HD FIRE PROTECT H3 User manual

MARCH, 2022 HD 235PAGE 1 OF 16

HD FIRE PROTECT

PVT. LTD.

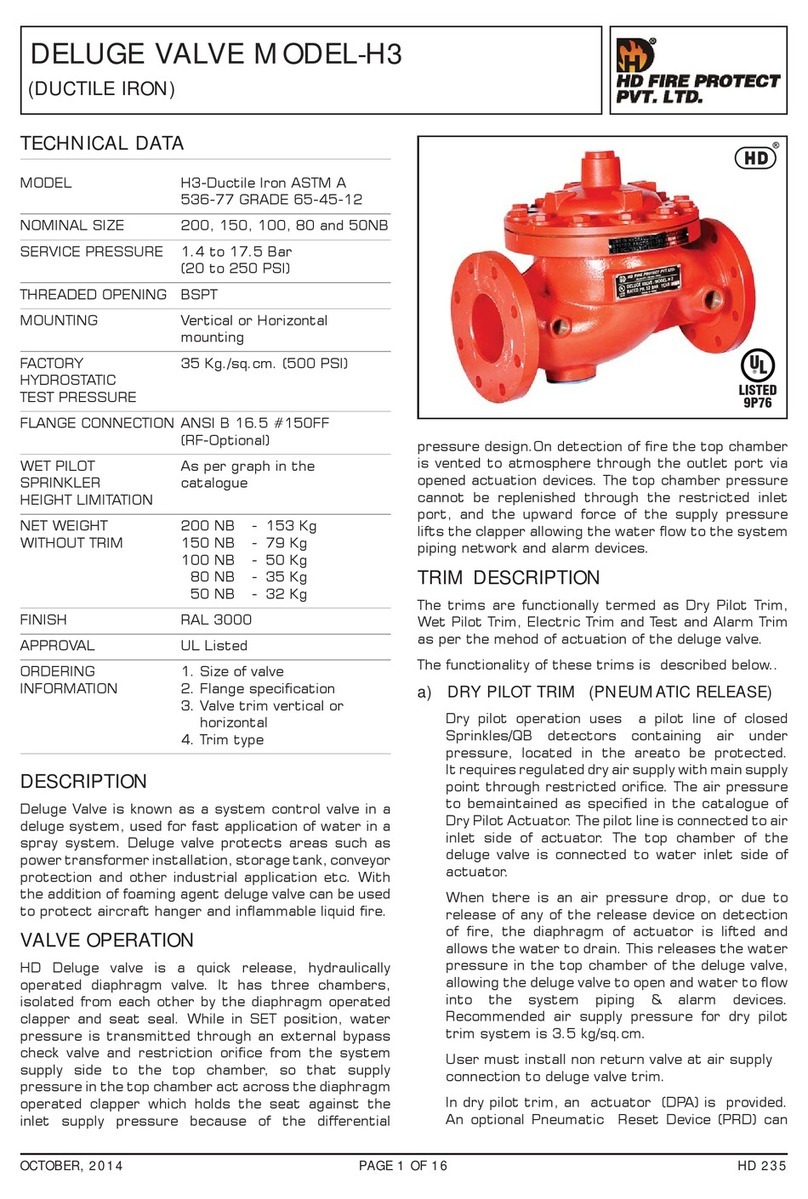

DELUGE VALVE

MODEL-H3 (DUCTILE IRON)

TECHNICAL DATA

MODEL H3-Ductile Iron ASTM A

536-77 GRADE 65-45-12

NOMINAL SIZE 200, 150, 100, 80 & 50NB

SERVICE PRESSURE 1.4 to 17.6 kg/sq.cm

(20 to 250 psi)

END CONNECTION Flange X Flange

Groove X Groove

THREADED OPENING BSPT

MOUNTING Vertical or Horizontal

FACTORY 35 kg/sq.cm (500 psi)

HYDROSTATIC

TEST PRESSURE

FLANGE ANSI B 16.5 #150 FF

CONNECTION is standard supply.

(Contact HD Sales for other

options)

WET PILOT As per graph in the

SPRINKLER catalogue

HEIGHT LIMITATION

NET WEIGHT FXF GXG

WITHOUT TRIM 200 NB - 153 kg 143 kg

150 NB - 79 kg 68 kg

100 NB - 50 kg 42 kg

80 NB - 35 kg 29 kg

50 NB - 32 kg 27 kg

FINISH Red to RAL 3001

APPROVAL UL Listed

ORDERING 1. Size of valve

INFORMATION 2. Flange specification or for

Grooved end specify pipe

outside diameter

3. Valve mounting- Horizontal

or Vertical

4. Trim type

GROOVE PIPE SIZE:

NOMINAL SIZE Pipe OD in mm

2” (50 NB) 60.3

3” (80 NB) 89.0

4” (100 NB) 114.3

6” (150 NB) 165.1

6” (150 NB) 168.3

8” (200 NB) 219.1

NOTE:

FOR 6”(150 NB) STANDARD SUPPLY IS 168.3 mm OD

GROOVE PIPE.

FOR 165.1mm REQUIREMENT, SPECIFY IN ORDER

DESCRIPTION

Deluge Valve is known as a system control valve in

a deluge system, used for fast application of water

in a spray system. Deluge valve protects areas such

as power transformer installation, storage tank,

conveyor protection and other industrial application

etc. With the addition of foaming agent, deluge valve

can be used to protect aircraft hanger and inflammable

liquid fire.

VALVE OPERATION

HD Deluge Valve is a quick release, hydraulically

operated diaphragm valve. It has three chambers,

isolated from each other by the diaphragm operated

clapper and seat seal. While in SET position, water

pressure is transmitted through an external bypass

check valve and restriction orifice from the system

supply side to the top chamber, so that supply

pressure in the top chamber act across the diaphragm

operated clapper which holds the seat against the

inlet supply pressure, because of the differential

pressure design. On detection of fire, the top chamber

is vented to atmosphere through the outlet port via

opened actuation devices. The top chamber pressure

cannot be replenished through the restricted inlet

port, and the upward force of the supply pressure

lifts the clapper allowing the water flow to the system

piping network and alarm devices.

MARCH, 2022 HD 235PAGE 2 OF 16

HD FIRE PROTECT

PVT. LTD.

TRIM DESCRIPTION

The trims are functionally termed as Dry Pilot Trim,

Wet Pilot Trim, Electric Trim and Test & Alarm Trim as

per the method of actuation of the deluge valve.

The functionality of these trims are described below:

a) DRY PILOT TRIM (PNEUMATIC RELEASE)

Dry pilot operation uses a pilot line of closed

Sprinklers/ QB Detectors containing air under

pressure, located in the area to be protected.

It requires regulated dry air supply with main

supply point through restricted orifice. The air

pressure to be maintained as specified in the

catalogue of Dry Pilot Actuator (HD 252). The

pilot line is connected to air inlet side of actuator.

The top chamber of the deluge valve is connected

to water inlet side of actuator.

When there is an air pressure drop, or due to

release of any of the releasing device on detection

of fire, the diaphragm of actuator is lifted and

allows the water to drain. This releases the water

pressure in the top chamber of the deluge valve,

allowing the deluge valve to open and water to

flow into the system piping & alarm devices.

