HD Electric Company NoMAX 900 Series User manual

OFFICIAL

L.

CHARLENE

BER

JsTROM

NOTARY

PUIUC

-

STA

-

7

JP

LLINOIS

MY

colanSION

EXP

•

,

7‘

1

6

/

1

7

/

1

7

Declaration

of

Kimberly

Ann

Bengson

regarding

Public

Availability

of

NoMAX

900

Series

Instruction

Manual

1.

My

name

is

Kimberly

Ann

Bengson.

I

am

a

marketing

manager

at

HD

Electric

Company,

which

is

an

electrical

products

company

based

in

Waukegan,

Illinois.

2.

I

have

been

employed

by

HD

Electric

since

1999.

3.

Since

approximately

2006,

HD

Electric

Company

has

offered

for

sale

a

series

of

switched

capacitor

control

products

marketed

as

the

NoMAX

900

Series.

4.

Attached

to

this

Declaration

as

Exhibit

A

is

a

Manual

titled

NoMAX

900

Series

Instruction

Manual

—

Switched

Capacitor

Controls

("the

"Manual").

The

last

page

of

the

Manual

bears

a

2007

copyright

date

and

includes

an

identifying

reference

to

Bulletin

No.

NoMax900-200b.

The

Manual

was

produced

by

HD

Electric

Company

and

was

distributed

and

otherwise

provided

to

users

and

potential

users

of

the

NoMAX

900

Series

products

as

detailed

below.

5.

I

am

personally

familiar

with

the

circumstances

surrounding

the

printing

and

distribution

of

the

Manual

as

described

below.

6.

Commencing

on

or

around

2007,

the

Manual

was

distributed

with

NoMax

900

Series

switched

capacitor

control

units

sold

by

HD

Electric

Company

without

any

obligations

of

confidentiality.

7

The

foregoing

is

true

and

correct

to

the

best

of

my

knowledge

and

belief.

8.

Sworn

to

on

this

/day

of

March,

2017.

LA)

7

1taclhitti

‘3e44,14,-,,

Kimberly

Ann

Brengson

11363886.1

11543595.1

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 1/22

EXHIBIT

A

—

THE

MANUAL

-iNei".*dis".....0

•

•

;

1

:1

,

r

11363886.r

4v

g

31431SAH3

.ouetri

YAATOv.

1t0i8201.1:)

3

11543595.1

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 2/22

I

--

:

HD ELECTRIC COMPANY

1 4 7 L A K E S I D E D R I V E • WA U K E G A N , I L L I N O I S 6 0 0 8 U .S. A .

PHONE 847.473.4980 • FAX 847.473.4981 • website: www.HDElectricCompany.com

®

NoMAX

®

900 SERIES

SWITCHED CAPACITOR CONTROLS

Instru tion

Manual

NoMax®900

NoMax®900T

NoMax®950

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 3/22

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 4/22

3

TABLE o CONTENTS

Overview . . . . . . . . . . . . . . . . . . . . . . . . 4

Ordering Information . . . . . . . . . . . . . 5-6

Installation . . . . . . . . . . . . . . . . . . . . . . . 6

Control Set Up . . . . . . . . . . . . . . . . . . 7-9

Display Messages . . . . . . . . . . . . . 10-11

Fusing . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation . . . . . . . . . . . . . . . . . . . . . . 12

