15

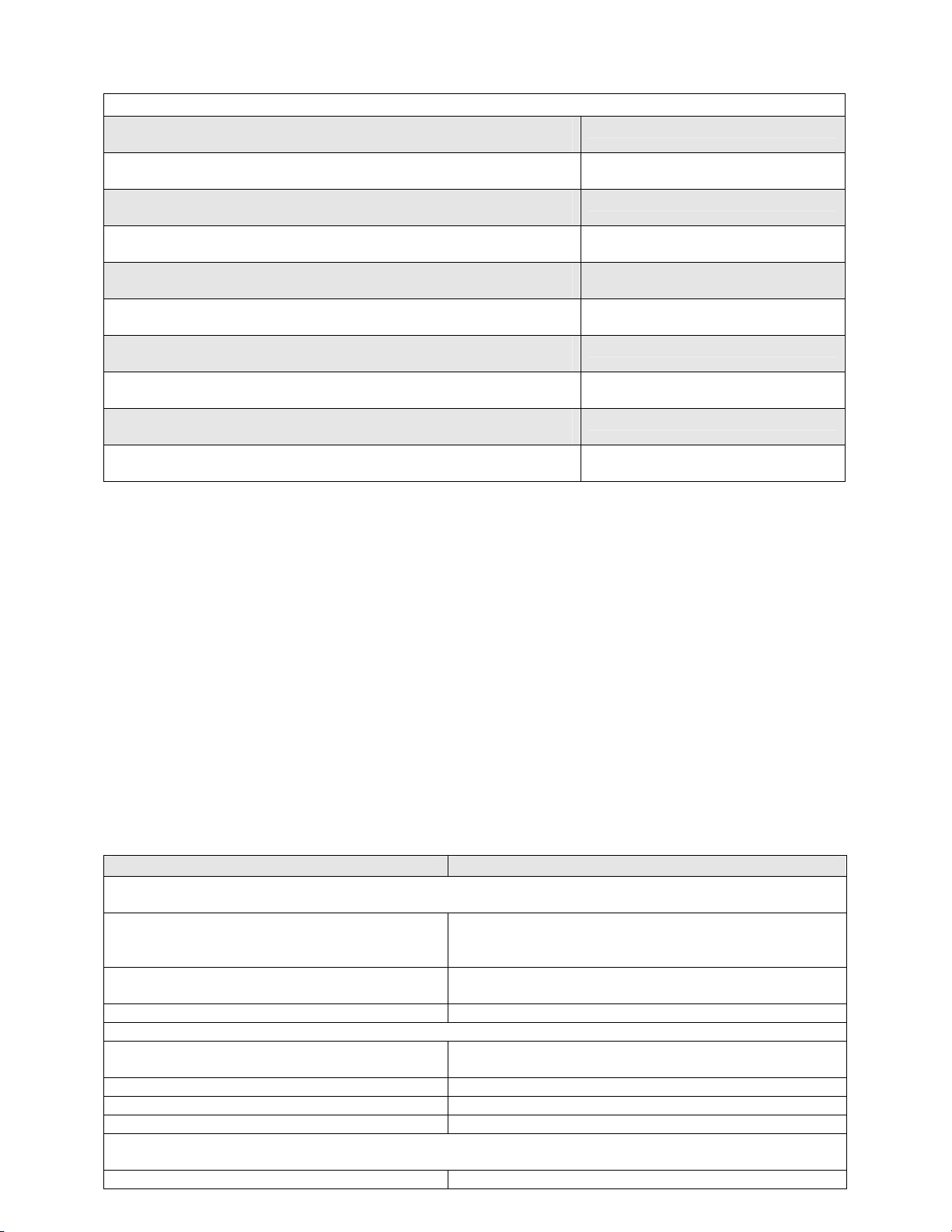

Use a combustion analyzer and record the readings below.

