Health in motion Sunset Swings 422SB Supplement

Sunset Swings®

By Health In Motion,

LLC

!

!

!

!

!

!

!

Model 422SB

Dual Recliner Swing

Assembly & Operation Manual

!

!

!

Record Serial Number Here

!

!

!

!

www.sunsetswings.com !

!

September 2018

!

Caution

:

READ! VERY

IMPORTANT

FOR ADULTS

ONLY

Ensure that the 422SB swing is set up on a firm level surface.

!

!

Make sure the swing has completely stopped before entering or exiting the swing. Be

careful as the swing may shift while sitting down or getting up from the swing.

!

!

The foot rest should be tucked under the seat when entering or existing the swing.

!

!

Keep all body parts within the swing seat while in motion.

!

!

Make sure bystanders are at least 5 feet away from the swing while it is in motion. Be

careful placing the swing too close to a structure as severe injury might occur if a

person gets caught between the structure and the swing or damage might occur if the

swing hits the structure.

!

!

Be cautious swinging while children are present as they may stray into the path of the

swing.

!

!

Review the maintenance schedule before each use to ensure the swing is in good

working order.

!

!

This swing is for casual relaxation swinging only.

!

!

In freezing climates, the canopy should be removed, folded and stored in a dry place before the

first freeze or snow and until the last freeze or snow has passed. Failure to follow these

instructions can cause damage to the canopy or canopy rods and will void the warranty.

!

!

The canopy is not designed for high winds. If high winds are expected, please remove the

canopy. Failure to follow this instruction can cause damage to the canopy or the canopy rods

and will void the warranty.

!

!

The swing uses a natural hardwood which might contain slight imperfections.

!

!

!

!

Page 1

!

Thank you for choosing Sunset Swings®. Please read the contents of this manual

thoroughly.

The information inside will help you in many different areas. You will need to send in

your

customer registration card at the back of this manual to validate your warranty. You may

also

complete your customer registration at

www.sunsetswings.com.

!

!

!

!

!

Table of Contents

!

Positioning Your Swing 3

!

!

Tools Required For Assembly 3

!

!

Helpful Installation Hints 3

!

!

