Heat Seal 112B Guide

2019

READ ALL INSTRUCTIONS CAREFULLY BEFORE OPERATING EQUIPMENT

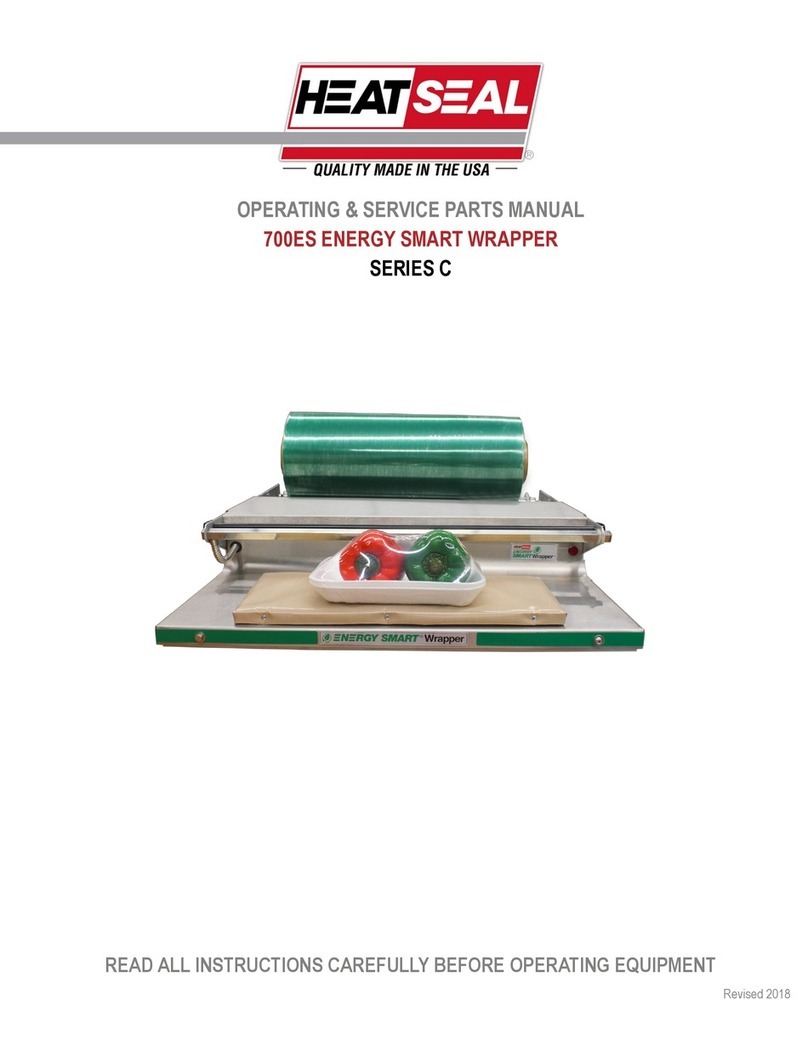

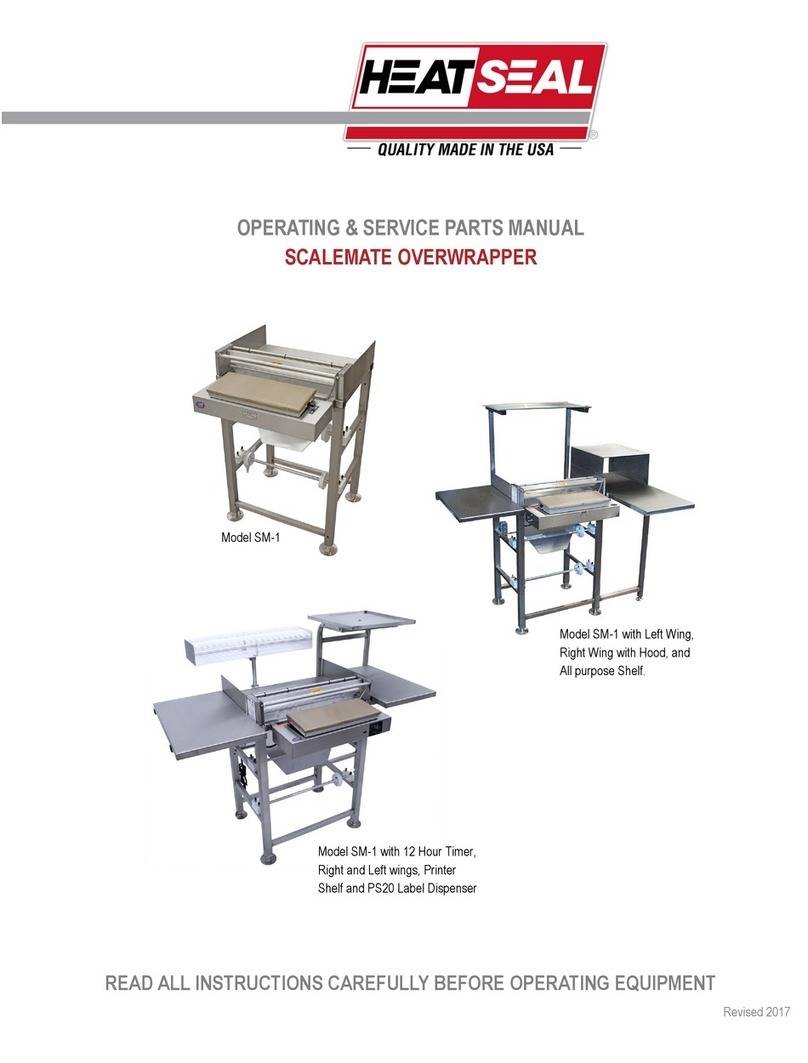

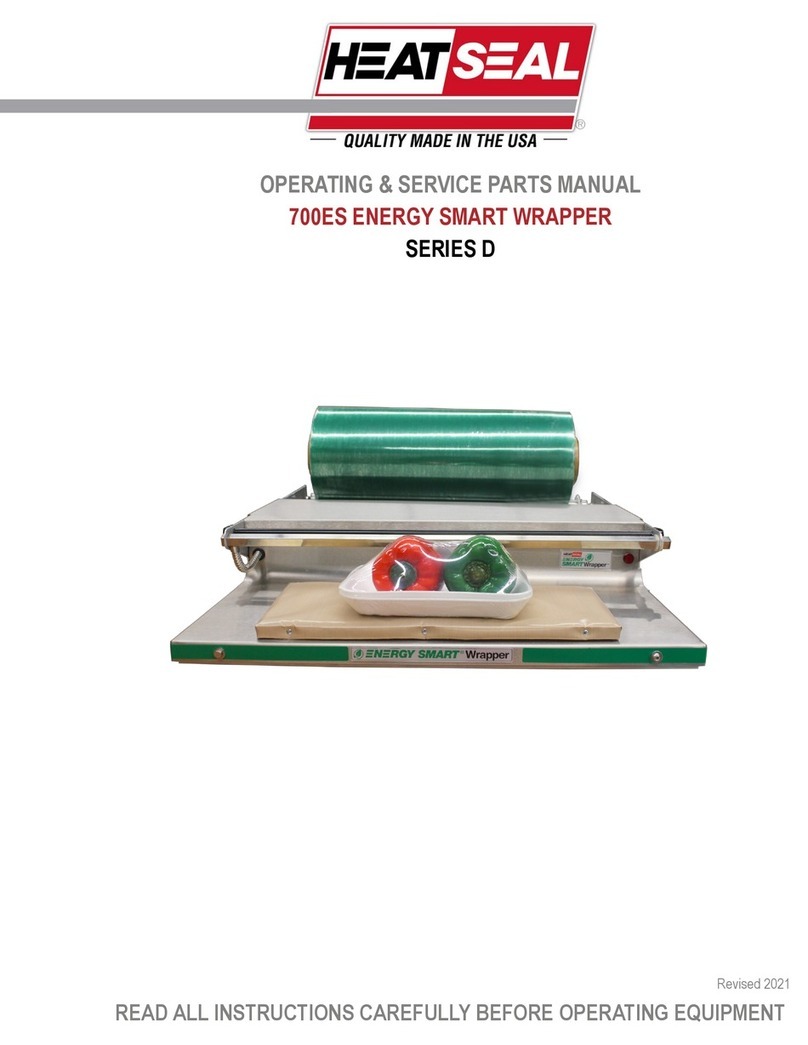

OPERATING & SERVICE PARTS MANUAL

112B FLOOR MODEL OVERWRAPPERS

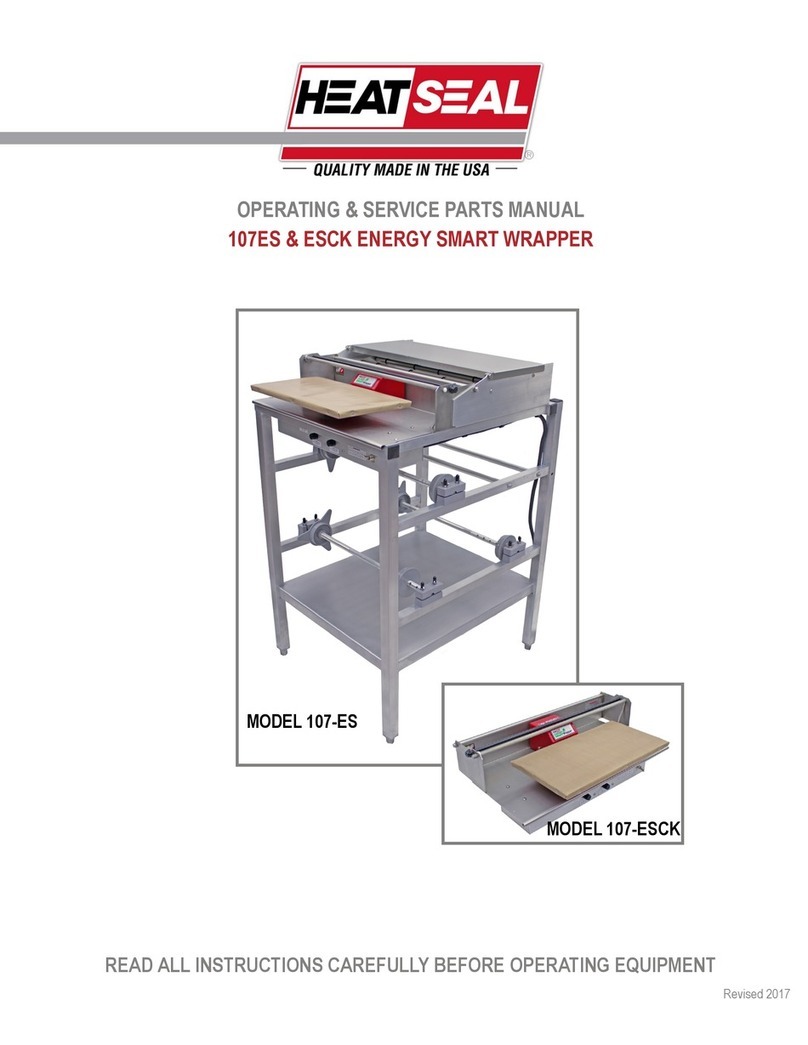

112B MODELS:

MODEL 112B

COMPACT TWO ROLL CAPACITY

FILM CRADLE AND PACKAGE REST

MODEL 112BW

COMPACT TWO ROLL CAPACITY

FILM CRADLE AND PACKAGE REST WITH SIDE WING

Model 112B

Model 112BW

2

Revised 2019

Film Threading & Mounting ..........................................................................................3

Preparing The Machine For Wrapping Packages........................................................4

Recommended Maintenance ........................................................................................6

Troubleshooting Guide .................................................................................................7

Electrical Diagram .........................................................................................................8

Replacement Parts ........................................................................................................9