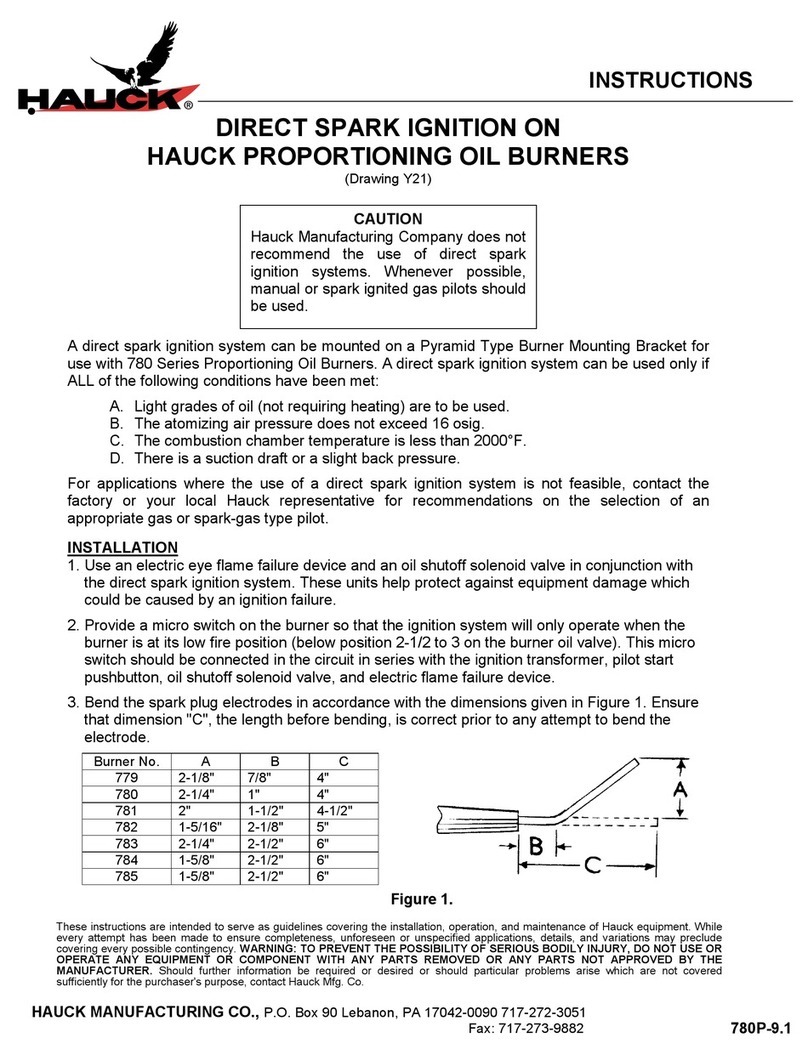

BURNER OPERATION: Record the Readings at Steady State

Draft over fire at steady state (should be Positive – refer to boiler manual)

Natural Gas CO

2

% = (8.5% to 10.0%) or O

2

% = (5.0% to 3.5%)

LP Gas CO

2

% = (10.5% to 11.5%) or O

2

% = (5.0% to 3.5%)

Gross Stack Temperature (350

o

F minimum, 450

o

F maximum)

NOx (If required)

Carbon Monoxide (CO) in PPM (less than 100 PPM ideal; should not

exceed 400 PPM Oxygen free)

Incoming Gas/LP pressure = “W.C. (minimum 5”, maximum 11”)

Manifold Pressure = “W.C.

Head Setting

Air Setting

Maintenance Instructions: TO BE FIXED/ATTACHED NEAR BURNER

At least once a year, a qualified service agency needs to be contracted for other than routine

maintenance.

1. The blower motor is the only moving part. It does not require lubrication, since the ball bearings

have been permanently lubricated.

2. The user should do periodic visual checks of the burner and the flame.

3. Laundry lint or dog and/or cat hairs should not go inside the blower. If they are seen, they

should be removed after disconnecting the power to the burner and cover parts should be

installed before starting the burner.

4. Keep the area around the conversion burner clear and free from combustible materials, gasoline,

and other flammable vapors and liquids.

