Headwall Nano-Hyperspec User manual

AIRBORNEOPERATIONS

NANO-HYPERSPEC®

AIRBORNE PACKAGE

Operations Manual

AIRBORNE OPERATIONS

2

Reproduction and Copyright Information

This document contains information which is Proprietary and Confidential. Any reproductions, adaptations, or

translations without prior written permission from Headwall Photonics, Inc. is strictly prohibited. All information

provided in this manual is believed to be accurate and reliable. No responsibility is assumed by Headwall Photonics, Inc.

for its use. Headwall Photonics, Inc. reserves the right to make changes to this information without notice.

Contact Headwall Photonics, Inc. for associated software license information on: Hyperspec© application software, Nokia

QT libraries, and LGPL Public License.

Contact information

Headwall Photonics

601 River Street

Fitchburg, MA 01420

TEL (978) 353-4100

FAX (978) 348-1864

e-mail: support@headwallphotonics.com

CHANGE TRACKING

1-a

DOCUMENT REVISION TRACKING

Table 1-1. Document Revisions

Date Name Page Detail

6/2016 Chenevert 46 Added note about closing the live video and waterfall views

to prevent GPS data drop. Added steps for remote trigger

using GPIO functionality.

7/5/2016 Chenevert 1-14,15 Added detail about IMU connections. Added information

about flight planning in that section of book. Included use of

FOV calculator for planning and operations.

9/2016 Chenevert 1-3, 1-5 Added details for features, identified positioning of IMU so

no interpretation by users, Updated for features added since

last editing

CHANGE TRACKING

1-b

AIRBORNE OPERATIONS

1

Table of Contents

Document Revision Tracking................................................................................. a

Airborne Package Operation ................................................................................. 3

Nano-Hyperspec®— Airborne Package Components ........................................3

Individual Components ........................................................................................4

Nano-Hyperspec®................................................................................................................. 4

IMU ........................................................................................................................................ 5

GPS Antenna. ........................................................................................................................ 6

IMU Connection and Orientation. ........................................................................7

Component Interconnection .................................................................................7

Nano Computer Connection ................................................................................................ 7

Power Connection. ................................................................................................................ 8

Nano-IMU Attachment. ....................................................................................................... 9

IMU Data/Power Connection. ............................................................................................. 11

IMU, GPS Connection. ......................................................................................................... 14

Confirm Nano to IMU Connection ......................................................................14

Flight Planning .....................................................................................................16

Setting Capture Options. ..................................................................................................... 16

Capture Function .................................................................................................................. 18

GPS/IMU Mapping................................................................................................. 19

Overview ..............................................................................................................19

Software Installation. ...........................................................................................19

Magnetic Mapping Process ..................................................................................25

GPS/IMU Assembly Process. ............................................................................................... 25

Magnetic Mapping Procedure ............................................................................................. 26

Calibration Method .............................................................................................................. 28

Examples of Scanning Errors .............................................................................................. 30

Ortho-rectification: Configure IMU .....................................................................32

Airborne Operations, Pre-Flight Procedures....................................................... 35

Hyperspec®III Procedures ...................................................................................35

GPS Configuration and Polygons ........................................................................37

Capture Polygons .................................................................................................39

AIRBORNE OPERATIONS

2

Headwall Polygon Tool ........................................................................................40

Polygon Tool Functions. ....................................................................................................... 42

Multiple Polygons. ................................................................................................................ 44

Adding Polygons to the GPS Polygon Editor. .................................................................... 45

GPS Triggers ........................................................................................................47

GPS Remote Triggers ...........................................................................................50

Pre-flight, Way point Planning .............................................................................51

AIRBORNE PACKAGE

1-3

CHAPTER 1 AIRBORNE PACKAGE OPERATION

The airborne package is a combination of hardware, consisting of the motion tracker, IMU and GPS antenna, and software

that operates with the Nano-Hyperspec®(Nano). The airborne tracking software is integrated into the Hyperspec® III

software installation and operation. The airborne package is used to seamlessly adjust the orthogonal perspective of data

collected during manned or UAV flights. The orthogonal adjustment is done within the SpectralView®application of

Hyperspec®III through the ortho-rectification process. For the software to effectively correct the data cube during the

ortho-rectification process the position of the IMU needs to be set so the correct orientation off-sets can be applied to the

post processing, ortho-rectification. The steps to accomplish this process are within the section of this document, Nano-

IMU Attachment.

