Heartland Appliances Legacy 3530 User manual

®

METRO LEGACY

SERIES II

SERVICE MANUAL Model 3530

30” Legacy

Model 3535

30” Metro

Model 3630

36” Legacy

Model 3635

36” Metro

Diagnosis Charts

Service Procedures

Component Data

Heartland Appliances Inc.

Manual No. MLSM2003-09-03

0910-1

MLSM2003-09-03Part# 0910-1 2

RepairManualforHeartlandAppliancesInc

Metro& Legacy Ranges

2003, September 3 HeartlandAppliancesInc.

1050FountainSt. N

Cambridge,Ontario;N3H 4R7

Allrights reserved. Nopart of thisbook may bereproduced in

anyformorbyanymeanswithoutwrittenpermissionfromHeartland

We have used all possible care to ensure the accuracy of

the information contained in this book. However, Heart-

land assumes no liability for any errors, omissions or any

defects whatsoever in the diagrams and/or repair proce-

dures or for any damage or injury resulting from utiliza-

tion of said diagrams and/or repair procedures.

Safety Information: Electric and Gas Ranges are complex

electromechanical devices. Any attempt to repair a range

may, if improperly performed, result in personal injury or

property damage. Heartland Appliances cannot be re-

sponsible for the interpretation of this manual, nor can it

assume any liability in connection with its use. For addi-

tional safety information, see page 5 of this manual.

3MLSM2003-09-03

Contents

Section 1: Safety Information ............................4

Section 2: Parts and Warranty ..........................5

Section 3: Technical Specifications ....................7

Section 4: Problem Diagnosis Chart ..................8

PleaseRefertoMainServiceManual

MLSM010601.

Amendment is intended to illustrate

changes made to the location of the relay

board and the new clock.

Section 5: Repair Procedures ........................... 9

A -Terminal Block 9

B-TimerReplacement 10

C-TimerProgramming 11

D - Broil Element 12

E - Self Clean Latch Mechanism 13

F-Timer Relay Board 14

G-TimerCoaxialCable 15

H-Cooling Fan & Thermodisk 16

I-Spark Module 17

J-RegulatorReplacement 18

K-GasConversion 19

L-Burner Caps 21

M - Electrodes 22

N-BurnerValves 23

O - Back Panel Access 24

P - StoveTop Prop Up 25

Section 6: Wiring Diagrams .............................26

Models3530/3535 26

Models3630/3635 27

Section 7: Exploded Views and Parts List ........28

NOTE: FORFULLSERVICENOTES,PLEASEREFER

TOSERVICEMANUAL#0910

Section 1

4MLSM2003-09-03

Safety Information

Important Safety Notice

HeartlandAppliances’Service

Manuals are intended for use by

individuals possessing

electrical, gas and mechanical

experience. Therefore,

Heartland Appliances cannot be

responsible for the interpretation

of its Service Manuals by those

not having a background of

electrical, gas and mechanical

experience, nor can it assume

any liability in connection with

their use.

Safe Servicing Practices

To preclude the possibility of

resultant personal injury and/or

property damage, it is imperative

that safe servicing practices be

observed. The following are

examples, but without limitation,

of such safe practices:

1. Before servicing, always

disconnect the product from

its source of electrical power

by removing the product’s

electrical plug from the wall

receptacle or tripping the

circuit breaker to OFF(or

removing the fuse) in the

branch circuit servicing the

product.

Note: If a specific diagnostic

check requires electrical

power to be applied such as

for voltage or amperage

measurements, reconnect

electrical power only for time

required for specific check,

and disconnect power

immediatelythereafter.

During any such check,

ensure no other conductive

parts, panels or yourself

come into contact with any

exposed current carrying

parts.

3. If a replacement part is

required ensure it meets

factory specifications.

4. Never by-pass or interfere

with the proper operation of

any feature, part or device

engineered into the product.

5. Prior to reconnecting

electrical power service to

the product, ensure that:

a) all electrical

connections

within the product

are correctly and

securely

connected,

b) all electrical

harness leads

areproperly

dressed and

secured away

from sharp

edges, high

temperature

components

(heaters, etc.)

and moving

parts,

c) any un-insulated

current-carrying

metal parts are

secured and

spaced

adequately from

all non-current-

carrying metal

parts,

d) all electrical

grounds (internal

and external to

the product) are

correctly and

securely

connected, and

e) all access panels

and covers are

properlyand

securely

assembled

followingthe

servicing and

prior to operating

the product.

6. On gas appliances, do not

disturb gas-carrying

components or connections

until gas service to it is shut

off, and do not use a flame

to test for gas leaks.

Following repair work,

ensure all gas connections

are properly secured by

testing for gas leaks with a

bubble (soap) solution.

7. Do not attempt a repair if you

have any doubts as to your

ability to complete it in a safe

and satisfactory manner.

Section 2

5MLSM2003-09-03

Parts & Warranty

HowTo Obtain Parts:

•Contact an authorized

Heartland dealer or Heartland

Appliances direct.

