VALVE ADDRESS:

#2

Options: Valve Address #1 (First Control Valve)

Valve Address #2 (Second Control Valve) (Default)

Valve Address #3 (Third Control Valve)

Valve Address #4 (Fourth Control Valve)

SYSTEM TYPE: 4

SINGLE UNIT

Options: System 4 (single unit)

System 5 (2-4 units) - Parallel Interlock

System 6 (2-4 units) - Parallel Series Regeneration

System 7 (2 units) - Alternating

System 9 (2-4 units) - Alternating

System 14 (2-4 units) - Demand Recall

Example:

System Type 4, Single Unit

Example:

Valve Address #2 (Second Control Valve) (Default)

SYSTEM SIZE:

2 VALVES

Options: 2 Valves in the System (Default)

3 Valves in the System

4 Valves in the System

Example:

2 Valves in the System (Default)

REGEN TYPE:

TIME CLK DELAYED

Options: Time Clock Delayed (System 4 Only) (Default)

Meter Immediate (All System Types)

Meter Delayed Fixed Reserve (Systems 4 & 6 Only)

Example:

Time Clock Delayed (Default)

VALVE TYPE:

STAGER-NOTCH CAM

Options: 2750

2850

2900

3150

3900

Stager - Notch Cam (Default)

Example:

Stager - Notch Cam (Default)

REMOTE SIGNAL

START:OFF

Options: 00:06:00 (Hours:Munutes:Seconds)

Range: 1 second to 99 minutes (1 hour, 39 minutes)

Example:

Off (Default)

DISPLAY FORMAT:

US-GALLONS

Options: U.S. - Gallons (Default)

EU-Metric - Liters (Metric)

Example:

U.S. Gallons (Default)

UNIT CAPACITY:

0300000 GRAINS

Options: Grains (in U.S. Format) (Default)

Grams (in Metric Format)

Example:

0300000 Grains (Default)

CAPACITY SAFETY

FACTOR: 00%

Range: 0 to 50%

Example:

00% (Default)

FEED WATER

HARDNESS: 15 GPG

Range: 1 to 199 Grains/Gallon (U.S. Format)

2 to 199 miligrams CaCOs/L (Metric Format)

Example:

15 GPG (U.S. Format) (Default)

SELECT LANGUAGE:

ENGLISH

Options: English

Espanol

Portugues

Deutsch

Francais

Example:

English

TRIP POINT 1:

000 gpm

Range: 2 to 4 Valves in the System

NOTE: This screen will not display for System Type 4.

NOTE: This screen will not display for System Type 4.

NOTE: In European Units - Liters (Metric) mode, the display will be in

24-hour time.

NOTE: In U.S. - Gallons mode, the display will be in 12-hour time.

NOTE: Use the Shift button to move to the left.

Range: 1 to 9,900,000 Grain Capacity in U.S. Format

1.0 to 190,000 grams CaCO3Capacity in Metric Format

NOTE: Use the Shift button to move to the left.

NOTE: Use the Shift button to move to the left.

NOTE: This screen will only display on the lead unit for System Types 6 & 7.

For all other System Types, it will display for all units.

NOTE: Display will only appear on the master timer and it must be

programmed as valve position #1. Use the Shift button to change each

decimal position.

NOTE: This screen will only display for System 14.

REGENERATION DAY

OVERRIDE:OFF

Example:

Off (Default for Meter)

On (Default for Time Clock)

REGENERATION DAY

OVERRIDE:01 DAYS

Options: Off (Default for Meter) or On (Default for Time Clock)

Example:

1 Day

Range: 1 to 99 Days

REGENERATION

TIME: 02:00AM

Example:

2:00 A.M. (Default)

Options: A.M. (U.S. Format)

HR (Metric Format)

NOTE: Regeneration time will not appear unless Regeneration Day Override

is on.