LED Indi ators . . . . . . . . . . . . . . . . . . 13

Automati Operations . . . . . . . . . . 14-18

Spe ifi ations . . . . . . . . . . . . . . . . . . . 18

Limitation of Warranty & Liability . . . . 19

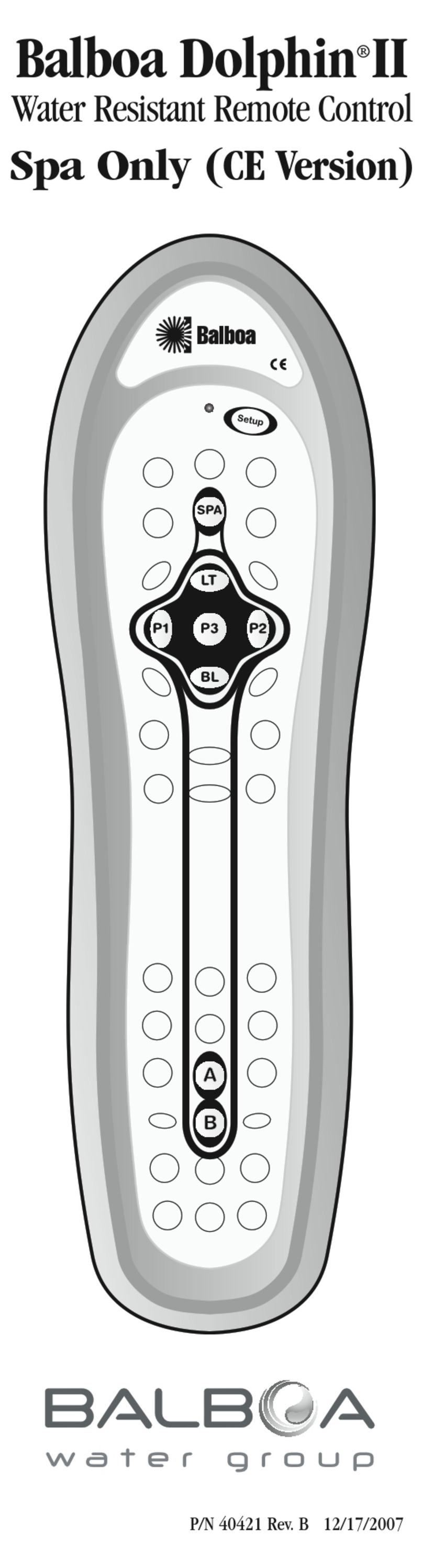

NoMax®900T

NoMax®900

NoMax®950

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 5/22

M

4

OVERVIEW

The NoMax®900 Series swit hed bank apa itor ontrols utilize user sele table

fun tions and parameters to ontrol swit hed apa itor banks in the following

operating modes:

Control Mode NoMax®900T NoMax®950 NoMax®900

Voltage XX

Time XXX

Time/Volt XX

Temp X

Temp/Volt X

Time/Temp X

Voltage

– The ontrol will lose the apa itor bank when the sensed line voltage drops

below the user sele ted CLOSE VOLTS setting. The ontrol will open the apa itor bank

when the sensed line voltage rises above the user sele ted OPEN VOLTS setting.

Time

– The ontrol will lose the apa itor bank when the user sele ted

CLOSE TIME o urs. The ontrol will open the apa itor bank when the user

sele ted OPEN TIME o urs. Both settings are subje t to the weekend settings.

Time/Volt

– The ontrol will fun tion a ording to the time mode, ex ept the time

mode operating onditions will be overridden by voltage onditions a ording to

the volt mode fun tion.

Temp

– For Summer S hedule (defined by CLOSE TEMP greater than OPEN

TEMP setting) – The ontrol will lose the apa itor bank when the sensed

ambient temperature rises above the user sele ted CLOSE TEMP setting. The

ontrol will open the apa itor bank when the sensed ambient temperature

drops below the user sele ted OPEN TEMP setting.

For Winter S hedule (defined by OPEN TEMP greater than CLOSE TEMP setting) –

The ontrol will lose the apa itor bank when the sensed ambient temperature

drops below the user sele ted CLOSE TEMP setting. The ontrol will open the

apa itor bank when the sensed ambient temperature rises above the user sele ted

OPEN TEMP setting.

Temp/Volt

– The ontrol will fun tion a ording to the temp mode, ex ept the

temp mode operating onditions will be overridden by voltage onditions a ord-

ing to the volt mode fun tion.

Time/Temp

– The ontrol will fun tion a ording to the time mode, ex ept the time

mode operating onditions will be overridden by temperature onditions a ording

to the temp mode fun tion.

All user settings are dire tly a essed with the front panel swit hes.

WARNING:

Prior to installing, operating, maintaining, or testing this equipment,

read and understand the material in this manual. Failure to omply an result

in death, severe injury or equipment damage. These instru tions are intended

to supplement, not repla e, lo al safety pra ti es and pro edures.

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 6/22

ORDERING INFORMATION

This atalog number matrix provides the ne essary information to reate the

appropriate desired apa itor ontrol produ t:

example: NMC 900T 1 4RNN

SERIES

900T Time functions only

9 0 Time with voltage override functions

900 Time with temperature and

voltage override function

VOLTAGE OPTION

1 120V, 60Hz

2 240V, 60Hz

3 220V, 0Hz

4 120V, 0Hz

MOUNTING OPTION*

4RNN 4 stab meter base with mounting ring

4SNN 4 stab meter base ringless

PNN Pole bracket mounted with terminal strip - specify hole

PANN Pole mounted with Amphenol connector

* See Figure 1 for standard 4-stab wiring diagram

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 7/22

m

Line

Open

Neutral

Close

Figure 1 – Wiring diagram or a standard 4-stab, 4-lead meter socket

The NoMax®900 Series Controls an be supplied ready for 4 jaw meter

so ket mounting or dire t pole mounting.

Installing into a Meter Socket

– So ket mounted ontrols are supplied ready

for either ringed or ringless meter so kets. The two types of so kets are not

inter hangeable; make sure you have the orre t type of ontrol for the meter

so ket to be used.

Installing into a Ringed Base

– Align the terminals on the ba k of the ontrol and

press firmly into the meter so ket. Use the supplied ring to omplete the installation.

Atta h a ground wire to the external ground lug. Seal or lo k the ring only after the

entire system has been verified.

Installing into a Ringless Base

– Align the terminals on the ba k of the ontrol and

press firmly into the meter so ket. Tighten the 3 lo king s rews lo ated on the

meter base. Atta h a ground wire to the external ground lug. Seal the 3 lo king

s rews only after the entire system has been verified.

Installing Pole Mounted Controls

– Pole Mounted Controls are mounted with

the in luded pole bra ket and user supplied mounting straps or lag s rews.

After the ontrol is atta hed to the pole, atta h a ground wire to the external

ground lug. Conne t the ontrol able from the Capa itor Bank jun tion box

to the 5-pin onne tor on the Control.

WARNING:

Before plugging the ontrol into a live ir uit, rotate the main

swit h out of the “AUTO” position or remove the front panel fuse, and observe

all safety pro edures for working with live ir uits. Failure to omply an result

in death, personal injury or equipment damage.

