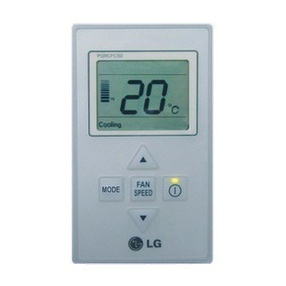

The remote control transmits the signals to the system.

START/STOP BUTTON

Operation starts when this button is pressed and stops

when the button is pressed again.

Operation mode selection button

Used to select the operation mode.

ROOM TEMPERATURE SETTING BUTTONS

Used to select the room temperature.

INDOOR FAN SPEED SELECTOR

Used to select fan speed in four steps

low, medium, high and CHAOS.

JET COOL

Used to start or stop the speed

cooling. (Speed cooling operates

super high fan speed in cooling mode.)

CHAOS SWING BUTTON

Used to stop or start louver movement and set the desired

up/down airflow direction.

ON/OFF TIMER BUTTONS

Used to set the time of starting and stopping operation.

TIME SETTING BUTTONS

Used to adjust the time.

TIMER SET/CANCEL BUTTON

Used to set the timer when the desired time is obtained and

to cancel the Timer operation.

SLEEP MODE AUTO BUTTON

Used to set Sleep Mode Auto operation.

AIR CIRCULATION BUTTON

Used to circulate the room air without cooling or heating.

ROOM TEMPERATURE CHECKING BUTTON

Used to check the room temperature.

PLASMA(OPTIONAL)

Used to start or stop the plasma-purification function.

HORIZONTAL AIRFLOW DIRECTION CONTROL

BUTTON (NOT ON ALL MODELS)

Used to set the desired horizontal airflow direction.

RESET BUTTON

Used prior to resetting time or after replacing batteries.

2nd F Button

Used prior to using modes printed in blue at the bottom of

buttons.

AUTO CLEAN(OPTIONAL)

Used to set Auto Clean mode.

1.

2.

3.

4.

5.

6.

7.

8.

9

10.

11.

12.

13.

14.

15.

16.

17.

ON OFF

CANCEL

SET

1

3

5

4

9

10

12

14

16

7

2

8

13

15

11

6

Cooling Operation

Auto Operation or Auto Changeover

Healthy Dehumidification Operation

Flip-up door

(opened)

Heating Operation

Signal transmitter

•

Cooling Model( ), Heat Pump Model( )

17

AUTO CLEAN

Operation Mode