TABLE OF CONTENTS

3

Revised 2019

FILM THREADING & MOUNTING

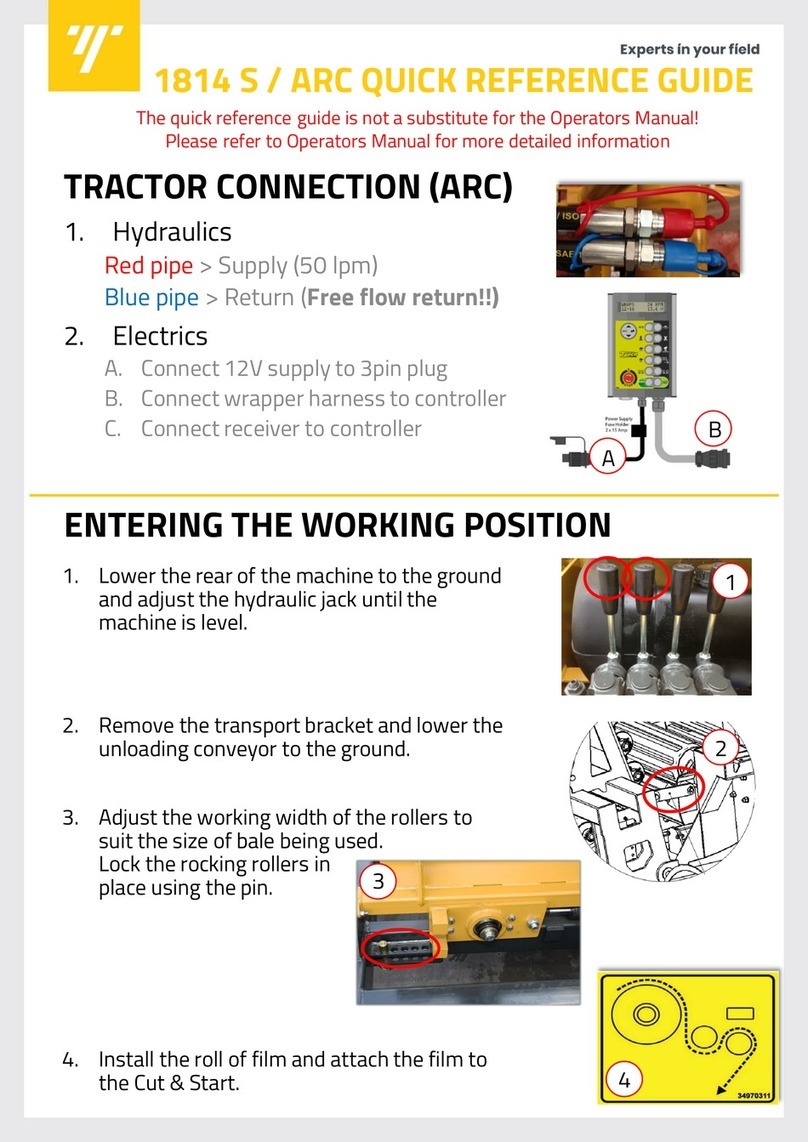

THREADING THE FILM:

Thread the film as shown, if only one roll of film is being used thread it in the bottom position.

ITEM PART #

Idle Roller 6106-305

Tension Roller 6106-307

Cradle Film Guide Roller 6106-304

Right Side

View

Load the machine from the RIGHT SIDE

Film needs to come off the roll

COUNTERCLOCKWISE

The film will pull itself down into the

cradle

Film MUST feed down BETWEEN the

IDLE

ROLLER

①and

TENSION ROLLER

②then

UNDER both the

TENSION ROLLER

②and

the

CRADLE FILM GUIDE ROLLER

③

4

Revised 2019

PREPARING THE MACHINE FOR WRAPPING PACKAGES

1. Spread roll centering clips out to the edge of

the roller.

2. Position new film roll so that the film is

coming off the top of the roll in a

counterclockwise direction when viewed from

the right side.

3. The film will come off the top of the film roll and

go in between the idle and tension rollers. Then

the film goes under the tension roller and to the

outside of the film guide roller.