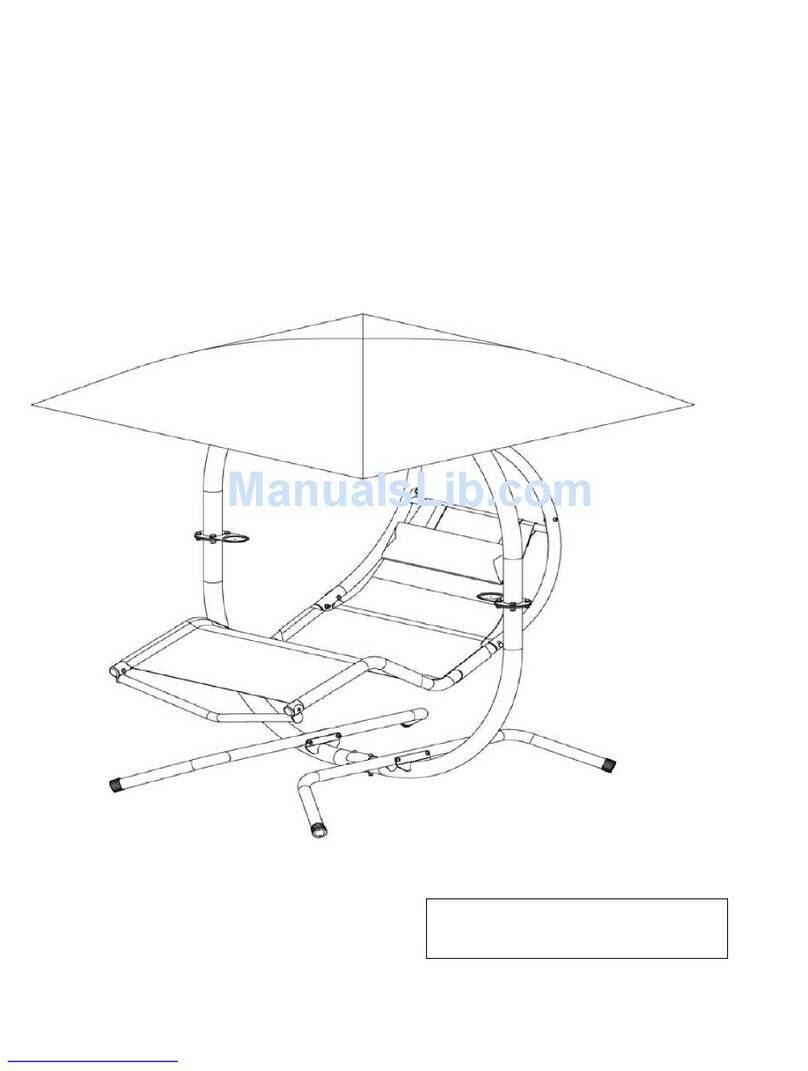

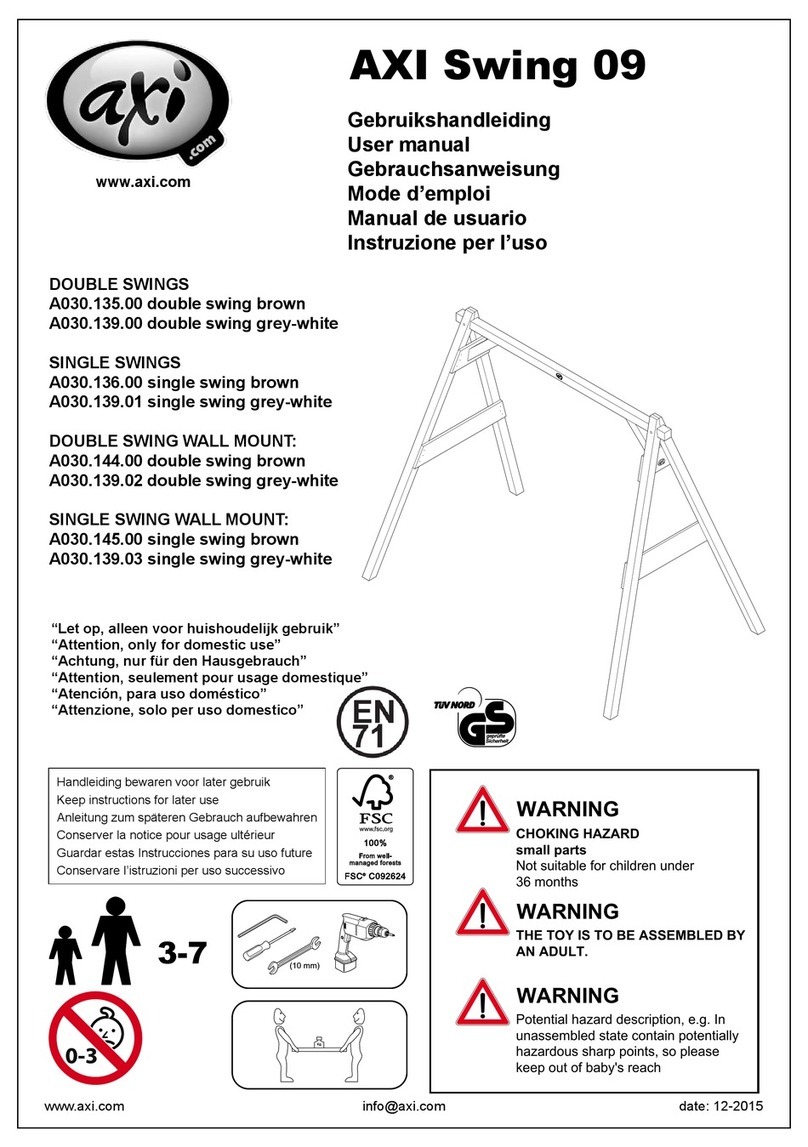

Exploded Swing Diagram 4

!

!

Hardware and Tool Diagram 5

!

!

Parts and Hardware List 6

!

!

Assembly Instructions 7-16

!

!

Adjustments 17-18

!

!

Weekly Maintenance Information 19

!

!

Safety Information 20

!

!

Label Reference 21

!

!

Limited Warranty 22

!

!

Warranty Claim Procedure 22

!

!

!

!

!

!

!!Sunset Swings® by Health In Motion LLC reserves the right to alter the specifications of this product at any time.

!

!

!

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!Page 2

!

Positioning Your Swing

!

!

1. The swing is designed to be installed on a firm level surface.

!

!

2. There should be a minimum clearance of five feet in front and back, and two feet on

each side of your swing. It should be placed in an area where children will not stray

or walk into the path of the swing.

!

!

3. Be careful placing the swing too close to a structure as severe injury might occur if

someone gets caught between the structure and the swing or damage might occur if

the swing hits the structure.

!

!

!

!

Tools required for assembly

!

!

1. 10, 14, 17 and 19 mm box or ratchet wrench

!

!

2. 4, 5 and 6 mm Allen wrenches (supplied with the hardware)

!

!

!

Helpful installation hints

!

!

1. At least 2 people are required to assemble this swing. Some parts are

large and heavy. Use care when handling.

!

!

2. Identify all of the parts for your swing. Empty the boxes and lay out the parts for

identification using the Parts List.

!

!

3. Read all the way through the instructions completely before beginning the assembly.

!

!

4. Do not tighten hardware completely until instructed. It helps to have some adjustment

for bolt alignment while you are connecting parts. Follow the tightening sequence as

mentioned in the steps. After you have completed the assembly, recheck

that all hardware is secure and tight.

!

!

!

!

!

!

Page 3

Page 4

65

55

67

24

31

17

5329

10

72

56

53

34 3419

43

71

69

56

35

30

11L

71

26 22R

19

12L

68

65

57

714

12R

11R

40

41

38

46

64

54

5958 555423

33

13

EXPLODED DIAGRAM

34

31

52

52

9

62

18

9

2

62

62

21

18

262

49

1

68

57

36 22L

52

52

5

39 5225

21

44

61

51

49

3R

1

73

50

873

50

504

51

3L

50

20

63

27

48

67

14

66

16

6

8

25

26

27

28

28

28

28

30

30 30

32

33

33

33

34

35

36

38

38

39

40

41

43

43

44

44

44

44

45

4545

45

45

45

45 45

4545

45 45

45

45

45

45

45

45

45

76

76

47

47

48

61

61

61

61 61

61

61

61

61

63

64

64

64

64

6464

66

66

66

66

70

70

70 70

70

70

70

70 70

70

70

70

70

70

70

70

70

72

!

Page 5

#46 M8 Lock Nut (Qty 4)

#56 M5 x 5

8" Socket Cap Head Bolt (Qty 4)

#50 M12 x 1 3

8" Hex Head Bolt (Qty 8)

#49 M10 x 3 1

2"Button Head Bolt (Qty 4)

0

0 1 2

mm

2"1" 3"

345 86 7

4" 5"

119 10 1412 13

6"

15

#53 M10 x 2 1

4" Carriage Bolt (Qty 8)

#51 M10 x 3 1

4" Carriage Bolt (Qty 2)

#52 M10 x 2 3

4" Carriage Bolt (Qty 16)

#55 M6 x 1 7

8" Hex Head Bolt (Qty 4)

#54 M6 x 1 1

8"T-Nut (Qty 4)

#63 M10 Flat Washer (Qty 2)

#61 M12 Flat Washer (Qty 16)

#70 M10 Arc Washer (Qty 30)

#66 M6 Flat Washer (Qty 16)

#64 M8 Flat Washer (Qty 1 6)

#45 M10 Lock Nut (Qty 32)

#44 M12 Lock Nut (Qty 8)

#72 M5 Lock Washer (Qty 4)

#57 M8 x 4 1

8" Button Head Bolt (Qty 4)

#58 M6 x 1 1

2" Button Head Bolt (Qty 4)

#76 M8 x 1 5

8"HexHead Bolt (Qty 4)

#68 M6 x 3

4" Button Head Bolt (Qty 4)

#69 M6 x 2 3

4" Button Head Bolt (Qty 2)

#41 M6 x 1 1

8" Hex Head Bolt (Qty 4)

#47 M10 x 3 1

8" Carriage Bolt (Qty 2)

#59 M6 Fender Washer (Qty 4)#60 TOOL:4mm Allen Wrench (Qty 1)

#38 M6 Lock Nut (Qty 10)

#42 M8 Fender Washer (Qty 4)

#43 M10 Big Flat Washer (Qty 12)

#74 TOOL:6mm Allen Wrench (Qty 1)

#75 TOOL:5mm Allen Wrench (Qty 1)

#48 M10 ThickLock Nut (Qty 4)

#67 M8 x 5

8"Button Head Bolt (Qty 4)

!