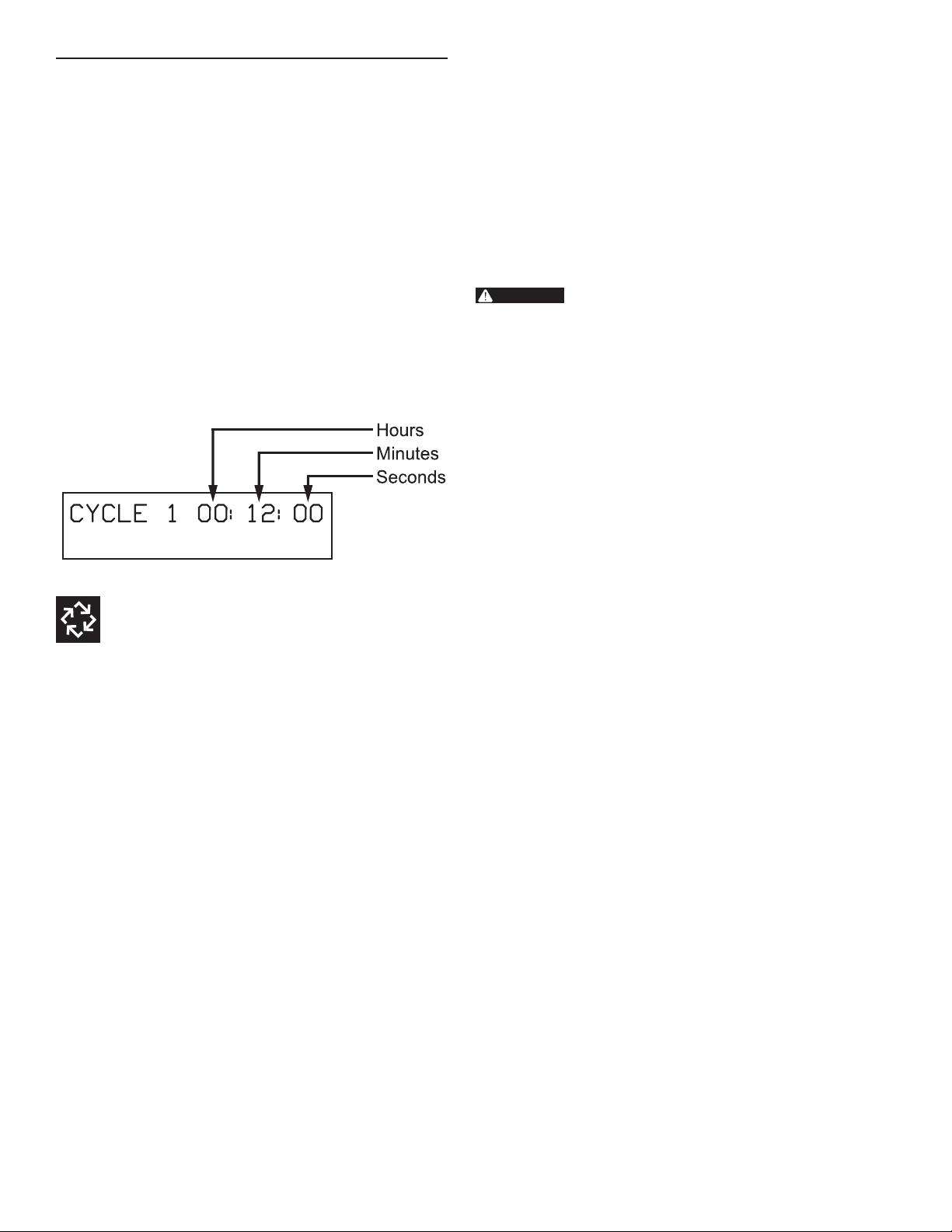

CYCLE 1 00:10:00 Example: Backwash

00:10:00 (Default 48-00 Stager & 51-09 Stager)

(Hours:Minutes:Seconds)

AUXILIARY RELAY:

DISABLED

Example:

Auxiliary Relay is Disabled

Options: Enabled

Disabled (Default)

AUX RELAY OUTPUT

START 1 00:00:00

Example:

Auxiliary Relay Output Start 1 at

0 hours, 0 minutes, & 0 seconds

Range: 00:00:00 to 18:00:00

NOTE: Only displayed if Auxiliary Relay is enabled in previous screen.

Auxiliary Relay will only display if Chemical Pump is OFF for System

Types 6 & 7.

AUX RELAY OUTPUT

END 1 00:00:00

Example:

Auxiliary Relay Output End 1 at

0 hours, 0 minutes, & 0 seconds

Range: 00:00:00 to 18:00:00

CHEMICAL PUMP:

DISABLED

Example:

Chemical Pump is Disabled

Options: Enabled

Disabled (Default)

NOTE: This screen will only display on the lead unit for System Types 6 & 7.

For all other System Types, it will display for all units.