The following is a list of the components that make up the airborne package covered in this section. The complete sensor

system, as delivered, may have additional or alternative components. These alternative components are identified in the

enclosed package of system documentation included with the unit. This chapter deals only with the IMU and Nano

combination airborne package.

1.1 NANO-HYPERSPEC®— AIRBORNE PACKAGE COMPONENTS

The Headwall Airborne Package contains the following hardware components.

(1) Nano-Hyperspec®Unit

(a) Nano-Hyperspec®sensor

(b) Provided lens

(2) Airborne Package (GPS)

(a) IMU

(b) USB Cable

(c) Flash drive with backup airborne software

(d) GPS Antenna

(e) Mounting hardware

(f) LEMO data cable

(3) Flash Drive with Hyperspec®III software and calibration data

(4) Cat 6 Cable, 5 ft.

The IMU is mounted onto the Nano-Hyperspec®prior to and during operations. The power to operate the supplied IMU

comes through a connection to the Nano-Hyperspec®. Once powered and operating, the IMU will transmit the unit’s GPS

location and orientation, such as yaw, pitch or roll, to the Nano for inclusion into the data cube for the particular scan. For

each performed scan, the Nano stores the data cube in the scan folder in its memory. Once the scanning is completed the

file contents can be downloaded, using the Transfer feature within Hyperspec®III, onto the computer that contains

Hyperspec®III and SpectralView®.

The operation of the Nano-Hyperspec®unit is covered in the manual for that device. The Nano-Hyperspec®is identified

within the individual components section of Airborne Operations for ease of instruction.

AIRBORNE PACKAGE

1-4

Figure 1-1. Nano-Hyperspec®— Airborne Package.

1.2 INDIVIDUAL COMPONENTS

1.2.1 Nano-Hyperspec®.

Figure 1-2. Nano-Hyperspec®,with Lens.

AIRBORNE PACKAGE

1-5

1.2.2 IMU.

NOTE

When using the IMU it is important that the power cables be secured the maximum

distance from the IMU. This will prevent magnetic interference, errors in data

storage, orientation problems or possible damage to the unit.

The IMU weighs 58 grams. When mounted to the Nano-Hyperspec®, it sends positional data to the Nano for storage, and

inclusion into the scan data file. The positional data from the unit is then used for ortho-rectification of the scan data

within the SpectralView®application. The Headwall supplied cable used to connect the IMU to the Nano is the minimal

length to eliminate an interference.

Figure 1-3. IMU

The software to operate the IMU and generate positional data is embedded within the device. The software to interpret the

positional data is integrated into the Hyperspec®III software. A flash drive containing the IMU MT-Manager is included

within the package. The MT-Manager is also available to install directly from the Hyperspec®III installer, when

Hyperspec®III is first installed onto the computer. During the system software loading and system set up process, the

Nano-Hyperspec®and IMU units are configured to operate together. When ordered together this integration is done at the

Headwall facility prior to shipping.

The IMU specifications are listed in the following table. The value CEP is (Circular Error Probability), defined as the

radius of a circle centered on the true value that contains 50% of the actual GPS measurements. So a receiver with 1 meter

CEP accuracy will be within one meter of the true measurement 50% of the time. The other 50% of the time the

measurement will be in error by more than one meter.

AIRBORNE PACKAGE

1-6

1.2.3 GPS Antenna.

The GPS antenna is used to define the initial location of the Nano-Hyperspec®unit once the IMU has been installed.

During the flight the GPS antenna captures the location of the system and sends that data to the IMU and Nano for

inclusion into the data. Within the data capture folders two files identify the GPS data, the Frame Index file and the

gpsMonitor file. To optimize results the GPS antenna should be positioned within 10 cm of the IMU device. The GPS

antenna positional information is also used for triggering the Nano remotely. This is a feature that is useful for flying a

defined polygon pattern. From the start point polygons and patterns are developed to enable the user to set data collection

parameters. The use of polygons and other patterns is found in Section, GPS Configuration and Polygons of this manual.

