HCP TC-038D User manual

Operation Manual Ver. 1.3

1

Table of Contents

1. Operation ..................................................................... 2

1.1 General specification ........................................................... 2

1.2 Front / rear panel introduction ............................................. 3

1.3 System setup ........................................................................ 4

1.4 Parameters setting ................................................................ 4

1.5 Error message ...................................................................... 5

2. Software ........................................................................ 6

2.1 Installation ........................................................................... 6

2.2 Operation ............................................................................. 9

3. OVEN ......................................................................... 13

3.1 Overview ............................................................................ 13

3.2 Setup procedure for chip holder ........................................ 15

4. Safety and warranty .................................................. 17

Appendix

A. Pin assignment .................................................................... 18

Operation Manual Ver. 1.3

2

1. Operation

1.1 General Specifications

1. PID control

2. Auto tuning and programmable

3. Input voltage: 24 VDC

4. Temperature tuning range: Room temperature to 200℃

5. Tuning tuning resolution: 0.1℃

6. Operation temperature: 0 to 55℃

8. Transportation and storage environment: -25 to 70℃

9. Maximum power consumption: 60W

10. Communication Interface: USB

11. Controller dimension: 150(L) x 90(W) x 65(H) cm3

12. Weight: Controller: 950±50 g

13. Accessories: Crystal oven, connection wire and power supply

Fig. 1.1.1 TC-038D controller, crystal oven, connection wire and power supply.