Recommended air supply pressure for dry pilot

trim system is 3.5 kg/sq.cm.

User must install non return valve at air supply

connection to deluge valve trim.

In dry pilot trim, an actuator (DPA) is provided.

An optional Pneumatic Reset Device (PRD) can

be provided, which acts as a manual reset device

in the dry pilot line.

b) WET PILOT TRIM (HYDRAULIC RELEASE)

Wet pilot operation uses a pilot line of closed

Sprinklers/QB Detectors containing pressurized

water, supplied through the upstream side of

the Deluge valve, through a restricted orifice. Due

to release of any one of the releasing device, the

water pressure in the top chamber of the Deluge

valve drops and the Deluge valve opens.

c) ELECTRIC RELEASE TRIM

To actuate a Deluge valve electrically, a solenoid

valve is provided to drain the water from the top

chamber of the Deluge valve. A pressure switch is

provided to activate an electric alarm, to shut

down the desired equipment or to give “Tripped”

indication of the Deluge valve. In addition to this a

pressure switch can also monitor “Low air

pressure” and “Fire condition” when used in dry

pilot air line.

d) TEST AND ALARM TRIM

This trim is supplied with a test valve provided to

test the normal operation of the sprinkler alarm

bell. The sprinkler alarm can be supplied additionally,

which bells on actuation of the Deluge valve.

e) DRAIN AND DRIP TRIM

This consists of main and system drain valve in

addition with drip valve.

TRIM

MODEL

NO.

TRIM DESCRIPTION MOUNTING SCHEMATIC

NO.

E T- W Basic Wet Pilot Trim Vertical Schematic 1

ET-D Basic Dry Pilot Trim Vertical Schematic 2

ETW-T Basic Wet Pilot Trim with Test & Alarm Trim Vertical Schematic 3

ETD-T Basic Dry Pilot Trim with Test & Alarm Trim Vertical Schematic 4

ETW-D Basic Wet Pilot Trim with Drip & Drain Trim Vertical Schematic 5

ETD-D Basic Dry Pilot Trim with Drip & Drain Trim Vertical Schematic 6

N T- W Basic Wet Pilot Trim with Test & Alarm Trim and Drip & Drain Trim Vertical Schematic 7

NT-D Basic Dry Pilot Trim with Test & Alarm Trim and Drip & Drain Trim Vertical Schematic 8

E T- W Basic Wet Pilot Trim Horizontal Schematic 9

ET-D Basic Dry Pilot Trim Horizontal Schematic 10

ETW-T Basic Wet Pilot Trim with Test & Alarm Trim Horizontal Schematic 11

ETD-T Basic Dry Pilot Trim with Test & Alarm Trim Horizontal Schematic 12

ETW-D Basic Wet Pilot Trim with Drip & Drain Trim Horizontal Schematic 13

ETD-D Basic Dry Pilot Trim with Drip & Drain Trim Horizontal Schematic 14

N T- W Basic Wet Pilot Trim with Test & Alarm Trim and Drip & Drain Trim Horizontal Schematic 15

NT-D Basic Dry Pilot Trim with Test & Alarm Trim and Drip & Drain Trim Horizontal Schematic 16

MARCH, 2022 HD 235PAGE 3 OF 16

HD FIRE PROTECT

PVT. LTD.

TRIM TYPES

The trims are designated as following:

W =Wet Pilot trim D = Dry Pilot Trim

a) Type ET-W and ET-D

This type of trim is basic trim required to

operate the deluge valve. A solenoid valve for

electric remote actuation and pressure switch

for sensing & annunciation are optional.

b) Type ETW-D and ETD-D

This trim type is a combination of components

of the ET trim along with the drip and drain

trim. A solenoid valve for electric remote actuation

and pressure switch for sensing & annunciation

are optional.

c) Type ETW-T and ETD-T

This trim type is a combination of components of

the ET trims along with the test & alarm trim.

A solenoid valve for electric remote actuation

and pressure switch for sensing & annunciation

are optional.

d) Type NT-W and NT-D

This trim type is a combination of components of

the ET trim along with the test and alarm trim

as well as the drip and drain trim. A solenoid valve

for electric remote actuation and pressure switch

for sensing & annunciation are optional.

RESETTING PROCEDURE

A. When priming connection is below the upstream

valve (Stop Valve)

(i) Close the upstream side stop valve provided below

the deluge valve to cease the flow of water.

(ii) Open both the drain valves/ drain plugs and close

when the flow of water has ceased.

(iii) Close the release device/replace the Sprinkler if

release was through Sprinkler/ QB Detector.

(iv) Inspect and restore/ replace/ repair if required,

the section of the detection system subjected to

“Fire condition”.

(v) In case of dry pilot detection system, open the

air supply valve to build-up air pressure. Open the

priming valve fully. When top chamber pressure is

more than 50% of the inlet pressure, open the

upstream side of the stop valve provided below

the Deluge valve. No water should flow into the

system.

(vi) When priming shut off valve (optional) is provided

for resetting, then the water need to be drained

from upstream side of valve.

B. When priming connection is from the inlet of

Deluge Valve (Auto resetting)

(i) The deluge valve will reset automatically when

releasing devices which were responsible for

deluge valve opening are closed or restored

back to their original status (i.e closing of ERS

or replacing the damaged Sprinkler if release

was through Sprinkler/ QB Detector or closing

of Solenoid valve). The reset time may be long or

cause vibration while closing depending upon the

system back pressure at the outlet of the valve.

CAUTION

(a) Do not close the priming valve, downstream and

upstream stop valves, while system is in service

(b) The releasing device must be maintained in the

open position, when actuated, to prevent the

deluge valve from closure if anti shut off valve is

not provided

(c) While using a deluge valve in the wet pilot system

the height and the length of the wet pilot

detection line is to be limited as shown in

the wet pilot sprinkler height limitation graph

(d) Do not connect the Sprinkler Alarm outlet drain

line to close a common drain as it may create

back pressure & Sprinkler Alarm may not function

(e) Deluge valve must have support to absorb sudden

opening or closing vibration shock to the piping

(f) To avoid water damage, take precautions when

opening the water supply main control valve, since

water will flow from all open system valves

(g) The responsibility of maintenance of the protection

system and devices in proper operating condition

lies with the owner of the system.

(h) Deluge Valve & its trim shall be maintained at a

minimum temperature of 4oC. Heat tracing is not

permitted.

(i) Deluge Valve must be used in pressurised system.

SYSTEM TESTING PROCEDURE

(i) Keep the upstream side of the stop valve partially

open. To avoid water flow to system side, close the

system side stop valve. This valve is to be kept in

open position after the testing is completed.

(ii) Let any of the release devices to trip. This will

result in a sudden drop of water pressure in

the deluge valve top chamber which in turn will

open the deluge valve. Close the upstream side

stop valve immediately.

(iii) Reset the valve as per the procedure given

under heading “RESETTING PROCEDURE FOR THE

DELUGE VALVE”

MARCH, 2022 HD 235PAGE 4 OF 16

HD FIRE PROTECT

PVT. LTD.