INSTALLATION

6

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 8/22

•

MOMi.X

OGOT

Goposykr

•

•

—

mums

•

•

The following se tion des ribes the swit h positions used to set up the

NoMax®900 Series Controls. Please refer to Figures 2, 3 & 4.

NoMax 900T, 950

and 900 Functions

1) Auto

This pla es the ontrol

in automati operation

allowing it to ontrol the

apa itor bank a ording

to the sele ted ontrol mode

and other settings.

2) Adjust-/+

This swit h is used to

de rease or in rease the

sele ted setting. Pushing

and releasing adjusts the

setting by its smallest

adjustment value. Pushing

and holding the ADJUST

swit h in reases or de reas-

es the setting at a faster rate.

Continuing to hold the swit h

in reases the adjustment rate.

Note:

All of the

settings rollover when

the maximum or minimum

value is ex eeded.

3) Time Delay

This sets the Operation

Time Delay period. This

delay is the amount of time,

in se onds, the ontrol will

wait between determining

the bank needs to swit h

states, and a tually energiz-

ing the Capa itor Bank

Motor Relay. This delay is

a tive for Open and Close

operations, and Automati or

Manual operations. The mini-

mum value is 3 se onds.

The maximum value is 600

se onds (10 minutes).

1

13

4

5

12

2

3

6

7

8

9

10

11

Figure 2 – NoMAX®900T Unit

CONTROL SET UP

1

17

4

5

13

12

2

3

14

15

16

6

7

8

9

10

11

Figure 3 – NoMAX®950 Unit

7

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 9/22

8

4) Time Functions –

When the upper rotary swit h is pla ed in this position the

lower rotary swit h be omes a tive.

5) Display Present Time/Date –

The present time and date of the ontrol lo k

will be displayed.

6) Set Time –

Adjusts the time of the ontrol lo k. The time is in remented in 5-

minute intervals and the rate of hange will in rease if the adjust swit h is held

for several se onds.

7) Set Year –

Adjusts the year of the ontrol lo k.

8) Set Month –

Adjusts the month of the ontrol lo k.

9) Set Day –

Adjusts the day of the ontrol lo k.

10) Close Time –

The time setting threshold for losing the apa itor bank.

11) Open Time –

The time setting threshold for opening the apa itor bank.

12) Daylight Savings Time –

When enabled, the ontrol lo k will automati ally

adjust for daylight savings time (i.e. Move ahead 1 hour at 2am on the first

Sunday in April and move ba k 1 hour at 2 am on the last Sunday in O tober).

13) Weekends –

When enabled, automati time ontrol will be a tive on Saturday

and Sunday if a time ontrol mode is a tive.

Note:

Automati time ontrol is always a tive Monday through Friday if a time

ontrol mode is a tive

NoMax 900 and 950 Functions

14) Max ops/day -

The number of Automati Close operations allowed by

the ontrol in a 24-hour period. The minimum value is two operations.

The maximum value is 24 operations.

Note:

“Manual” Close operations, and “Aborted” Automati Close pending

operations, are not ounted against the MAX OPS/DAY setting.

15) Open Volts -

The level of the line voltage whi h in rements the Volts Open

ounter. The minimum value is the CLOSE VOLTS setting plus 3.0 volts. The

maximum value is 130.0 volts.

16) Close Volts -

The level of the line voltage whi h in rements the Volts Close

ounter. The minimum value is 105.0 volts. The maximum value is the OPEN

VOLTS setting minus 3 volts.

17) Control Mode -

This sets the ontrol mode that will be used to automati ally

ontrol the apa itor bank.

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 10/22

•

•

4eNI

IDMAX

ei

Co

p3

C.;

iCF.

--111Tri

C

711111111

Pi

L•C'ui•

4

I

41.

•

milli

P3414:14

•

-

•

9

NoMax 900 Functions

18) OPEN TEMP -

The temperature setting threshold for opening the apa itor

bank. The minimum value is 5 degrees. The maximum value is 125 degrees

(The NoMAX®900 prevents the OPEN TEMP setting from being loser than 5

degrees to the CLOSE TEMP setting). The ontrol will issue an open ommand

to the apa itor bank based upon the Winter/Summer s hedule as follows:

Winter S hedule

(defined by OPEN

TEMP greater than

CLOSE TEMP setting)

– The apa itor bank

will Open when the

temperature rises

above the

OPEN TEMP setting.

Summer S hedule

(defined by CLOSE

TEMP greater than

OPEN TEMP setting) –

The apa itor bank

will Open when

temperature drops

below the OPEN

TEMP setting.

19) Close Temp -

The

temperature setting

threshold for losing the apa itor bank. The minimum value is 5 degrees.

The maximum value is 125 degrees (The NoMAX®900T prevents the CLOSE

TEMP setting from being loser than 5 degrees to the OPEN TEMP setting).

The ontrol will issue a lose ommand to the apa itor bank based upon the

Winter / Summer s hedule as follows:

Winter S hedule (defined by OPEN TEMP greater than CLOSE TEMP setting) –

The apa itor bank will Close when the temperature drops below the

CLOSE TEMP setting.

Summer S hedule (defined by CLOSE TEMP greater than OPEN TEMP

setting) – The apa itor bank will Close when the temperature rises above

the CLOSE TEMP setting.

