-#19 Reserved

*#20 Reset to Defaults and Preset. Default = 0

*#21 Offset, Gain Adjust Prohibit. Default = (0, 1) Permit

*#22 Offset, Gain Adjust G4 O4 G3 O3 G2 O2 G1 O1

*#23 Offset Value Default =0

*#24 Gain Value Default =5,000

#25-#28 Reserved

#29 Error status

#30 Identification code K2010

#31 Cannot be used

●The buffer memory also gives a facility to adjust the offset and gain via software.

●Offset (intercept): The analog input value when the digital output becomes 0.

●Gain (slope): The analog input value when the digital output becomes +1000.

1) Channel selection

Channel selection is made by a 4 character HEX number HOOOO in buffer memory BFM

#0.

The least significant character controls channel 1 and the 4th character controls channel

4.

Setting of each character is as follows:

O = 0: Preset range (-10V to +10V) O = 2: Preset range (-20mA to +20mA)

O = 1: Preset range (+4mA to +20mA) O = 3: Channel OFF

Example: H3310

CH1 : Preset range (-10V to +10V)

CH2 : Preset range (+4mA to +20mA)

CH3, CH4: Channel OFF

2) Analog to digital conversion speed change

HCFA Corporation Limited

6

By writing 0 or 1 to BFM #15 of the AD Block, the speed at which A/D conversion is

performed can be changed.

3) Adjusting Gain and Offset values

a) When buffer memory BFM #20 is activated by setting it to K1, all settings within the

analog special function block are reset to their default settings.

b) If (b1, b0) of BFM #21 is set to (1,0), gain and offset adjustments are prohibited to

prevent inadvertent changes by the operator. In order to adjust the gain and offset values,

bits (b1, b0) must be set to (0,1). The default is (0,1)

c) Offset and gain values in BFM #23 and #24 are in units of mV or µA.

4) Status information BFM#29

Bit device of BFM#29 ON OFF

b0:Error When any of b1to b4 is ON, A/D conversion of

all the channels is stopped.

No error

b1:Offset/Gain error Offset/Gain data in the EEPROM

is corrupted or adjustment error.

Offset/Gain data normal

b2:Power source abnormality 24V DC power supply failure Power supply normal

b3:Hardware error A/D converter or other hardware failure Hardware normal

b10:Digital range error Digital output value is less than -2048 or more

than +2047

Digital output value is normal.

b11:Averaging error Number of averaging samples is 4097 or

more or 0 or less

Averaging is normal.

b12:Offset/gain adjust prohibit

Prohibit-(b1, b0) of BFM #21 is set to (1, 0) Permit-(b1, b0) of BFM #21 is set to

(1,0)

4.2 Allocation of DA buffer memory(BFM)

BFM Contents

W #0E Output mode selection. Factory setting H000

#1

#2

#3(Not used in TX2N-4AD2DA)

#4(Not used in TX2N-4AD2DA)

#5E Data holding mode. Factory setting H000

#6,#7 Reserved

1) [BFM #0] Output mode selection: The value of BFM #0 switches the analog output

between voltage and current on each channel. It takes the form of a 4 digit hexadecimal

number. The first digit will be the command for channel 1 (CH1), and the second digit for

channel 2 (CH2) etc. The numeric values of these four digits respectively represent the

following items:

O=0:Sets the voltage output mode (-10 V to +10 V)

H O O O O O=1:Sets the current output mode (+4mA to + 20mA)

CH4 CH3 CH2 CH1 O=2:Sets the current output mode(0mA to + 20mA)

HCFA Corporation Limited

7

Switching the output mode resets the I/O characteristics to the factory-default

characteristics.