INSPECTION AND MAINTENANCE

Installed system piping network must be flushed

properly before placing the Deluge valve in service.

A qualified and trained person must commission

the system. After few initial successful tests,

an authorized person must be trained to perform

inspection and testing of the system. It is

recommended to have regular inspection and test run

of the system as per NFPA guideline or in accordance

to the organisation having local jurisdiction.

(i) WARNING

Inspection and testing is to be carried out only by

authorised and trained personnel. DO NOT TURN

OFF the water supply or close any valve to make

repair(s), or test the valve without placing a

roving fire patrol in the area covered by the

system. Also inform the local security personnel

and central alarm station, so that there is no

false alarm signal.

It is recommended to carry out physical inspection

of the system at least twice in a week. The

inspection should verify that all the control valves

are in proper position as per the system

requirement and that there are no damages to

any component.

The frequency of inspections must be increased

in the presence of contaminated water supplies,

corrosive/scaling water supplies, and corrosive

atmospheres.

(ii) NORMAL CONDITION

(a) All main valves are open and are sealed with

tamper proof seal

(b) Drain valves must be kept closed

(c) No leak or drip is detected from the drip valve

(d) All the gauges except the system side water

pressure gauge, should show the required

pressure

(e) There should be no leakage in the system

(iii) NORMAL CONDITION TEST

(a) The system should be checked for normal

condition at least once in a week

(b) Test the sprinkler alarm bell or electric alarm

by turning the alarm test valve to the test

position. The alarm should sound. This test should

be carried out at least once in a week

(c) Depress the drip valve knob. Significant

accumulation indicates a possible seat leakage

(d) Conduct the water flow test as per the system

testing procedure at least once a month

(iv) PERIODIC CHECK

Conduct the water flow test by actuating few of

the release devices provided in the system. Clean

all strainer(s) and line restriction nipple. This

test is to be carried out at least once in three

months.

ABNORMAL CONDITION

(i) ALARM FAILS TO SOUND

(a) Check for any obstruction in the alarm test

line, make certain that the sprinkler alarm is free

to operate

(b) If an electric alarm is provided, check the

electrical circuitry to the alarm

(ii) FALSE TRIPS

(a) Check for clogging in priming line, restriction

orifice check valve, priming valve & strainer

(b) Leakage in the release system

(c) The deluge air line restriction orifice clogged or

low supply pressure

(iii) LEAKAGE THROUGH THE DELUGE VALVE

(a) Damaged deluge valve seat or obstruction on

the seat face by foreign object

(b) Leakage in release system

(c) Partly clogged priming line restriction orifice

check valve

(d) Low air pressure on release system line or

leakage in release system

NOTE:

(1) UL Listing is valid only when Deluge Valve is

installed with trim set as per trim drawing.

(2) The trip time of deluge valve on-off device through

detection network, will depend on volume of

detection network. If the trip time of deluge valve

is more, then it can be substantially reduced by

installing check valve in branch of release line in

the detection network. The check valve flow shall

be towards releasing device.

(3) The pneumatic system must have restricted

orifice at air or gas supply point. The restriction

nozzle are supplied with HD dry pilot actuation

trim.

(4) UL Listing is valid only when Listed Solenoid Valve

provided for electric operation of the deluge valve

is retained in the trim. If any other solenoid valve

is used, the deluge valve trip time may be quite

high or deluge valve may not trip.

(5) The Pressure Gauges standard supply is 300 psi

for water gauge for system pressure upto 175

psi. If system pressure is more than 175 psi,

then order for 600 psi water pressure gauges.

MARCH, 2022 HD 235PAGE 5 OF 16

HD FIRE PROTECT

PVT. LTD.

DELUGE VALVE MODEL - H3 SIZE 200 / 150 / 100 / 80/ 50 NB

2

4

5

6

7

8

9

10

12

13

14

15

16

17

19

11

18

20

21

3

1

Groove x Groove Flange x Flange

MARCH, 2022 HD 235PAGE 6 OF 16

HD FIRE PROTECT

PVT. LTD.

DELUGE VALVE MODEL - H3 SIZE 200 / 150 / 100 / 80 / 50 NB

VALVE NOMINAL SIZE AB

F x F G x G

200 NB 552 580 332

150 NB 462 490 282

100 NB 412 440 245

80 NB 372 400 232

50 NB 320 350 232

DIMENSION in millimeter (Approximate)

* Stainless Steel is standard supply, Bronze is an optional supply.

** Ductile Iron is standard supply, Bronze/Stainless Steel is an optional supply.

*** EPDM is standard supply with Stainless Steel Seat, Neoprene is an optional supply with Stainless Steel & Bronze Seat.

NA - PART REPLACEMENT NOT AVAILABLE

B

A

A

B

ITEM

NO.

PART NO. DESCRIPTION QTY

MATERIAL

SPECIFICATION

200

NB 150

NB 100

NB 80

NB 50

NB 200

NB 150

NB 100

NB 80/50

NB

1 NA NA NA NA NA HOUSING 1 1 1 1 DUCTILE IRON

2 8561 9783 9784 9791 9791 “O” RING 1 1 1 1 NEOPRENE RUBBER

3 3937 3936 3935 3934 3934 SEAT 1 1 1 1 STAINLESS STEEL *

4 9151 9112 9112 - - BOLT 8 4 4 - STAINLESS STEEL

5 3546 3545 3544 3543 3543 RUBBER CLAMP 1 1 1 1 DUCTILE IRON **

6 117466 117465 117464 117463 117463 RUBBER SEAT 1 1 1 1 EPDM ***

7 4034 3990 4011 4041 4041 CLAPPER 1 1 1 1 DUCTILE IRON **

8117462 117461 117460 117459 117459 DIAPHRAGM 1 1 1 1 EPDM ***

9 3542 3541 3540 3539 3539 CLAMP RING 1 1 1 1 DUCTILE IRON **

10 8806 9151 9151 9151 9151 BOLT 12 8 8 8 STAINLESS STEEL

11 114221 114221 114221 114221 114221 “O” RING 1 1 1 1 NEOPRENE RUBBER

12 4029 3996 4007 4020 4020 SPINDLE 1 1 1 1 STAINLESS STEEL

13 8838 8838 8838 8838 8838 NUT 1 1 1 1 STAINLESS STEEL

14 9184 9184 9184 9184 9184 LOCK NUT 1 1 1 1 STAINLESS STEEL

15 2980 2979 2978 2977 2977 SPRING 1 1 1 1 STAINLESS STEEL

16 4033 3998 4010 3983 3983 ADAPTOR 1 1 1 1 BRASS

17 NA NA NA NA NA COVER 1 1 1 1 DUCTILE IRON

18 9008 9049 9051 9027 9027 BOLT 16 12 12 12 CARBON STEEL

19 9982 9982 9982 9982 9982 “O” RING 1 1 1 1 NEOPRENE RUBBER

20 2514 2514 2514 2514 2514 PLUG 1 1 1 1 STEEL PLATED

21 8843 - - - - ALLEN BOLT 6 - - - STAINLESS STEEL

MARCH, 2022 HD 235PAGE 7 OF 16

HD FIRE PROTECT

PVT. LTD.

