Heatcraft intelliGen H-IM-iFM User manual

H-IM-iFM July 2023 Part No. 25011801

intelliGen Field Mount

(iFM) Kit

Installation and Operation Manual

intelliGen Components

intelliGen Board (iRC) Layout ................................ 2

intelliGen User Interface (iRCUI) Layout ................ 3

IntelliGen Remote Access Cards (iWC, iIC)............ 3

Installation & Wiring

Installation Tips .................................................... 4

Evaporator Unit ................................................... 4

Condensing Unit by Others .................................. 4

Special Condensing Unit by Heatcraft ................... 5

Refrigerant Line Brazing ...................................... 5

Leak Testing ....................................................... 5

Refrigerant Charging ............................................ 5

Power Supply....................................................... 5

Wiring .............................................................. 5-7

Wiring Terminals .................................................. 8

Wiring Diagrams .............................................9-20

Installation Checklist ......................................... 21

Start-up & Operation

Check-Out Installation........................................ 22

Initial Power On ................................................. 22

System Start-up ............................................... 23

Cooling Start-up Operation ............................... 23

Home Menus & PIN............................................. 24

Navigation, System & Local .............................. 24

Menus and Settings .....................................25-31

Cooling Sequence of Operation .......................... 32

Defrost Sequence of Operation............................ 33

Table of Contents

intelliGen Field Mount (iFM) Kits ...................... 2

Components needed for Installation ................2

Preparation for Installation ..............................3

Components Included in Kit..........................4-7

Components Not Included in Kit ...................... 8

Electronic Expansion Valve EXV ....................8-9

Field Wire Connections.................................. 10

Unit Cooler Product Families Supported......... 11

Main Control Board (iRC) Layout.................... 12

User Interface (iRCUI) Layout......................... 13

Optional Remote Access Cards...................... 13

Typical Wiring Diagrams........................... 14-15

Remote Mount intelliGen Controller .......... 16-17

Components Installation in Unit Cooler ..... 18-21

Retrofit of an Existing Unit Cooler .................. 22

Check-Out Installation................................... 23

System Start Ups ..................................... 24-25

iFM Kit Accessories....................................... 26

Scan QR code to view the

manual online

2

intelliGen Field Mount (iFM) Kits for

Unit Coolers

The intelliGen™Field Mount Kit is designed to install in the

field for new unit coolers without factory mounted controls

or retrofit of existing unit coolers with mechanical control

to upgrade to electronic control. The intelliGen control can

be remote mounted up to 40 feet from the unit cooler at a

convenient location for easy access. The intelliGen control is

pre-assembled in a IP65 rated housing for both indoor and

Components Needed for Installation

The iFM kit comes with the intelliGen controller, 3 tempera-

ture sensors, 1 pressure transducer with cable, 1 terminal

board and mounting accessories. The temperature sensors

and pressure transducer cable are 25 feet in length. Other

wire lengths are available as optional kit in separate part

numbers. See Components Included section for details.

There are individual system dependent components are

not included but required for each installation. These

components include the 24VAC control power transformer,

the electronic expansion valve (EXV), the power wires for

control power, fan motors, defrost heaters and solenoid

outdoor applications. It supports Heatcraft’s major unit cooler

product lines such as the Low Profile, Center Mount and

Low Velocity Center Mount, Medium Profile, High Profile

Large Unit Coolers and others. It is universal fit for field

mount and retrofit for all air and electric defrost unit coolers

for refrigeration.

valve. Not all applications require defrost heaters and solenoid

valve, check the system requirement for wiring needs.

See Components NOT Included section for details and avail-

ability options.

Field wire runs between the intelliGen controller and the unit

cooler should be in conduits and have to meet local building

and electric code requirements. Conduit fittings are needed

for the conduit runs. Please conduct a site survey and review

your local codes for detailed requirements prior to installation.

Low voltage and communication wires need to run in separate

conduit from the high voltage wires to minimize interference.

Field Mount Kit Includes

Pre-Assembled, Wall-Mount

Controller Assembly

- intelliGen™ main control board and

display board inside water resistant

plastic housing with connection cable

3X Temperature Sensors (with 25ft leads)

Pressure Transducer with Harness (25ft)