2)Example: H2110

[BFM #1, #2, #3 and #4]: Output data channels CH1,CH2,CH3 and CH4

BFM #1: Output data of CH1(Initial value:0) BFM #2: Output data of CH2(Initial value:0)

BFM #3: Output data of CH3(Initial value:0) BFM #4: Output data of CH4(Initial value:0)

3) [BFM #5]: Data holding mode: While the programmable controller is in the STOP

mode, the last output value in the RUN mode will be held. To reset the value to the offset

value, write the hexadecimal value in BFM #5 as follows:

H O O O O O=1:Sets the current output mode(+4mA to + 20mA)

CH4 CH3 CH2 CH1 O=2:Sets the current output mode (0mA to + 20mA)

Example: H0011· · · · · · · · ·CH1 and CH2= Offset value CH3 and CH4= Output holding

In addition to above functions, the buffer memory can adjust the I/O characteristics of D/A

and report the D/A status to PLC.

BFM Description

W #8(E) Offset/Gain setting command of CH1, CH2, Initial value H0000

#9(E) Offset/Gain setting command of CH3, CH4, Initial value

H0000(Not used in TX2N-4AD2DA)

#10 Offset data CH1*1 Unit: mV or µA

Initial offset value:0

Initial gain value: +5,000

#11 Gain data CH1*2

#12 Offset data CH2*1

#13 Gain data CH2*2

#14(Not used in TX2N-4AD2DA) Offset data CH3*1

#15(Not used in TX2N-4AD2DA) Gain data CH3*2

#16(Not used in TX2N-4AD2DA) Offset data CH4*1

#17(Not used in TX2N-4AD2DA) Gain data CH4*2

#18,#19 Reserved

W #20(E) Initialize. initial value = 0

#21E I/O characteristics adjustment inhibit (Initial value 1)

#22-#28 Reserved

#29 Error status

#30 K3020 identification code

#31 Reserved

4) [BFM #8 and #9] Offset/gain setting command: Changes offset and gain values of

channels CH1 through CH4 by writing 1 to the corresponding Hex digits of BFM #8 or #9.

The current values will be valid until this command is output.

BFM #8 BFM #9 O=0:No changes done

H O O O O H O O O O O=1:Change data value

G2 O2 G1 O1 G4 O4 G3 O3

5) [BFM #10 to #17] Offset/ gain data: The offset and gain values are changed by writing

HCFA Corporation Limited

8

new data to BFM #10 through to #17. The units of the data to be written is mV or µA. The

data should be written and then BFM #8 and #9 set. Note that the data value will be

rounded down to the nearest 5mV or 20µA.

6) [BFM #20] Initialize: When K1 is written in BFM #20, all values will be initialized to the

factory-default. (Note that the BFM #20 data will override the BFM #21 data.) The initial

function is convenient when you have an error in adjustment.

7) [BFM #21] I/O characteristics adjustment inhibit: Setting BFM #21 to 2 inhibits user from

inadvertent adjustment of I/O characteristics. The adjustment inhibit function, once set,

will be valid until the Permit command (BFM#21=1)is set. The initial vale is 1(Permit).

The set value will be retained even after power-OFF.

8) [BFM #29] Error status: When error occurs, use the FROM command to read out the

details of error.

Bit Name Status when bit is set to “1”

(turned on)

Status when bit is set to “0”

(turned off)

b0 Error Error if any of b1 through b4 is turned on

No error

b1 O/G error Offset/gain data in EEPROM is abnormal

or a data setting error occurs

Offset/ gain data normal

b2 Power supply error 24V DC power failure Power supplied normally

b3 Hardware error Defective D/A converter or other

hardware

Non-defective hardware

b10 Range error The digital input or analog output value is

out of the specified range.

The input and output value is in the

specified range.

b12 G/O-adjustment prohibit

status

BFM#21 is not set to “1”. Adjustable status(BFM#21=1)

Bits b4 through b9, b11, b13 to b15 are not defined.

9) [BFM #30] The identification code for a special function block is read using the FROM

instruction. The identification code for 4DA is K3020. The main unit can use this facility in

the program to identify the special block before commencing any data transfers from and

to the special function block.

Note: BFM #’s marked E/(E).

●Values of BFM #0, #5, and #21, (marked E) are stored in the EEPROM memory of the

TX2N-4AD4DA. BFM #10 to #17 are copied to EEPROM when the gain/offset setting

command BFM #8, #9 is used. Also, BFM #20 causes the resetting of the EEPROM

memory. The EEPROM has a life of about 10,000 cycles (changes), so do not use

programs which frequently change these BFMs.