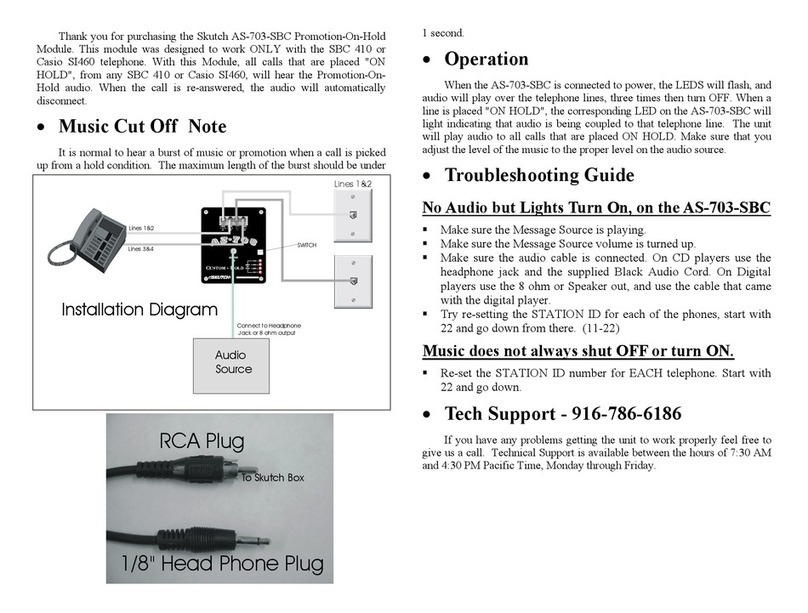

SCHEMATIC FOR BASIC WET PILOT TRIM FOR DELUGE VALVE

MODEL - H3 FOR VERTICAL MOUNTING

SCHEMATIC FOR BASIC DRY PILOT TRIM FOR DELUGE VALVE

MODEL - H3 FOR VERTICAL MOUNTING

SCHEMATIC 1

SCHEMATIC 2

ABBREVIATION & SYMBOLS

DV DELUGE VALVE G SPRINKLER ALARM (WMG) NRV WITH RESTRICTION HEX NIPPLE

M EMERGENCY RELEASE STATION PG PRESSURE GAUGE VALVE

RN RESTRICTIOIN NOZZLE (AIR LINE) OD OPEN DRAIN STRAINER

SV SOLENOID VALVE DPA DRY PILOT ACTUATOR --- BY USER

PS1 LOW AIR ALARM PRESSURE SWITCH NRV NON RETURN VALVE

PS2 WATER FLOW PRESSURE ALARM SWITCH ** OPTIONAL

FLANGE X FLANGE GROOVE X GROOVE

FLANGE X FLANGE GROOVE X GROOVE

PG

~

M

OD

INLET

OUTLET

OD

DV

~

PS2

PG

DPA

RN

LINE

TO DETECTION

OD

AIR SUPPLY

**

PS1

**

PG

NRV

SV

PG

~

M

OD

INLET

OUTLET

OD

DV

~

PS2

PG

DPA

RN

LINE

TO DETECTION

OD

AIR SUPPLY

**

PS1

**

PG

NRV

SV

**

**

PG

~

M

OD

INLET

OUTLET

OD

DV

~

TO DETECTION LINE

PG

PS2

**

SV

**

PG

~

M

OD

INLET

OUTLET

OD

DV

~

TO DETECTION LINE

PG

PS2

**

SV

**

ET-W

ET-D

MARCH, 2022 HD 235PAGE 8 OF 16

HD FIRE PROTECT

PVT. LTD.