!

!

Page 6!

Part# Description Q'ty (pcs) Part# Description Q'ty (pcs)

1Bent Leg 238 M6 Lock Nut 10

2Curved Flange 239 Bearing 4

3L Right Upright Assembly 140 Dock Washer 4

3R Left Upright Assembly 141 M6*1 1/8" Hex Head Bolt 4

4Top Beam Assembly(with Bearing Housings installed) 142 M8 Fender Washer 4

5Bearing Housing 243 M10 Fender Washer 12

6Adjustable Canopy Support Assembly 144 M12 Lock Nut 8

7Extension Spring 445 M10 Lock Nut 36

8Pivot Shaft 246 M8 Lock Nut 4

9Swing Support Arm 447 M10*3 1/8" Carriage Bolt 2

10 Seat Frame 248 M10 Thick Lock Nut 4

11R Left Seat Bottom Tube 249 M10*3 1/2" Button Head Bolt 4

11L Right Seat Bottom Tube 250 M12*1 3/8" Hex Head Bolt 8

12R Left Seat Back Tube 251 M10*3 1/4" Carriage Bolt 2

12L Right Seat Back Tube 252 M10*2 3/4" Carriage Bolt 16

13 Head Board Bracket 253 M10*2 1/4" Carriage Bolt 8

14 Ratchet mechanism 454 T-Nut 4

15 Headrest Base Frame 255 M6*1 7/8" Hex Head Bolt 4

16 Tilting Headrest Assembly(pre-assembled) 256 M5*5/8"Socket Cap Screw 4

17 Footrest Frame 257 M8*4 1/8" Button Head Bolt 4

18 Wood Support Bracket 258 M6*1 1/2" Button Head Bolt 4

19 Fabric 459 M6 Fender Washer 4

20 Canopy 160 4mm Allen Wrench 1

21 Wood Table 261 M12 Flat Washer 16

22L Left Wood Arm 262 M10*3" Carriage Bolt 4

22R Right Wood Arm 263 M10 Flat Washer 2

23 Head Board 264 M8 Flat Washer 16

24 Footrest Pad 265 M10*2 1/8" Button Head Bolt 4

25 Φ1" Spacer 466 M6 Flat Washer 16

26 Fabric Rod 867 M8*5/8" Button Head Bolt 4

27 Canopy Rod 468 M6*3/4" Button Head Bolt 4

28 Swing Foot 469 M6*2 3/4" Button Head Bolt 2

29 Retainer End Bumper 270 M10 Arc Washer 30

30 30*40*45 Deg End Cap 871 ST3.5*1" Wood Screw 8

31 Foot Rest Left 272 M5 Lock Washer 4

32 Foot Rest Right 273 Set Screw 4

33 30*40 End Cap 874 6mm Allen Wrench 1

34

Φ2" End Cap 475 5mm Allen Wrench 1

35 Film Washer 876

M8*5/8" Hex Head Bolts 4

36 Thick Plastic Washer 4

parts list

hardware list

!

!

!

! !

!

!