Figure 1-4. GPA Antenna.

Table 1-1. IMU Specifications

Parameter Value

GPS Update Rate 4 Hz

Horizontal Accuracy Position SPS 2.5 m CEP

SBAS 2.0 m CEP

Vertical Accuracy Position SPS 5 m

Velocity accuracy 0.1 m/s @ 30 m/s

Start-up Time, Cold start 27 s

Re-acquisition < 1 s

Tracking Sensitivity -161 dBm

Timing Accuracy 30 ns RMS

Maximum Altitude 18 km

Maximum Velocity 515 m/s

Max dynamics GPS 4 g

AIRBORNE PACKAGE

1-7

1.3 IMU CONNECTION AND ORIENTATION.

The IMU has internally defined coordinate systems to identify the X, Y and Z coordinates. It also contains an internal

magnetometer that can be disturbed when proximate to power cables which generate a flux field.

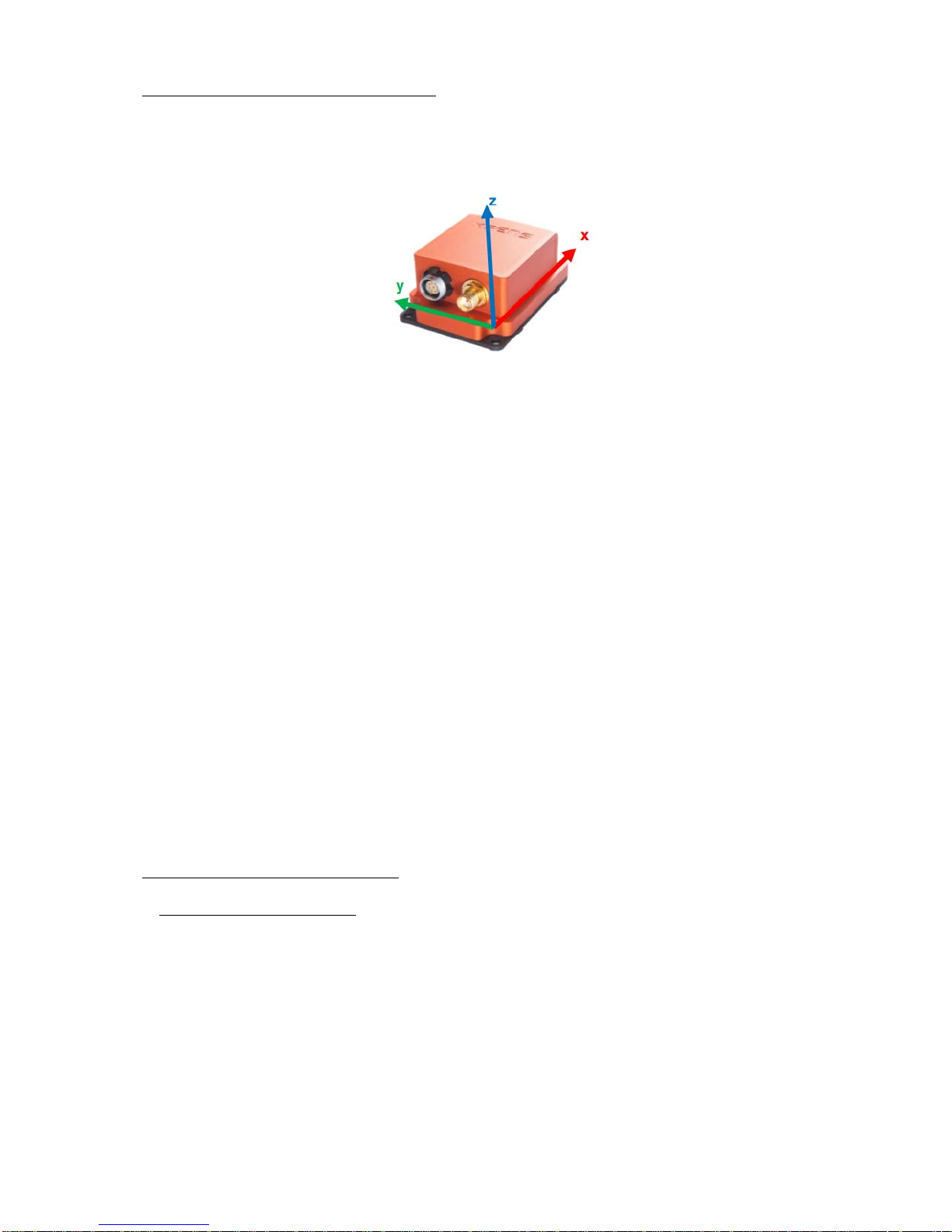

Figure 1-5. IMU Coordinates.