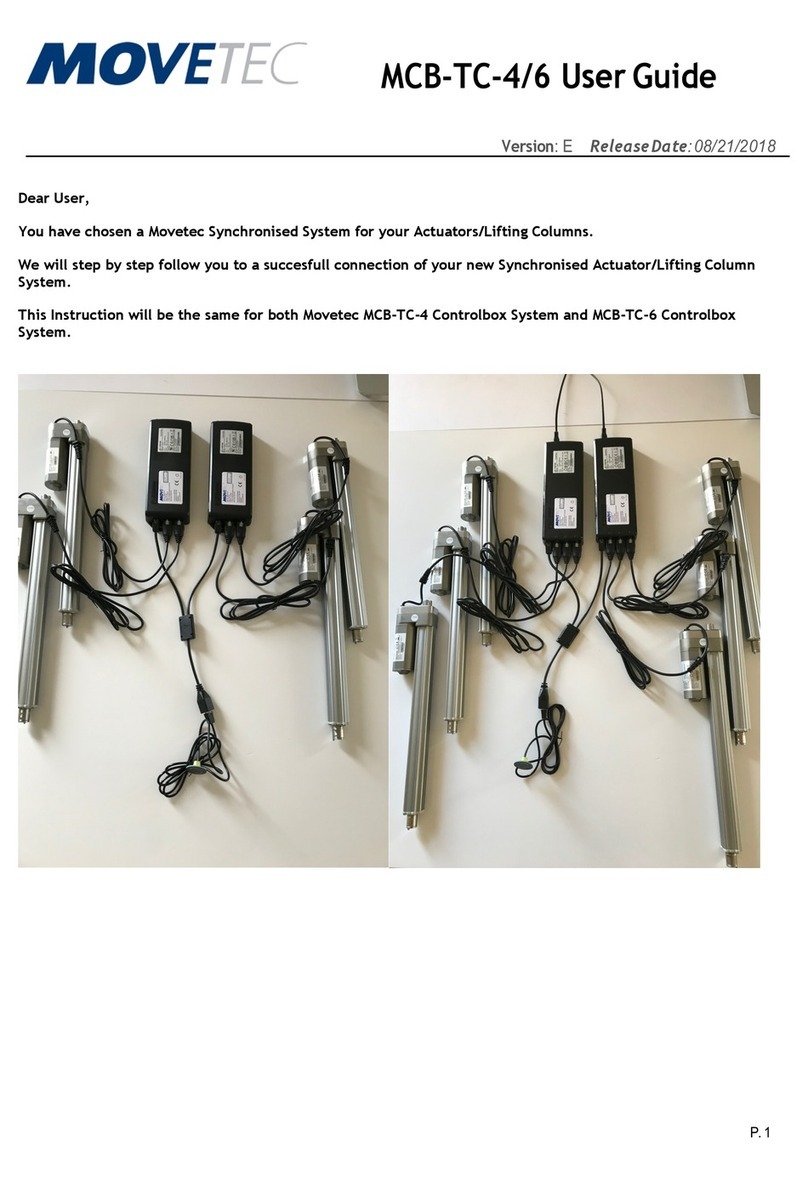

SCHEMATIC FOR BASIC WET PILOT TRIM FOR DELUGE VALVE

MODEL - H3 FOR VERTICAL MOUNTING

SCHEMATIC FOR BASIC DRY PILOT TRIM FOR DELUGE VALVE

MODEL - H3 FOR VERTICAL MOUNTING

SCHEMATIC 3

SCHEMATIC 4

FLANGE X FLANGE

FLANGE X FLANGE

GROOVE X GROOVE

GROOVE X GROOVE

ABBREVIATION & SYMBOLS

DV DELUGE VALVE G SPRINKLER ALARM (WMG) NRV WITH RESTRICTION HEX NIPPLE

M EMERGENCY RELEASE STATION PG PRESSURE GAUGE VALVE

RN RESTRICTIOIN NOZZLE (AIR LINE) OD OPEN DRAIN STRAINER

SV SOLENOID VALVE DPA DRY PILOT ACTUATOR --- BY USER

PS1 LOW AIR ALARM PRESSURE SWITCH NRV NON RETURN VALVE

PS2 WATER FLOW PRESSURE ALARM SWITCH ** OPTIONAL

PG

~

M

OD

INLET

OUTLET

OD

DV

~

G

OD

TO DETECTION LINE

PG

NRV

PS2

**

SV

**

PG

~

M

OD

INLET

OUTLET

OD

DV

~

G

OD

TO DETECTION LINE

PG

NRV

PS2

**

SV

**

PG

~

M

OD

INLET

OUTLET

OD

DV

~

G

OD

PS2

PG

DPA

RN

LINE

TO DETECTION

OD

AIR SUPPLY

**

PS1

**

PG

NRV

NRV

SV

**

PG

~

M

OD

INLET

OUTLET

OD

DV

~

G

OD

PG

DPA

RN

LINE

TO DETECTION

OD

AIR SUPPLY

PG

NRV

NRV

SV

**

PS2

**

PS1

**

ETW-T

ETD-T

MARCH, 2022 HD 235PAGE 9 OF 16

HD FIRE PROTECT

PVT. LTD.

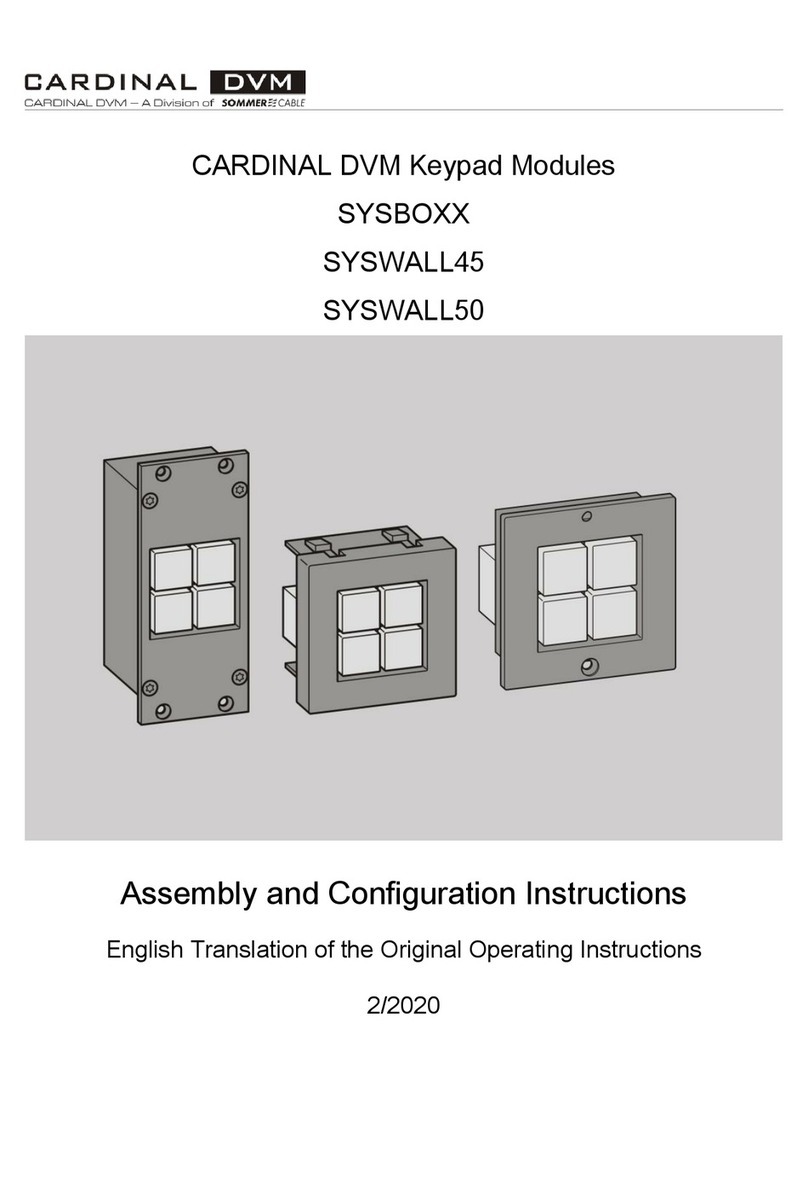

SCHEMATIC FOR BASIC WET PILOT TRIM FOR DELUGE VALVE

MODEL - H3 FOR VERTICAL MOUNTING

SCHEMATIC FOR BASIC DRY PILOT TRIM FOR DELUGE VALVE

MODEL - H3 FOR VERTICAL MOUNTING

SCHEMATIC 5

SCHEMATIC 6

FLANGE X FLANGE

FLANGE X FLANGE

GROOVE X GROOVE

GROOVE X GROOVE

ABBREVIATION & SYMBOLS

DV DELUGE VALVE G SPRINKLER ALARM (WMG) NRV WITH RESTRICTION HEX NIPPLE

M EMERGENCY RELEASE STATION PG PRESSURE GAUGE VALVE

RN RESTRICTIOIN NOZZLE (AIR LINE) OD OPEN DRAIN STRAINER

SV SOLENOID VALVE DPA DRY PILOT ACTUATOR ANGLE VALVE

PS1 LOW AIR ALARM PRESSURE SWITCH DR.V DRIP VALVE --- BY USER

PS2 WATER FLOW PRESSURE ALARM SWITCH NRV NON RETURN VALVE ** OPTIONAL

PG

~

M

OD

INLET

PG

OUTLET

OD

DV

~

DR.V

OD

OD

~

OD

TO DETECTION LINE

PS2

**

SV

**

PG

~

M

OD

INLET

PG

OUTLET

OD

DV

~

DR.V

OD

OD

~

OD

TO DETECTION LINE

PS2

**

SV

**

~

M

OD

INLET

PG

OUTLET

OD

DV

SV

~

PG

DR.V

DPA

RN

LINE

TO DETECTION

OD

OD

OD

~

OD

AIR SUPPLY

PS1

**

PS2

**

PG

NRV

**

~

M

OD

INLET

PG

OUTLET

OD

DV

~

PG

DR.V

DPA

RN

LINE

TO DETECTION

OD

OD

OD

~

OD

AIR SUPPLY

PG

NRV

SV

**

PS2

**

PS1

**

ETW-D

ETD-D

MARCH, 2022 HD 235PAGE 10 OF 16

HD FIRE PROTECT

PVT. LTD.