CPO AUX RELAY

TIME: 00:00:00

Example:

Each time chemical pump relay is on, run for

30 seconds (00:00:30)

Range: 00:00:00 to 02:00:00

FLOW METER:

1.0 PADDLE

Example:

1.0 Paddle Flow Meter

Options: 1.0 Paddle (Fleck)

1.0 Turbine (Fleck)

1.5 Paddle (Fleck)

1.5 Turbine (Fleck)

2.0 Paddle (Fleck)

3.0 Paddle (Fleck)

Generic

NOTE: Default flow meter type is based on the valve type. This screen will

only display on the lead unit for System Types 6 & 7. All other system types

it will display for all units.

MAXIMUM FLOW

RATE: 0000 gpm

Example:

Maximum Flow Rate of 0 gpm

Range: 20 - 2000 gpm (U.S. Format)

20 - 2000 Lpm (Metric Format)

NOTE: Only displayed if “Generic” is chosen for the flow meter.

Range: 1 - 99 Gallons (U.S. Format)

0.1 - 09.9 L (Metric Format)

Pulses: 1 - 99

Options: Gallons (U.S. Format)

Liters (Metric Format)

ADD 01 GALLONS

EVERY 001 PULSES

Example:

Add 1 Gallon for Each Pulse in U.S. Format

NOTE: Only displayed if “Generic” is chosen for the flow meter.

PROGRAMMING UNIT

PLEASE WAIT...

Example:

Master Programming Mode is Exiting

CPO AUX RELAY

VOLUME: 000 9

Example:

Energize Chemical Pump relay every 50 gals (50)

Energize Chemical Pump relay every 200 L (200)

Range: 1 to 999 gallons in U.S. Format

1 to 9999 L in Metric Format

NOTE: Display will only appear on the master timer and it must be

programmed as valve position #1. System size must be 3 or 4 to appear. Use

the Shift button to move one space to the left.

NOTE: This screen will only display for System 14.

TRIP DELAY 2:

30 SECONDS

NOTE: Display will only appear on the master timer and it must be

programmed as valve position #1. System size must be 3 or 4 to appear. Use

the Shift button to move one space to the left.

NOTE: This screen will only display for System 14.

TRIP POINT 2:

gpm

NOTE: Display will only appear on the master timer and it must be

programmed as valve position #1. System size must be 4 to appear. Use the

Shift button to move one space to the left.

NOTE: This screen will only display for System 14.

TRIP POINT 3:

gpm

NOTE: Display will only appear on the master timer and it must be

programmed as valve position #1. System size must be 4 to appear. Use the

Shift button to move one space to the left.

NOTE: This screen will only display for System 14.

TRIP DELAY 3:

30 SECONDS

NOTE: This display will not be viewed in System 14.

NOTE: Display will only appear on the master timer and it must be

programmed as valve position #1. Use the Shift button to move one space

to the left.

TRIP DELAY 1:

30 SECONDS

NOTE: This screen will only display for System 14.

CYCLE 2 01:00:00 Example: Brine

01:00:00 (Default 48-00 Stager & 51-09 Stager)

(Hours:Minutes:Seconds)

Options: 01:00:00 for Conditioner for the 48-00 Stager & 51-09 Stager

(Default)

00:00:00 for Filter for the 48-00 Stager

CYCLE 3 00:10:00 Example: Fast Rinse

00:10:00 (Default 48-00 Stager & 51-09 Stager)

(Hours:Minutes:Seconds)

CYCLE 4 OFF Example:

Off (Default 48-00 Stager)

CYCLE 4 00:12:00 Example: Refill

00:12:00 (Default 51-09 Stager)

(Hours:Minutes:Seconds)

NOTE: This screen will only display when cycle 4 is not OFF.

CYCLE 5 OFF Example:

Off (Default 51-09 Stager)

1 to 997 gpm

1 to 3997 Lpm

2 to 998 gpm

1 to 3997 Lpm

3 to 999 gpm

1 to 3997 Lpm

VALVE ADDRESS:

#2

Options: Valve Address #1 (First Control Valve)

Valve Address #2 (Second Control Valve) (Default)

Valve Address #3 (Third Control Valve)

Valve Address #4 (Fourth Control Valve)

SYSTEM TYPE: 4

SINGLE UNIT

Options: System 4 (single unit)

System 5 (2-4 units) - Parallel Interlock

System 6 (2-4 units) - Parallel Series Regeneration

System 7 (2 units) - Alternating

System 9 (2-4 units) - Alternating

System 14 (2-4 units) - Demand Recall

Example:

System Type 4, Single Unit

Example:

Valve Address #2 (Second Control Valve) (Default)

SYSTEM SIZE:

2 VALVES

Options: 2 Valves in the System (Default)

3 Valves in the System

4 Valves in the System

Example:

2 Valves in the System (Default)

REGEN TYPE:

TIME CLK DELAYED

Options: Time Clock Delayed (System 4 Only) (Default)

Meter Immediate (All System Types)

Meter Delayed Fixed Reserve (Systems 4 & 6 Only)

Example:

Time Clock Delayed (Default)

VALVE TYPE:

STAGER-NOTCH CAM

Options: 2750

2850

2900

3150

3900

Stager - Notch Cam (Default)

Example:

Stager - Notch Cam (Default)

REMOTE SIGNAL

START:OFF

Options: 00:06:00 (Hours:Munutes:Seconds)

Range: 1 second to 99 minutes (1 hour, 39 minutes)

Example:

Off (Default)

DISPLAY FORMAT:

US-GALLONS

Options: U.S. - Gallons (Default)

EU-Metric - Liters (Metric)

Example:

U.S. Gallons (Default)

UNIT CAPACITY:

0300000 GRAINS

Options: Grains (in U.S. Format) (Default)

Grams (in Metric Format)

Example:

0300000 Grains (Default)

CAPACITY SAFETY

FACTOR: 00%

Range: 0 to 50%

Example:

00% (Default)

FEED WATER

HARDNESS: 15 GPG

Range: 1 to 199 Grains/Gallon (U.S. Format)

2 to 199 miligrams CaCOs/L (Metric Format)

Example:

15 GPG (U.S. Format) (Default)

SELECT LANGUAGE:

ENGLISH

Options: English

Espanol

Portugues

Deutsch

Francais

Example:

English

Range: 2 to 4 Valves in the System

NOTE: This screen will not display for System Type 4.

NOTE: This screen will not display for System Type 4.

NOTE: In European Units - Liters (Metric) mode, the display will be in

24-hour time.

NOTE: In U.S. - Gallons mode, the display will be in 12-hour time.

NOTE: Use the Shift button to move to the left.

Range: 1 to 9,900,000 Grain Capacity in U.S. Format

1.0 to 190,000 grams CaCO3Capacity in Metric Format

NOTE: Use the Shift button to move to the left.

NOTE: Use the Shift button to move to the left.

NOTE: This screen will only display on the lead unit for System Types 6 & 7.

For all other System Types, it will display for all units.

NOTE: Display will only appear on the master timer and it must be

programmed as valve position #1. Use the Shift button to change each

decimal position.

NOTE: This screen will only display for System 14.

REGENERATION DAY

OVERRIDE:OFF

Example:

Off (Default for Meter)

On (Default for Time Clock)

REGENERATION DAY

OVERRIDE:01 DAYS

Options: Off (Default for Meter) or On (Default for Time Clock)

Example:

1 Day

Range: 1 to 99 Days

REGENERATION

TIME: 02:00AM

Example:

2:00 A.M. (Default)

Options: A.M. (U.S. Format)

HR (Metric Format)

NOTE: Regeneration time will not appear unless Regeneration Day Override

is on.

CYCLE 1 00:10:00 Example: Backwash

00:10:00 (Default 48-00 Stager & 51-09 Stager)

(Hours:Minutes:Seconds)

AUXILIARY RELAY:

DISABLED

Example:

Auxiliary Relay is Disabled

Options: Enabled

Disabled (Default)

AUX RELAY OUTPUT

START 1 00:00:00

Example:

Auxiliary Relay Output Start 1 at

0 hours, 0 minutes, & 0 seconds

Range: 00:00:00 to 18:00:00

NOTE: Only displayed if Auxiliary Relay is enabled in previous screen.

Auxiliary Relay will only display if Chemical Pump is OFF for System

Types 6 & 7.

AUX RELAY OUTPUT

END 1 00:00:00

Example:

Auxiliary Relay Output End 1 at

0 hours, 0 minutes, & 0 seconds

Range: 00:00:00 to 18:00:00

CHEMICAL PUMP:

DISABLED

Example:

Chemical Pump is Disabled

Options: Enabled

Disabled (Default)

NOTE: This screen will only display on the lead unit for System Types 6 & 7.

For all other System Types, it will display for all units.