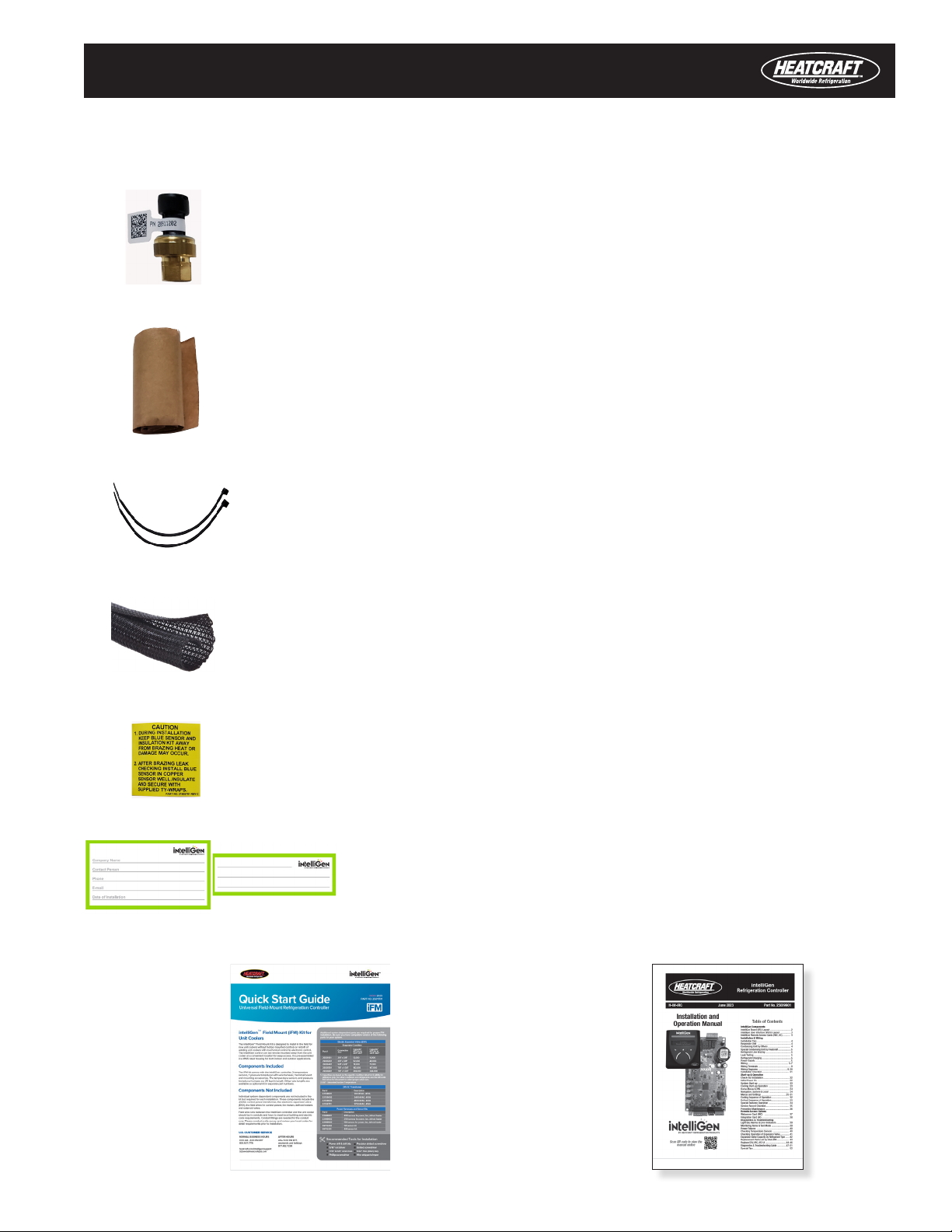

Terminal Board with Screws

and Accessories

Easy-to-Follow Wiring Diagram

User Manual

intelliGen™ controllers are the simple,

intuitive alternative for refrigeration control.

Easy-to-read 3-color LED status bar

Text message display

Easy setup and no more service codes to look up

Simple turn & press navigation knob

Optional webserver and integration cards

One per system, supports up to 8 unit-coolers

Free remote monitoring with webserver upgrade*

Energy-saving Smart Defrost

* Requires optional intelliGen Webserver card or BMS integration card. FPO FOR FINAL LEGAL Lorem ipsum dolor sit amet, consectetuer adipiscing elit,

tincidunt ut laoreet dolore magna aliquam erat volutpat. Ut wisi enim ad minim veniam, quis nostrud exerci tation ullamcorper suscipit lobortis nisl ut

aliquip ex ea commodo consequat. Duis autem vel eum iriure dolor in hendrerit in vulputate velit esse molestie consequat, vel illum dolore eu feugiat

nulla facilisis at vero eros et accumsan et iusto odio dignissim qui blandit praesent luptatum zzril delenit augue duis dolore.

Universal Field-Mount

Refrigeration Controller

with temperature sensors and pressure transducer kit

Simple setup

with intelliGen™

Quick Start

Intuitive and

easy to use

user interface

On board

USB port for

data logging and

software update

Remote

monitoring

with optional

webserver card*

Support up to

8 unit coolers in a

single system

Connect. Control. Diagnose. Relax.

Scan the QR Code

or visit

intelliGenControls.com

INTUITIVE

design

SIMPLE

setup

SMART

servicing

User-friendly

interface for easy

install and service.

Quick Start system

configuration allows for

setup in minutes, not hours.

Light Bar Alerts

Color coded LED immediately

shows the status of your system.

Full-Text Display

Guided text instruction

for setup and service.

Quick Menu Buttons

Establish preferred settings

and quickly make changes.

Turn & Press Knob

Quickly navigate system

configuration and servicing.

Ready-to-Mount

Plastic Housing

Waterproof seal for indoor &

outdoor applications.

All electronics pre-installed.

Reduce diagnosis, service

and downtime with intuitive

user interface, data logging

and optional remote monitoring.

The intelliGen™ Field Mount kit

is the simple, easy-to-install

solution for remote refrigeration

monitoring and control.

HARNESS

Sensor Harnesses (X3)

Pressure Transducer

Harness (X1)

ACCESSORIES

Screws and

Installation

Accessories

CONTROLLER

intelliGen™ Controller

Pre-Installed in IP64

Water-Resistant Case

ICON

TO

COME

IMPORTANT!

Additional components are required for

proper iFM installation. Be sure you have

compatible version of the following parts.