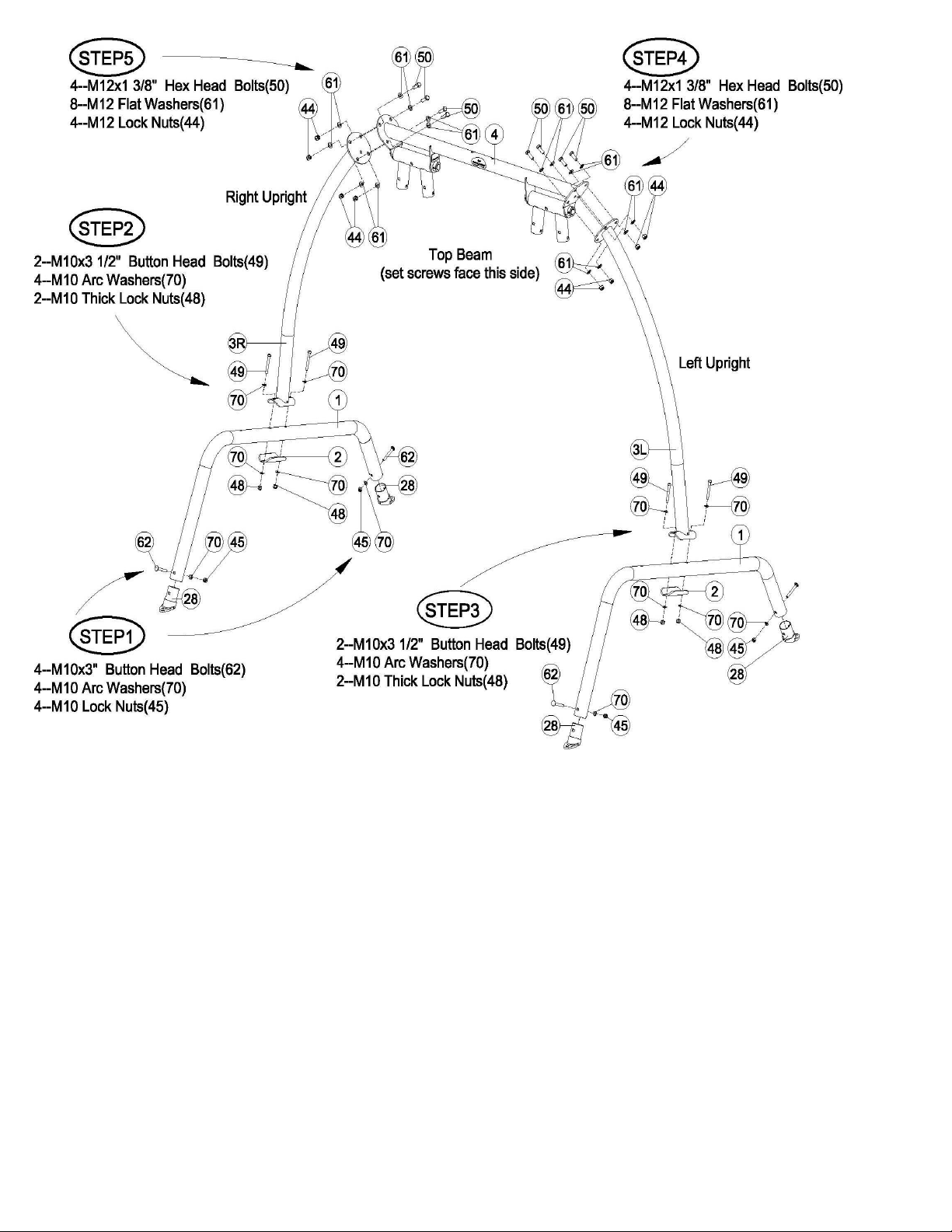

!!!!!!!!!!!!!!!Two people are required for Steps 1 through 5

!

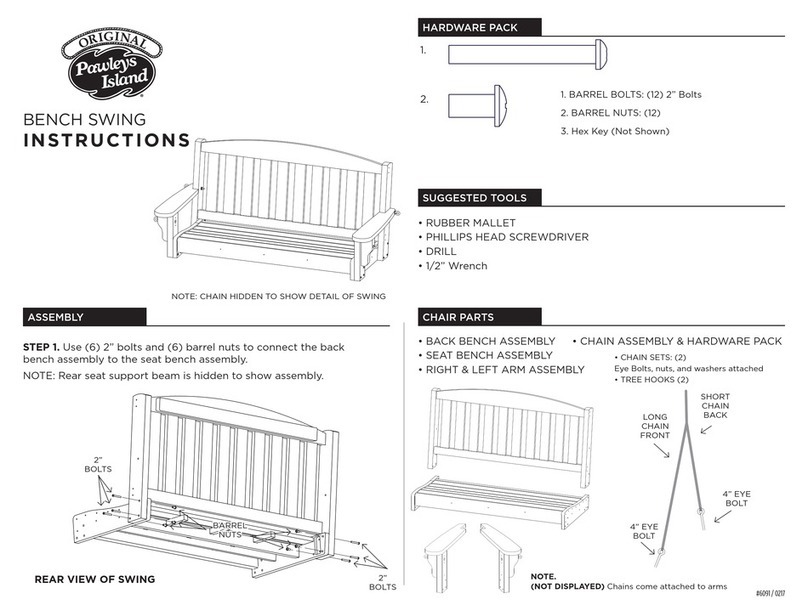

Steps 1. Attach the Swing Feet(#28) to both Bent Legs(#1)

Steps 2 and 3. Attach the Bent Legs(#1) to the Right(#3R) and Left(#3L) Uprights.

Steps 4 and 5. Attach the Top Beam(#4) to the Right(#3R) and Left(#3L) Uprights. Ensure that the Set

Screws that hold the Bearing Shaft to the Top Beam(#4) are facing towards the front of the swing.

!!!

!!!!Wrench tighten all hardware now

!

!

Page 7

!

!

!

!

Step 6. Attach the Canopy Mount(#7) to the Top Beam(#4).

Wrench tighten all hardware now.

Page 8

!

!

!

!