CPO AUX RELAY

TIME: 00:00:00

Example:

Each time chemical pump relay is on, run for

30 seconds (00:00:30)

Range: 00:00:00 to 02:00:00

FLOW METER:

1.0 PADDLE

Example:

1.0 Paddle Flow Meter

Options: 1.0 Paddle (Fleck)

1.0 Turbine (Fleck)

1.5 Paddle (Fleck)

1.5 Turbine (Fleck)

2.0 Paddle (Fleck)

3.0 Paddle (Fleck)

Generic

NOTE: Default flow meter type is based on the valve type. This screen will

only display on the lead unit for System Types 6 & 7. All other system types

it will display for all units.

MAXIMUM FLOW

RATE: 0000 gpm

Example:

Maximum Flow Rate of 0 gpm

Range: 20 - 2000 gpm (U.S. Format)

20 - 2000 Lpm (Metric Format)

NOTE: Only displayed if “Generic” is chosen for the flow meter.

Range: 1 - 99 Gallons (U.S. Format)

0.1 - 09.9 L (Metric Format)

Pulses: 1 - 99

Options: Gallons (U.S. Format)

Liters (Metric Format)

ADD 01 GALLONS

EVERY 001 PULSES

Example:

Add 1 Gallon for Each Pulse in U.S. Format

NOTE: Only displayed if “Generic” is chosen for the flow meter.

PROGRAMMING UNIT

PLEASE WAIT...

Example:

Master Programming Mode is Exiting

CPO AUX RELAY

VOLUME: 000 9

Example:

Energize Chemical Pump relay every 50 gals (50)

Energize Chemical Pump relay every 200 L (200)

Range: 1 to 999 gallons in U.S. Format

1 to 9999 L in Metric Format

NOTE: Display will only appear on the master timer and it must be

programmed as valve position #1. System size must be 3 or 4 to appear. Use

the Shift button to move one space to the left.

NOTE: This screen will only display for System 14.

TRIP DELAY 2:

30 SECONDS

NOTE: Display will only appear on the master timer and it must be

programmed as valve position #1. System size must be 3 or 4 to appear. Use

the Shift button to move one space to the left.

NOTE: This screen will only display for System 14.

TRIP POINT 2:

gpm

NOTE: Display will only appear on the master timer and it must be

programmed as valve position #1. System size must be 4 to appear. Use the

Shift button to move one space to the left.

NOTE: This screen will only display for System 14.

TRIP POINT 3:

gpm

NOTE: Display will only appear on the master timer and it must be

programmed as valve position #1. System size must be 4 to appear. Use the

Shift button to move one space to the left.

NOTE: This screen will only display for System 14.

TRIP DELAY 3:

30 SECONDS

NOTE: This display will not be viewed in System 14.

NOTE: Display will only appear on the master timer and it must be

programmed as valve position #1. Use the Shift button to move one space

to the left.

TRIP DELAY 1:

30 SECONDS

NOTE: This screen will only display for System 14.

CYCLE 2 01:00:00 Example: Brine

01:00:00 (Default 48-00 Stager & 51-09 Stager)

(Hours:Minutes:Seconds)

Options: 01:00:00 for Conditioner for the 48-00 Stager & 51-09 Stager

(Default)

00:00:00 for Filter for the 48-00 Stager

CYCLE 3 00:10:00 Example: Fast Rinse

00:10:00 (Default 48-00 Stager & 51-09 Stager)

(Hours:Minutes:Seconds)

CYCLE 4 OFF Example:

Off (Default 48-00 Stager)

CYCLE 4 00:12:00 Example: Refill

00:12:00 (Default 51-09 Stager)

(Hours:Minutes:Seconds)

NOTE: This screen will only display when cycle 4 is not OFF.

CYCLE 5 OFF Example:

Off (Default 51-09 Stager)