Recommended Tools for Installation

Scan QR Code for details and

to view our installation video

or visit

intelliGenControls.com

24VAC Transformer

EEV Kit with Cable

High Voltage Control Harness

Uni-bit

Power drill & drill bits

5/16” nut driver

7/16” & 5/8” wrenches

Phillips screwdriver

Precision slotted screwdriver

Wire Stripper/Crimper

Multimeter

intelliGen Field Mount (iFM) Kits

3

intelliGen Field Mount (iFM) Kits

Preparation for Installation

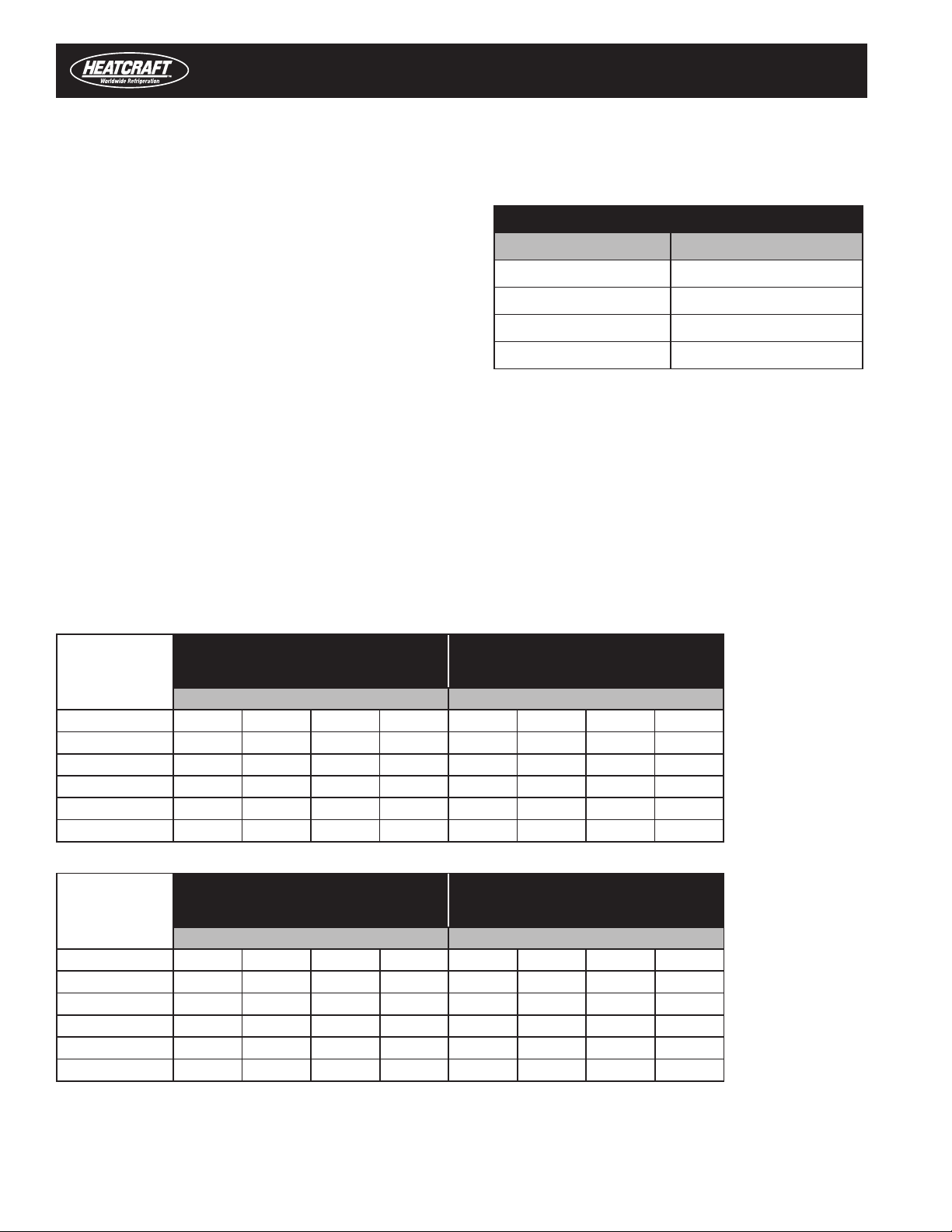

Tools Use Tools Use

Slotted Screwdrive Wrench, 7/16 and

5/8

Phillips

Screwdriver Adjustable Wrench

Precision Slotted

Screwdrive

Wire Stripper /

Crimper

5/16 Nut Driver Multimeter

Power Drill & Drill

Bits Marker

Needed Tools

Tools Use Tools Use

Slotted Screwdrive

Wrench, 7/16 and

5/8

Phillips

Screwdriver Adjustable Wrench

Precision Slotted

Screwdrive

Wire Stripper /

Crimper

5/16 Nut Driver Multimeter

Power Drill & Drill

Bits Marker

Needed Tools

Tools Use Tools Use

Slotted Screwdrive

Wrench, 7/16 and

5/8

Phillips

Screwdriver Adjustable Wrench

Precision Slotted

Screwdrive

Wire Stripper /

Crimper

5/16 Nut Driver Multimeter

Power Drill & Drill

Bits Marker

Needed Tools

Tools Use Tools Use

Slotted Screwdrive

Wrench, 7/16 and

5/8

Phillips

Screwdriver Adjustable Wrench

Precision Slotted

Screwdrive

Wire Stripper /

Crimper

5/16 Nut Driver Multimeter

Power Drill & Drill

Bits Marker

Needed Tools

Power Drill &

Drill Bits Marker

5/16" Nut Driver 5/32" Hex (Allen) Key

Precision Slotted

Screwdriver

Wire Stripper/

Crimper

Phillips

Screwdriver Adjustable Wrench

Slotted

Screwdriver

Wrench, 7/16"

and 5/8"

Tools Use Tools Use

Slotted Screwdrive

Wrench, 7/16 and

5/8

Phillips

Screwdriver

Adjustable Wrench

Precision Slotted

Screwdrive

Wire Stripper /

Crimper

5/16 Nut Driver Multimeter

Power Drill & Drill

Bits Marker

Needed Tools

Wire Puller

(Fish Tape)

Hacksaw

Tools Use Tools Use

Slotted Screwdrive Wrench, 7/16 and

5/8

Phillips

Screwdriver Adjustable Wrench

Precision Slotted

Screwdrive

Wire Stripper /

Crimper

5/16 Nut Driver Multimeter

Power Drill & Drill

Bits Marker

Needed Tools

Tools Use Tools Use

Slotted Screwdrive

Wrench, 7/16 and

5/8

Phillips

Screwdriver Adjustable Wrench

Precision Slotted

Screwdrive

Wire Stripper /

Crimper

5/16 Nut Driver Multimeter

Power Drill & Drill

Bits Marker

Needed Tools

Tools Use Tools Use

Slotted Screwdrive

Wrench, 7/16 and

5/8

Phillips

Screwdriver Adjustable Wrench

Precision Slotted

Screwdrive

Wire Stripper /

Crimper

5/16 Nut Driver Multimeter

Power Drill & Drill

Bits Marker

Needed Tools

Tools Might Be Needed

Wire Marker

Label Electrical Tape

Multimeter Marker

Needed Tools

Tools Description Tools Description

Tools Might Be Needed

Tools Description Tools Description

Brazing Tools

4

Components Included in the Kit

Terminal

Board

Pressure Transducer

Harness

Quick Start Guide & Manual

intelliGen Controller

Temperature

Sensor Brackets

Temperature Sensors

Pressure Transducer

& Accessories

intelliGen Field Mount (iFM) Kits

Wire Sheathing

5

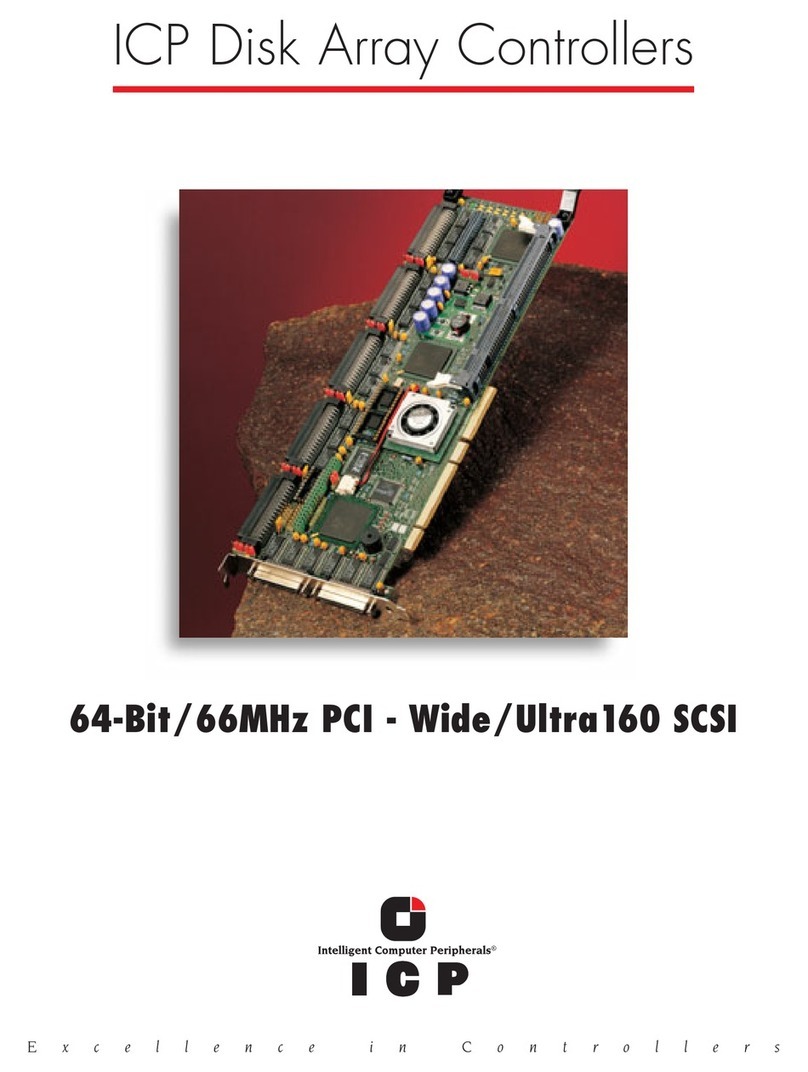

• intelliGen Controller - Quantity of 1

Main control board and user interface board are pre-assembled in a IP65

rated housing.