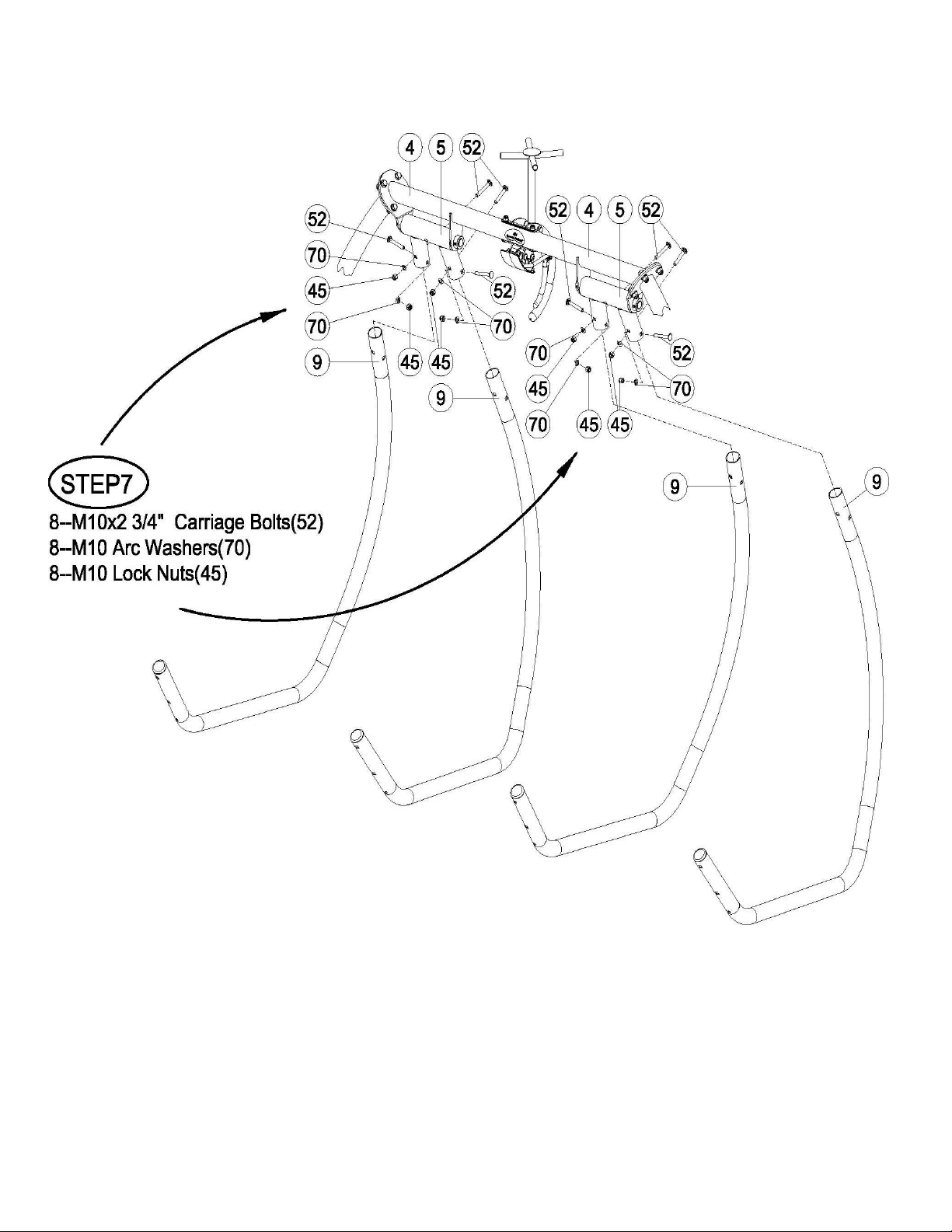

Step 7. Attach the Swing Support Arms(#9) to the Bearing Housing(#5).

Finger tighten the hardware at this time.

Page 9

!

!

!

!

!

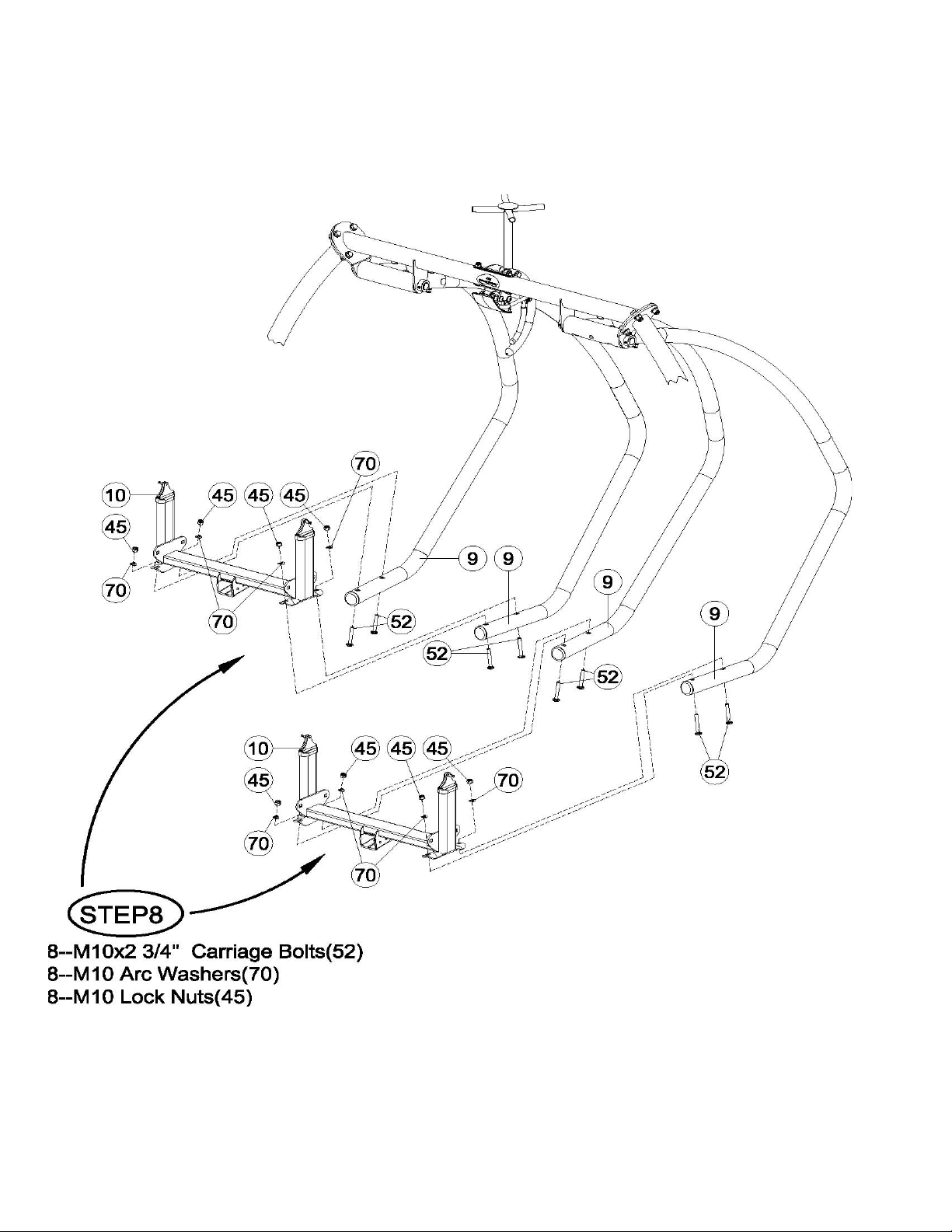

Step 8. Attach the Seat Frame(#10) to the Swing Support Arms(#9).

Tighten all the hardware in Steps 7 and 8 now.

Page 10

!

!

!

!

Make sure the fabric has been fully inserted into the groove of the Seat Bottom Tubes

before tightening the hardware. The fabric can not be adjusted afterwards.

Step 9. Attach the Left(#11L) and Right(#11R) Seat Bottom Tubes to the Seat Frame(#10). Apply the

four nuts to the four 2 1⁄4 bolts with only 3 to 4 turns before continuing to fully tighten each bolt to

stretch the fabric.

This step stretches the fabric. If the hardware on one side of the Seat Bottom Tube is fully tightened

to the Seat Frame before the hardware on the other side of the same chair, the other side can not be

attached without loosening the first side. After applying all 4 nuts by about three turns each,

incrementally tighten all 4 nuts in sequence until the Seat Tubes are fully tightened against the Seat

Frame Flanges.

Repeat Step 9 for the other seat.

Wrench tighten all the hardware after getting all 4 nuts started on the bolts.

Page 11

!

Step 10. With the metal ratchet mechanism, under each wooden armrest, placed so that it is closest to

the Seat Frame Mounting Arm, attach the end of each Left(#22L) and Right(22R) Wood Arm to the

Left(#12L) and Right(#12R) Seat Back Tube.