SCHEMATIC FOR BASIC WET PILOT TRIM FOR DELUGE VALVE

MODEL - H3 FOR VERTICAL MOUNTING

SCHEMATIC FOR BASIC DRY PILOT TRIM FOR DELUGE VALVE

MODEL - H3 FOR VERTICAL MOUNTING

SCHEMATIC 7

SCHEMATIC 8

FLANGE X FLANGE

FLANGE X FLANGE

GROOVE X GROOVE

GROOVE X GROOVE

PG

~

M

OD

INLET

PG

OUTLET

OD

DV

~

G

OD

DR.V

OD

OD

~

OD

NRV

TO DETECTION LINE

PS2

**

SV

**

PG

~

M

OD

INLET

PG

OUTLET

OD

DV

~

G

OD

DR.V

OD

OD

~

OD

NRV

TO DETECTION LINE

PS2

**

SV

**

PG

~

M

OD

INLET

PG

OUTLET

OD

DV

SV

~

G

OD

PS2 PG

DR.V

DPA

RN

LINE

TO DETECTION

OD

OD

OD

~

OD

AIR SUPPLY

NRV

**

**

PS1

**

NRV PG

~

M

OD

INLET

PG

OUTLET

OD

DV

~

G

OD

PG

DR.V

DPA

RN

LINE

TO DETECTION

OD

OD

OD

~

OD

AIR SUPPLY

NRV

NRV

SV

PS2

**

**

PS1

**

ABBREVIATION & SYMBOLS

DV DELUGE VALVE G SPRINKLER ALARM (WMG) NRV WITH RESTRICTION HEX NIPPLE

M EMERGENCY RELEASE STATION PG PRESSURE GAUGE VALVE

RN RESTRICTIOIN NOZZLE (AIR LINE) OD OPEN DRAIN STRAINER

SV SOLENOID VALVE DPA DRY PILOT ACTUATOR ANGLE VALVE

PS1 LOW AIR ALARM PRESSURE SWITCH DR.V DRIP VALVE --- BY USER

PS2 WATER FLOW PRESSURE ALARM SWITCH NRV NON RETURN VALVE ** OPTIONAL

NT-W

NT-D

MARCH, 2022 HD 235PAGE 11 OF 16

HD FIRE PROTECT

PVT. LTD.

FLANGE X FLANGE

FLANGE X FLANGE

GROOVE X GROOVE

GROOVE X GROOVE

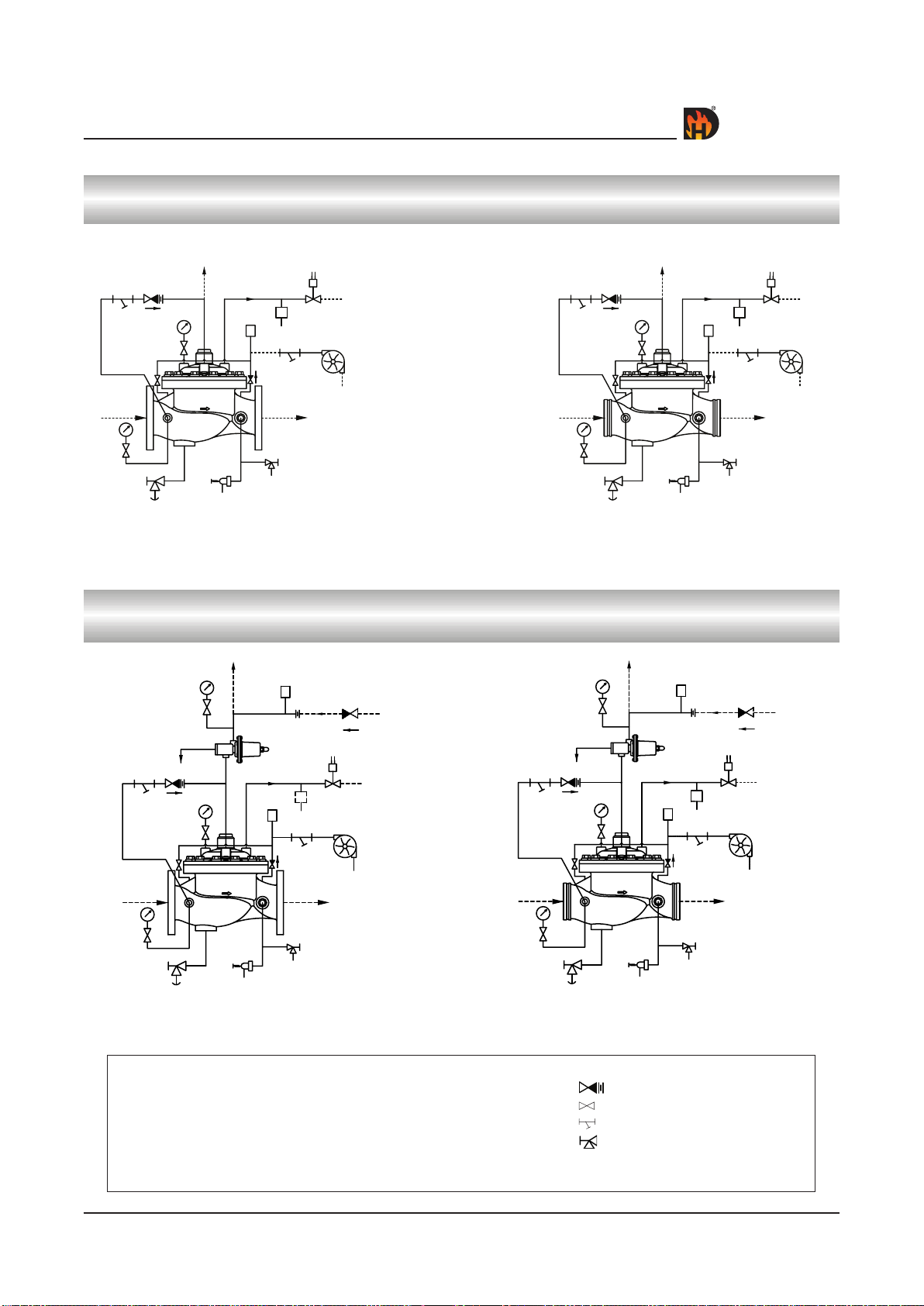

SCHEMATIC FOR BASIC WET PILOT TRIM FOR DELUGE VALVE

MODEL - H3 FOR HORIZONTAL MOUNTING

SCHEMATIC FOR BASIC DRY PILOT TRIM FOR DELUGE VALVE

MODEL - H3 FOR HORIZONTAL MOUNTING

SCHEMATIC 9

SCHEMATIC 10

ABBREVIATION & SYMBOLS

DV DELUGE VALVE G SPRINKLER ALARM (WMG) NRV WITH RESTRICTION HEX NIPPLE

M EMERGENCY RELEASE STATION PG PRESSURE GAUGE VALVE

RN RESTRICTIOIN NOZZLE (AIR LINE) OD OPEN DRAIN STRAINER

SV SOLENOID VALVE D PA DRY PILOT ACTUATOR --- BY USER

PS1 LOW AIR ALARM PRESSURE SWITCH NRV NON RETURN VALVE

PS2 WATER FLOW PRESSURE ALARM SWITCH ** OPTIONAL

INLET

PG

OUTLET

PG

OD

M

OD

DV

~

~

TO DETECTION

LINE

SV

**

PS2

**

INLET

PG

OUTLET

PG

OD

M

OD

DV

~

~

TO DETECTION

LINE

SV

**

PS2

**

INLET

PG

OUTLET

TO DETECTION

PG

LINE

PG

AIR SUPPLY

OD

RN

DPA

M

OD

DV

~

OD

~

NRV

PS1

**

SV

**

PS2

**

INLET

PG

OUTLET

TO DETECTION

PG

LINE

PG

AIR SUPPLY

OD

RN

DPA

M

OD

DV

~

OD

~

NRV

PS1

**

SV

**

PS2

**

ET-W

ET-D

MARCH, 2022 HD 235PAGE 12 OF 16

HD FIRE PROTECT

PVT. LTD.