For room temperature, suction temperature and coil temperature (25 feet

length)

• Temperature Sensors - Quantity of 3

For suction pressure transducer connection (25 feet length)

• Pressure Transducer Harness - Quantity of 1

For power, fan motors and defrost heater wire connections

• Terminal Board - Quantity of 1

Components Included in the Kit

intelliGen Field Mount (iFM) Kits

Knockouts

Knockouts (top & bottom)

6

Temperature Sensor Brackets & Accessories Bag

For mounting the room temperature sensor at the return air side of the unit

cooler.

• Room Temperature Sensor Bracket - Quantity of 1

For mounting the suction temperature sensor to the suction refrigeration line.

• Suction Temperature Sensor Tube - Quantity of 1

For mounting the coil temperature sensor to the coil.

• Coil Temperature Sensor Bracket - Quantity of 1

Two screws for the coil temperature sensor mounting bracket. Two screws for

the terminal board.

• Mounting Screws - Quantity of 4

Cable ties for securing the room temperature sensor to the mounting bracket.

• Cable Ties - Quantity of 2

intelliGen Field Mount (iFM) Kits

7

intelliGen Field Mount (iFM) Kits

Pressure Transducer & Accessories Bag

Mount on the main suction line port to measure suction pressure.

• 300 PSI Pressure Transducer - Quantity of 1

Insulation tape for suction temperature sensor tube to prevent condensation

• Cork Tape Roll - Quantity of 1

Caution label for suction temperature sensor installation

• Caution Label - Quantity of 1

Instruction Manuals Bag

• intelliGen Installation

and Operation Manual

• iFM Kit Quick

Start Guide

Cable ties for securing suction temperature sensor inside the metal tube and

the suction line

• Cable Ties - Quantity of 2

Information labels to apply on user interface swinging panel

• Labels for User Interface Panel - Quantity of 1

Wrap wires inside the iFM kit housing for additional protection

• Wire Sheathing - Quantity of 4

8

Components NOT Included in the kit but are needed for

installation

These are system dependent components based on ap-

plication. Field installer to provide these components

separately based on the specific system requirement.

• 24VAC Control Power Transformer – quantity of 1

A 24VAC step down transformer from system voltages

(120VAC, 208-230VAC, 460VAC or 575VAC) is needed

to power the intelliGen control.

Note: For small unit coolers like Heatcraft's Low Profile

Unit Coolers with 460VAC or 575VAC system

voltages, external contactors are required to power

the motors and heaters due to limited cabinet space

to mount the components.

Heatcraft 24V AC Transformers

PART # Description

22529601 120/24VAC, 40VA

22529602 240/24VAC, 40VA

22529603 460/24VAC, 40VA

22529701 575/24VAC, 40VA

• Electronic Expansion Valve EXV -

Quantity of 1 (If use EXV is preferred)

These EXVs are available from Heatcraft. Field installer to select and provide one of these valves to match the system

capacity requirement. A valve cable with the length matches the conduit run is also required.

intelliGen Field Mount (iFM) Kits

intelliGen Field Mount (iFM) Kits

R-22

Evaporator Temperature (°F)

100 psi Pressure Drop

R-404A/R-507

Evaporator Temperature (°F)

100 psi Pressure Drop

+20 -20 +20 -20

PART NUMBER TONS BTUH TONS BTUH TONS BTUH TONS BTUH

29326101 0.44 5220 0.41 4920 0.73 8706 0.64 7692

29326201 4.25 51000 3.99 47900 3.11 37309 2.75 32966

29326401 7.52 90260 7.54 90480 4.66 55964 4.12 49449

29326501 15.14 181680 14.25 171000 10.89 130692 9.62 115480

29326601 22.18 266160 20.87 250440 16.08 192985 14.21 170521

R-407A

Evaporator Temperature (°F)

100 psi Pressure Drop

R-407C

Evaporator Temperature (°F)

100 psi Pressure Drop

+20 -20 +20 -20

PART NUMBER TONS BTUH TONS BTUH TONS BTUH TONS BTUH

29326101 0.99 11831 0.90 10808 1.07 12898 0.99 11863

29326201 4.23 50704 3.86 46320 4.61 55279 4.24 50839

29326401 6.34 76056 5.79 69481 6.91 82919 6.35 76258

29326501 14.80 177616 13.52 162259 16.14 193641 14.84 178088

29326601 21.86 262273 19.97 239598 23.83 285938 21.91 262970

9

These EXVs are available from Heatcraft. Field installer to select and provide one of these valves to match the system

capacity requirement. A valve cable with the length matches the conduit run is also required.

intelliGen Field Mount (iFM) Kits

intelliGen Field Mount (iFM) Kits

Sporlan SER and SERI Series of Electronic Expansion Valve Support

The Sporlan SER and SERI Series of electronic expansion valves are supported. This valve option is selectable in the

intelliGen Quick Start initial setup process. See Sporlan's website and document for SER and SERI Series valve sizes and

selection https://solutions.parker.com/sporlanvirtualengineer

R-449A

Evaporator Temperature (°F)

100 psi Pressure Drop

+20 -20

PART NUMBER TONS BTUH TONS BTUH

29326101 1.01 12125 0.92 11083

29326201 4.33 51965 3.96 47499

29326401 6.50 77947 5.94 71249

29326501 15.17 182030 13.87 166389

29326601 22.40 268793 20.47 245696

R-407F

Evaporator Temperature (°F)

100 psi Pressure Drop

R-448A

Evaporator Temperature (°F)

100 psi Pressure Drop

+20 -20 +20 -20

PART NUMBER TONS BTUH TONS BTUH TONS BTUH TONS BTUH

29326101 1.09 13067 1.01 12094 1.01 12128 0.92 11098

29326201 4.67 56001 4.32 51831 4.33 51977 3.96 47561

29326401 7.00 84001 6.48 77746 6.50 77966 5.95 71341

29326501 16.35 196168 15.13 181562 15.17 182075 13.88 166604

29326601 24.14 289669 22.34 268100 22.40 268859 20.50 246014

Cables for Carel EXV

PART NUMBER DESCRIPTION

22592201 10ft cable for Carel EXV

22592102 25ft cable for Carel EXV

22592103 40ft cable for Carel EXV

10

The field wire connections are to be provided by the field installer. A 25 feet long power harness with connectors and

terminals preassembled is available from Heatcraft for ease of installation. The part number is 22699902. It includes the

power wires listed below.

• 24VAC power wires for intelliGen control – two 18 AWG wire with ¼” quick connect terminal on one end and ¼”

piggyback quick connect terminal on the other end

• Fan motor wires – two 18 AWG wires with ¼” female quick connect terminals on both ends

• Defrost heater wires – two 14 AWG wires with fully insulated ¼” female quick connect terminals on both ends,

and two 18 AWG wires with fully insulated ¼” female quick connect terminals on both ends. (Wires need depend on

application.)