The coordinates, x,y,z, are shown in the previous figure and correspond to the local earth-fixed reference co-ordinate

system. This coordinate system is defined as a right handed Cartesian co-ordinate system with:

a. X positive to the East (E).

b. Y positive to the North (N).

c. Z positive when pointing up (U).

The coordinate system is also known as ENU and is the standard in inertial navigation for aviation and geodetic

applications. Note that it is possible to change the coordinate system with respect to the IMU using an alignment matrix or

orientation reset. However, for this manual the default coordinate system will be used.

The IMU is mechanically attached to the Nano-Hyperspec®with the supplied mounting screws. The Nano has mounting

holes on more than one surface of the unit. The motion tracking device can be mechanically attached to the Nano in a

number of configurations that depend upon how the Nano-Hyperspec®will be mounted to the support or scanning

platform. The most common and preferred configuration is shown below in Figure 1-7. This is the position number 2

identified in Figure 1-7. Each customer application of the Nano may have its own preferred configuration with the IMU,

depending upon the platform used and orientation needed.

The IMU is attached to the Nano such that when the Nano is mounted on the moving platform the y axis is aligned with

the body of the platform. When performing initial system set up the y axis should be pointing positive North and the x axis

pointing positive East.

The particular IMU device shipped with the Nano is oriented and factory set in position number 2. This has proven to

optimize results and ortho-rectification processes.

1.4 COMPONENT INTERCONNECTION

1.4.1 Nano Computer Connection.

To set the Nano for remote scanning, connect one end of a Cat 6 cable to the Nano RJ-45 port and the other end to the

computer operating Hyperspec®III. Set the parameters for the flight, leave the Nano powered ON and disconnect the Cat

6 cable. Once the scan is complete, the data from the Nano-Hyperspec®needs to be downloaded to the operating

computer for storage and analysis. Reconnect the Nano-Hyperspec®to the computer, with a Cat 6 cable to the RJ-45 port

on the Nano-Hyperspec®and the other to the RJ-45 port of the operating computer. With the computer and Nano powered

ON, open the Hyperspec®III application and select the File Transfer button. Use the pop up and navigate to the desired

capture folder and the files will be unpacked and saved.

AIRBORNE PACKAGE

1-8

1.4.2 Power Connection.

The Nano-Hyperspec® uses 9.5 to 25 VDC power. Connect the positive and negative leads to an appropriate power

source. Insert the power connector into the Nano Power Connector location, identified the following figure.

Figure 1-6. Nano Power Location.

The IMU receives the power from the Nano through the LEMO-Data cable, supplied with the airborne package.

The following table identifies the wires coming from the Nano power connector.

Table 1-2. Power Connector Pin Out

Pin # Function IO Format Wire Color Comments

1 Ground Power Black

2 Voltage Input Power Red Voltage Input Range

+9.5V to +25V

3 Ground Power Black

4 Voltage Input Power Red Voltage Input Range

+9.5V to +25V

5 Voltage Output Power Blue Voltage output is +5V

with a maximum

current of 250mA

6 Voltage Output Return Power Black

7 GPIO3 General Purpose IO Brown 0 to 5V range

AIRBORNE PACKAGE

1-9

1.4.3 Nano-IMU Attachment.

Figure 1-7. Nano-Hyperspec®with IMU.

NOTE

The particular IMU device, shown above, and shipped with the Nano should be

oriented such that the X axis points in the direction of travel for the Nano/IMU

assembly.

For aerial data collection the user attaches the IMU to a Headwall sensor and mounts the pair onto a viewing platform.