Step 11. Hook the forward end of the Extension Spring to the top of the Seat Frame Mounting Arm

as shown in the circle in the lower right area of the picture.

Mount the ratchet mechanism under the Wood Arm to the Seat Frame. Repeat Steps 10 and 11 for

the other seat.

Wrench tighten all hardware now but do not over tighten the arms or ratchet which

would prevent smooth motion for the seat back adjustment.

Page 12

!

!

!

Step 12. Attach the metal Head Board Bracket(#13) to the Right(#12R) and Left(#12L) Seat Back Tubes.

This step stretches the fabric at the top of the seat back. Start the hardware with just 3 to 4 threads until

you get both sides started. Continue to tighten the bolts until you can get the hardware in Step 12 started.

Step 13. Finish attaching the metal Head Board Bracket to the Right and Left Seat Back Tubes.

Repeat Steps 12 and 13 for the other seat.

Wrench tighten all the hardware now.

Page 13

!

!

!

!

!

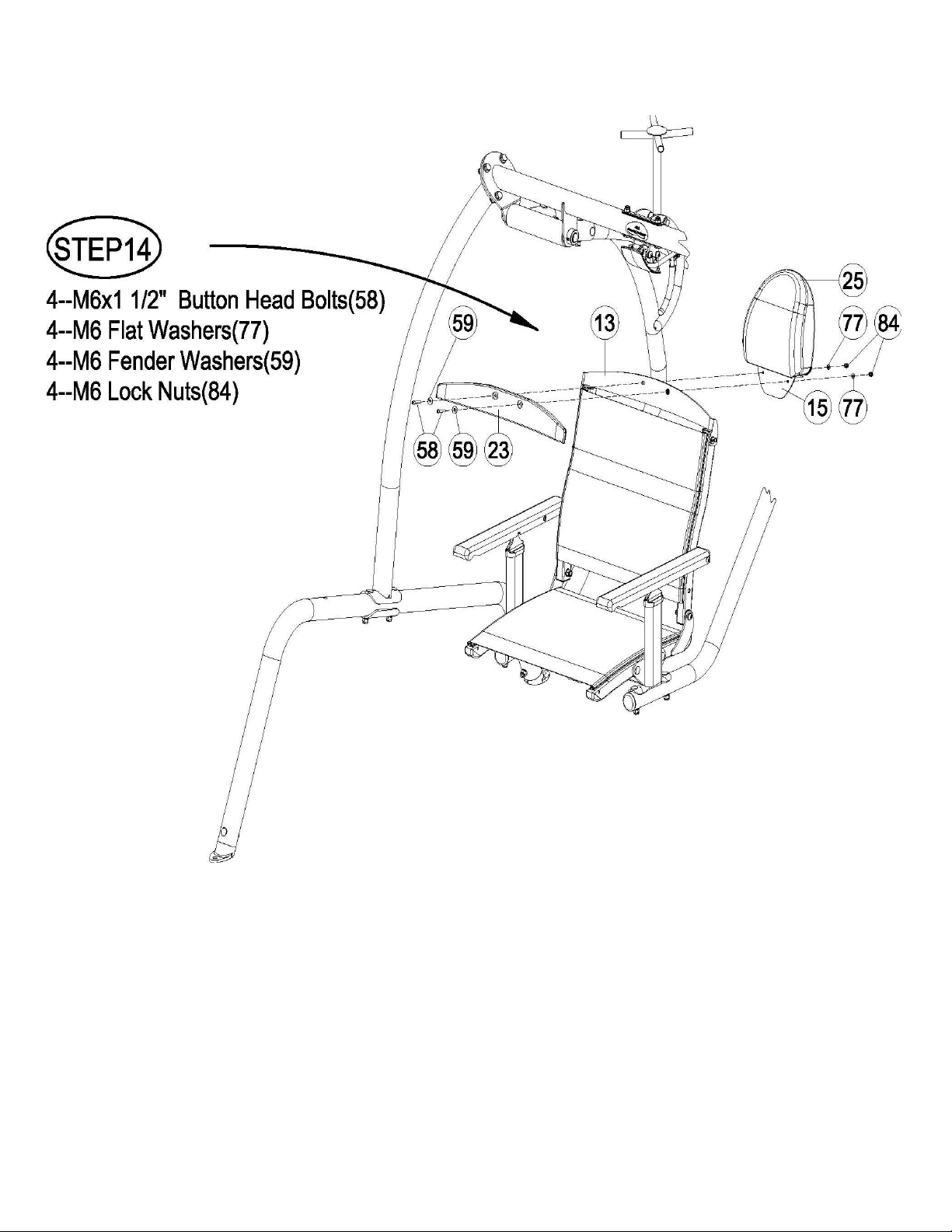

Step 14. Attach the Head Board(#23) and Head Rest(#25) to the Head Board Bracket(#13).

Complete Step 14 for the other chair

Wrench tighten all the hardware now

Page 14

!

Step 15. Attach the Footrest Pad(#24) to the Footrest Frame(#17).!Step 16. Attach the Retainer End

Bumper(#29) to the back of the Footrest Frame(#17).

Complete Steps 15 and 16 for the other chair

Wrench tighten all the hardware now but do not over tighten or damage will occur the

Footrest Pad and the soft rubber Retainer End bumper.

Page 15

!

Step 17 and 18. Attach the table Wood Support Brackets(#18) to the Bent Legs(#1) and attach the Wood

Table(#21) to the Wood Support Brackets(#18). Tighten the hardware now.

Step 19 Place the Canopy Rods(#27) into the rod holder tubes on the Canopy Support Assembly(#6). They will

just sit in the tubes until the Canopy(#20) is put on the swing.

Note: If the canopy is too cold it will not stretch enough to get it over the last canopy rod.

Place the canopy in a warm room of the house until it warms up enough to stretch over the

last canopy rod.

Step 20 The Canopy is a rectangular piece of fabric with pocketed corners. Begin by laying the canopy on

top of the Canopy Rods. Then slide one of the pocketed corners of the Canopy onto one of the Canopy

rods. Continue around the Canopy until the last corner. Getting the last corner onto the Canopy Rod

requires stretching the fabric by pulling the canopy fabric towards the end of the canopy rod and slightly

down. Continue stretching the Canopy towards the end of the Canopy Rod until it slides into the corner

pocket of the Canopy.