• Solenoid valve control wires – two 18 AWG wires with ¼” female quick connect terminals on one end and bare

wires on the other end. (Wires need depend on application.)

Heatcraft Power Harnesses

PART # Description

22699903 15ft harness for power, fan, defrost heater

22699902 25ft harness for power, fan, defrost heater

22699901 40ft harness for power, fan, defrost heater

intelliGen Field Mount (iFM) Kits

Conduit runs for field wires

Field wires between the intelliGen controller and the unit cooler should be in conduits and meet local building and

electric code requirements. Conduit fittings are also needed based on installation application. A site survey and instal-

lation planning is recommended to determine conduit lengths and the type of conduit fittings and quantity needed. It is

required to run power wires and low voltage (sensors and communication) wires in separate conduits.

Wire Protection

High voltage and low voltages wires inside the iFM kit requires additional insulation protection. Wire sheathing should

cover all wiring within the iFM enclosure. Sets of wire sheathing are provided with the iFM kit. High voltage wires may

share a sheath, and low voltage wires may share a sheath, but each group should be separately sheathed to maintain

separation.

Field Wire Connections

Power wires between system components and the intelliGen controller

Note:

For systems with defrost heater load higher than 30 Amp, external contactors are required to power the defrost

heaters. The defrost heaters relay on the intelliGen controller use as pilot relay for the external contactors.

11

intelliGen Field Mount (iFM) Kits

Unit Cooler Product Families Supported

The iFM Kit is designed to universal fit for Heatcraft’s Unit Coolers and other manufacturer’s Unit Coolers also.

Low Profile Unit Cooler

Center Mount Unit Cooler

Medium Profile Unit Cooler

Low Velocity Center Mount Unit Cooler

High Profile Large Unit Cooler

12

intelliGen Main Control Board (iRC) Layout

intelliGen Field Mount (iFM) Kits

Defrost

Heater

Relay

EXV

Grounded

Mounting

Screw

Evap

Fans

Relay

EXV

Capacitor

24V

Power

Supply

Central

Processing

Unit

USB Data

Port

Suction

Pressure

Aux

Temp Product Load

Switch

iRC-UI

Connection

Chasis

Ground

Grounded

Mounting

Screw

Condensing

Unit Connection

Door Switch

Evap

Communication

Connection

Grounded

Mounting

Screw

Coil

Temp

Suction

Temp

Box

Temp

Clock

Battery

Evap 2

Speed

Fans

Spare I/O

Alarm

Contacts

LLSV

Relay

13

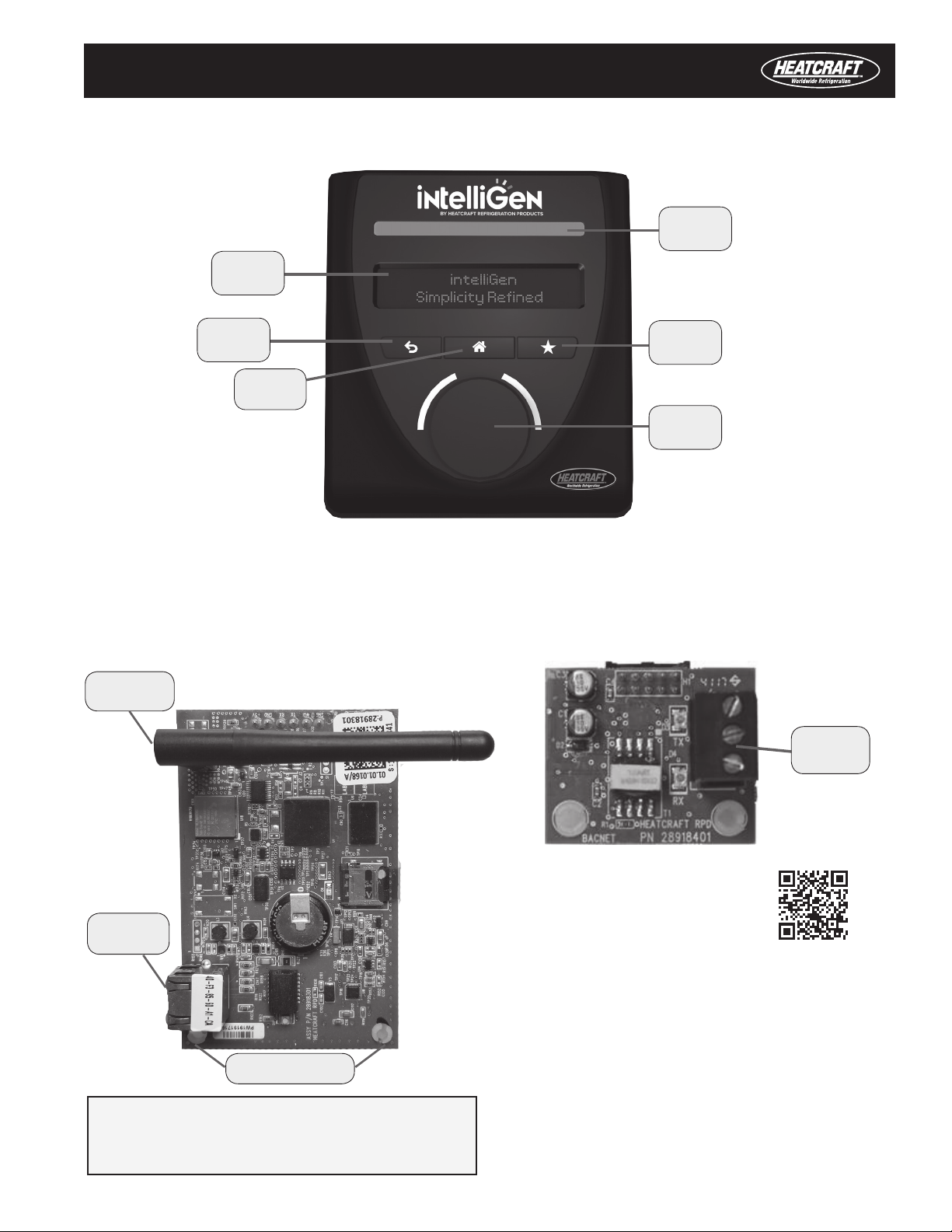

OLED

Display

Return

Button

Home

Button

Status

Light Bar

Favorites

Button

Control

Button

intelliGen User Interface (iRCUI) Layout

intelliGen Optional Remote Access Cards

intelliGen Field Mount (iFM) Kits

INTEGRATION CARD - iIC

MULTI-SYSTEM CONTROL CARD - MSC

WEBSERVER CARD - iWC

Wiring

Terminal

Long Name Abbrev. Name

Evap/Evaporator EV

Set-Point SP

Auxiliary AUX

Temperature/Temp TEMP

Calibration CALIB

Electronic Expansion Valve EXV

Condensing Unit CU

Compressor COMP

Connection CXN

Lead-Lag LL

LEGEND

NOTE: Refer to iWC & MSC Installation & Operation Manual

(H-IM-iWC/MSC for installation and maintenance instructions.