●A mode change of BFM #0 automatically involves a change of the corresponding offset

and gain values . Because of the time needed to write the new values to the internal

EEPROM memory, a delay of 3s is required between instructions changing BFM #0 and

instructions writing to the corresponding BFM #10 through BFM #17. Therefore, a delay

timer should be used before writing to BFM #10 through #17.

5 Defining gain and offset

5.1 AD gain and offset

HCFA Corporation Limited

9

Gain determines the angle or slope of Offset is the ‘position’ of calibration line,

calibration line, identified at a digital identified at a digital value of 0.

value of 1000.

a)Small gain value: Large steps in d)Negative offset

digital reading e)Zero offset: Default(0V or 4mA)

b)Zero gain value: Default(5V or 20mA) f)Positive offset

c)Big gain value: Small steps in

digital reading

5.2 DA gain and offset

The standard characteristics (factory default) are shown by the solid lines in the figure

below. These characteristics can be adjusted according to the conditions of the user’s

system.

Standard characteristics Standard characteristics Standard characteristics

of voltage output of current output of current output

(+4mA to +20mA) (0mA to +20mA)

● Gain value Analog output value when digital input is +1,000.

▲ Offset value Analog output value when digital input is 0.

When the slope of the I/O characteristic line is steep:

Slight changes to the digital input will greatly increase or reduce the analog output.

When the slope of the I/O characteristic line is gentle:

Slight changes to the digital input will not always change the analog output

Note that the resolution (minimum possible change of analog output) of the DA is fixed

6 Example program

6.1 Outline of FROM and TO commands

HCFA Corporation Limited

10

m1:Special unit or block number (K0 to K7, numbered from the MPU)

m2:Buffer memory head address (K0 to K31)

D*:Head device number of destination data. T, C, D, KnM, KnY, KnS, V, and Z can be

used to designate the head device. Each device number can be qualified using an index.

n:Number of transfer points (K1 to K32) (K1 to K16 for 32-bit command)

m1,m2,n:Same as above

S*:Head device number of source data. T, C, D, KnX, KnM, KnY, KnS, V, Z, K, and H can

be used to designate the head device. Each device number can be qualified using an

index.

When X010 and X011 are off, transfer will not be executed, therefore the destination data

value will not be changed.