Operation Manual Ver. 1.3

3

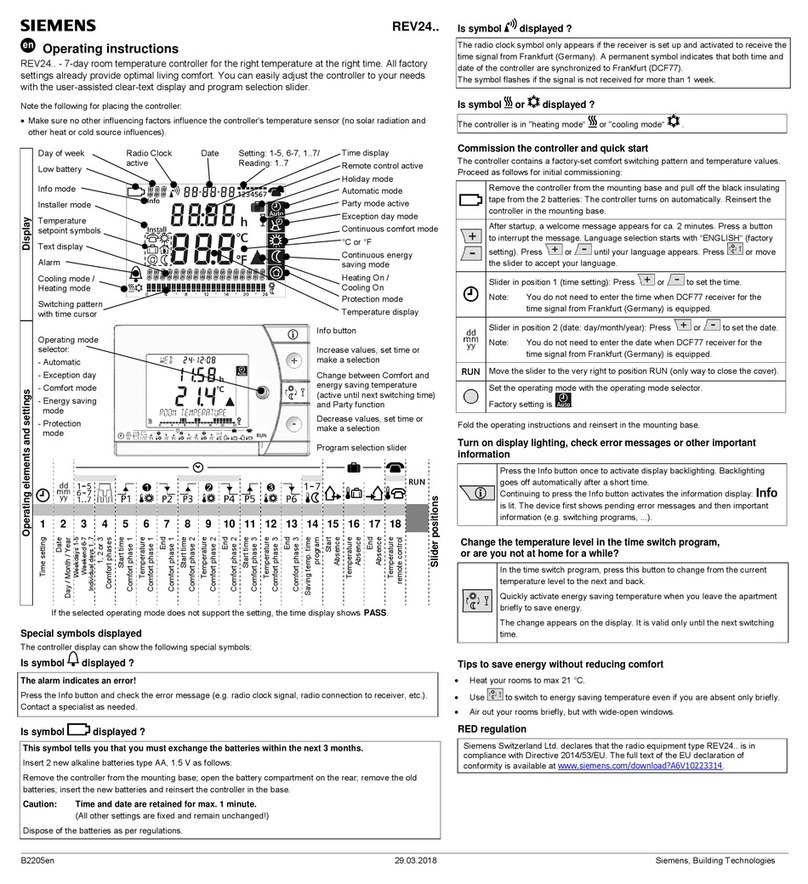

1.2 Front / Rear Panel Introduction

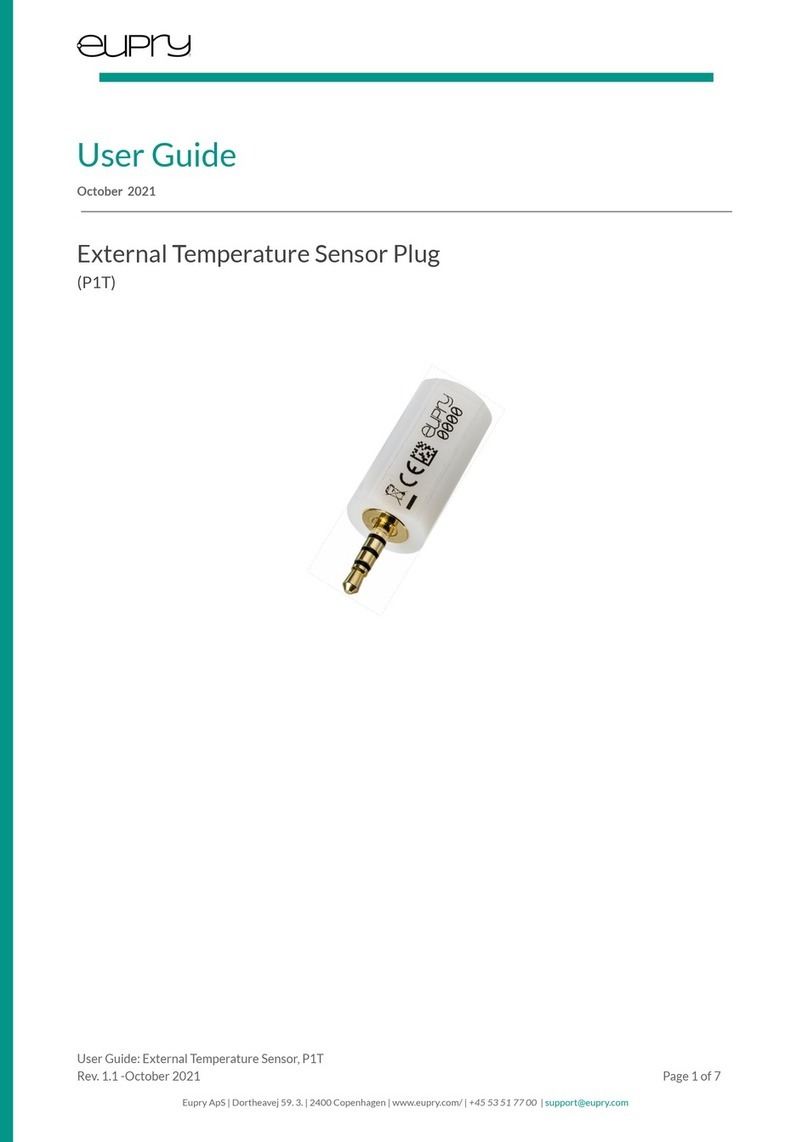

Fig. 1.2.1 The front panel of TC-038D controller, the function of A~G has been

listed in the table below.

Name

Function

A

PV display

Indicates PV (measured temperature) or function codes

B

SV display

Indicates SV (target set temperature) or function values

C

Data change key

Changes the value on SV, press to increase the value.

Holding down the key will gradually increase the speed of change.

D

Data change key

Changes the parameter value on SV, press to decrease the value.

Holding down the key will gradually increase the speed of change.

E

Shift key

Shift the digits on SV, press to shift the digits left.

F

Mode key

Change the displayed function on PV, press to change the content

on display.

G

Level key

Change the levels on PV.

Press to change the levels (Initial setting level, operation level,

adjustment level)