Roll centering clips

5

Revised 2019

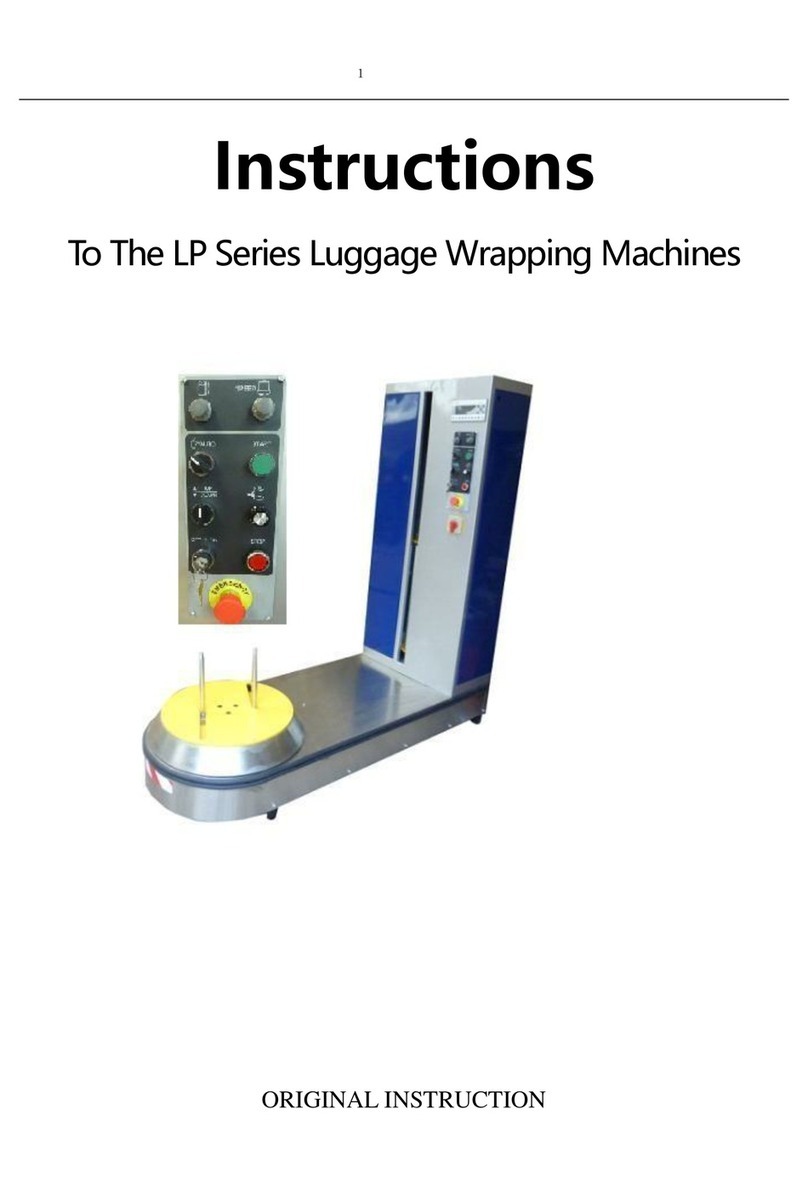

PREPARING THE MACHINE FOR WRAPPING PACKAGES

4. The bottom film roll should be threaded

through the position closest to the operator. The

top film roll should be threaded through the

position farthest away from the operator.

Note: In pulling the film up through the guide, the operator will want to create light tension so that when it

gets cut by the hot rod, the film snaps back slightly. There are two black knobs on the right side of the

frame. Tension on the film can be increased by moving the knob clockwise and decreased by moving the

knob counterclockwise.

5. Turn on the machine using the on/off switch to

the right front of the machine. It will take

approximately 12 minutes for the film cut off rod

to come up to cutting temperature.