•When ordering replacement

parts (warranty or not) always

provide the following

information:

Serial Number

Model Number

Component Description

Part number

•Commonly replaced parts are

listed in Section 7 at the end of

this book and at the back of the

owner’s manual.

•To obtain replacement parts

directly from Heartland, contact

the following departments:

Heartland Appliances Inc.

1050 Fountain St. N.

Cambridge, Ontario

N3H 4R7

ph: 877-650-5775

fx: 800-327-5609

Warranty & Non-Warranty

Replacement Parts:

Service Dept. Ext. 2241 & 2264

Note: Please contact Heartland

Appliances Service Department

prior to performing service work in

order to assist in the diagnosis of

the problem, this should result in

having to go to the customer’s

home only once.

How To Set Up Warranty Service:

•Contact one of the

manufacturer’s service

technicians to obtain a CSF

reference number. CSF

numberwillserveasauthoriza-

tiontoproceed with warranty

workandwillbereferencedfor

anyfuturewarrantywork.

ContactHeartlandAppliances

ServiceDepartmentat:

Heartland Appliances Inc.

1050 Fountain St. N.

Cambridge, Ontario

N3H 4R7

ph: 877-650-5775

fx: 800-327-5609

Service Department:

Extensions 2241 & 2264

•CSF number to be referenced

in all warranty claims

•ContactingHeartland

Appliances prior to performing

service work, will assist in the

diagnosis of the problem, this

should result in having to go to

the customer’s home only

once.

How To Submit Warranty Claims:

•For prompt warranty claim

processing, submit your

standard service form (i.e.

Narda style) completely filled

out to:

Heartland Appliances Inc.

Service Department

1050 Fountain St. N.

Cambridge, Ontario

N3H 4R7

fx:800-327-5609

•Warranty Claim forms to in-

clude, but not limited to, the

followinginformation:

•CustomerName,Addressand

PhoneNumber

•SerialNumber

•Model Number

•Date of Service

•Work Performed

••

••

•Full Description of Work

Performed

••

••

•CSF Reference number (see

“How To Set Up Warranty

Service” section above for

details).

How to Return Merchandise:

•Contact Heartland Appliances’

Service Department to obtain

authorization for any

merchandise returns at:

Heartland Appliances Inc.

1050 Fountain St. N.

Cambridge, Ontario; N3H

4R7

ph: 877-650-5775

fx: 800-327-5609

Service Department:

Extensions 2241 & 2264

•Depending on the nature of the

merchandise to be returned, an

RGA number (Return Goods

Authorization) may be issued.

A comprehensive RGA Kit

package will be expedited with

instructions and back up

paperworkforthepromptand

safereturnofthe goods.