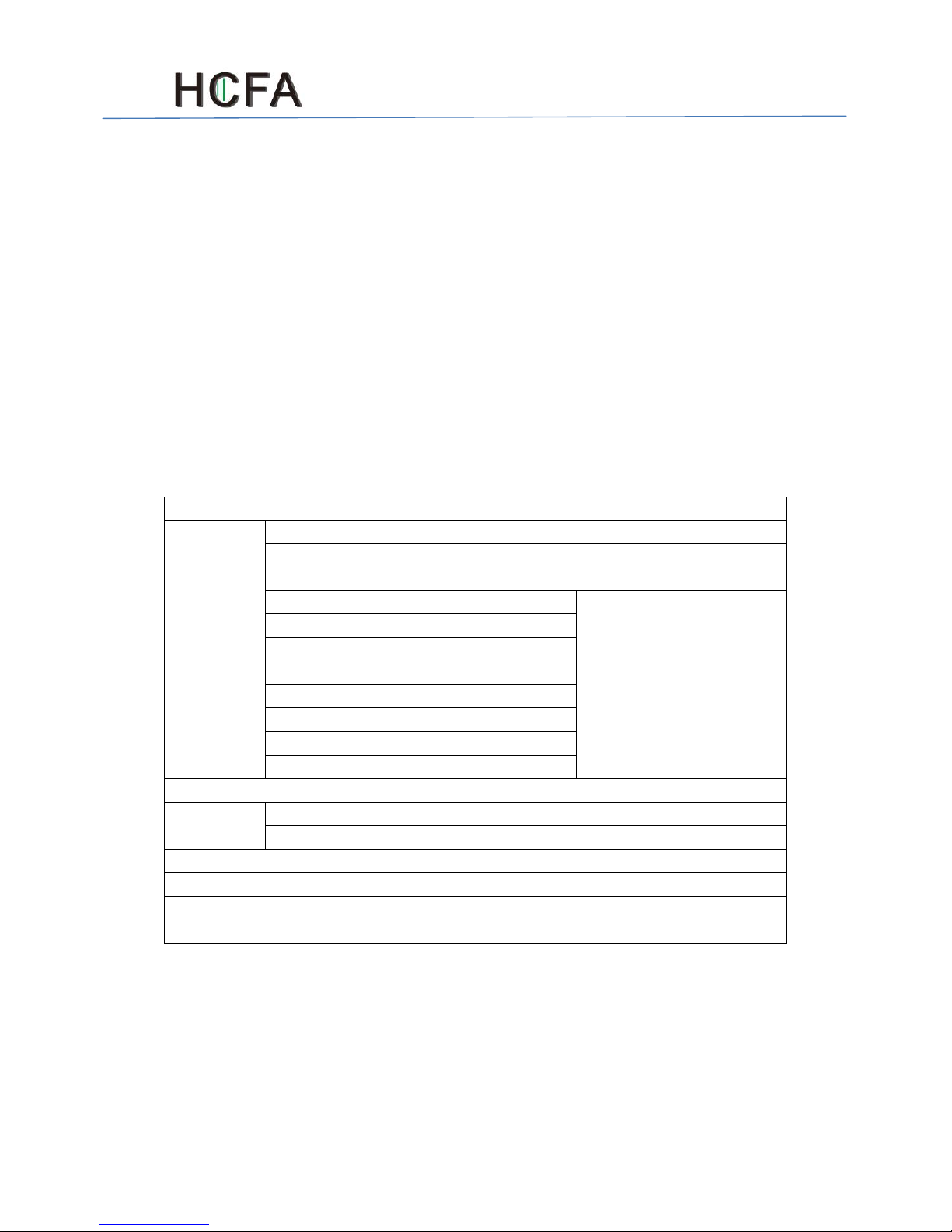

6.2 AD Basic program

In the following example, CH1 and CH2 are used as voltage input. The TX2N-4AD4DA

AD block is connected at the position of special function block NO.1. The number of

averaged samples is set at 4 and data registers D0 and D1 of the main unit receive the

averaged digital data.

The ID code for the special function block at

position "1" is read from BFM #30 of that block and

stored at D4 in the main unit. This is compared

with K2010 to check that the block is AD block, if

OK M1 is turned ON.

The analog input channels (CH1, CH2) are setup

by writing H3300 to the BFM #0 of the AD block.

The number of average samples for CH1 and CH2

is set to 4 by writing 4 to BFM #1 and #2

respectively.

The operational status of 4AD is read from BFM

#29. If there are no errors in the operation of the

AD, then the averaged data BFM's are read.

In the case of this example BFM #5 and #6 are

read into the main unit and stored in D0 and D1.

These devices contain the averaged data for CH1

and CH2 respectively.

The push-button switch of PLC input terminal can adjust the gain/offset of 4AD in PLC

programming. The following is an example of changing the offset value on input channel

CH1 to 0V and the gain value to 2.5V. The 4AD block is in the position of block No.1.

HCFA Corporation Limited

11

Adjustment starts.

(H000)→BFM #0 (input channels selection)

Input instruction as shown in the left and PC run.

(K1)→BFM #21

BFM #21 (gain/offset prohibition) must be set to

permission with (b1, b0) = (0,1)

(K0)→BFM #22 (Offset/gain adjustment)

Reset adjustment bits.

(K0)→BFM #23 (Offset)

(K2500)→BFM #24(Gain)

(H003)→BFM #22(Offset/gain adjustment)

3= 0011 i. e. O1 = 1, G1 = 1

Channel 1 is adjusted.

End of adjustment.