When ordered, the IMU can be installed and configured at the Headwall facility prior to shipping. When the Nano is

prepared for use, the IMU can be attached to only one of the four sides of the Nano that match the mounting holes of the

IMU. The decision on which face to mount the IMU depends on how the Nano is mounted to the aerial platform and the

flight plan. The following image shows the four possible Nano/IMU orientations. The strongly recommended mounting

orientation is labeled #2 in the following figure. This orientation corresponds to the ortho-rectification identified in the

SpectralView®section of Headwall manuals. If the IMU mounting is different it may affect the ortho-rectification.

8 GPIO2 General Purpose IO Yellow 0 to 5V range

9 GPIO1 General Purpose IO Purple 0 to 5V range

10 GPIO0 General Purpose IO Orange 0 to 5V range

Table 1-2. Power Connector Pin Out

Pin # Function IO Format Wire Color Comments

AIRBORNE PACKAGE

1-10

Figure 1-8. Four IMU Orientations.

Notice in the above figure that from left to right the word HEADWALL rotates from the twelve-o-clock position through

to the nine-o-clock position. Additionally, the orientation of the IMU to the front/back axis of the Nano varies. These

positional variations are what need to be accounted for in the Ortho-rectification step of the data cube analysis. The

factory configuration for the Nano/IMU configuration is #2 above. Contact Headwall Support if this configuration cannot

be used.

Attaching an IMU to the Nano requires that the three holes in the central part of the face plate be used. Do not attempt the

use screws longer other than the supplied M3 x 0.5 x 6mm. Using longer screws will damage the Nano.

Use the following steps to attach the IMU to the Nano.

a. Remove the IMU and supplied mounting screws from the package.

b. Remove the Nano from the package and place onto the workspace, with the lens facing forward and the ON/OFF

switch to the right of the lens. This is position 2 above. The mounting holes are circled in the following figure.

Figure 1-9. Position 2, No IMU.

a. Place the IMU onto the top of the Nano. Orient the IMU according to the y axis being aligned with the platform’s

body and the z axis facing upward.

b. Move the IMU so the clearance holes for the screws match the mounting holes on the Nano, Figure 1-3.

AIRBORNE PACKAGE

1-11

Figure 1-10. IMU on Top of Nano.

c. Insert and finger tighten the screws, M3 x 0.5 x 6mm, into the respective holes in the IMU.

d. Gently tighten the screws in place, using an Allen wrench.

Once the Nano/IMU assembly is complete, to become operational, the IMU requires power. To power the IMU perform

the following steps.

1.4.4 IMU Data/Power Connection.

NOTE

When using the IMU it is important that the system power cables be secured the

maximum distance from the IMU. This will prevent magnetic interference,

orientation problems or possible damage to the unit.

a. Orient the Nano, with the IMU attached, so the Nano serial number label and cooling fan are facing forward, as in the

following figure. The IMU data port is the white connector, as shown.

Figure 1-11. Nano-Hyperspec® Data Port View.

AIRBORNE PACKAGE

1-12

b. Remove the LEMO-Data cable from the airborne package.

Figure 1-12. LEMO-Data Cable.

c. Hold the data serial connector and orient it so the holes in the cable-end connector match the pins in the Nano data

port connector.

d. Place the cable-end connector into place in the Nano data port connector and press down on connector edges until it is

completely secure.

NOTE

The LEMO to Serial cable is sized to the customer’s configuration. For this reason the

cable may be a different length than that shown in the above figure.

Figure 1-13. Cable Connector secured in Nano Connector Housing.

e. Hold the LEMO-Data cable, take the LEMO connector and align the red dot on the LEMO connector to the red dot on

the IMU connector, shown in Figure 1-14.

AIRBORNE PACKAGE

1-13

Figure 1-14. Align Red Dots, LEMO and IMU.

CAUTION

Do not twist the LEMO connector into the IMU connector. This will damage the pins

and make the cable useless. The LEMO is a push-pull connector.

f. Hold the Nano in place and gently press the two connector pieces together until the connectors appear as below,

Figure 1-15.

Figure 1-15. Secured LEMO-IMU Connectors.

g. Once the two halves are pressed together, turn the locking wheel clockwise until it stops. This secures the LEMO

connector into place.

h. Secure the slack cable, if any.