Section 2

6MLSM2003-09-03

Parts & Warranty

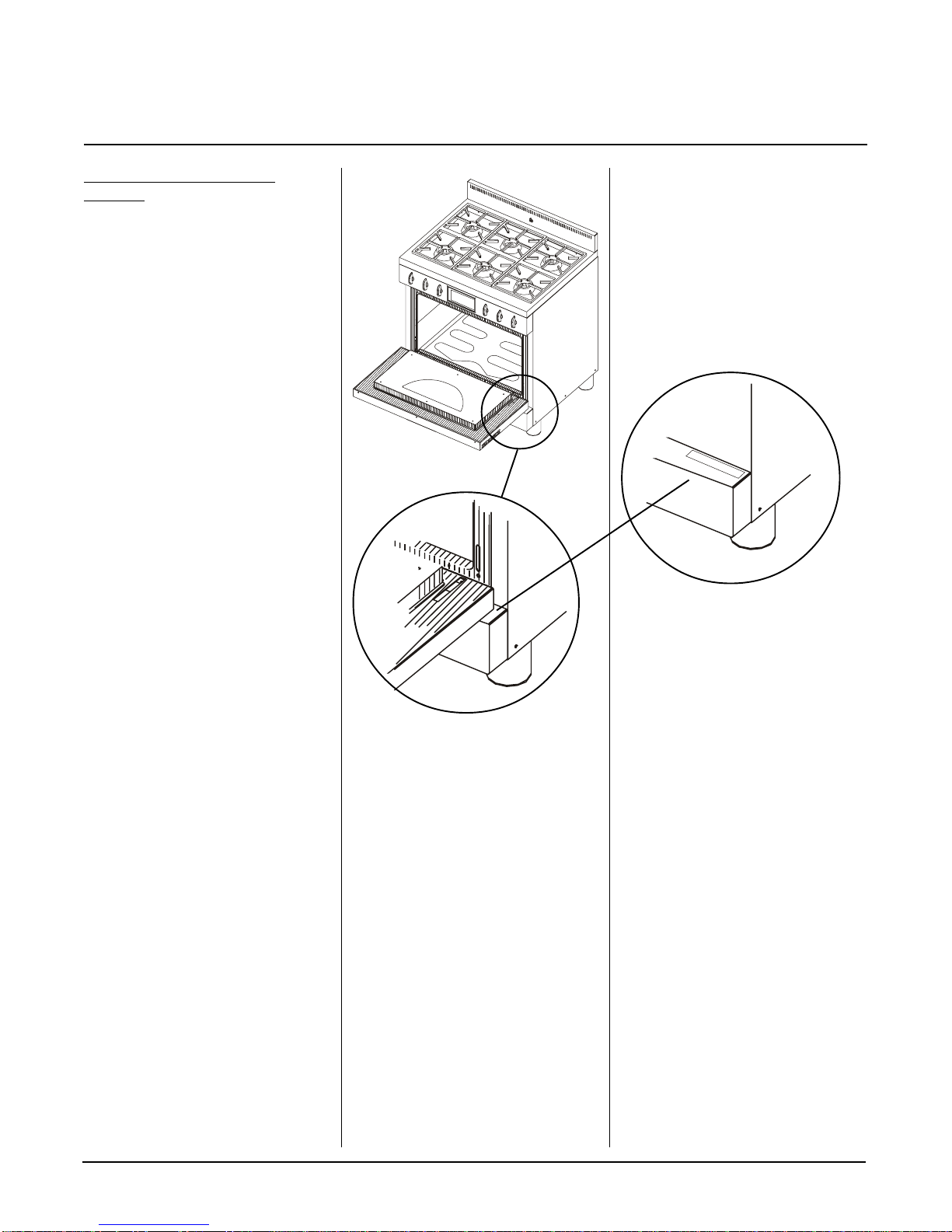

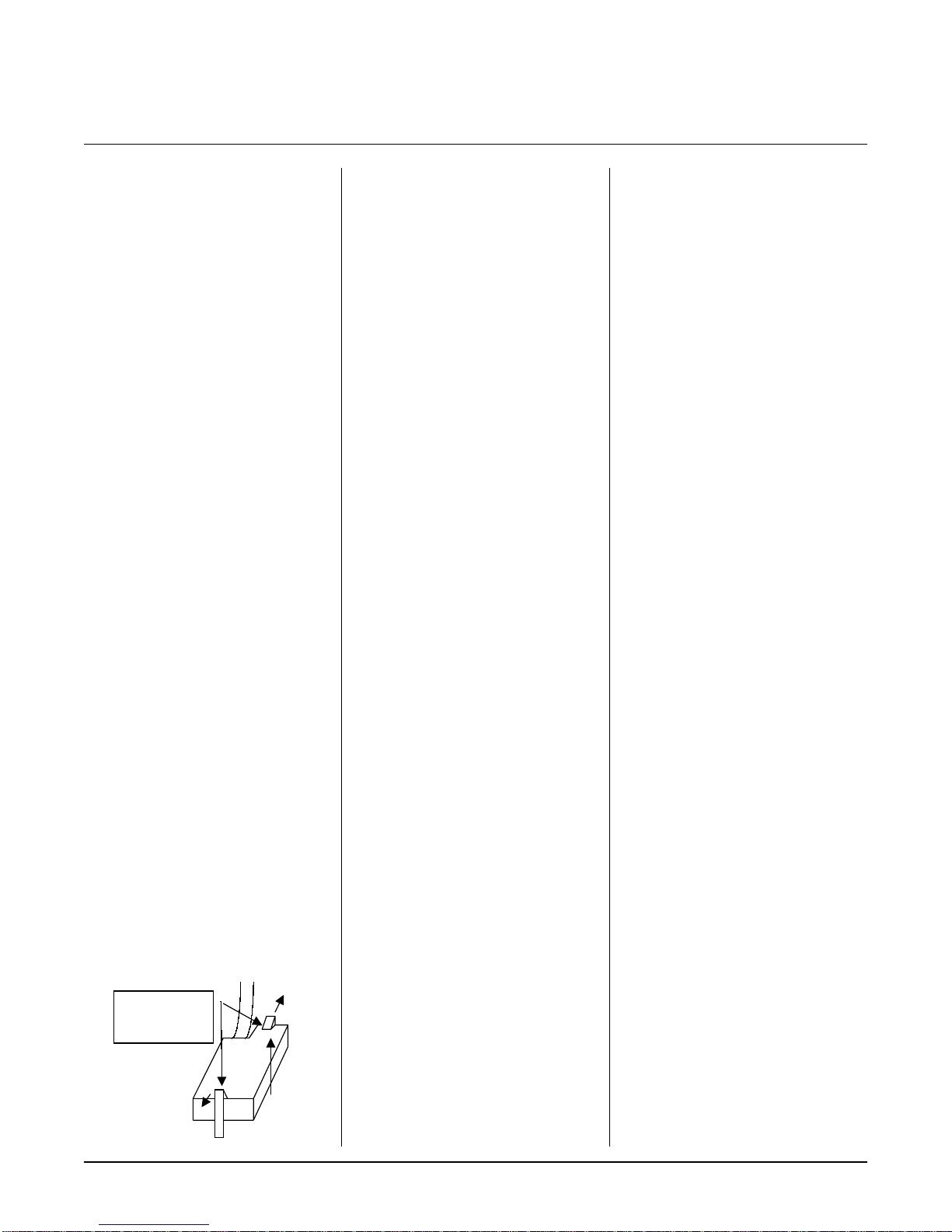

Serial Number Location in

Ranges:

•Metro & Legacy ranges have

the serial number located at the

back of the range and on the

kick plate.