(K1)→BFM #21(Offset/gain adjustment)

BFM#21 gain/offset prohibition

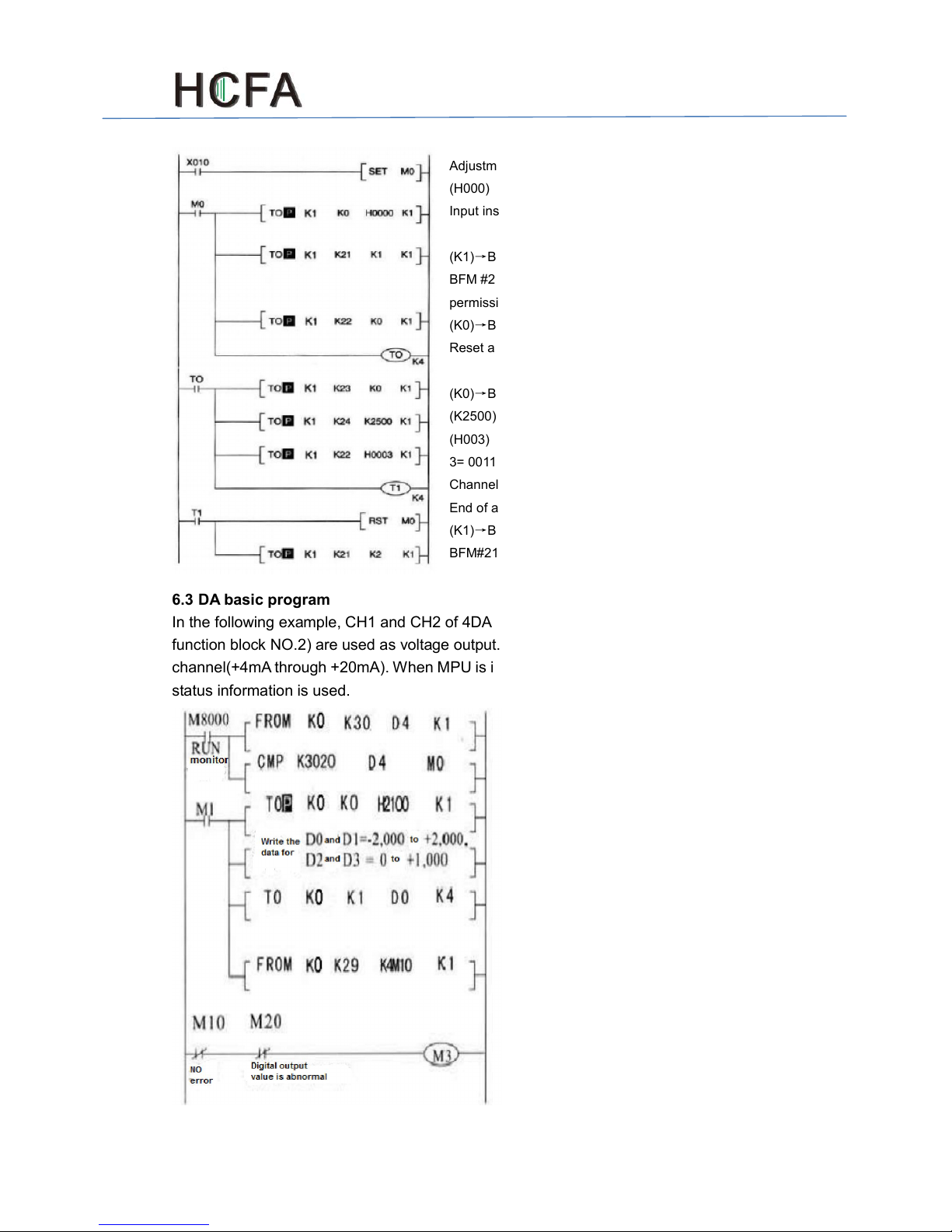

6.3 DA basic program

In the following example, CH1 and CH2 of 4DA block(connected in the position of special

function block NO.2) are used as voltage output. CH3 is used as current output

channel(+4mA through +20mA). When MPU is in STOP status, output reserved. Moreover,

status information is used.

The BFM#30 data(model code) in block NO.0

will be transferred to data register D4. M1 will

be turned on when the model code is set to

K3020.