5. No obstruction for the flow of combustion and ventilating air.

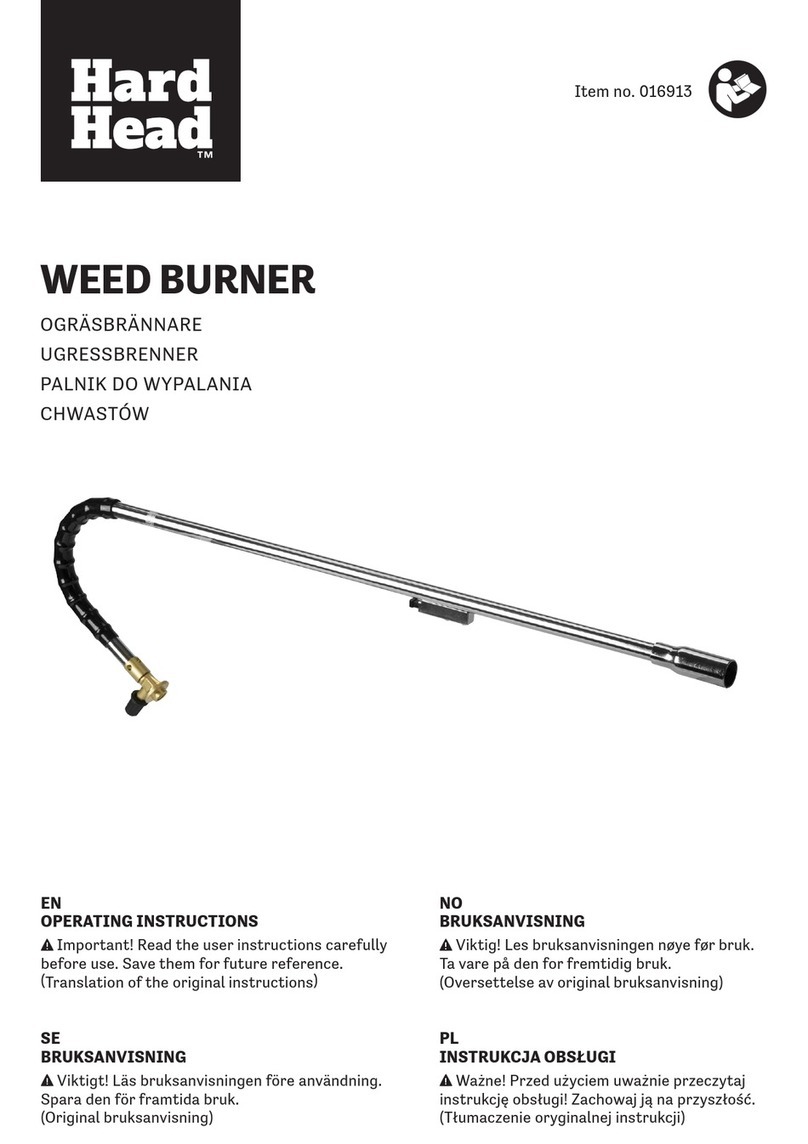

Trouble shooting:

There are three factors to operate the gas burner properly:

1. Electricity {(main Power 120V/60 Hz /1 Ph) ( secondary 24V)}

2. Gas flow (Incoming pressure should be 10” w.c. with proper gas line without pressure drop

during burner operation).

3. Combustion air.

Check these three items properly before proceeding in detail for other problems.