* MSC card comes with Wi-Fi Direct antenna and the iWC

webserver card does not come with Wi-Fi Direct antenna.

Scan QR code to view the manual or visit

www.intelliGencontrols.com/resources

Wi-Fi Direct

Antenna*

Ethernet

Connector

Screw Mount Holes

14

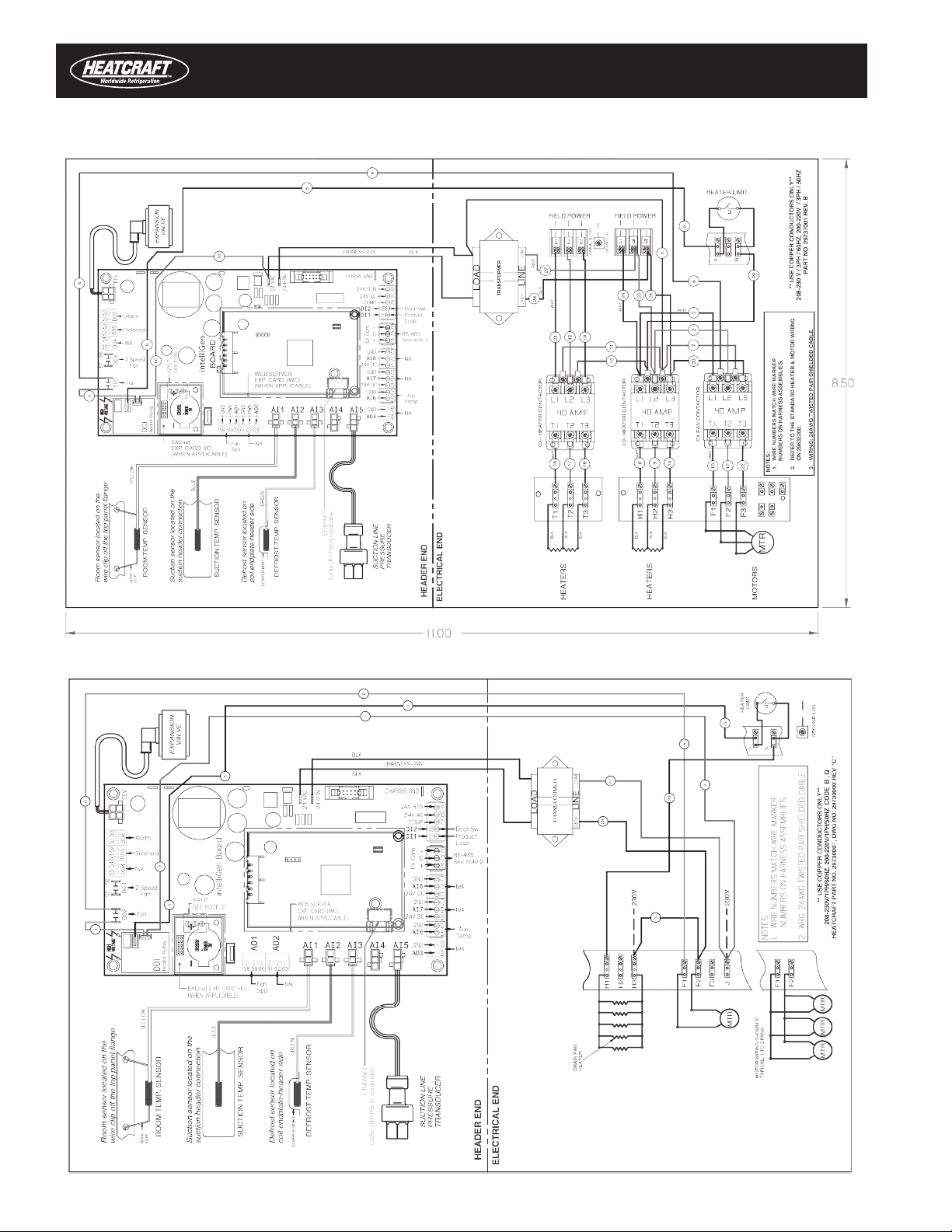

Typical Wiring Diagram For Applications Without Contactors

Typical Wiring Diagram For Applications With Contactors

iFM Kit Installation Section

15

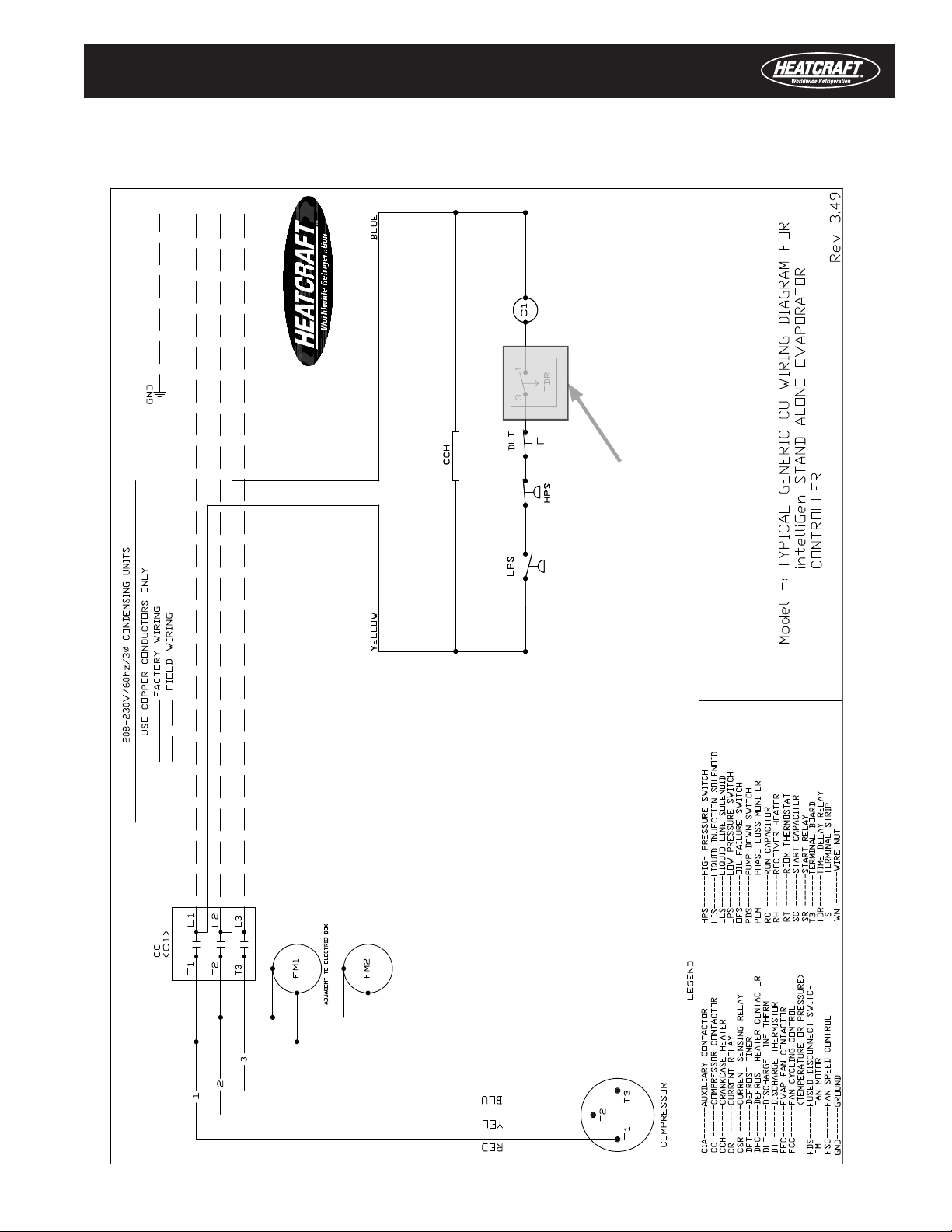

Typical Generic Condensing Unit Wiring Diagram

for intelliGen Stand-alone Evaporator Controller

iFM Kit Installation Section

TDR to be bypassed or

removed when installing

16

Remote Mount intelliGen Controller

1. Identify Remote Mount Location

The iFM kit designed to be remote mounted up to 40 feet

away from the unit cooler. The kit comes with 25 feet

long wire sensors. A 40 feet long wire sensors kit is

available separately. It can be mounted outside of a

walk-in cooler, near the entrance door.

a) Identify a flat surface to mount the iFM kit

b) Prepare the mounting location and mark screw

holes

Pro Tip: Use the iFM kit housing or the housing outline on the

Quick Start Guide and mark the four screw holes

2. Route Conduits and Wires to Unit Cooler

a) Determine length and conduit routing base on ap-

plication need

b) Determine the knockout on the iFM kit housing

to use for conduit and wires routing. (1-1/2” and

7/8” knockouts are available at the top, bottom

and the top left side of the housing.)

c) Determine the conduit fittings for connecting the

conduit to the iFM housing