Page 16

!

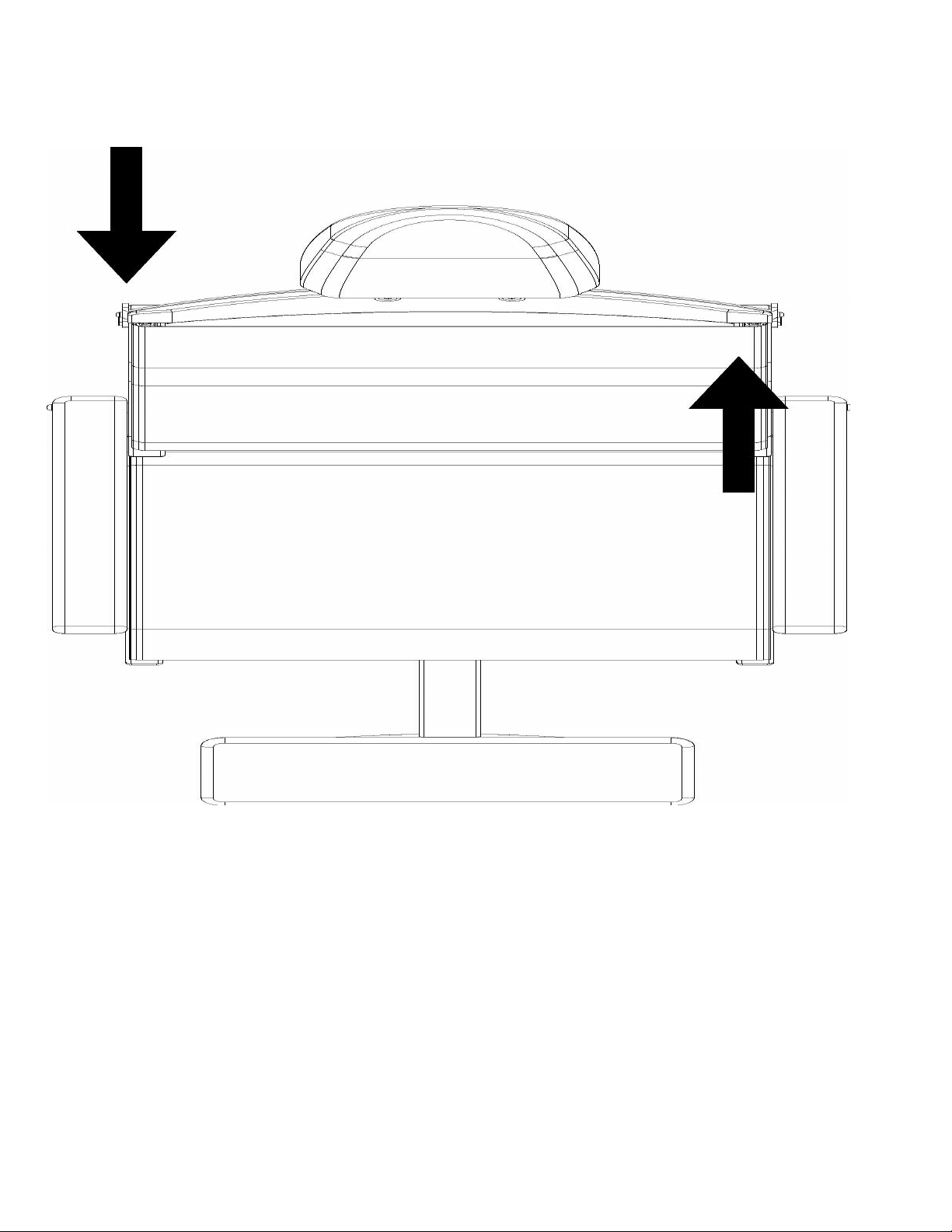

Seatback Adjustment

The seat back may need adjustment to appear even on both sides when looking down

from on top or if both armrests are not catching to hold the seat back firmly in place when

you lean back in the chair. Looking down from the top of the seat back if one side of the

seat back is further back than the other, gently twist the Seat Back Tubes to alter the seat

back’s natural position until it remains even without any force. Pressure should only be

applied in the directions shown above or in their reverse directions. When properly

adjusted, the ratchets on both sides of the seats will engage at each position at the same

time as the seat back is reclined and raised.

Page 17

!

Headrest Adjustment

If the headrest rotates too easily or too hard, adjust the resistance by tightening nut to

increase resistance or loosening the nut to decrease the resistance.

Page 18

!

422SB Swing Weekly Maintenance

!

!

Inspect and familiarize yourself with the safety warnings and other information that

is posted on the decals located on the swing or in the owner’s manual.

!

!

Inspect all fabric areas for tears and fabric seams for loose or damaged threads.

Replace immediately if needed.

!

!

Inspect all the hardware for proper tightness, Retighten if needed.

!

!

Inspect the wood for weather cracking. The wood is a natural product and there might

be slight imperfections that are visible. During normal weathering the wood may crack

slightly due to changes in moisture. This is a natural occurrence and does not affect the

structural integrity of your swing. The wood should be treated every 3 months, or as

needed, with a wood preservative. See your local hardware retailer for suggestions for

wood preservatives. Failure to protect the wood will void its warranty.

!

!

The canopy is not designed for high winds. If high winds are expected remove the

canopy. Failure to follow these instructions can cause damage to the canopy or canopy

rods and will void the warranty.

!

!

In freezing climates the canopy should be removed, folded and stored in a dry place

before the first freeze or snow and until the last freeze or snow has passed. Failure to

follow

these instructions can cause damage to the canopy or canopy rods and will void

the warranty.

