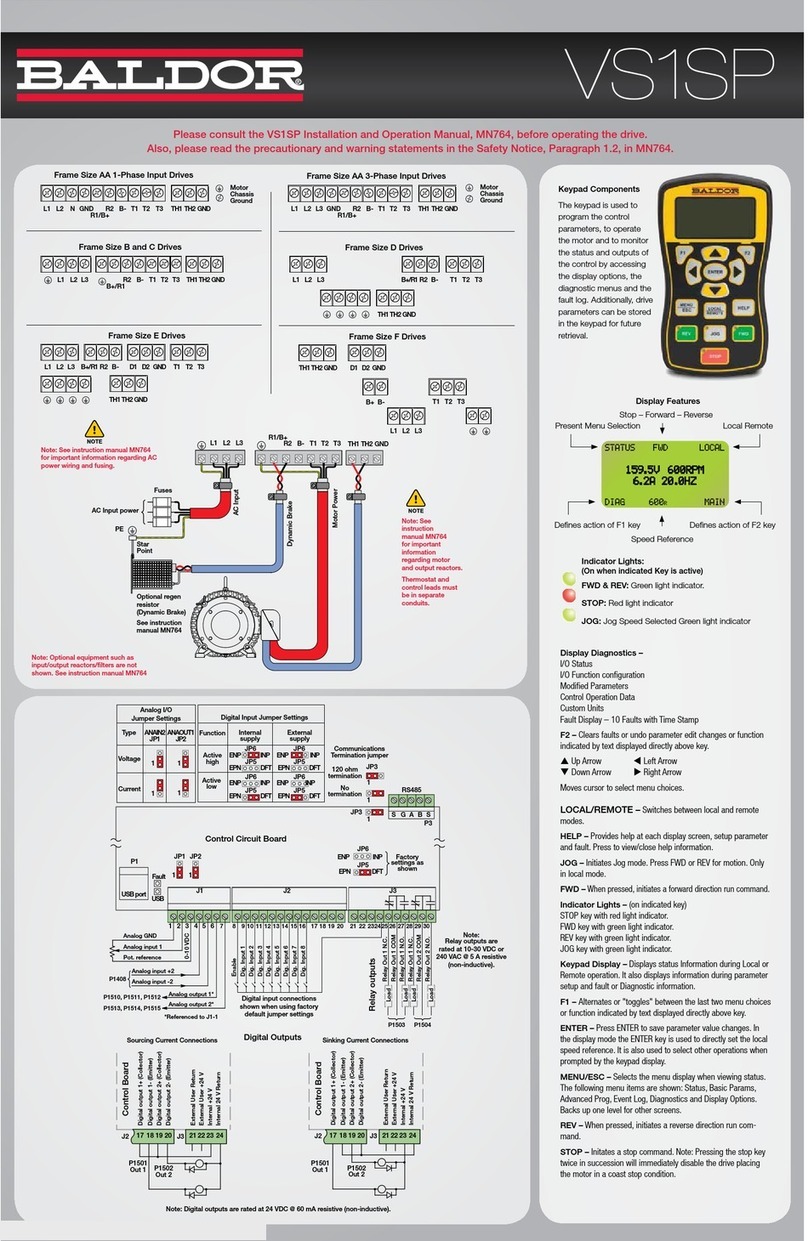

Regeneration resistor (optional)

A suitable regeneration resistor may be required to

dissipate excess power from the internal DC bus

during motor deceleration.

The regeneration resistor must have a resistance of

at least 39Ω, inductance of less than 100µH, and a

power rating suitable for the application. Baldor parts

RG56 (44W) or RG39 (100W) are recommended.

Connect the regeneration resistor to R1 and R2.

X1

R1

R2

Step & direction inputs (optional)

+5V step and direction signals can be used to provide the

position reference when operating in position control mode.

Connect the step and direction signals to pins 9, 10 and 11

of connector X3.

Step and direction signals are not required if the analog

demand input is to be used as a torque or speed reference

(see below).

X3

STEP

DIR

DGND

Motor feedback input

The MicroFlex can operate with incremental or SSI encoder

feedback devices. The device type is configured in

WorkBench v5. Suitable cables are available from Baldor.

Connect the motor feedback signal to connector X8.

X8

Serial communication

The MicroFlex communicates with the host PC using RS232

communication.

Connect an RS232 cable between connector X6 and the host

PC’s COM port.

X6

AC power, fuses and filter

MicroFlex can accept supply voltages of

105-250VAC 50/60Hz, 1-phase or 3-phase.

For three phase supplies, connect phases to L1, L2

and L3.

For single phase supplies, connect supply to any two

line inputs, for example L1 and L2.

The AC supply must incorporate a circuit breaker (or

fuse) and the specified filter. For ideal earthing, mount

filter on the same metal surface as MicroFlex.

Protective earth must be connected to the MicroFlex

case using an M4 screw in the top of the metal

heatsink.

X1

L1

L2

L3

Motor U V W outputs

Connect the motor to the U, V and W outputs.

The U, V and W outputs must be connected to

their corresponding U, V or W terminal on the

motor. Misconnection may result in uncontrolled

motor movement.

Motor earth should be connected to the

MicroFlex case using an M4 screw in the top of

the metal heatsink.

The motor cable shield should be connected

using a conductive earth/ground clamp,

attached to the M4 threaded hole in the top of the

metal heatsink.

X1

V

W

U

24VDC control supply and filter

MicroFlex requires a 24VDC (20-30VDC) supply to power

the control electronics.

Connect the control supply at connector X2.

A fused DC supply should be provided for the MicroFlex.

If other devices are to be powered from the same 24V

supply, a filter (Baldor catalog number FI0014A00) should

be installed to isolate the MicroFlex from the rest of the

system. Alternatively, a ferrite sleeve may be attached to

the supply cable near connector X2.

X2

24V

0V Drive enable input

To enable the MicroFlex, 24VDC (12-30VDC) must be

applied to the drive enable input.

Connect the drive enable signal to pins 6 and 7 of

connector X3.

X3

Drive enable+

Drive enable-

Analog demand input (optional)

A ±10VDC signal can be used to provide the demand

reference for torque and speed control modes.

For differential operation, connect the demand signal to pins

12 and 13 of connector X3. For single ended operation,

connect the positive signal to pin 13; connect the 0V side of

the signal and AIN- to AGND (pin 14).

An analog demand signal is not required if the step and

direction inputs are to be used as a position reference (see

above).

X3

AIN+

AIN-

3

4

5

6

7

8

9a

9b

10

AGND

COM

Host PCAC power

Motor power U V W

Serial

communication

Control circuit supply.

Use twisted pair cable

with a ferrite sleeve.

Motor

+24V 0V

Filter

L1

L2

L1

L2

L3

Star

point

L1

L2

L3

Optional regen resistor

(Dynamic brake)

L3 Connect motor power cable

shield at protective earth point,

using conductive shield clamp.

Drive enable

input

+24V 0V

PE

From

fuses AC power in

Motor feedback

Regen

Shielded twisted pair, clamped to

metal backplane near drive using

conductive shield earth/ground

clamp.

Connect AC power cable shield to

metal backplane using conductive

shield clamp.

Demand input: ±10V analog input

(shown) or +5V step and direction

inputs. Use shielded twisted pair(s) for

demand input(s). Connect cable shield

to the bottom of MicroFlex using

conductive shield earth/ground clamp.