Film hold down bar

Bottom film

roll &

position

closest to

operator

Top film roll

& position

furthest from

operator

6

Revised 2019

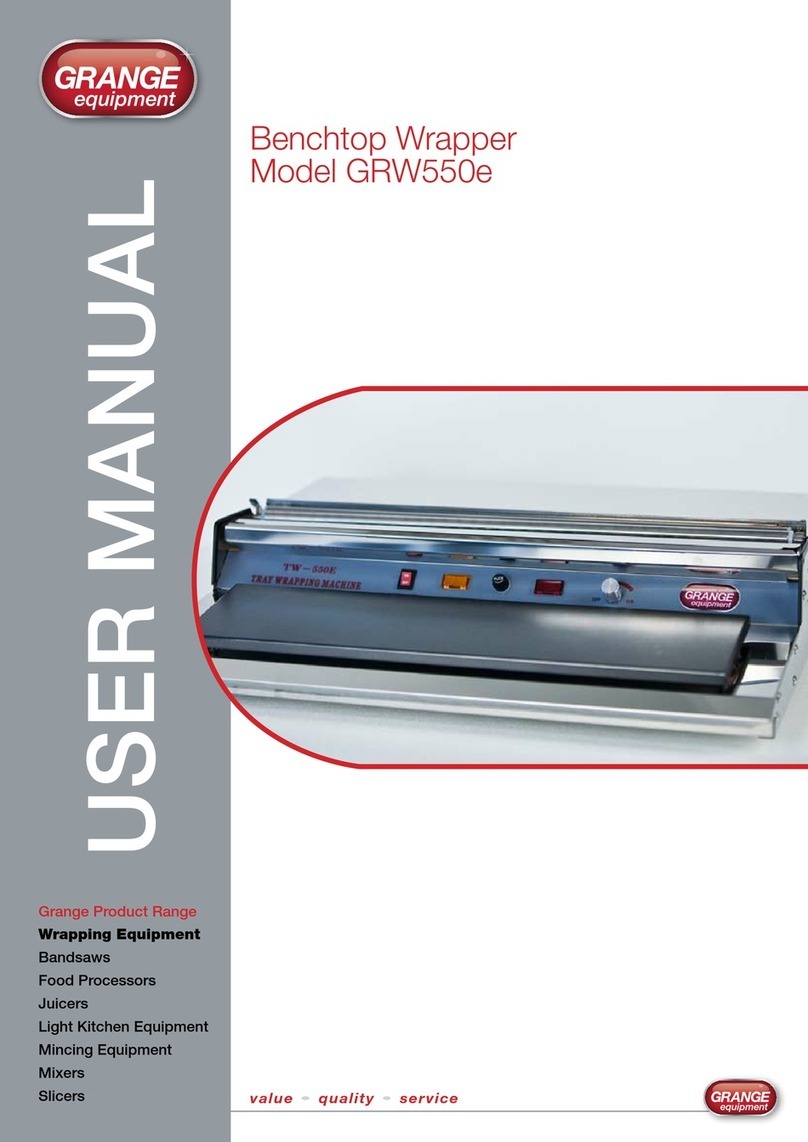

USING THE FILM SELECTOR

Positioning the bridge for the correct film allows

the operator to wrap packages quicker and

provides a bump to help stretch the film tightly for

a more professional package look.

There is a shelf-shaped channel that the bridge

bar sits in. This allows for the operator to select

which film roll to use (bottom roll or top roll). To

operate, simply lift up the bridge from the front of

the machine using two hands. Then, position the

bridge bar to rest in either:

Position 1: back notch of the channel (to access

the top roll) or the

Position 2: front notch of the channel (to access

the bottom film roll).

Bridge Channel

(Back Notch) Position 1 (Front Notch) Position 2

Film Selector in Back Position to use Top Film Roll Film Selector in Front Position to use Bottom Film Roll

Bridge Bar

7

Revised 2019

RECOMMENDED MAINTENANCE

* MAKE SURE TO TURN OFF THE UNIT, UNPLUG IT

AND LET THE MACHINE COOL DOWN BEFORE CLEANING *

FILM CUT-OFF ROD

When the film cut-off rod is at room temperature it can be cleaned. Cleaning it will keep the rod clear of

debris that can affect its ability to cut.

First, cover the surface below the film cut-off rod with paper towels to catch any debris or overspray.

Then spray the film cut-off rod with FDA approved degreaser and allow it to soak. After a few minutes of

soaking, scrub the rod with a Scotch-Brite™ type of pad to remove any debris and wipe it clean.

CLEANING THE UNIT

The rest of the machine can be completely wiped down using a mild cleaning detergent and soft rags or

paper towels.

Occasionally wiping the cradle rollers when replacing film rolls is recommended. The film cradles are

stainless steel and should not be affected by floor cleanings. Food grade oil can be used to lubricate

the bearing surfaces in the cradle system as needed.

8

Revised 2019

TROUBLESHOOTING OVERWRAPPERS

FAQ’S

If a new machine doesn’t turn on (heat

up), what steps should be taken?

Ensure that the power switch is turned on. Push the circuit

breaker button to reset the circuit. If electricity is powering the

unit, the red pilot light should be on.

What is the standard voltage on this

wrapping machine?

110V

What kind of film should be used? PVC stretch film for wrapping meat, seafood, and produce. Its

chemical characteristics provide barriers to protect the product.

Stretch film for pallet wrap is Polyethylene and is not to be used

on wrappers.