SCHEMATIC FOR BASIC WET PILOT TRIM FOR DELUGE VALVE

MODEL - H3 FOR HORIZONTAL MOUNTING

SCHEMATIC FOR BASIC DRY PILOT TRIM FOR DELUGE VALVE

MODEL - H3 FOR HORIZONTAL MOUNTING

SCHEMATIC 11

SCHEMATIC 12

FLANGE X FLANGE

FLANGE X FLANGE

GROOVE X GROOVE

GROOVE X GROOVE

ABBREVIATION & SYMBOLS

DV DELUGE VALVE G SPRINKLER ALARM (WMG) NRV WITH RESTRICTION HEX NIPPLE

M EMERGENCY RELEASE STATION PG PRESSURE GAUGE VALVE

RN RESTRICTIOIN NOZZLE (AIR LINE) OD OPEN DRAIN STRAINER

SV SOLENOID VALVE DPA DRY PILOT ACTUATOR --- BY USER

PS1 LOW AIR ALARM PRESSURE SWITCH NRV NON RETURN VALVE

PS2 WATER FLOW PRESSURE ALARM SWITCH ** OPTIONAL

INLET

PG

OUTLET

PG

OD

M

OD

DV

~

~

G

~

OD

TO DETECTION

LINE

NRV

SV

**

PS2

**

INLET

PG

OUTLET

PG

OD

M

OD

DV

~

~

G

~

OD

TO DETECTION

LINE

NRV

SV

**

PS2

**

INLET

PG

OUTLET

TO DETECTION

PG

LINE

PG

OD

RN

DPA

M

OD

DV

~

OD

~

G

~

OD

AIR SUPPLY

NRV

NRV

PS1

**

SV

**

PS2

**

INLET

PG

OUTLET

TO DETECTION

PG

LINE

PG

OD

RN

DPA

M

OD

DV

~

OD

~

G

~

OD

AIR SUPPLY

NRV

NRV

PS1

**

SV

**

PS2

**

ETW-T

ETD-T

MARCH, 2022 HD 235PAGE 13 OF 16

HD FIRE PROTECT

PVT. LTD.

SCHEMATIC FOR BASIC WET PILOT TRIM FOR DELUGE VALVE

MODEL - H3 FOR HORIZONTAL MOUNTING

SCHEMATIC FOR BASIC DRY PILOT TRIM FOR DELUGE VALVE

MODEL - H3 FOR HORIZONTAL MOUNTING

SCHEMATIC 14

FLANGE X FLANGE

FLANGE X FLANGE

GROOVE X GROOVE

GROOVE X GROOVE

ABBREVIATION & SYMBOLS

DV DELUGE VALVE G SPRINKLER ALARM (WMG) NRV WITH RESTRICTION HEX NIPPLE

M EMERGENCY RELEASE STATION PG PRESSURE GAUGE VALVE

RN RESTRICTIOIN NOZZLE (AIR LINE) OD OPEN DRAIN STRAINER

SV SOLENOID VALVE DPA DRY PILOT ACTUATOR ANGLE VALVE

PS1 LOW AIR ALARM PRESSURE SWITCH DR.V DRIP VALVE --- BY USER

PS2 WATER FLOW PRESSURE ALARM SWITCH NRV NON RETURN VALVE ** OPTIONAL

INLET

PG

OUTLET

PG

OD

M

OD

DV

~

~

OD

~

OD

DR.V ~

OD

TO DETECTION

LINE

SV

**

PS2

**

INLET

PG

OUTLET

PG

OD

M

OD

DV

~

~

OD

~

OD

DR.V ~

OD

TO DETECTION

LINE

SV

**

PS2

**

INLET

PG

OUTLET

TO DETECTION

PG

LINE

PG

OD

RN

DPA

M

OD

DV

~

OD

~

OD

~

OD

DR.V ~

OD

AIR SUPPLY

NRV

PS1

**

SV

**

PS2

**

INLET

PG

OUTLET

TO DETECTION

PG

LINE

PG

OD

RN

DPA

M

OD

DV

~

OD

~

OD

~

OD

DR.V ~

OD

AIR SUPPLY

NRV

PS1

**

SV

**

PS2

**

SCHEMATIC 11

ETW-D

ETD-D

MARCH, 2022 HD 235PAGE 14 OF 16

HD FIRE PROTECT

PVT. LTD.

SCHEMATIC FOR BASIC WET PILOT TRIM FOR DELUGE VALVE

MODEL - H3 FOR HORIZONTAL MOUNTING

SCHEMATIC FOR BASIC DRY PILOT TRIM FOR DELUGE VALVE

MODEL - H3 FOR HORIZONTAL MOUNTING

SCHEMATIC 15

SCHEMATIC 16

FLANGE X FLANGE

FLANGE X FLANGE

GROOVE X GROOVE

GROOVE X GROOVE

OD

~

OD

DR.V

PG

~

OD

PG

OD

M

OD

~

~

INLET OUTLET

DV

TO DETECTION

LINE

G

~

OD

NRV

PS2

**

SV

**

OD

~

OD

DR.V

PG

~

OD

PG

OD

M

OD

~

~

INLET OUTLET

DV

TO DETECTION

LINE

G

~

OD

NRV

PS2

**

SV

**

ABBREVIATION & SYMBOLS

DV DELUGE VALVE G SPRINKLER ALARM (WMG) NRV WITH RESTRICTION HEX NIPPLE

M EMERGENCY RELEASE STATION PG PRESSURE GAUGE VALVE

RN RESTRICTIOIN NOZZLE (AIR LINE) OD OPEN DRAIN STRAINER

SV SOLENOID VALVE DPA DRY PILOT ACTUATOR ANGLE VALVE

PS1 LOW AIR ALARM PRESSURE SWITCH DR.V DRIP VALVE --- BY USER

PS2 WATER FLOW PRESSURE ALARM SWITCH NRV NON RETURN VALVE ** OPTIONAL

OD

~

OD

DR.V

PG

~

OD

TO DETECTION

PG

LINE

PG

OD

RN

DPA

M

OD

PS1

**

SV

**

~

OD

~

INLET OUTLET

DV

G

~

OD

AIR SUPPLY

NRV

PS2

**

NRV

OD

~

OD

DR.V

PG

~

OD

TO DETECTION

PG

LINE

PG

OD

RN

DPA

M

OD

PS1

**

SV

**

~

OD

~

INLET OUTLET

DV

G

~

OD

AIR SUPPLY

NRV

PS2

**

NRV

NT-W

NT-D

MARCH, 2022 HD 235PAGE 15 OF 16

HD FIRE PROTECT

PVT. LTD.