1

17

19

18

4

5

13

12

2

3

14

15

16

6

7

8

9

10

11

Figure 4 – NoMAX®900 Unit

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 11/22

10

DISPLAY MESSAGES

The following des ribes the messages the user an expe t to see on the

Liquid Crystal Display.

• “Total Ops xxxxxx” The total number of Close operations sin e installation

• “24Hr Auto Ops xx” The number of Automati Close operations today

• “Close Inh. xx:xx” The remaining time Close Inhibit is a tive

• “Auto In xx:xx” The remaining time a Manual Open or Manual Close

maintenan e operation is a tive before the ontrol

returns to automati operation

• “Opening In xx:xx” The remaining time until an AUTOMATIC Open Operation o urs

• “Closing In xx:xx” The remaining time until an AUTOMATIC Close Operation o urs

• “Bank Swit hing!” Indi ates an IMMEDIATE operation is in progress

• “Bank Volts x.x” The Delta Volts measurement

• “Line Volts xxx.x” The Line Volts measurement

• “Fahrenheit +xxx” The Temperature measurement (positive) (NoMax®900 only)

• “Fahrenheit -xxx” The Temperature measurement (negative) (NoMax®900 only)

• “Time xx:xx:xx” The present ontrol lo k time

• “Date xx/xx/xx” The present ontrol lo k date

• “Sunday” (or other day) The present ontrol lo k day

Note:

All messages whi h in lude an equality sign “=” indi ates the user is

a essing a set point.

• “Se onds = xxx” The OPERATION TIME DELAY setting

• “Max. Ops./24 Hr. = xx” The MAX OPS/DAY setting

• “Open V = xxx.x” The OPEN VOLTS setting

• “Close V = xxx.x” The CLOSE VOLTS setting

• “Close Temp. = xxx” The CLOSE TEMP setting (NoMax®900 only)

• “Open Temp. = xxx” The OPEN TEMP setting (NoMax®900 only)

• “Mode = Time” The CONTROL MODE is Time only

• “Mode = Time/Temp” The CONTROL MODE is Time with Temperature Override

(NoMax®900 only)

• “Mode = Time/Volt” The CONTROL MODE is Time with Voltage Override

(NoMax®900 and 950)

• “Mode = Voltage” The CONTROL MODE is Voltage Only

• “Mode = Temp” The CONTROL MODE is Temperature Only

(NoMax®900 only)

• “Mode = Temp/Volt” The CONTROL MODE is Temperature with

Voltage Override (NoMax®900 and 950)

• “Time = xx:xx:xx” The ontrol lo k time setting

• “Year = xxxx” The ontrol lo k year setting

• “Month = xx” The ontrol lo k month setting

• “Day = xx” The ontrol lo k day setting

• “Close = xx:xx” The CLOSE TIME setting

• “Open = xx:xx” The OPEN TIME setting

• “DST = xxxxxxxx” Daylight Savings Time Enabled/Disabled

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 12/22

11

DISPLAY MESSAGES continued

• “Wkend = xxxxxxxx” Weekend Enabled/Disabled

• “Volt Sensor Err.” The ontrol has determined the Voltage Sensor has failed

(NoMax®900 and 950)

• “Temp. Sensor Err.” The ontrol has determined the Temperature Sensor

has failed (NoMax®900 only)

• “Clo k Error” The internal ba k-up battery for the lo k has failed

Note 1:

Ea h time the ontrol is turned on the ontrol will energize ALL

LEDS and the LCD will display “HD Ele tri Co” followed by the

ontrol type and firmware version (“Model NoMax 900 Vx.xx”,

“Model NoMax 950 Vx.xx”, or “Model NoMax 900T Vx.xx”).

Note 2:

For the NoMax®900: If the Voltage Sensor fails, the ontrol will initiate an

Open operation.

For the NoMax®900: If both the Voltage and Temperature Sensors fail,

the ontrol will initiate an Open operation. If Voltage Only Mode is

a tive, and the Voltage Sensor fails, the ontrol will initiate an Open

operation. If Temperature Only Mode is a tive, and the Temperature

Sensor fails, the ontrol will initiate an Open operation.

Note 3:

While in a failure Mode (see Note 2) Manual Close, while in AUTO, is

disabled. Manual Close, when NOT in AUTO, is still enabled.

FUSING

The NoMax®900 Series Controls are supplied with a 15 Amp Slo-Blo®fuse,

a essible from the front panel. This fuse disables the ontrol and prote ts the

apa itor bank swit hes. If it was removed before installation, the fuse should be

reinstalled after installation is omplete.

The ontrol ir uitry is also prote ted by an internal fuse whi h is not repla eable.

All repairs should be referred to the fa tory.

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 13/22

12

OPERATION

The following settings and features are ommon to all ontrol modes:

Time Delay

– Sets the operation time delay period. Using the Adjust swit h, sele t

the desired time delay, in se onds, from 3 to 600. This will delay both Open and

Close operations in both Manual and Automati operation mode by the time sele ted.

The Operation Pending light flashes before every Open or Close operation for the

period of time sele ted for the time delay. If in AUTOMATIC operation, the LCD

displays the operation type (Close or Open) and time until the operation will o ur.