d) Run wires through the conduits

e) Connect fittings to the conduits

Pro Tip: Use knockouts on the left side or the top side for power wires and use the knockouts on the bottom for sensors and

communication wires.

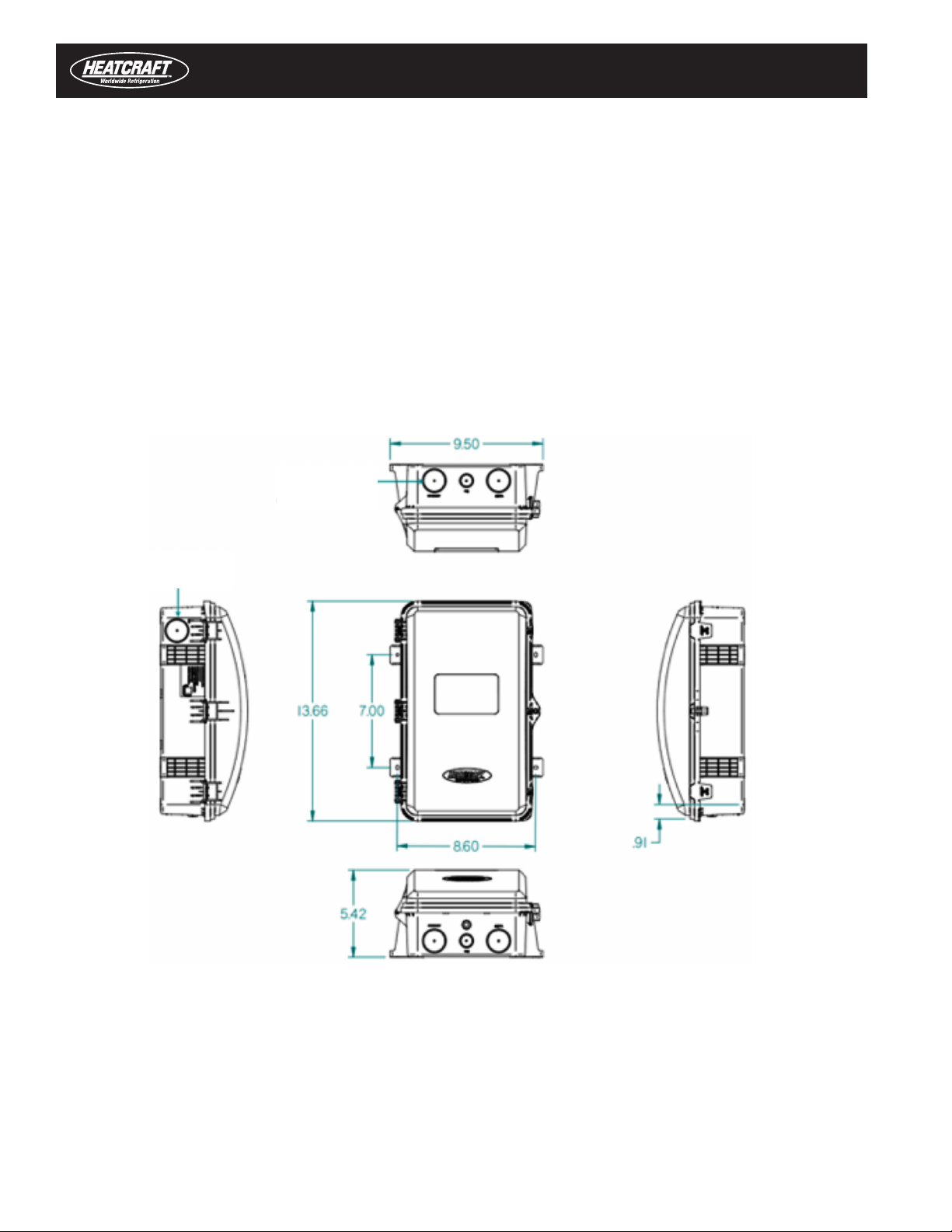

iFM Kit Assembly Dimensions (inch)

Knockouts

(top & bottom)

Knockouts

iFM Kit Installation Section

17

IntelliGen Board Layout

Remote Mount intelliGen Controller (Cont.)

3. Mount the iFM Kit

a) Mount the iFM kit housing to the marked screw hole

locations with #10, 1-1/4" long screws

b) Pull the wires through the knockouts on the iFM housing

c) Tighten the conduit fittings to the conduit and to the

iFM housing

4. Connect the wires to the intelliGen control board

a) Connect wires to the iRC main control board per the

connections layout below.

Defrost

Heater

Relay

EXV

Grounded

Mounting

Screw

Evap

Fans

Relay

EXV

Capacitor

24V

Power

Supply

Central

Processing

Unit

USB Data

Port

Suction

Pressure

Aux

Temp Product Load

Switch

iRC-UI

Connection

Chasis

Ground

Grounded

Mounting

Screw

Condensing

Unit Connection

Door Switch

Evap

Communication

Connection

Grounded

Mounting

Screw

Coil

Temp

Suction

Temp

Box

Temp

Clock

Battery

Evap 2

Speed

Fans

Spare I/O

Alarm

Contacts

LLSV

Relay

18

Components Installation in Unit Cooler

5. Power Transformer

a) Select a 24VAC transformer with the primary voltage

matches the system voltage

b) Connect the wires (transformer power, heater wires,

motor fan wires, solenoid valve wires) as needed per

the system requirement to the terminal board.