To view serial number plate,

open door, and look at

kickplate’s right top corner.

(view shown with door removed)

Section 3

7MLSM2003-09-03

Technical Specifications

Dual Fuel Ranges (Electric Oven

& Gas Top)

•30”Models3530/3535

240V, 60Hz, 4.1 Kw (3 prong or

4 prong)

Bake Element: 3400 W

Broil Ribbon Element: 4000 W

Conv. ring element: 2400 W

Natural Gas (6” w.c.)

Propane (11”w.c.)

½” NPT (5/8” flex line)

Surface Burners (4):15,500 Btu

Note: Service Amperage to be

calculated by a qualified

electrician.

•36”Models3630/3635

240V, 60Hz, 5.6 Kw (3 prong or

4 prong)

Bake Element: 5000 W

Broil Ribbon Element: 5000 W

Conv. ring element: 4800 W

Natural Gas (6” w.c.)

Propane (11”w.c.)

½” NPT (5/8” flex line)

Surface Burners (6):15,500 Btu

Note: Service Amperage to be

calculated by a qualified

electrician.

•36”Models with Grill

3630B/3635B

240V, 60Hz, 5.6 Kw (3 prong or

4 prong)

Bake Element: 5000 W

Broil Ribbon Element: 5000 W

Conv. ring element: 4800 W

Natural Gas (6” w.c.)

Propane (11”w.c.)

½” NPT (5/8” flex line)

Surface Burners (4):15,500 Btu

Grill Burners (2): 7,500 Btu

Note: Service Amperage to be

calculated by a qualified

electrician.

Electrical Requirements:

•Standard 240V; 60 Hz

receptacle,properly polarized,

on its own dedicated line must

be used.

•Ranges are provided with a

molded plug cap power cord

rated at 120/240 Volts.

•Ranges must be electrically

grounded in compliance with

local codes. In absence of

local codes, the installation

must conform with the National

Electrical Code.

Gas Requirements:

•During any pressure testing of

the gas supply piping system at

test pressures equal to or less

than 2.5 kps, the appliance

must be isolated from the gas

supply system by closing its

individual manual shut off valve.

•The maximum propane/natural

gas supply inlet pressure must

not exceed 14” of water column

•Gas ranges must be installed in

compliance with local gas

codes. In absence of local

codes, the installation must

conform with the National Gas

Code.

8MLSM010601

Section 4

Problem Diagnosis Charts

Models 3530/3535; 3630/3635 & 3630B/3635B

PLEASE REFER TO

SERVICE MANUAL #0910

FOR FULL TROUBLE

SHOOTING GUIDE

DETAILS

THIS AMENDMENT IS

INTENTED TO

ILLUSTRATE CHANGES

MADE TO THE LOCATION

OF THE RELAY BOARD,

CLOCK MOUNTING, AND

ASSOCIATED

COMPONENTS.

F2code Doornot locked during self clean

Problem PossibleCause Repair/Test Procedure

StuckDoor Latch (Procedure E)

Check Wire from Door lock to Clock

(ProcedureE)

F3 code High Limit Tripped in clock Faulty Clock (ProcedureB)

Section 5

9MLSM2003-09-03

Procedure A

- Terminal Block

Step 1:

Disconnect power supply to

range.Pullrangeawayfromwall

andremovebackguardheldby3

screwsandwashers.

Step 2:

PropTop Up.See Proce-

dure P. Inspect top terminal block

forburntterminal connections. If

damaged,replace.Ifnopower to top

terminal, check terminal block at

power cord connection.Seebelow.

Step 3:

To replace back of stove

terminalblock,removepowercord

by unscrewing the three screws that

retain the ends of the cord to the

terminalblock.

Step 4:

Mark and disconnect all

wires attached to the terminal block

(includingwireto ground stud for 4

prongpowercords)

Step 5:

Terminal block can be

removedfromrangebyremovingthe

two center screws.

Step 6:

Install new terminal block,

attach all red, white and black wires

asoriginallymarked

Step 7:

Attach power cord back on

terminal block. Be sure all wires are

secure. 3prongpowercordshave

jumper cable from center (neutral)

side of terminal block to stud. 4

prong power cords have copper

wire from cord directly attached to

groundstud.

Step 8:

To replace top of stove

terminal block, disconnect wires to

terminal block and repeat steps 3

through7.

Section 5

MLSM2003-09-03

10

Procedure B

- Timer Replacement

Step 1:

For oven to operate, time of

day must be set in timer. See Timer

Programming(ProcedureC)for

details.