If initiated by a MANUAL OPEN or MANUAL CLOSE ommand, the pending

operation an be aborted by swit hing to AUTO.

If initiated by a MANUAL OPEN ommand, and the Capa itor Bank is Closed, the

pending Open operation an be aborted by operating the MANUAL CLOSE swit h.

If initiated by a MANUAL CLOSE ommand, and the Capa itor Bank is Open, the

pending Close operation an be aborted by operating the MANUAL OPEN swit h.

Max Ops/Day

– Sets the maximum allowable number of automati apa itor

bank lose operations per 24 hour period. This an be set from 2 to 24 operations

using the Adjust swit h. This setting overrides all other automati operation

settings. Manual operations do not ount against the limit set by MAX OPS/DAY.

Five Minute Close Inhibit

– The ontrols use a built-in time delay to prevent the

line from losing into a harged Capa itor Bank. This “Close Inhibit” delay begins

after every Open operation and is a tive for 5 minutes. Neither Automati nor

Manual Close operations will take pla e while “Close Inhibit” is a tive.

Other Operational Features

– If the ontrol loses power while the Capa itor

Bank Motorized Swit h is operating (either Open or Close Dire tion), an IMMEDIATE

operation o urs upon restoration of power, bypassing the OPERATION TIME DELAY.

This insures the Motorized Swit h finishes it’s travel.

If the ontrol loses power while CLOSE INHIBIT is a tive, an IMMEDIATE OPEN

operation o urs upon restoration of power, bypassing the OPERATION TIME DELAY.

If the user swit hes from AUTO to any of the rotary swit h Setup positions, and an

operation is pending, the operation is suspended.

If the user swit hes from any of the rotary swit h Setup positions to AUTO, and an

operation is pending, the operation is suspended.

Voltage Monitor (NoMAX®900 and 950)

– When the front panel rotary swit h is

set to VOLT MONITOR, the display will show the sensed line voltage.

Temperature Monitor (NoMAX®900 only)

– When the front panel rotary swit h

is set to TEMP MONITOR the display will show the measured ambient temperature.

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 14/22

13

LED INDICATORS

Auto

– Indi ates the Control is in Automati mode and is using the operator

settings to ontrol the Capa itor Bank state.

Operation Pending

– Flashes to warn the operator an operation is about to o ur.

In Automati mode, the LCD displays the type of operation about to o ur (i.e.

Close or Open), and the amount of time before it o urs. The OPERATION TIME

DELAY setting determines OPERATION PENDING period.

Close

– When flashing, the CLOSE LED indi ates the Close Motor Relay

is energized. When solid, the CLOSE LED indi ates the Capa itor Bank is

onne ted to the line.

Open

– When flashing, the OPEN LED indi ates the Open Motor Relay is

energized. When solid, the OPEN LED indi ates the Capa itor Bank is NOT

onne ted to the line.

Note:

Both OPEN and CLOSE LEDs off indi ates the Control has re ently powered

on and the Line Voltage is within the Open and Close settings. There is not a

preferred Capa itor Bank state on the NoMAX®900; the operator settings and

Manual operations ontrol the Capa itor Bank state.

Manual Bank Control

– The MANUAL OPEN and MANUAL CLOSE toggle swit h

is used to “Manually” Open or Close the Capa itor Bank. To manually CLOSE or

OPEN the apa itor bank:

Swit h the ontrol out of the AUTO mode, verify the red LED is off, and

sele t TIME DELAY. Using the ADJUST swit h, sele t the desired time delay,

in se onds, from 3 to 600.

Use the toggle swit h to OPEN or CLOSE the apa itor bank. The OPERATION

PENDING LED will flash for the duration of the sele ted time delay. The CLOSE or

OPEN LED will flash during the time the output is energized and will remain on.

Note 1:

Pending manual operations an be an elled by turning the ontrol to AUTO.

Note 2:

The apa itor bank annot be losed within less than 5 minutes from the

previous open operation to allow dis harge of the apa itor bank. See

Five Minute Close Inhibit se tion, page 12.

Note 3:

Manual operations are ounted by the operations ounter ( lose operations

only), but manual operations do not ount against the preset daily limit set

by 24Hr Auto Ops. See Automati Operation se tion, page 14.

Manual Maintenance Operation

– When the rotary swit h is in the AUTO posi-

tion, a Manual Open or Close is onsidered a maintenan e operation. The Manual

operation ompletes and the Control suspends its Automati testing for ten min-

utes. At the end of ten minutes, the Control reverts to Automati operation and will

automati ally Open or Close the apa itor bank based upon the Automati

Operation programmed settings. While in AUTO, the amount of time remaining

before Automati testing resumes is y led on the LCD.

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 15/22

-

1111111.

111

.

1

.1k

deNOMAX

900

Ccoxicik

,

C..

,

1

1

1

1

1

..•

1

1

1

1

11

1

1

11

11•1

111

11

1

4.14

1

:

1

11111.111

..

1

1

1

1

1

L

1

:41.Z4

—rm

14

WARNING:

The Control will revert to Automati operation after 10 minutes

following a Manual Maintenan e Operation. The ontrol will then automati ally

Open or Close the apa itor bank based upon the Automati Operation

programmed settings.