H2100→BFM #0(NO.0 unit)

CH1 and CH2:voltage output; CH3:current

output (+4mA to +20mA); CH4:current

output(0mAto +20mA)

D0→BFM #1 (CH1 output) D1→BFM #2

(CH2

output)

D2→BFM #3 (CH3 output) D3→BFM #4(CH3

output)

BFM #29(b15 to b0) →(M25 to M10)

Reads out the status data.

HCFA Corporation Limited

12

Adjustment of I/O characteristics

To adjust the I/O characteristics, either the push-button switch connected to PLC input

terminal or forced ON/OFF function on programming panel can set offset/gain value in

4DA. To change the offset/gain, just change the conversion constant of 4DA. There is no

need to be adjusted by instrument measure analog output. However, programming is

needed in MPU. An example program for adjustment is shown below. The example shows

that for channel CH2 of 4DA block No.1, the offset value is changed to 7 mA, and the gain

value to 20 mA. Note that for CH1,CH3, and CH4, the standard voltage output

characteristics are set.

Operation start

(H0010)→BFM#0 Sets the mode of the output channel

(K1)→BFM#21 Permits adjustment of I/O

Characteristics

(K7000)→BFM#12

Sets the offset data. (Offset value: 7 mA)

(K20000)→BFM#13

Sets the gain data. (Gain value: 20 mA)

(H1100)→BFM#8

CH2 offset/gain setting command

Operation end

(K2)→BFM#21 Inhibits adjustment of I/O characteristics

After adjustment, the I/O characteristics will be as follows.

7 Diagnostics

If the TX2N-4AD4DA special function block does not operate properly, check the following

items.

1) Check the external wiring

2) Check status of the BUS LINK power indicator lamp (LED) of the TX2N-4AD4DA.

ON: The extension cable is properly connected.

OFF or Flash: Check the connection of extension cable. Also check the 5V power

supply capacity.

3) Check status of the 24 V power indicator lamp (LED) of the TX2N-4AD4DA.

HCFA Corporation Limited

13

ON: 24V DC is supplied.

OFF: Supply 24V DC(±10%)to the TX2N-4AD4DA

4) Check status of the A/D conversion indicator lamp (LED) of the TX2N-4AD4DA

ON: A/D conversion is proceeding normally.

Otherwise: Check buffer memory #29(error status). If any bits (b2 and b3) is ON,

then this is why A/D LED is OFF.

5) Check status of the D/A conversion indicator lamp(LED) of the TX2N-4AD4DA.

Flash : D/A conversion is normal.

ON or OFF: The ambient conditions are suitable for TX2N-4AD4DA, or the

TX2N-4AD4DA D/A is defective.

6) Check the external load resistance connected to each analog output terminals does not

exceed the capacity of TX2N-4AD4DA DA drive. (Voltage output : 2KΩto 1MΩ/current

output: 500Ω)

7) Check the output voltage or current value using a voltmeter or ammeter, and confirm

that the output meets the I/O characteristics. If the output does not meet the I/O

characteristics, adjust the offset and gain again.

Note: To test the withstand voltage of the TX2N-4AD4DA, connect all the terminals to the

grounding terminal.

This manual suits for next models

1

Popular Media Converter manuals by other brands

H&B

H&B TX-100 Installation and instruction manual

Bolin Technology

Bolin Technology D Series user manual

IFM Electronic

IFM Electronic Efector 400 RN30 Series Device manual

GRASS VALLEY

GRASS VALLEY KUDOSPRO ULC2000 user manual

Linear Technology

Linear Technology DC1523A Demo Manual

Lika

Lika ROTAPULS I28 Series quick start guide

Weidmuller

Weidmuller IE-MC-VL Series Hardware installation guide

Optical Systems Design

Optical Systems Design OSD2139 Series Operator's manual

Tema Telecomunicazioni

Tema Telecomunicazioni AD615/S product manual

KTI Networks

KTI Networks KGC-352 Series installation guide

Gira

Gira 0588 Series operating instructions

Lika

Lika SFA-5000-FD user guide