Step 2:

Disconnect power supply to

range.Pullrangeawayfromwall

andremovebackguard.SeeProce-

dure A Step 1.

Step 3:

PropTop Up.See Proce-

dure P.

Step 3:

Remove4screwsholding

timertocontrol panel and transfer

wires to new clock.

Step 4:

Disconnect coaxial power

supply cable by lifting both locking

tabs.

Step 5:

Disconnect two molex

plugs from clock. Please note that

clock has specific markings for

eachmolex plug: a)solenoiddoor

“lock” has a smooth grey wire and

is attached to the left side of the

clockand b) oven “probe” withhigh

temperature shield is connected to

the right side of the clock.

Note: Ifthesewiresareversed,

code F1 will be display as soon as

any cooking function is selected.

Step 6:

Transfer all wires to the

new timer in the exact same loca-

tion.

Note: Whenre-attachingthe coaxial

computer cable, please ensure it is

fully inserted and that both locking

tabsaresecurelyengaged.

Section 5

11 MLSM2003-09-03

Procedure C

- Timer Programming

Step 1:

For oven to operate, time

of day must be set in timer.

Step 2:

Press

clock

symbol

Step 3:

Press

increase

or

decrease

symbols to select

time

Step 4:

Press

start

symbol to

set

Note: Pressing twice the clock

symbol toggles time of day

between 0-12 hrs and 0-24

hrs

Step 5:

To set cooking, press

desired function (bake ,

convection bake or broil ).

Note:

automatically sets to 325F for

bake and convection bake and to

550F for broil.

Step 6:

Press

increase

or

decrease

symbols to select

time

Step 7:

Press

start

symbol to

start.

Note:To toggle between Fahrenheit

(F) and Celcius (C), press

cooking symbol twice in a

row.

Self Clean Programming: all

cookware, racks, and rack supports

to be removed from oven during

self clean cycle to prevent them

from becoming dull and blue-gray.

Step 8:

Press

self clean

symbol (automatically set for 3 hrs)

Step 9:

Press

decrease

cleaning time.

Step 10:

Press

start

symbol

to begin

self clean.