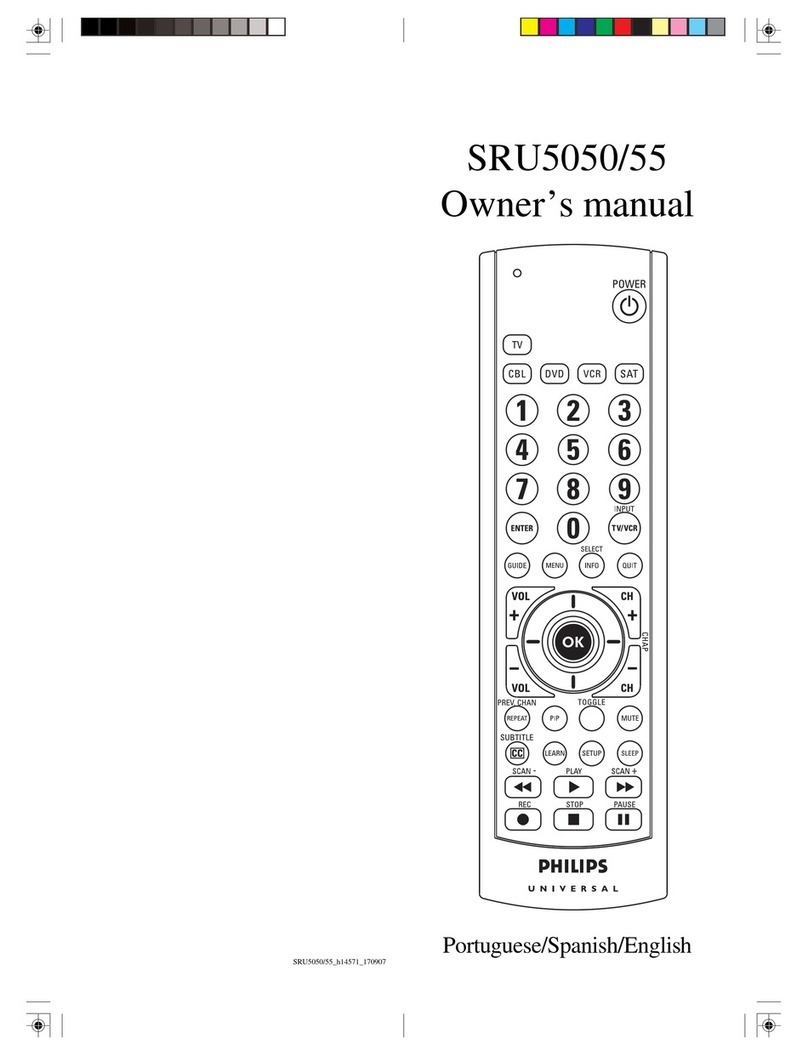

AUTOMATIC

OPERATIONS

For the following operations,

please reference the

Overview Section (pg. 4)

to see if the operation

pertains to your control.

Automatic Voltage Operation

–

Automati Voltage Control Mode

is a tive when the front panel

rotary swit h position is set to

AUTO, and the Control Mode is

set to VOLTAGE. The AUTO LED

will also light. When Automati

Voltage Control Mode is a tive,

the ontrol tests the Voltage

against the programmed Open

and Close settings. To adjust the

set points for automati voltage

operation, use the front panel rotary swit h to sele t the

parameter. Please refer to Figure 5.

1) OPEN VOLTS is the set point for opening the apa itor bank based upon

sensed line voltage. When the sensed line voltage rises above this set point for

one minute ontinuous, the ontrol will open the apa itor bank after the preset

time delay. Use the Adjust swit h to sele t the desired value. The minimum

value is the Close Volts setting plus 3 volts. The maximum value is 130 volts.

2) CLOSE VOLTS is the set point for losing the apa itor bank based upon

sensed line voltage. When the sensed line voltage drops below this set point for

one minute ontinuous, the ontrol will lose the apa itor bank after the preset

time delay. Use the Adjust swit h to sele t the desired value. The minimum

value is 105 volts. The maximum value is the Open Volts setting minus 3 volts.

The Line Voltage is tested at one-se ond intervals. The Line Voltage is averaged

over eight y les per interval.

The ontrol also in orporates an Adaptive Trip feature utilizing the Delta

Volt measurement. The Delta Volt measurement is the voltage ontribution

of the Capa itor Bank. If the next lose operation would ause the ontrol

voltage to be above the open voltage set point, the lose operation is not

performed until the voltage falls below the open voltage set point minus Delta

5

61

2

3

4

Figure 5 – NoMAX®900 Unit

Check your control for specific functions

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 16/22

1

Volts. Similarly, if the next open operation would ause the ontrol voltage to

be below the lose voltage set point, the operation is not performed until the

voltage rises above the lose voltage set point plus Delta Volts. Upon power

on, Delta Volts is preset to 0.5 volts. At the first AUTOMATIC Close operation,

Delta Volts is set to the differen e measured just before the Bank Closes and

one-minute later. From that point on every four AUTOMATIC Close operations

are averaged. This average is used as the Delta Volts measurement.

Automatic Voltage Operation Control Priority

The OPEN VOLTS setting has priority over the CLOSE VOLTS setting.

Capacitor Bank Switching Coordination Feature

– The OPERATION TIME

DELAY feature an be used to have the ontrol automati ally abort Voltage Open or

Close operations, thus allowing Capa itor Bank swit hing oordination.