Setting -> operation: Hold for >1s

Operation -> Setting: Hold for >3s

Operation <-> Adjustment: Press for <1s

Operation Manual Ver. 1.3

4

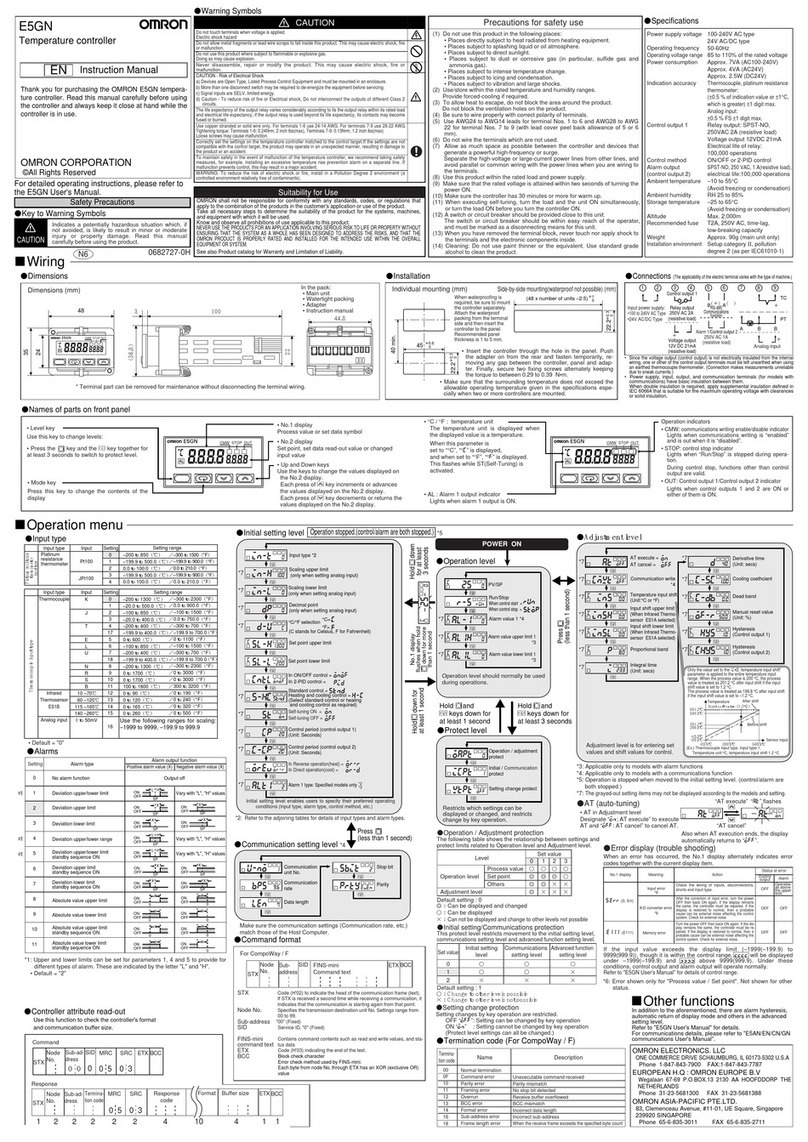

Fig. 1.2.2 The rear panel of the TC-038D controller, A: Connection port to crystal

oven, B: ON/OFF power switch, C: Connection port to PC; D: Connection port to

power supply.

1.3 System Setup

1. Connect the power supply to the temperature controller (Rear - D).

2. Connect the crystal oven to the temperature controller (Rear - A).

3. Open the power switch (Rear - B)

4. Set the target temperature (Front - C/D)

5. Wait till the temperature becomes stable

1.4 Parameters setting

Warning: All the parameters will be set before shipment and not recommend to be

changed, table lists below only shows the description for some important parameters

for reference.

Operation Manual Ver. 1.3

5

Level

Name

Function

Description

Setting

Sensor input type

Setting the type and the range for the input

sensor, value 1 for PT100 sensor with

-199~500 deg. C range.

Setting

Set point upper ;imit

Setting the set point upper bound for the

current operation.

Setting

Set point lower limit

Setting the set point lower bound for the

current operation.

Adjustment

Communications

ON/OFF: Communication enabled /

disabled

Adjustment

PID auto tuning

Press the switch key and select to

execute PID auto tuning, when the

execution ends, it returns to off.

1.5 Error message

Table below shows the error message which can be used quick failure analysis.

Message

Name

Description

Sensor input

error

Temperature sensing error or out of range, typically due to

the OVEN has not been connected correctly or the sensor

type has been set wrong.

AD converter

Error

Error from the internal circuit, if turns off/on the controller

doesn't help, need to send back for further investigation.

Memory error

Error from the internal circuit, if turns off/on the controller

doesn't help, need to send back for further investigation.

Operation Manual Ver. 1.3

6

2. Software

2.1 Installation:

2.1.1 Install drivers

1. Enter the folder “1. Driver”.

2. Select and enter the folder according to your system OS.

3. Select and install the driver according to your system type(x86 or x64). The

system type can be checked in computer -> properties.