ABOUT HOT ROD

Hot rod is cold, what should I do? a) Ensure that the wrapper is plugged in

b) Reset the circuit breaker

c) Check for loose wires in the electrical tubing

d) If it is still cold, replace the hot rod

Hot rod is warm and not cutting the film

cleanly?

a) Clean the hot rod per the maintenance instructions

b) If it is still not cutting properly, replace the hot rod

9

Revised 2019

ELECTRICAL DIAGRAMS

10

Revised 2019

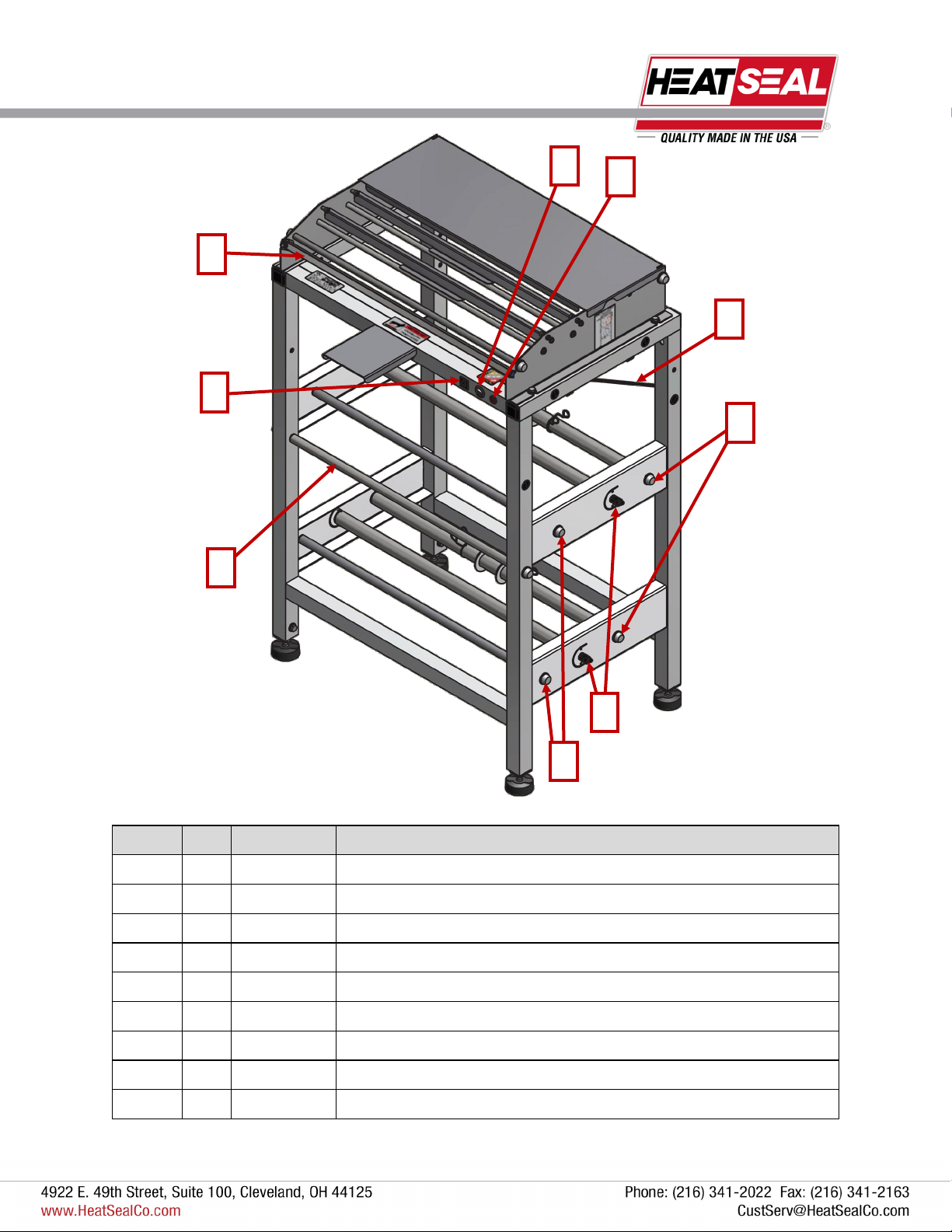

112B REPLACEMENT PARTS

PART # DESCRIPTIONITEM QTY

6106-304 Cradle Film Guide Kit1 2

6106-305 Idle Roller Kit2 2

6106-306 Directional Film Guide Roller Kit3 1

6106-307 Tension Roller Kit4 2

1872-131 Power Switch5 1

1836-004 Power Light, Red6 1

1824-030 Square Cutoff Rod7 1

1815-030 1 Amp Circuit Breaker8 1

1851-052 Power Cord9 1

5

8

7

9

6

1

2

4

3

This manual suits for next models

1

Table of contents

Other Heat Seal Stretch Wrapping System manuals