Page 19

Table of contents

Other Health in motion Baby Swing manuals

Popular Baby Swing manuals by other brands

CANGAROO

CANGAROO JESSICA instruction manual

Kids II

Kids II Bright Starts Kaleidoscope Safari manual

Fisher-Price

Fisher-Price P6135 Assembly instructions

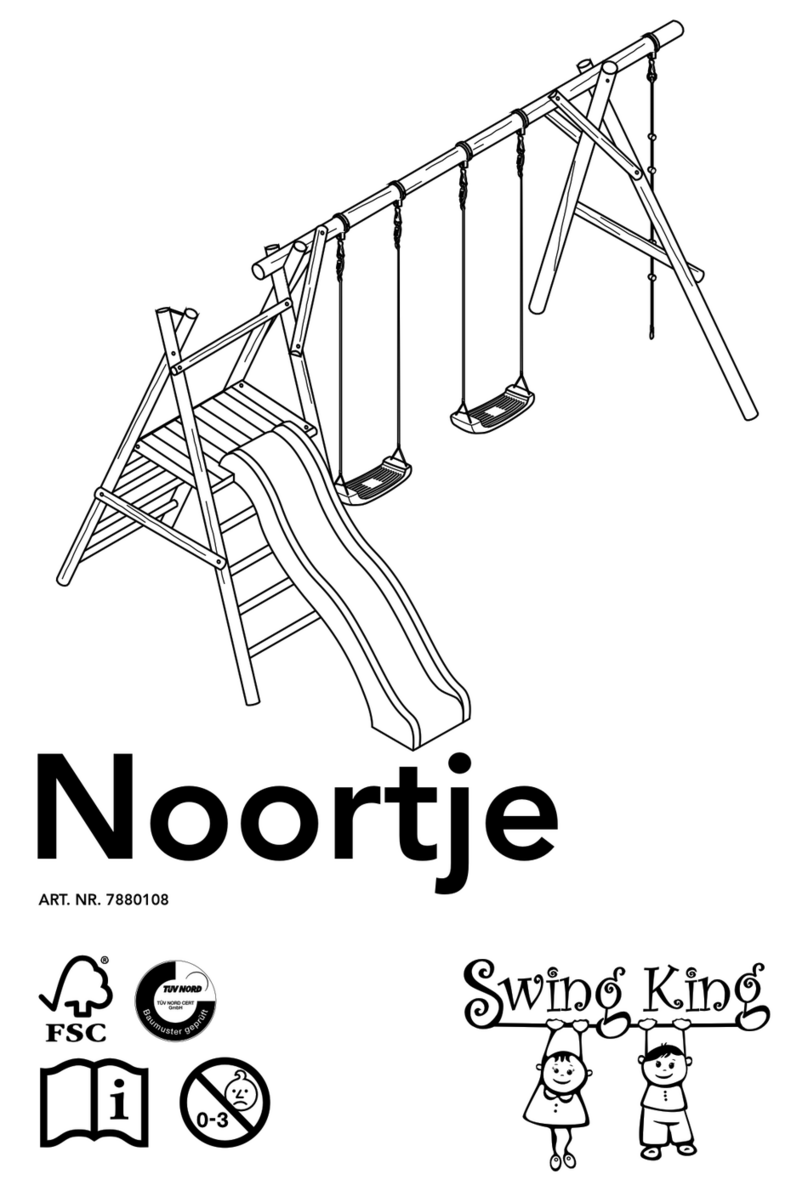

Swing King

Swing King Noortje quick start guide

Graco

Graco Simple Sway owner's manual

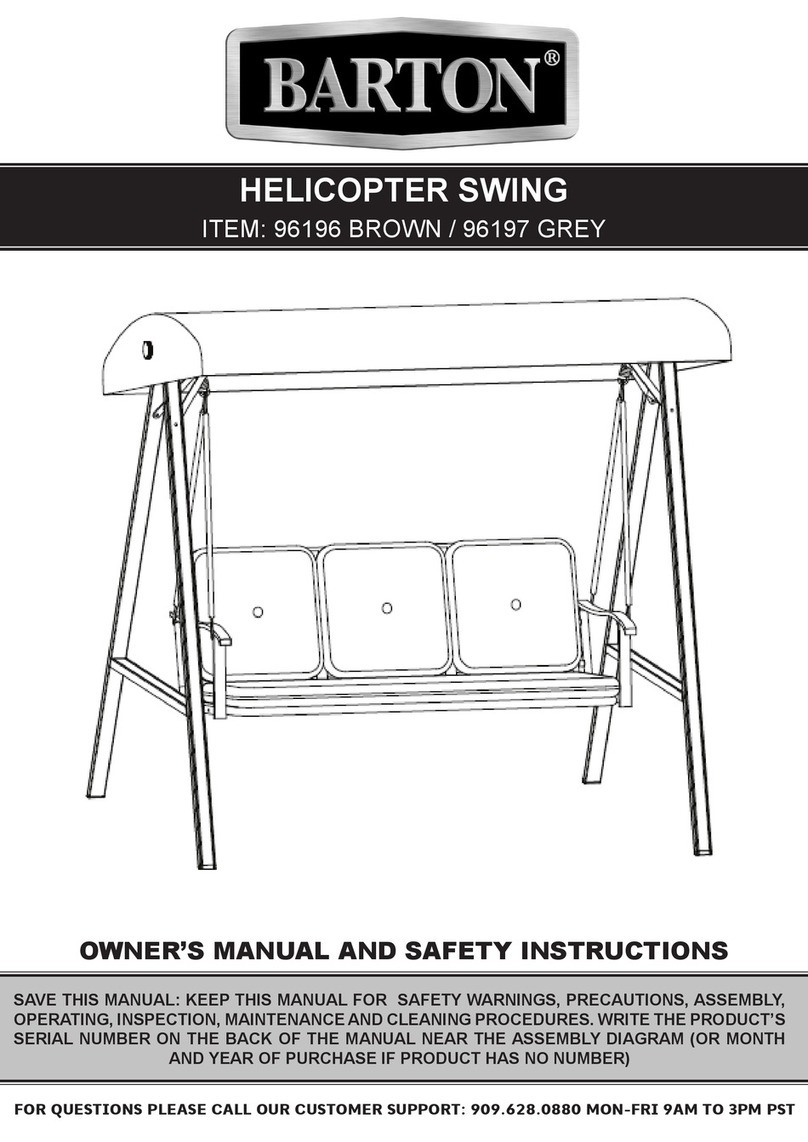

Barton

Barton HELICOPTER SWING 96196 Owner's manual and safety instructions