1.2 Install TC-038D PC Utility

1. Enter the folder “2. TC-038D PC Utility”.

2. Double click the “setup.exe”.

Operation Manual Ver. 1.3

7

3. Choose the installation folder and target. Then press “Next” button.

4. Press “Next” button to start installation.

Operation Manual Ver. 1.3

8

5. Press “Finish” button to finish the installation process.

Operation Manual Ver. 1.3

9

2.2 Operation:

2.2.1 Program Overview:

Name

Function

a.

PV

Show the current temperature.

b.

SV

Show the current set temperature.

c.

SV Set

Set the temperature shown in SV.

d.

Program status

Show the current program status.

e.

PV graph

Temperature recording and displaying.

f.

Time period

Set the PV reading period.

g.

Save graph button

Export the graph data into excel format.

h.

Clear graph button

Clear the graph.

i.

End button

End the software.

a

b

c

d

e

f

g

h

i

Operation Manual Ver. 1.3

10

2.2.2 Start To Use:

1. Connect the TC-038Dpower cord and switch on power.

2. Connect the TC-038DUSB cable to PC.

3. Run TC-038D on desktop.

4. The process of initializing will take few seconds, please wait for complete.

Operation Manual Ver. 1.3

11

5. Begin to Use.

6. If the process of initializing has any problem, the error dialog will show on

screen. Please check the power and USB, then press “OK” button.

Operation Manual Ver. 1.3

12

2.2.3 Temperature control:

1. Adjust the temperature set point in SV textbox. You can key in the set point or

adjust by up and down arrow.

2. Set the temperature to the set point by pressing “SV SET” button.

2.2.4 Setting the PV reading period.

Adjust the PV reading period by “Time Period” textbox.

2.2.5 Save data:

Press the “Save Graph” button, an excel window will be popped up that contains the

graph data.

2.2.6 Clear graph:

Press the “Clear Graph” button. It will clear all the data on graph.

Operation Manual Ver. 1.3

13

3. OVEN

3.1 Overview:

The HCP OV-X0D oven is designed for temperature control using the TC-038D

controller, the general specification including the dimensions and drawing are shown

in the table below.

3.1.1 General specifications

General specification

Sensor

PT100

Material

Brass and Teflon

Operation range

Ambient temperature to 200 deg. C

Temperature stability

±0.1 deg. C

Power

24V/40W

Storage temperature

-25 ~ 65 deg. C

Over heating protection

~210 deg. C

3.1.2 Dimension

OV-30D

OV-50D

Dimension (mm)

40x50x43

60x70x43

Heating plate (mm)