1 to 997 gpm

1 to 3997 Lpm

2 to 998 gpm

1 to 3997 Lpm

3 to 999 gpm

1 to 3997 Lpm

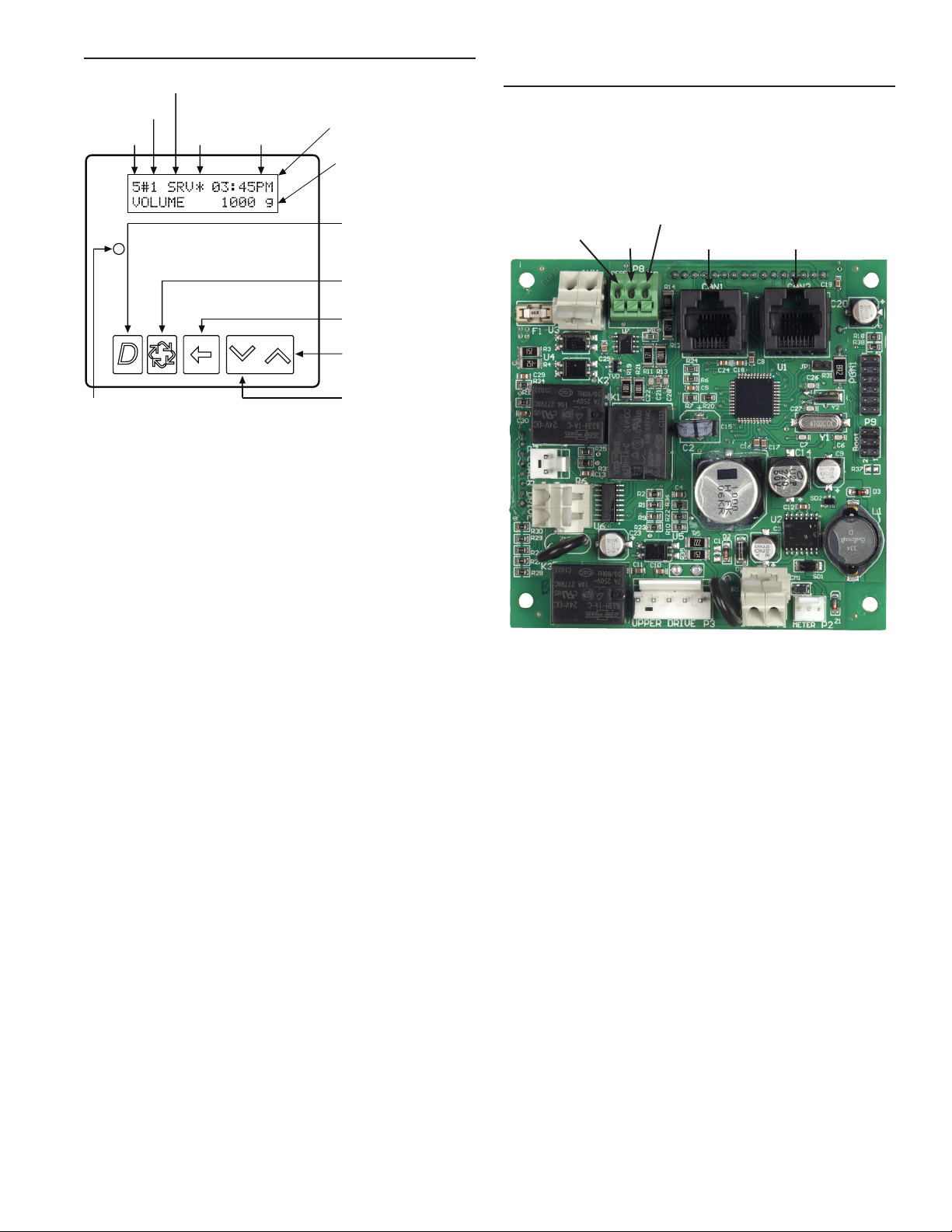

MASTER PROGRAMMING MODE FLOW

CHART

Before entering Master Programming, please

contact your local professional water dealer.

WhentheMasterProgrammingModeisentered,parameters

canbesettomakethetimer(s)functionasneeded.

NOTE: Depending on current option settings, some

displays cannot be viewed or set.

Entering Master Programming Mode

1. PressandholdtheShiftandUpbuttonsfor5seconds.

OR

2. Setthetimeofdaydisplayto12:01PMor12:01HR.Press

andholdUporDownbuttonstosetthetime.Thenpress

theUpandDownbuttonsatthesametimefor5seconds.

Exiting Master Programming Mode

1. PresstheExtraCyclebuttononceperdisplayuntilall

areviewed.MasterProgrammingModeisexitedandthe

normaldisplayscreenappears.

2. ToexittheMasterProgrammingModewithoutsaving

changes,presstheDiagnosticbutton.

NOTE: If no keypad activity is made for 5 minutes while

in the Master Programming Mode, or if there is a

power failure, no changes will be saved, and the

unit will go back to the main display screen.

Resets

Soft Reset: PressandholdtheUpandDownbuttonsfor25

secondsuntil12:00PM(or12:00HR)appears.Thisresetsall

parametersexceptfortheowmetertotalizervolume.

Master Reset: HoldtheExtraCyclebuttonwhilepoweringup

theunit.Thisresetsalloftheparametersintheunit.Check

andverifythechoicesselectedinMasterProgrammingMode.

NXTStagerControllerFE11•7