SPRINKLER HEIGHT LIMITATION

DV 150NBDV 200NB

DV 100NB DV 80NB

DV - 50NB

SYSTEM SUPPLY PRESSURE - PSI ------

EQUIVALENT LENGTH BASED ON 1/2” SCHEDULE 40 PIPE WITH C=120

KG/SQ.CM

METERS

MAXIMUM PILOT LINE HEIGHT - FT. ------

SYSTEM SUPPLY PRESSURE - PSI ------

EQUIVALENT LENGTH BASED ON 1/2” SCHEDULE 40 PIPE WITH C=120

KG/SQ.CM

METERS

MAXIMUM PILOT LINE HEIGHT - FT. ------

SYSTEM SUPPLY PRESSURE - PSI ------

EQUIVALENT LENGTH BASED ON 1/2” SCHEDULE 40 PIPE WITH C=120

KG/SQ.CM

METERS

MAXIMUM PILOT LINE HEIGHT - FT. ------

SYSTEM SUPPLY PRESSURE - PSI ------

EQUIVALENT LENGTH BASED ON 1/2” SCHEDULE 40 PIPE WITH C=120

KG/SQ.CM

METERS

MAXIMUM PILOT LINE HEIGHT - FT. ------

SYSTEM SUPPLY PRESSURE - PSI ------

EQUIVALENT LENGTH BASED ON 1/2” SCHEDULE 40 PIPE WITH C=120

KG/SQ.CM

METERS

MAXIMUM PILOT LINE HEIGHT - FT. ------

60

20

20

40

120

80

100

140

5

10

15

20

25

30

35

40

40

246810 12

160

180

200

14 16 18

45

50

55

60

50 100 150 200 250

0

220.

65

25 FEET

250 FEET

500 FEET

60

20

20

40

120

80

100

140

5

10

15

20

25

30

35

40

40

246810 12

160

180

200

14 16 18

45

50

55

60

50 100 150 200 250

0

220.

65

25 FEET

250 FEET

500 FEET

60

20

20

40

120

80

100

140

5

10

15

20

25

30

35

40

40

246810 12

160

180

200

14 16 18

45

50

55

60

50 100 150 200 250

0

220.

240

65

70

25 FEET

250 FEET

500 FEET

60

20

20

40

120

80

100

140

5

10

15

20

25

30

35

40

40

246810 12

160

180

200

14 16 18

45

50

55

60

50 100 150 200 250

0

220.

240

65

70

25 FEET

250 FEET

500 FEET

60

20

20

40

120

80

100

140

5

10

15

20

25

30

35

40

40

246810 12

160

180

200

14 16 18

45

50

55

60

50 100 150 200 250

0

220.

65

25 FEET

250 FEET

500 FEET

MARCH, 2022 HD 235PAGE 16 OF 16

LIMITED WARRANTY

HD FIRE PROTECT PVT. LTD. hereby referred to as HD FIRE warrants to the original purchaser of the fire protection products manufactured by HD FIRE and to any other person

to whom such equipment is transferred, that such products will be free from defect in material and workmanship under normal use and care, for two (2) years from the date of

shipment by HD FIRE. Products or Components supplied or used by HD FIRE, but manufactured by others, are warranted only to the extent of the manufacturer’s warranty.

No warranty is given for product or components which have been subject to misuse, improper installation, corrosion, unauthorized repair, alteration or un-maintained.

HD FIRE shall not be responsible for system design errors or improper installation or inaccurate or incomplete information supplied by buyer or buyer’s representatives.

HD FIRE will repair or replace defective material free of charge, which is returned to our factory, transportation charge prepaid, provided after our inspection the material is

found to have been defective at the time of initial shipment from our works. HD FIRE shall not be liable for any incidental or consequential loss, damage or expense arising directly

or indirectly from the use of the product including damages for injury to person, damages to property and penalties resulting from any products and components manufactured

by HD FIRE. HD FIRE shall not be liable for any damages or labour charges or expense in making repair or adjustment to the product. HD FIRE shall not be liable for any

damages or charges sustained in the adaptation or use of its engineering data & services. In no event shall HD Fire’s product liability exceed an amount equal to the sale price.

The foregoing warranty is exclusive and in lieu of all other warranties and representation whether expressed, implied, oral or written, including but not limited

to, any implied warranties or merchantability or fitness for a particular purpose. All such other warranties and representations are hereby cancelled.

NOTICE :

The equipment presented in this bulletin is to be installed in accordance with the latest publication standards of NFPA or other similar organisations and also with the

provision of government codes or ordinances wherever applicable.

The information provided by us is to the best of our knowledge and belief, and consist of general guidelines only. Site handling and installation control is not in our scope.

Hence we give no guarantee for result and take no liability for damages, loss or penalties whatsoever, resulting from our suggestion, information, recommendation or

damages due to our product.

Product development is a continuous programme of HD FIRE PROTECT PVT. LTD. and hence the right to modify any specification without prior notice is reserved with

the company.

D-6/2, ROAD NO. 34, WAGLE INDUSTRIAL ESTATE, THANE 400 604, INDIA.

• TEL: + (91) 22 2158 2600 • FAX: +(91) 22 2158 2602

HD FIRE PROTECT PVT. LTD.

Protecting What Matters Most to You

HD FIRE PROTECT

PVT. LTD.

DELUGE VALVE MODEL H3

0.1

0.2

0.3

0.4

0.5

0.6

0.8

1.0

2

3

4

5

6

8

10

20

30

40

100 1000

800

600400300200 2000 10000 20000700050003000

5

0

N

B

(

2

I

N

C

H

)

8

0

N

B

(

3

I

N

C

H

)

1

00

N

B

(

4

I

N

C

H

)

1

5

0

N

B

(

6

I

N

C

H

)

2

00

N

B

(

8

I

N

C

H

)

*

**

**

* 2.3 psi Pressure loss @ 15 feet per second (4.57 m/s) velocity having ow of 594 lpm through 50NB DV

* 4.7 psi Pressure loss @ 15 feet per second (4.57 m/s) velocity having ow of 1308 lpm through 80NB DV

* 4.7 psi Pressure loss @ 15 feet per second (4.57 m/s) velocity having ow of 2255 lpm through 100NB DV

* 7.5 psi Pressure loss @ 15 feet per second (4.57 m/s) velocity having ow of 5117 lpm through 150NB DV

* 8.4 psi Pressure loss @ 15 feet per second (4.57 m/s) velocity having ow of 8854 lpm through 200NB DV

Nominal Pressure Loss vs Flow

(* Flow at 15 feet per second [4.57 meter per second]) velocity

Nominal Pressure Loss in Pounds per Square Inch (psi)

Flow Rate in Liters Per Minute (lpm)

Other manuals for H3

2

Table of contents

Other HD FIRE PROTECT Control Unit manuals