AIRBORNE PACKAGE

1-14

1.4.5 IMU, GPS Connection.

a. Remove the GPS Antenna from the package.

Figure 1-16. GPS Antenna.

b. Take the motion tracker connector and align it with the gold connector on the IMU.

Figure 1-17. GPS to IMU Connection.

c. Once aligned, press the two halves together and turn the ferrule clockwise to secure the connector to the IMU.

d. Secure the GPS antenna to a location on the aerial platform and secure any excess cable. If the GPS antenna is used

on a UAV body that is conductive material, such as aluminum, the GPS antenna performs best when mounted outside

the body. For optimal results, it is suggested that the GPS antenna be located within 10cm of the IMU device.

1.5 CONFIRM NANO TO IMU CONNECTION

With the IMU/ GPS connected to the Nano, use the Cat 6 cable to connect the Nano to the computer that contains the

Hyperspec®software.

Power ON the computer and then power ON the Nano. Wait for the Nano LED to turn green. Open Hyperspec®III. The

Log Dock should show blue letters. If red letters appear an error requires correction. There are two possible sources or

errors: The first is identified as White and Dark references. These are minor errors and require the user to establish new

AIRBORNE PACKAGE

1-15

references prior to operation. Follow the steps in the Hyperspec®III manual for this procedure. The second possible error

may be the connection between the Nano and the GPS. If a GpsMonitor Command error occurs it indicates the Nano is

not recognizing the IMU. The source can be either system configuration or a cable fault. To correct the configuration error

perform the following steps:

(1) Click the Settings button in Hyperspec®III.

(2) Click the Sensor tab in the Settings window.

(3) Within the Sensor tab there is a section for Devices, one of which is the GPS.

free

Figure 1-18. Identified GPS Selection.

(4) Click the GPS drop down, select the IMU that is attached to the Nano.

(5) Click the Save button and close Hyperspec®III. Then re-open Hyperspec®III.

The Log Dock should have no error messages if this was the source. If a red error message shows, check the cable

connections, verifying they are both correct and firmly secured. If the cables are secure, there is a fault in one of them

which needs to be replaced.

AIRBORNE PACKAGE

1-16

1.6 FLIGHT PLANNING

The Nano performs hyperspectral scanning, identified as push broom scans. This means that during the flights the sensor

should always move in a forward facing direction. Moving in one direction, holding the sensor facing forward, side

slipping and then reversing direction may capture raw scan data, while creating difficulty in post processing steps. This

back and forward flight is not recommended.

There are two operational platforms to capture scans while in flight: manned and unmanned, UAS, aircraft. This section

deals with UAS flights. When setting the flight plan for a UAV/UAS the best results can be gathered when all factors are

considered in the pre-flight process.

The first step is planning for optimal atmospheric conditions. This generally means flights in the morning, before

environmental heating generates wind and thermals in the scanning area. These can affect the UAS flight stability and

subsequent scan clarity. Also, the topography is important, flights aimed at uniform terrain will yield better results that

those including random, irregular elevations.

A second consideration is whether to use manual triggering or GPS/automatic triggering. The manual triggering is done

through the UAS flight controller and the UAS power source sending a trigger signal to the Nano. To obtain a good scan,

the operator needs to very accurately observe way-points, and scan only when they are reached. When scanning large

areas, this may prove problematic through a combination of distance and visual accuracy. GPS triggering can be set using

the Headwall Polygon tool. Headwall recommends using the polygon tool, http://www.headwallphotonics.com/polygon-

tool, as a means of identifying the scan area and setting the GPS start and stop triggers for the Nano. This, coupled with

preprogrammed, automatic flight, eliminates the operator variable in the scanning process, and generally leads to better

results.

1.6.1 Setting Capture Options.

Connect the Nano, using the Cat 6 cable, to the computer with Hyperspec®III installed.

Power ON the computer, allow it to fully boot.

Open Hyperspec®III.

Power ON the Nano. Wait for the LED to glow green.

Check the Log Dock in Hyperspec®III and confirm the Nano is connected to the software.

Remove the lens cap from the Nano and click the Live Video button on the Button Dock. The result should be similar to

the following figure.

Figure 1-19. Nano, Connected to Computer.

Other manuals for Nano-Hyperspec

1

Table of contents