Note: A thermostatically controlled

cooling fan will start shortly

after the self clean cycle is

programmed (once the door

is locked). The fan will

automatically shut off when

the self clean cycle is

finished and the unit is

sufficientlycool

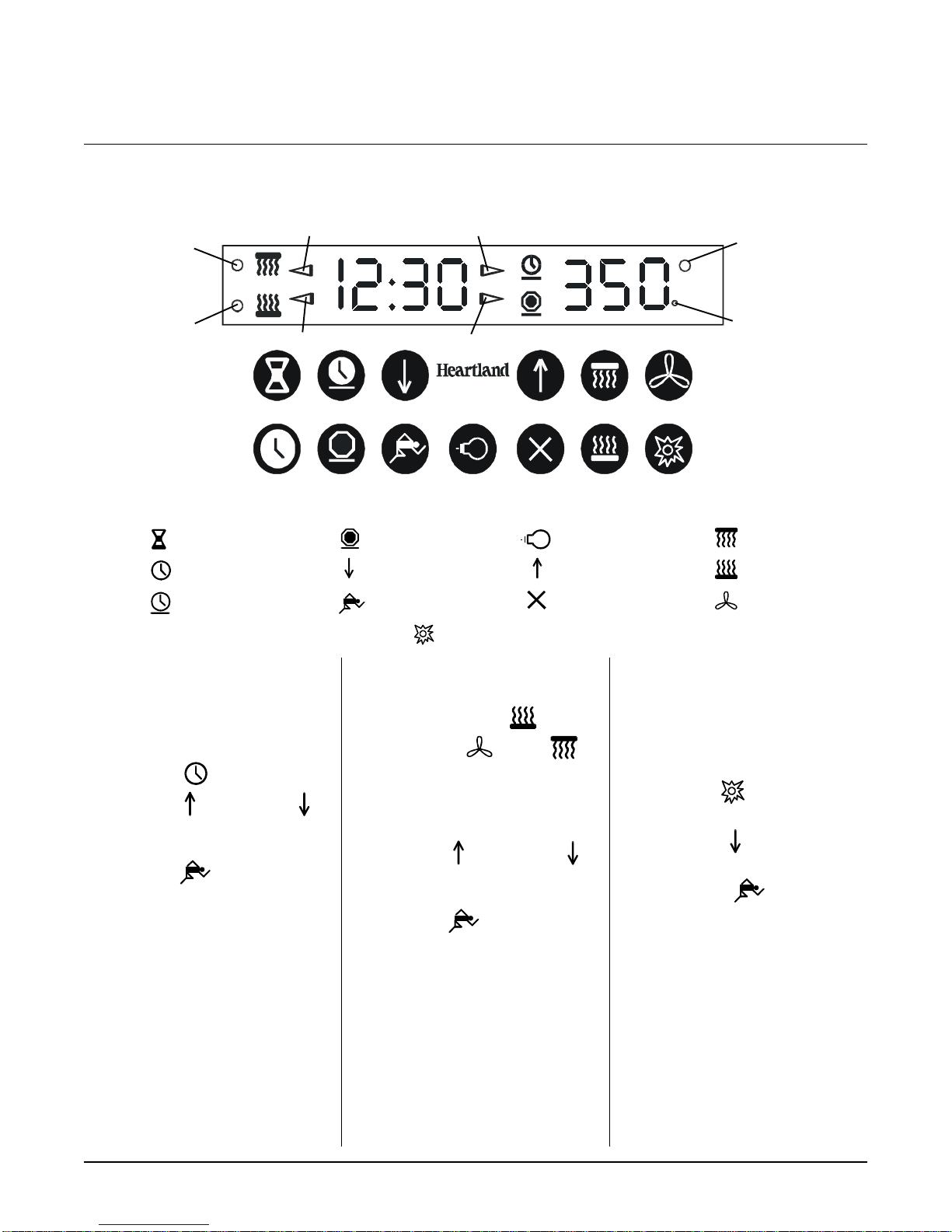

clock

cook time

minute minder

Element “ON”

Indicator

Convection Broil

Indicator

Convection Bake

Indicator

Broil Indicator Start Time Indicator

Stop Time IndicatorBake Indicator

stop time broil

start

increase

decrease

convection

bake

cancel

self clean

oven light

Celsius

Indicator

When finished ensure probe sits inside clip

Section 5

MLSM2003-09-03

12

Procedure D

- Broil Element

Step 1:

Disconnect power supply to

range.Pullrangeawayfromwall

andremovebackguardheldby3

screwsand washers. See Proce-

dure A Step 1.

Step 2:

PropTop Up.See Proce-

dure P.

Step 3:

Markandremovewiring

ends from broil element by pulling

endsupandaway from element

terminals-please note sequence of

black and red wires to ensure they

areplaced on newelementin the

samesequence.

Step 4:

Test for continuity. Place

test probes on each terminal.

Needleshouldreadapproximately

24 ohms for 3500W elements. 36”

models use two 2500W broil plates

and each plate has four leads. Test

the two outer and the two inner

leadsforapproximately 45 ohms.. If

noreadingorsignificantlydifferent

fromrange,replace.

Step 5:

If element faulty - Replace.

Step 6:

Openovendoorandremove

foreasieraccess (please refer to

owner’smanual). Removescrews

holdingbroilelementtoovenand

pull element into oven cavity. Trans-

fer the wiring in same position as

originally.

Step 7:

If broil element tests in

good condition, test continuity in

wiringto relay board, bake/limitbroil

limit and terminal block.

Section 5

13 MLSM2003-09-03

Procedure E

-

Self Clean Latch Mechanism

Step 1:

Disconnect power supply to

range.Pullrangeawayfromwall

andremovebackguardheldby3

screws and washers. See Proce-

dure A Step 1.

Step 2:

PropTop Up.See Proce-

dure P.

Step 3:

If self clean results are

poor, check all switches, wiring and

connections to self clean

microswitch.

Note: Black microswitch allows

signal from latch to confirm timer

that oven door is locked - this

allows self clean cycle to begin. If

latch is stuck or switch is

disconnected or faulty, self clean

will not commence.

Step 4:

Test switch with multimeter

for continuity - switch is normally

open, close switch and test.

Step 5:

To replace switch, with a

slot screwdriver push on the two

clips and pull the switch upwards

Replace black wires on new switch

in same two left positions, right

position is empty.

Step 6:

Check microswitch to

cooling fan - top white switch.

Chech to ensure wiring is making

good contact to the two outer

positions(centerposition remains

empty). If incorrectly wired, unit will

not self clean properly since cooling

fanwillnotengage during self clean

and safety temperature limit in timer

willshutdownoperation.

Step 7:

Test microswitch for

continuitywhen button is depressed

across terminals 1 and 2 by placing

test probes on terminals. If no

continuity in the on position, replace

switch.

Step 8:

To replacem unscrew

microswitchfromsupportplace and

transferredwires from old switch.

Step 9:

If all switches and wiringto

switches test in good order, latch is

not operational, Disconnect all

wires from micro switches, one at

the time and place on new latch

assembly.

Step 10:

With short Phillips

screwdriverremovefourscrews

holdingassembly to top ofstove

Push both clips

away from

switch to release

Step 11:

Replacewithnew

assembly

Step 12:

LatchReplacement (latch

warpedorbent): Removetwo

Phillips screws holding latch in

place and replace with new latch.

Note:

Donot over tighten screws

as they must allow movement of

the latch back and forth.

Self Clean Operation:

During selfclean,door automati-

cally locks (wax motor energized

and pushes latch to lock) and

coolingfan starts. temperatures

cycle off the timer.

When door locks, “black”

microswitch closes, sends signal to

timer to confirm door locked - unit

will begin self clean cycle.

If latch is stuck and door does not

lock, self clean program will shut

down.