If a Volt Open operation is pending, and the Line Voltage drops below the OPEN

VOLTS setting (minus 1 Volt) for 50% of the OPERATION TIME DELAY setting, the

Volt Open operation will be aborted.

Likewise, if a Volts Close operation is pending, and the Line Voltage in reases

above the CLOSE VOLTS setting ( plus 1 volt) for 50% of the OPERATION TIME

DELAY setting, the Volt Close operation will be aborted.

Example:

Two sites are ontrolled by a NoMAX®900 Control. The Cap Bank Voltage

ontribution is 2.2 Volts (i.e. Delta Volts is 2.2 volts).

Site 1’s CLOSE VOLTS setting is 118.0 and the OPERATION TIME DELAY setting

is 60 se onds.

Site 2’s CLOSE VOLTS setting is 118.0 and the OPERATION TIME DELAY setting

is 180 se onds.

The Line Voltage drops below 118.0 for more than 60 se onds, both Site 1 & 2

initiate pending Close operations (i.e. the Close Event ounters ex eed 60).

After another 60 se onds, Site 1’s Close Motor Relay energizes

(i.e. the OPERATION TIME DELAY for Site 1 is 60). Shortly thereafter, the

Line Voltage in reases to 120.2 volts (118.0 + 2.2 Volts Delta).

Site 2 is 60 se onds into its Operation Time Delay.

90 se onds later Site 2’s Close operation automati ally aborts

(i.e. the OPERATION TIME DELAY for Site 2 is 180) approximately

30 se onds before its Close Motor Relays would have energized.

Note:

If a pending operation aborts, the Voltage ondition ounter

whi h initiated the operation, resets to zero.

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 17/22

16

While in Automati Voltage Control Mode, the ontrol will y le through several

different status messages. The messages in lude the Total Operations ounter, the

number of 24 hour Auto operations, the Line Voltage, the Present Time and either

the Delta Volts or any a tivated timer (i.e. the “Close Inhibit” timer, or the Manual

Open/Close maintenan e timer).

If the ontrol powers on into a high Line Voltage ondition (> 130.0 volts) an IMME-

DIATE OPEN operation o urs, bypassing the OPERATION TIME DELAY time.

Automatic Time Operation

– Automati Time Control Mode is a tive when the

front panel rotary swit h position is set to AUTO and the Control Mode is set to

“Time”. The AUTO LED will also light. When Automati Time Control Mode is a tive,

the ontrol will open the apa itor bank when the ontrol lo k rea hes the “Open”

set point and the ontrol will lose the apa itor bank when the ontrol lo k rea hes

the “Close” set point, subje t to the weekend settings. To adjust the set points for

automati time operation, use the front panel rotary swit hes to sele t the

parameter. Please refer to Figure 5.

3) CLOSE TIME is the set point for losing the apa itor bank based upon the

ontrol lo k. To adjust this setting, the upper rotary swit h must be set to

TIME FUNCTIONS and the lower rotary swit h set to CLOSE TIME. Use the

Adjust swit h to sele t the desired time.

4) OPEN TIME is the set point for opening the apa itor bank based upon the

ontrol lo k. To adjust this setting, the upper rotary swit h must be set to

TIME FUNCTIONS and the lower rotary swit h set to OPEN TIME. Use the

Adjust swit h to sele t the desired time.

While in Automati Time Control Mode, the ontrol will y le through several

different status messages. The messages in lude the Total Operation ounter,

the number of 24 hour Auto operations and the present time.

Automatic Time Operation with Voltage Override Operation

– Automati

Time with Voltage Override Control Mode is a tive when the front panel rotary

swit h is set to Auto and the Control Mode is set to “Time/Volt”. The Auto LED will

also light. When this mode is a tive, the ontrol will operate as des ribed for

Automati Time Operation as long as the sensed voltage is in the “non-Voltage

Control Range” (below the OPEN VOLT setting and above the CLOSE VOLT

setting). Automati Voltage Override will o ur when the sensed voltage rosses

either the OPEN VOLT or CLOSE VOLT setting with the following priority:

The OPEN VOLT setting has priority over the CLOSE VOLT setting, the CLOSE

TIME setting and the OPEN TIME setting.

The CLOSE VOLT setting has priority over the CLOSE TIME setting and the OPEN

TIME setting.

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 18/22

17

Automatic Temperature Operation

– Automati Temperature Control Mode is

a tive for the NoMAX 900®when the Control Mode is set to “Temp. Only”

and the rotary swit h position is set to AUTO. The AUTO LED will also light.

When Automati Temperature Control Mode is a tive, the ontrol tests the

ambient temperature against the programmed OPEN TEMP and CLOSE

TEMP settings. To adjust the set points, use the front panel rotary swit h

to sele t the parameter. Please refer to Figure 5.

5) OPEN TEMP is the set point for opening the apa itor bank based upon

measured ambient temperature. Use the Adjust swit h to sele t the desired

value. The minimum value is 5 degrees. The maximum value is 125 degrees

(The Control prevents the OPEN TEMP setting from being loser than 5 degrees

to the CLOSE TEMP setting). The ontrol will issue an open ommand to the

apa itor bank based upon the Winter/Summer s hedule as follows:

Winter S hedule (defined by OPEN TEMP greater than CLOSE TEMP setting) –

When the ambient temperature rises above the OPEN TEMP setting for 5

minutes ontinuous, the apa itor bank will Open after the preset time delay.