See wiring diagrams in the System Wiring Diagrams Section

on Pages 14 and 15.

b) Mount the transformer to the electrical end of the unit

cooler, see picture shown as example

6. Terminal Board

a) Mount the terminal board to the electrical end with the

screws provided

Pro Tip: Mount the new terminal board at the same loca-

tion of the existing terminal board for incoming power

New Unit Cooler Installation

STEP 5 & 6

Terminal Board

24VAC

Transformer

19

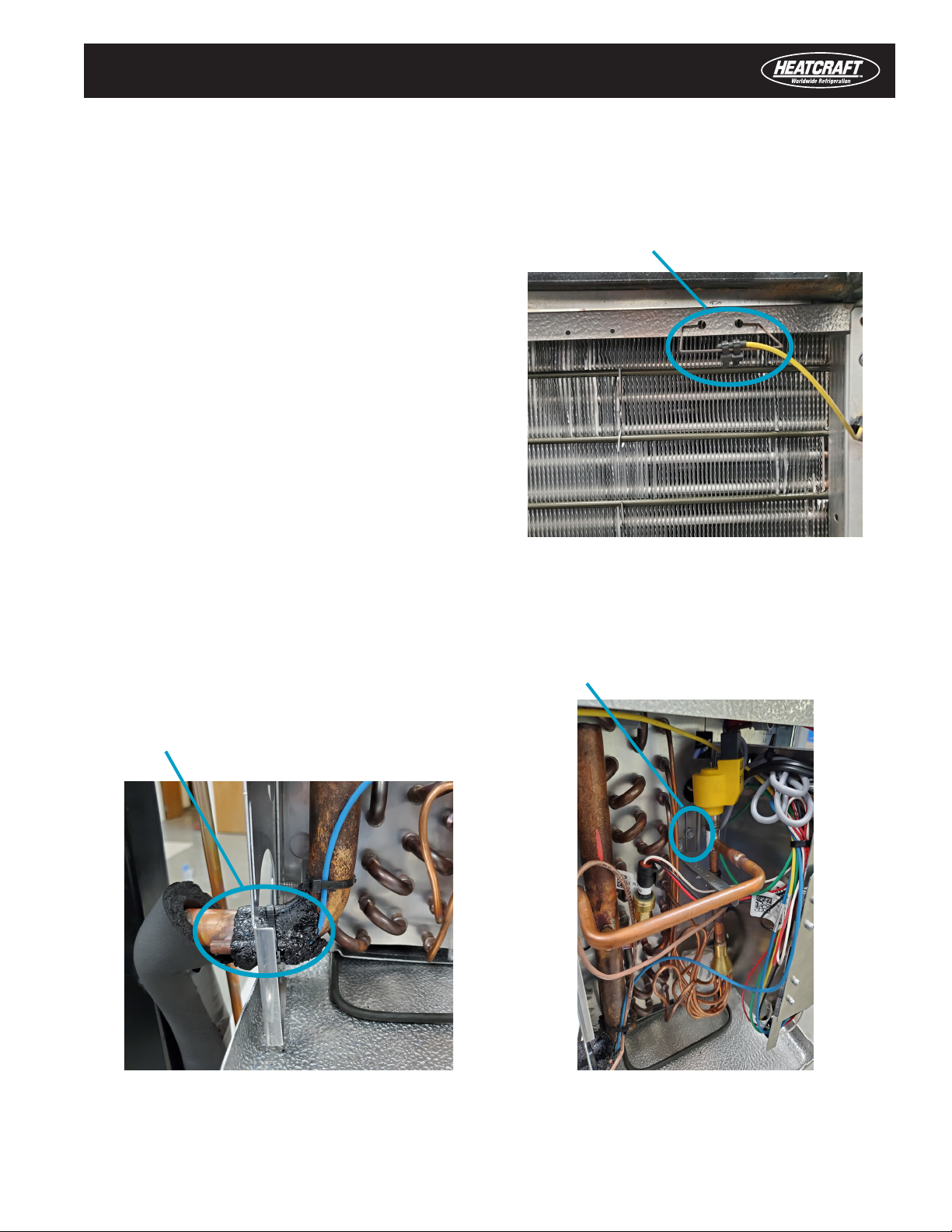

Components Installation in Unit Cooler (Cont.)

7. Temperature Sensors

a) Room Temperature Sensor

i. Drill two ¼” holes, 1-1/4" apart, on the return air area

of the unit cooler (typically at the back of the unit)

ii. Insert the Room Temperature Sensor Bracket into

the two drilled holes as shown in the picture

iii. Use cable ties to secure the Room Temperature

Sensor to the bracket as shown in the picture

b) Suction Temperature Sensor

i. Braze the metal Suction Temperature Sensor Tube

onto the suction line

ii. Insert the temperature sensor into the metal tube

iii. Wrap the temperature sensor and the metal tube

with cork tape

iv. Secure the temperature sensor with the cable ties

provided as shown in the picture

c) Coil Temperature Sensor

i. Attached the Coil Temperature Sensor onto the Coil

Temperature Sensor Bracket provided

ii. Screw tight the sensor bracket onto the coil end

plate with the self-drilling screws provided. See

picture as example

New Unit Cooler Installation

STEP 7b

STEP 7a

Room Temperature

Sensor

Suction Temperature

Sensor

STEP 7c

Coil Temperature

Sensor

20

8. Pressure Transducer

a) Locate the Schrader valve on the suction line.

(Depends on system, a new Schrader valve may have

to be installed or brazed onto the suction line.)

b) Screw the pressure transducer onto the Schrader

valve.

Pro Tip: Use correct tools to prevent damage to the

Schrader valve and the copper pipe. Use 7/16” wrench

to hold steady of the Schrader valve at the bottom, then

tighten the pressure transducer at the top with a 5/8”

wrench

c) Plug in the pressure transducer harness and make

sure the harness clip securely latches over the

pressure transducer, see picture as example

New Unit Cooler Installation

STEP 8

Pressure Tranducer

Components Installation in Unit Cooler (Cont.)

Components Installation in Unit Cooler (Cont.)

This manual suits for next models

1

Table of contents

Other Heatcraft Controllers manuals

Popular Controllers manuals by other brands

dixell

dixell XM470K Installing and operating instructions

Onkyo

Onkyo SC886 - PR Preamplifier / Processor instruction manual

Wilo

Wilo fluidcontrol ek Assembly instructions

Milnor

Milnor MilTouch Operator's guide

Baldor

Baldor MicroFlex quick start guide

Full Gauge Controls

Full Gauge Controls TC-910R quick start guide