If any of the 2 microswitches on the

selfclean assembly malfunction,

unit will not self clean properly.

Section 5

MLSM2003-09-03

14

Procedure F

- Timer Relay Board

Step 1:

Disconnect power supply to

range.Pullrangeawayfromwall

andremovebackguardheldby3

screws and washers. See Proce-

dure A Step 1.

Step 2:

PropTop Up.See Proce-

dure P.

Step 3:

Remove one wire at a time

fromfaultyrelayboarduntonew

board.

Step 4:

Removefournutsholding

relay board to access panel -

ensure that non conductive spacers

are also transferred to new board.

Section 5

15 MLSM2003-09-03

Procedure G

- Timer Coaxial Cable

Step 1:

Disconnect power supply to

range.Pullrangeawayfromwall

andremovebackguardheldby3

screwsand washers. See Proce-

dure A Step 1.

Step 2:

PropTop Up.See Proce-

dure P.

Step 3:

Inspectcable for visible

damageandreplaceasneeded. If

timer does not operate properly,

one of probable components is the

coaxial cable (other probable

components are the timer and the

relayboard)

Step 4:

Pull locking tabs away and

releasecablefromrelayboard.

Step 5:

Release coaxial cable from

timer(see Procedure B for timer

access).

Step 6:

Replace cable - please

cable is routed exactly as it was

and that it does not interfere with

anyotherwiring.

Section 5

MLSM2003-09-03

16

Procedure H

- Cooling Fan & Limit

Step 1:

Disconnect power supply to

range.Pullrangeawayfromwall

andremovebackguardheldby3

screwsand washers. See Proce-

dure A Step 1.

Step 2:

Removerange’sbackpanel

(Seeprocedurexxx)

Step 3:

Test continuity across

cooling fan’s terminals (pull black

and red wires). If fan test in good

condition, test wiring.

Step 4:

To test wiring, place

multimeterprobeoneachwireand

testforcontinuity between fan and

terminal block and to fan limit.

Step 5:

To access fan limit.

Prop

TopUp.SeeProcedureXXX.

Step 6:

Iffan and wiring in good

condition, test fan limit for continu-

ity. Remove both red wires and test

across, limit should be open and no

readingtakenacross terminals.

Step 7:

If limit test in good condi-

tion, inspect self clean assembly

microswitch(seeProcedureC).

Step 8:

If limit is faulty, replace.

remove wires to limit and transfer

red wires to new temperature limit.

Step 9:

Remove one nut/bolt

holding limit to mounting bracket.

Note:

Please ensure that red wires

do not run parallel with coaxial timer

cable or oven thermostat probe

when finished.

Section 5-3

17 MLSM2003-09-03

Procedure I

- Spark Module

Step 1:

Disconnect power supply to

range.Pullrangeawayfromwall

andremovebackguardheldby3

screwsand washers. See Proce-

dure A Step 1.

Step 2:

PropTop Up.See Proce-

dure P.

Step 3:

Disconnect screw holding

spark module to top and gently drop

down.

Step 4:

Test wiring and connections

to spark module, particularly black,

whiteandgreenwiresto ensure

they are tightly connected.

Step 4:

There should be no conti-

nuity across any of the correspond-

ing terminals from one side of the

module to the other. If any show

continuity, replace spark module.

Step 5:

To replace faulty spark

module,removeonewire at a time

from old module and transfer to

new module in the exact same

terminals as the original. Please

ensure quick connect leads are

properlyandfully inserted into the

spark module spades (use pliers if

needed).

Step 6:

Spark modules are held in

placebyvelcro.

Step 7:

Test wiringfromspark

moduleto ignition switchesfor

continuity and/or wires to elec-

trodes. Replaceas needed.

IMPORTANT: ALL GASWORKTO

BEPERFORMEDBYA QUALIFIED

GASTECHNICIAN.

Section 5-3

18 MLSM2003-09-03

Procedure J

- Regulator Replacement

Step 1:

Disconnect power supply to

range and shut off gas supply.Pull

rangeawayfromwallandremove

backguard held by 3 screws and

washers. See Procedure A Step 1.

Step 2:

PropTop Up.See Proce-

dure P.

Step 3:

Beforereplacingregulator

becauseflames are toohighor too

low,checkregulatorcapfor proper

gas setting.

Step 4:

Cap is stamped with either:

”NAT” on the convex side or “LP”on

the hollow concave side. If stove is

set for Nat Gas and it receives

Propane, the flames will be large. If

stove is set to Propane and it

receivesNat Gas, flames will be

small. See Procedure K for Gas

conversionsteps.

Step 5:

If no gas flows through

regulator but there is gas to the

regulator,it is either mounted

backwards (although unlikely,

howeverthereisanarrowstamped

on the body of the regulator to

ensureproperorientation); or it is

faulty.

Step 6:

If installed backwards,

disconnectregulatorfrommanifold

andinletpiping,reverseorientation

and re-install. Check all gas con-

nections with soapy water solution

to ensure no gas leaks.