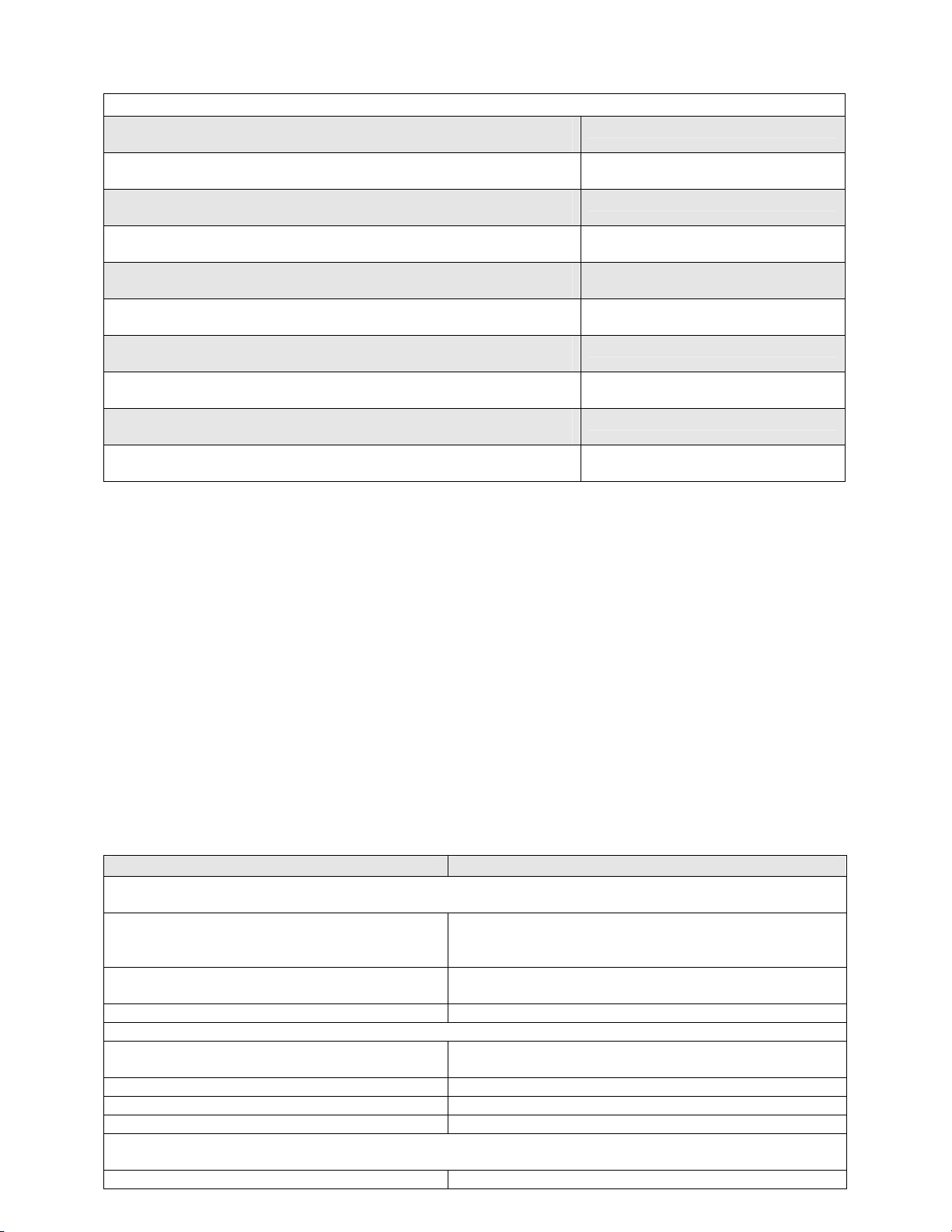

Condition Solutions

1. Burner motor runs and:

No flame after pre-purge & no fuel indicator (where

applicable)

Check 24V feed to airflow switch & after airflow switch to

control. Fix or replace the airflow switch. If there is no

secondary power, then replace the 24Vtransformer.

No flame, fuel indicator on (where applicable),

faulty ignition transformer or spark separately

Check ignition transformer, electrode, cracked electrode or

gap. Fix or replace.

Fenwal control defective after above tests. Replace

Burner locks out after 4 seconds

First, check ionization electrode, ionization cable (for

cracks) and boot. Fix as needed.

Polarity reversed Check power feed for broken polarity

Bad earth grounding Fix the ground wire

Gas pressure is too low Check the gas pressure and adjust to proper pressure

2. Pulsation at start

First, check the burner head location with respect to the end