35x25

55x45

Over heat protection

Yes

Yes

Operation Manual Ver. 1.3

14

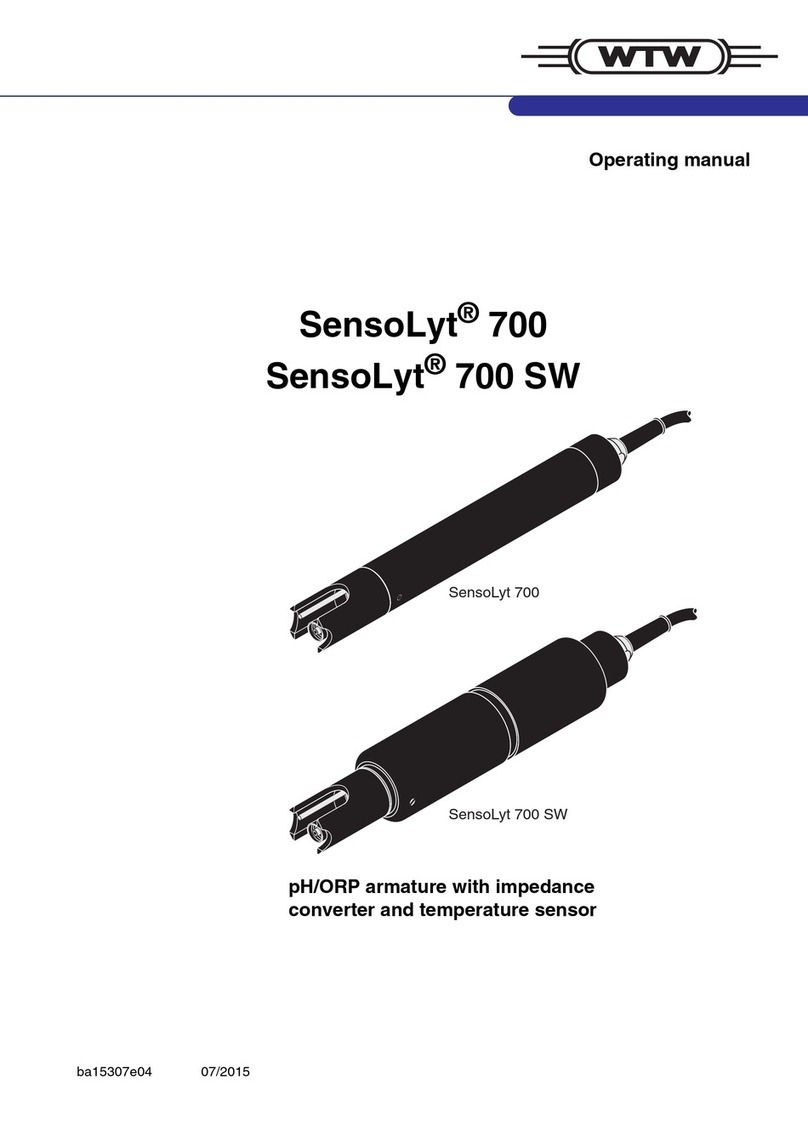

3.1.3 Drawing

1. OV-30D

Fig 3.1.3.1 Mechanical drawing of the OV-30D including L-adaptor board

2. OV-50D

Fig 3.1.3.2 Mechanical drawing of the OV-50D.

Operation Manual Ver. 1.3

15

3.1.3 Bottom plate and L-adaptor board

Fig 3.1.3.3 Mechanical drawing of the bottom plate and L-adaptor board.

3.2 Setup procedure for chip holder

No

Figure

Description

1

1.1 Open the Teflon cover.

2

2.1 Slightly loose the screw.

2.2 Move the white teflon to the left slightly.

2.3 Put the crystal into the holder by a clip

carefully.

* Make sure of avoiding any surface scratch

or damage on input/ output surfaces.

Operation Manual Ver. 1.3

16

3

3.1 Push the white teflon to the right slightly

until the crystal has been clamped.

3.2 Tight the screw

* Operate without the cover will affect the

uniformity of crystal temperature. Please put the

cover on after alignment.

Operation Manual Ver. 1.3

17

4. Safety and warranty

The following are definitions of the warnings that are used to call your attention to

important information regarding your safety, the safety and preservation of your

equipment or an important tip. WARNING situation has the potential to cause

bodily harm or death. CAUTION situation has the potential to cause damage to

property or equipment. NOTE Additional information the user or operator should

consider.

WARNING

Situation has the potential to cause bodily harm or death.

CAUTION

Situation has the potential to cause damage to property or equipment.

NOTE

Additional information the user or operator should consider.

General Warnings

Observe these general warnings when operating or servicing this equipment:

•Heed all warnings on the unit and in the operating instructions.

•Do not use this equipment in or near water.

•This equipment is grounded through the grounding conductor of the power cord.

•Route power cords and other cables so they are not likely to be damaged.

•Disconnect power before cleaning the equipment. Do not use liquid or aerosol

cleaners; use only a damp lint-free cloth.

•Lockout all electrical power sources before servicing the equipment.

Warranty

HCP provides warranty of TC-038D for 1 year starting from the day of shipment, for

the repair service, the customer needs to contact HCP and carry the shipping cost,

repair cost and shipping back cost will be carried from HCP if the failure occurs in

proper use.

Operation Manual Ver. 1.3

18

Appendix

A. Pin assignment

TC-038D & Crystal Oven

9 pins layout

Pin

Number

Functionality

1

Empty

2

Empty

3

GND

4

Sensor

5

Sensor

6

Heater

7

Heater

8

Empty

9

Empty

Table of contents