Step 7:

If regulator is faulty (i.e no

gas flow, leak, etc.) then replace

regulator.

Step 8:

To remove regulator,

carefully rotate and unscrew from

manifold. Ensure new regulator is

oriented with arrow pointing in

directionofgasflowand ensure pipe

dope is used in all threaded connec-

tions.

Step 9:

When finished check all

gas connections with soapy water

solution to ensure no leaks are

present.

IMPORTANT: ALL GAS WORK TO

BE PERFORMED BY A

QUALIFIED GAS TECHNICIAN.

Section 5-3

19 MLSM2003-09-03

Procedure K

- Gas Conversion

Serial number of range must be

provided to ensure correct kit is

ordered. See Table below.

ConversionSteps:

Step 1:

Disconnect power supply to

range and shut off gas supply.Pull

rangeawayfromwallandremove

backguard held by 3 screws and

washers. See Procedure A Step 1.

Step 2:

PropTop Up.See Proce-

dure P.

Step 3:

Remove4screws securing

metal partition to stove top to

access all burners.

Step 4:

Pressureregulatorconver-

sion. Regulatorhasreversiblecap

foreitherNaturalGasorPropane.

SeeProcedureJ for details on

regulatoraccess.

Step 5:

To reverse regulator cap,

removewithlargeflatbladescrew-

driverturning CCW. The gas being

convertedto must be stamped on

the outside of the cap. Position cap

backonregulator, press andturn

CW to lock in place

Step 6:

Burnervalvessimmer jet

conversion. Removecontrolpanel:

pry open the metal plugs using a

smallbladescrewdriver(ensure

powerisoffunit).

Step 7:

using 3/8” deep socket

wrench,loosennutholdingcontrol

panel to stove top and gently pull

forwardtoexposevalves.

Step 8:

Use small flat blade screw-

drivertoremoveoriginalsimmerjets

andreplacewithappropriately

numberedsimmerjets (all jets have

theirnumberstamped on the head -

refertoconversionkitchart for

details). Donotovertighten. There

aretwosimmerjetsper valve,

exceptforgrillburnerswhichhave

onlyonepervalve.

Step 9:

Surfaceburnerorifice

conversion-outerflamering.

Removeexistingorificesandreplace

with new ones as indicated in

conversion kit chart. Use two

wrenchestopreventtwistingofgas

tubing.

Step 10:

Surfaceburnerorifice

conversion-innerflamering.Re-

movebrassnut(using two

wrenches)andremoveold“cap”.

Replaceandtighten.

Section 5-3

20 MLSM2003-09-03

Procedure K

- Gas Conversion

Step 12:

Air shutter adjustment will

be needed for small simmer setting.

Approximateairholecoverageis1/2

coveredforNatGas.

Step 13:

Grill models only. There

isonly valve simmer jet andone

burnerjet.

Air shutter will need adjusting: LP

fullyopen, Nat Gas open0.40”.

North American Natural Gas

Description Size Part no./Model

3520/3525 3620/3625 3620/3625BBQ

#38109 #38110 #38111

main jet simmer 34 #3669 4 6 4

main jet 1.7 #3860 4 6 4

valveouter 0.4 #7640OR#3856 4 6 4

valveinner 0.88 #3857 4 6 4

grillJet 1.18* #3516 0 0 2

grillvalve 0.58 7636 0 0 2

venturi #3667 4 6 4

North American Liquid Propane

Description Size Part no./Model

3520/3525 3620/3625 3620/3625BBQ

#38112 #38113 #38114

main jet simmer 7 #3670 4 6 4

main jet 1.1 #3861 4 6 4

valveouter 0.25 #3858 4 6 4

valveinner 0.54 #3859 4 6 4

grillJet 0.85* #3517 0 0 2

grillvalve 0.4 #7640OR#3856 0 0 2

venturi #3667 4 6 4

* These orifices use standard size orifice #3519 0.74 drilled out to following size:

#35170.85for North American Liquid Propane (L/P) kits

Conversion/Orifice Charts

Step 11:

Air shutter adjustment will

be needed for small simmer setting.

Approximateairholecoverageis1/4

coveredforLP

IMPORTANT: ALL GASWORKTO

BEPERFORMEDBYA QUALIFIED

GASTECHNICIAN.

Air Shutter Adjustments may be

needed to adjust flame patterns

in the field after conversion or

new appliance installation.

Other manuals for Legacy 3530

1

This manual suits for next models

5

Table of contents

Other Heartland Appliances Range manuals

Heartland Appliances

Heartland Appliances 7100 User manual

Heartland Appliances

Heartland Appliances 5200 User manual

Heartland Appliances

Heartland Appliances 9100 User manual

Heartland Appliances

Heartland Appliances Legacy 3630 User manual

Heartland Appliances

Heartland Appliances U109760-02 User manual

Heartland Appliances

Heartland Appliances 3825 User manual

Heartland Appliances

Heartland Appliances Metro User manual

Heartland Appliances

Heartland Appliances 4200 User manual