Summer S hedule (defined by CLOSE TEMP greater than OPEN TEMP setting) –

When the ambient temperature drops below the OPEN TEMP setting for 5

minutes ontinuous, the apa itor bank will Open after the preset time delay.

6) CLOSE TEMP is the set point for losing the apa itor bank based upon measured

ambient temperature. Use the Adjust swit h to sele t the desired value. The

minimum value is 5 degrees. The maximum value is 125 degrees (The Control

prevents the CLOSE TEMP setting from being loser than 5 degrees to the

OPEN TEMP setting). The ontrol will issue a lose ommand to the apa itor

bank based upon the Winter/Summer s hedule as follows:

Winter S hedule (defined by OPEN TEMP greater than CLOSE TEMP setting) –

When the ambient temperature drops below the CLOSE TEMP setting for 5

minutes ontinuous, the apa itor bank will Close after the preset time delay.

Summer S hedule (defined by CLOSE TEMP greater than OPEN TEMP setting) –

When the ambient temperature rises above the CLOSE TEMP setting for 5

minutes ontinuous, the apa itor bank will Close after the preset time delay.

While in Automati Temperature Control Mode, the ontrol will y le through

several different status messages. The messages in lude the total operations

ounter, the number of 24 hour Auto operations, the present time and the

sensed temperature (Fahrenheit).

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 19/22

18

Automatic Temperature With Voltage Override Operation

Automati Temperature with Voltage Override Control Mode is a tive for the

NoMax®900 when the Control Mode is set to “Temp/Volt” and the rotary swit h

position is set to AUTO. The AUTO LED will also light. When this mode is a tive, the

ontrol will operate as des ribed for Automati Temperature Operation as long as the

sensed voltage is in the “non-Voltage Control Range” (below the OPEN VOLT set-

ting and above the CLOSE VOLT setting). Automati Voltage Override will o ur

when the sensed voltage rosses either the OPEN VOLTS or CLOSE VOLTS settings

with the following priority:

The OPEN VOLTS setting has priority over the CLOSE VOLTS setting, the OPEN

TEMP setting and the CLOSE TEMP setting.

The CLOSE VOLTS setting has priority over the OPEN TEMP setting and the

CLOSE TEMP setting.

Automatic Time with Temperature Override Operation

Automati Time with Temperature Override Control Mode is a tive when the front

panel rotary swit h is set to Auto and the Control Mode is set to “Time/Temp”. The

Auto LED will also light. When this mode is a tive, the ontrol will operate as des ribed

for Automati Time Operation as long as the sensed ambient temperature is in the

“non-Temperature Control Range” (sensed temperature between the OPEN TEMP and

CLOSE TEMP set points). Automati Temperature Override will o ur when the

sensed temperature rosses either the OPEN TEMP or CLOSE TEMP setting with the

following priority:

The OPEN TEMP setting has priority over the CLOSE TEMP setting, the CLOSE

TIME setting and the OPEN TIME setting.

The CLOSE TEMP setting has priority over the CLOSE TIME setting and the OPEN

TIME setting.

SPECIFICATIONS

• 16 bit High Performan e in- ir uit re-programmable Flash Pro essor

• 16 Chara ter x 1 Line Liquid Crystal Display

• Front Panel Voltage Test points

• En losure – NEMA 4x, Dimensions 6”x 8”

• Mounting – 4 Jaw Meter So ket or Dire t Pole Mount

• Environmental – -22° to +185° F (-30° to +85°C) 5-95% non- ondensing humidity

• Voltage Sensor is True RMS and Transformer Isolated (Galvani isolation)

• Voltage Input a ura y – +/- 1% Full S ale -22° to +176° F (-30° to +80°C)

• Voltage Input resolution – .15 VRMS internal, .1 VRMS displayed

• Voltage range – 80 to 145 VRMS

• Temperature Sensor a ura y – {+/- 0.9° F (0.5°C)} 32° to +158° F (0° to 70°C),

{+/- 1.8° F (1°C)} 14° to +185°F (-10° to 85°C)

• Temperature Sensor range – -22° to +185° F (-30° to +85°C)

• Motor Relays – Rated 30 Amps, fused 15Amp SloBlo®, 15 Se ond ON duration

• Relay Prote tion – MOV and Snubbers a ross onta ts

• Control Prote tion – MOV and Snubbers Line 1 to Neutral, Neutral to Ground,

Line 1 to Ground Fused at 1 amp

Gridco, Inc. v. Varentec, Inc. IPR2017-01135

GRIDCO 1008 - 20/22

This manual suits for next models

3

Table of contents

Popular Remote Control manuals by other brands

Niles

Niles TVC-1 Installation & operation guide

Sunricher

Sunricher SR-ZG2868 instructions

Mitsubishi Heavy Industries

Mitsubishi Heavy Industries eco touch RC-EXC3A quick reference

JVC

JVC RMP-2580U - Remote Controller For Color... Product overview and specifications

Lince

Lince 4037S137PLUS Installation and operation manual

NAD

NAD S70 owner's manual